coolant reservoir OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1064 of 6000

ENGINE COOLING6B–11

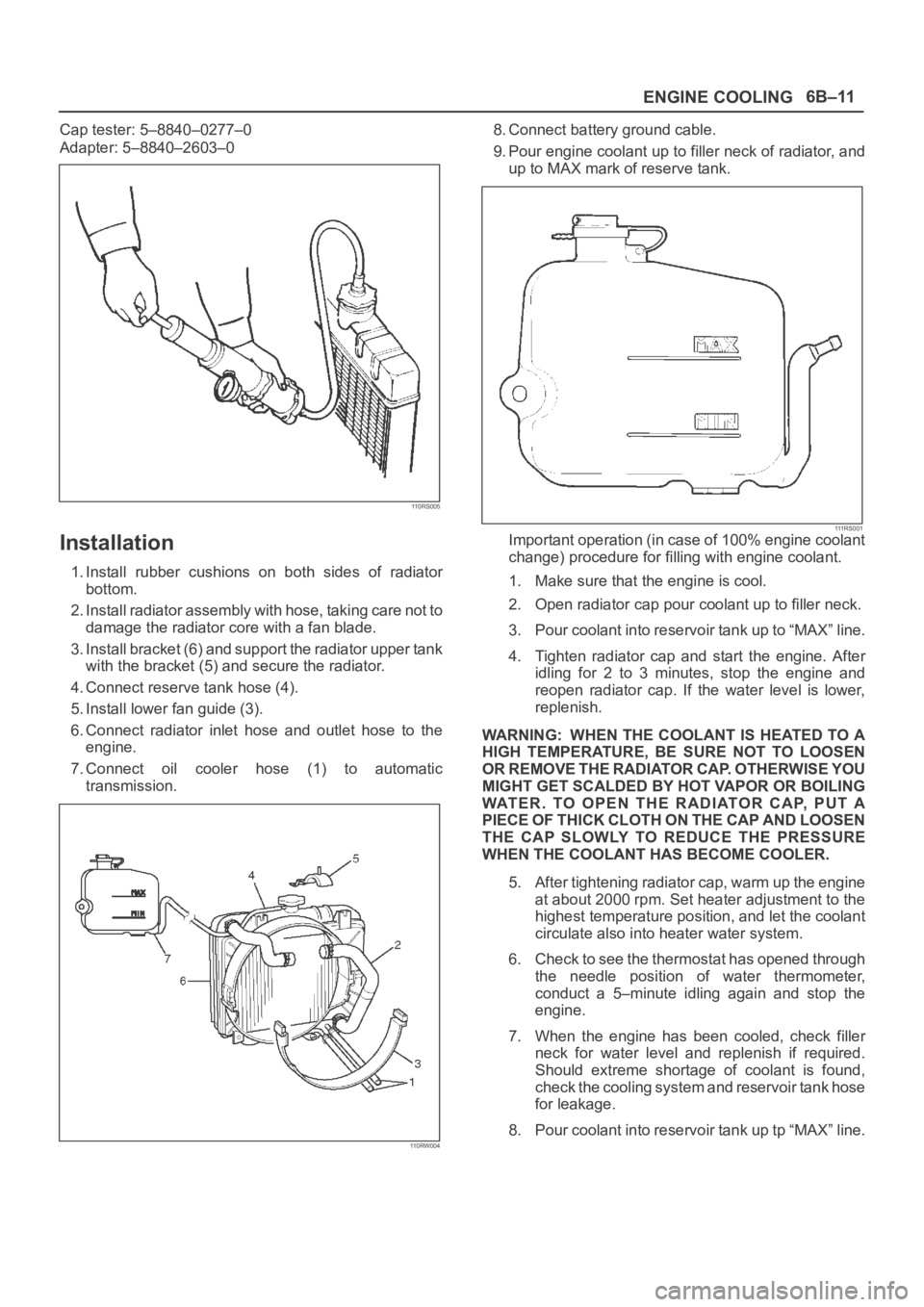

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

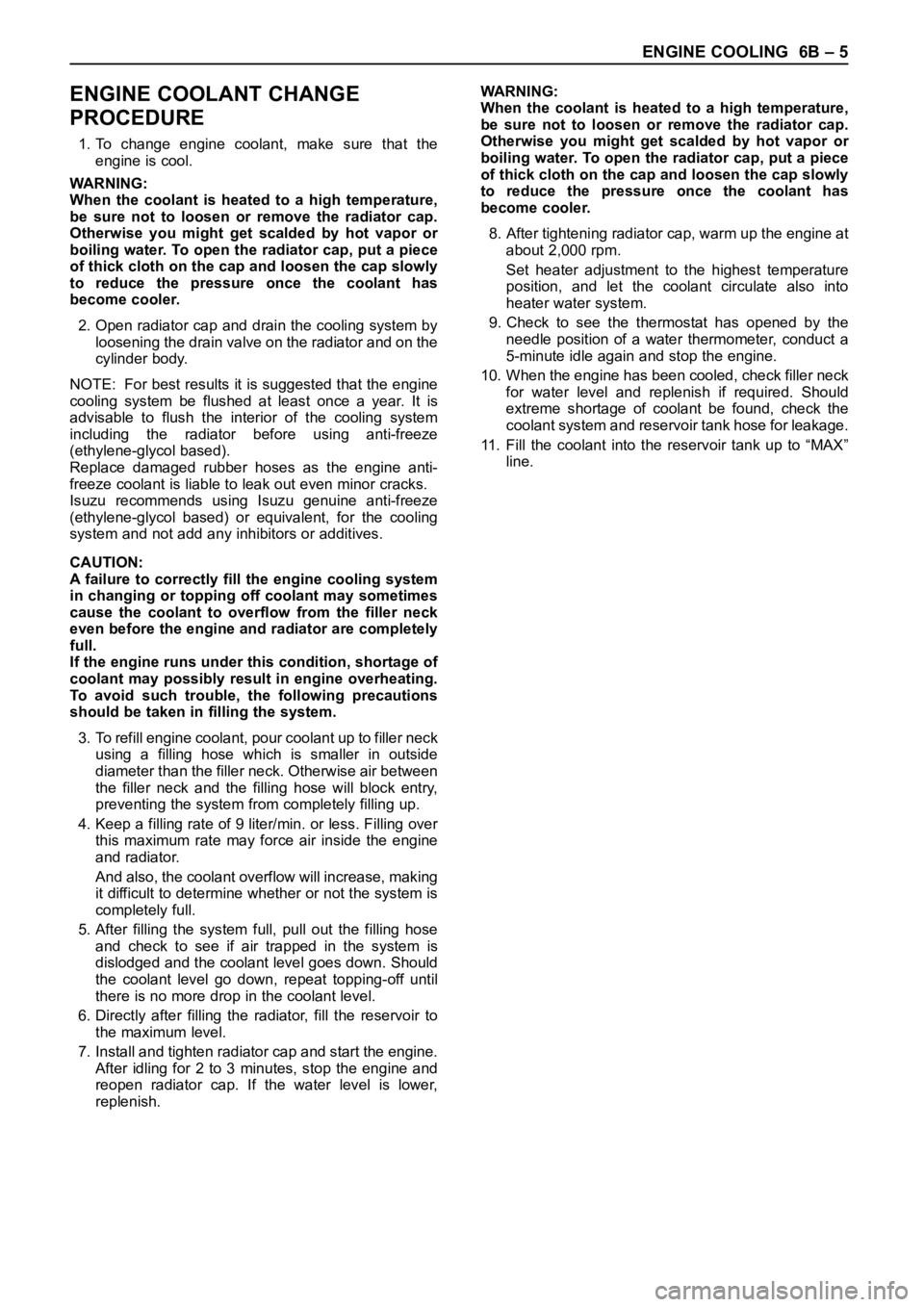

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

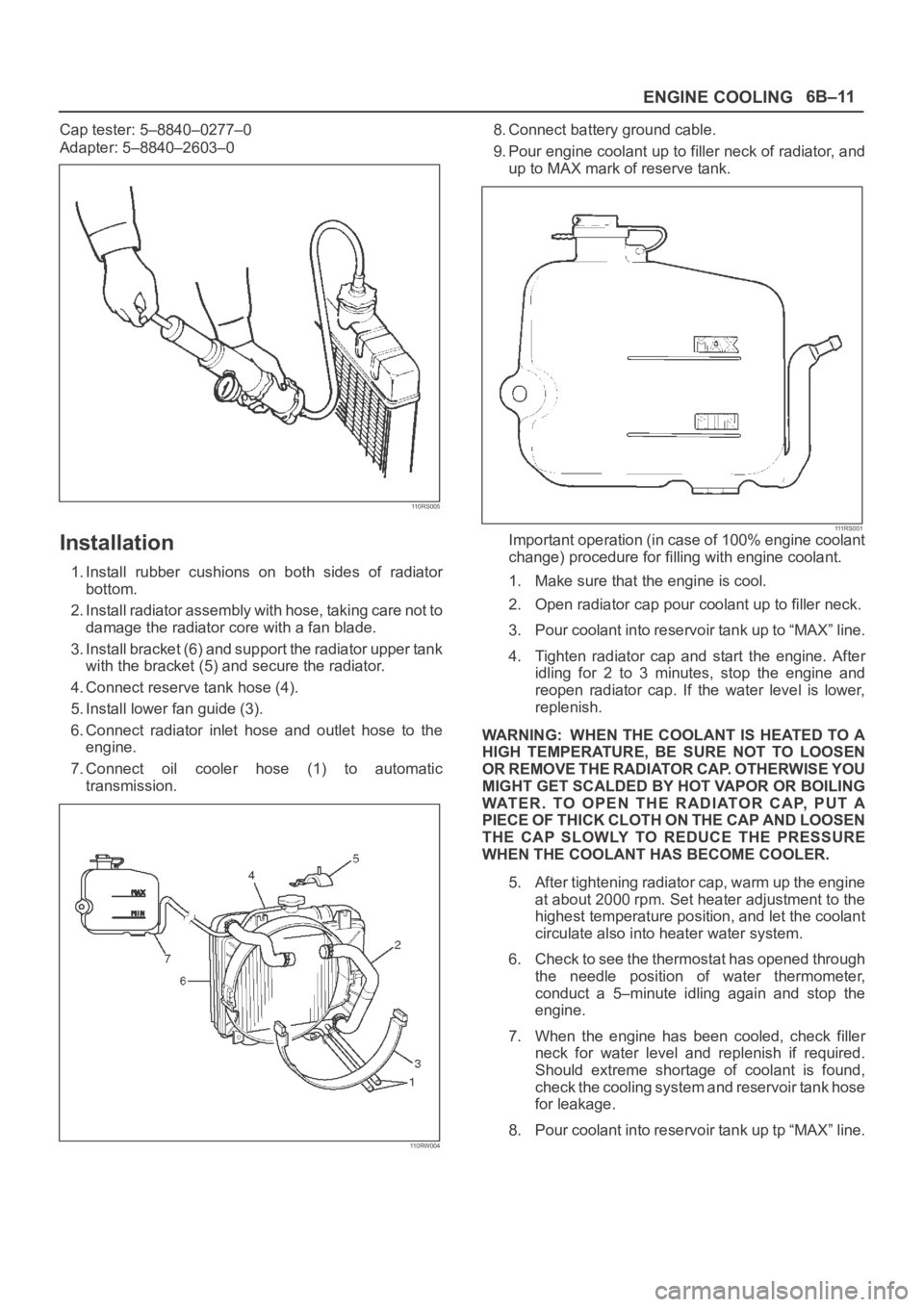

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 1835 of 6000

6B – 2 ENGINE COOLING

Legend

(1) Turbocharger

(2) Thermostat

(3) Reservoir Tank

(4) Radiator

(5) Bypass(6) Oil Cooler

(7) Cooling fan

(8) Water Pump

(9) Thermo Valve

(10) Car Heater

(11) EGR Cooler

GENERAL DESCRIPTION

COOLANT FLOW

1

6

9

9

For Europe only

10

8

4

325

7

11

032R200001

The cooling system is a pressurized coolant forced

circulation type which consists of water pump,

thermostat, cooling fan, radiator and other components. The circulating coolant cools the lubricating oil in the oil

cooler and turbocharger.

Page 1838 of 6000

ENGINE COOLING 6B – 5

ENGINE COOLANT CHANGE

PROCEDURE

1. To change engine coolant, make sure that the

engine is cool.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

2. Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE: For best results it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flush the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-

freeze coolant is liable to leak out even minor cracks.

Isuzu recommends using Isuzu genuine anti-freeze

(ethylene-glycol based) or equivalent, for the cooling

system and not add any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling system

in changing or topping off coolant may sometimes

cause the coolant to overflow from the filler neck

even before the engine and radiator are completely

full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

3. To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter than the filler neck. Otherwise air between

the filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4. Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5. After filling the system full, pull out the filling hose

and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-off until

there is no more drop in the coolant level.

6. Directly after filling the radiator, fill the reservoir to

the maximum level.

7. Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

8. After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into

heater water system.

9. Check to see the thermostat has opened by the

needle position of a water thermometer, conduct a

5-minute idle again and stop the engine.

10. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant be found, check the

coolant system and reservoir tank hose for leakage.

11. Fill the coolant into the reservoir tank up to “MAX”

line.

Page 1842 of 6000

ENGINE COOLING 6B – 9

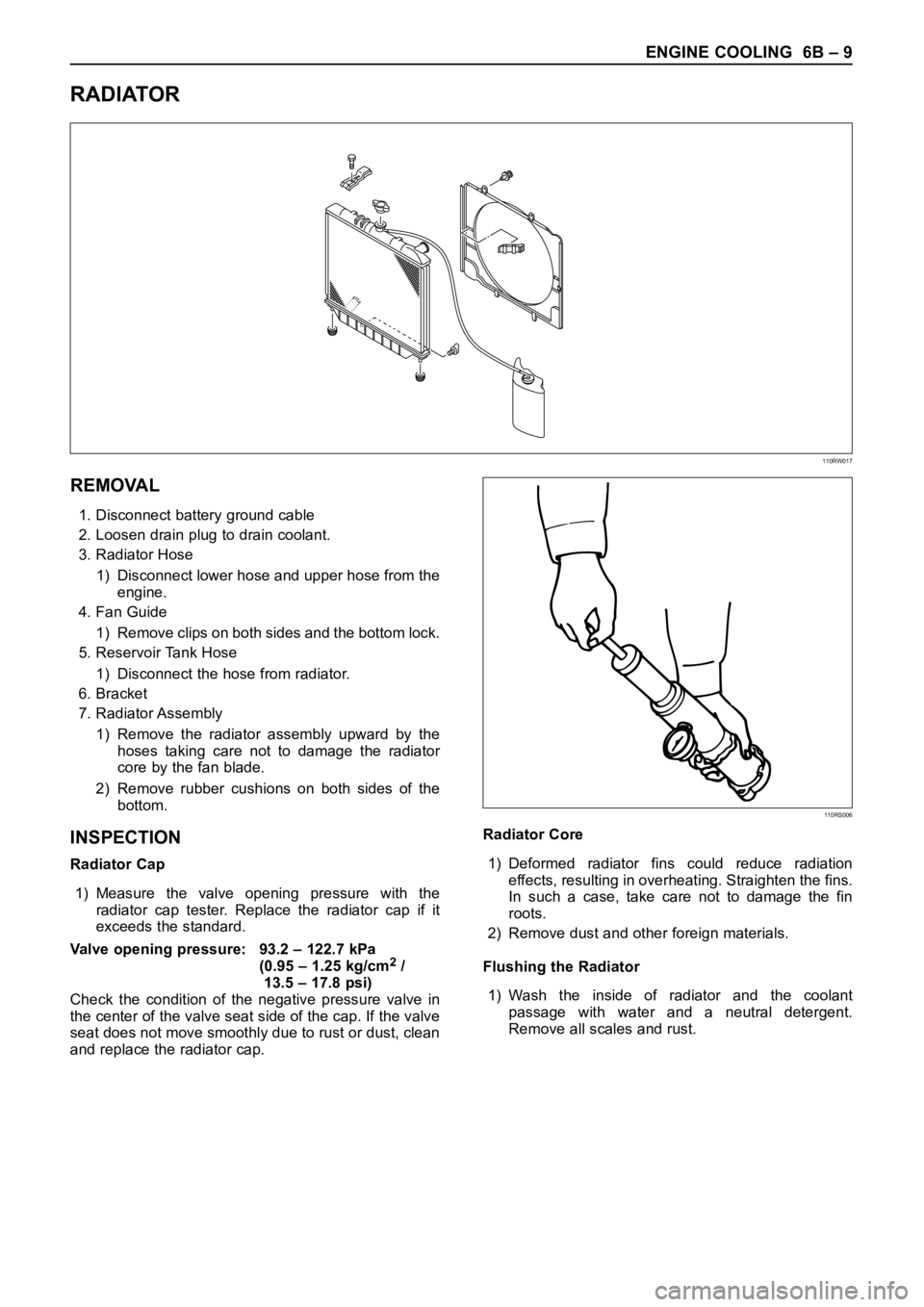

RADIATOR

REMOVAL

1. Disconnect battery ground cable

2. Loosen drain plug to drain coolant.

3. Radiator Hose

1) Disconnect lower hose and upper hose from the

engine.

4. Fan Guide

1) Remove clips on both sides and the bottom lock.

5. Reservoir Tank Hose

1) Disconnect the hose from radiator.

6. Bracket

7. Radiator Assembly

1) Remove the radiator assembly upward by the

hoses taking care not to damage the radiator

core by the fan blade.

2) Remove rubber cushions on both sides of the

bottom.

INSPECTION

Radiator Cap

1) Measure the valve opening pressure with the

radiator cap tester. Replace the radiator cap if it

exceeds the standard.

Valve opening pressure: 93.2 – 122.7 kPa

(0.95 – 1.25 kg/cm

2/

13.5 – 17.8 psi)

Check the condition of the negative pressure valve in

the center of the valve seat side of the cap. If the valve

seat does not move smoothly due to rust or dust, clean

and replace the radiator cap.Radiator Core

1) Deformed radiator fins could reduce radiation

effects, resulting in overheating. Straighten the fins.

In such a case, take care not to damage the fin

roots.

2) Remove dust and other foreign materials.

Flushing the Radiator

1) Wash the inside of radiator and the coolant

passage with water and a neutral detergent.

Remove all scales and rust.

110RW017

110RS006

Page 4604 of 6000

ENGINE COOLING6B–11

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 5371 of 6000

6B – 2 ENGINE COOLING

Legend

(1) Turbocharger

(2) Thermostat

(3) Reservoir Tank

(4) Radiator

(5) Bypass(6) Oil Cooler

(7) Cooling fan

(8) Water Pump

(9) Thermo Valve

(10) Car Heater

GENERAL DESCRIPTION

COOLANT FLOW

1

6

9

10

8

4

325

7

032RW001

The cooling system is a pressurized coolant forced

circulation type which consists of water pump,

thermostat, cooling fan, radiator and other components. The circulating coolant cools the lubricating oil in the oil

cooler and turbocharger.

Page 5374 of 6000

ENGINE COOLING 6B – 5

ENGINE COOLANT CHANGE

PROCEDURE

1. To change engine coolant, make sure that the

engine is cool.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

2. Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE: For best results it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flush the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-

freeze coolant is liable to leak out even minor cracks.

Isuzu recommends using Isuzu genuine anti-freeze

(ethylene-glycol based) or equivalent, for the cooling

system and not add any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling system

in changing or topping off coolant may sometimes

cause the coolant to overflow from the filler neck

even before the engine and radiator are completely

full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

3. To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter than the filler neck. Otherwise air between

the filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4. Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5. After filling the system full, pull out the filling hose

and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-off until

there is no more drop in the coolant level.

6. Directly after filling the radiator, fill the reservoir to

the maximum level.

7. Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

8. After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into

heater water system.

9. Check to see the thermostat has opened by the

needle position of a water thermometer, conduct a

5-minute idle again and stop the engine.

10. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant be found, check the

coolant system and reservoir tank hose for leakage.

11. Fill the coolant into the reservoir tank up to “MAX”

line.

Page 5378 of 6000

ENGINE COOLING 6B – 9

RADIATOR

REMOVAL

1. Disconnect battery ground cable

2. Loosen drain plug to drain coolant.

3. Radiator Hose

1) Disconnect lower hose and upper hose from the

engine.

4. Fan Guide

1) Remove clips on both sides and the bottom lock.

5. Reservoir Tank Hose

1) Disconnect the hose from radiator.

6. Bracket

7. Radiator Assembly

1) Remove the radiator assembly upward by the

hoses taking care not to damage the radiator

core by the fan blade.

2) Remove rubber cushions on both sides of the

bottom.

INSPECTION

Radiator Cap

1) Measure the valve opening pressure with the

radiator cap tester. Replace the radiator cap if it

exceeds the standard.

Valve opening pressure: 93.2 – 122.7 kPa

(0.95 – 1.25 kg/cm

2/

13.5 – 17.8 psi)

Check the condition of the negative pressure valve in

the center of the valve seat side of the cap. If the valve

seat does not move smoothly due to rust or dust, clean

and replace the radiator cap.Radiator Core

1) Deformed radiator fins could reduce radiation

effects, resulting in overheating. Straighten the fins.

In such a case, take care not to damage the fin

roots.

2) Remove dust and other foreign materials.

Flushing the Radiator

1) Wash the inside of radiator and the coolant

passage with water and a neutral detergent.

Remove all scales and rust.

110RW017

110RS006