check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1986 of 6000

6E–93 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description

The rail pressure control valve (RPCV) is built in the high

pressure oil circuit.

RPCV is an important device which is used to control oil

pressure in the HEUI system.

The circuit receives current through Engine 15A fuse from

the battery, current flowing in the order of RPCV.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1196 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Rail Pressure Control display on the Tech 2 while

moving connectors and wiring harnesses related to the

Rail Pressure Control. A change in the Rail Pressure

Control display will indicate the location of the fault.

If DTC P1196 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

DTC P1196 – RP System High Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Engine is running.

2. Observe the “Rail Pressure Control” display on the

Te c h 2 .

Is the action correct?

—Go to Step 4Go to Step 3

3Replace the RPCV.

Is the action complete?

—Verify repairGo to Step 4

41. Engine is running.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1196.

Does the Tech 2 indicate DTC P1196 failed this

ignition?

—Go to Step 5—

51. Check the 2 way valve.

2. Observe the “RP Control” display on the Tech 2.

Is the action correct?

—Go to Step 4Go to Step 6

6Replace the 2 way valve.

Is the action complete?

—Verify repair—

Page 1987 of 6000

6E–94

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0197 (Flash DTC 16)

Oil Temp Sensor Low Voltage

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted in the oil rail. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine oil is cold, the

sensor (thermistor) resistance is high, therefore the ECM

will measure a high signal voltage. As the engine oil

warms, the sensor resistance becomes lower, and the OT

signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0197 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

OT display on the Tech 2 while moving connectors and

wiring harnesses related to the OT sensor. A change

in the OT display will indicate the location of the fault.

If DTC P0197 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Page 1988 of 6000

6E–95 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

3. If DTC P0197 can be repeated only by duplicating

the Failure Records conditions, refer to the

“Temperature vs. Resistance Values” table. The

table may be used to test the OT sensor at various

temperatures to evaluate the possibility of a

“shifted” sensor that may be shorted above or below

a certain temperature. If this is the case, replace

the OT sensor. If the OT sensor appears to be OK,

the fault is intermittent; refer to

Diagnostic Aids.

Engine Oil Temperature Sensor

CFOhms

Temperature vs. Resistance Values

(approximate)

80176332

25772796

15594450

DTC P0197 – OT Sensor Low Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Observe the “Eng Oil Temp” display on the Tech 2.

Is the “Eng Oil Temp” below the specified value?

139C

(282

F)Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P0197.

Does the Tech 2 indicate DTC P0197 failed this

ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Disconnect the OT sensor electrical connector.

2. Observe the “Eng Oil Temp” display on the Tech 2.

Is the “Eng Oil Temp” at the specified value?

–39C

(–38

F)Go to Step 6Go to Step 5

51. Ignition “OFF.”

2. Disconnect the ECM and check the OT signal circuit

for a short to ground or a short to the sensor ground

circuit.

3. If the OT signal circuit is shorted. repair it as

necessary.

Was the OT signal circuit shorted to ground?

—Verify repairGo to Step 7

6Replace the OT sensor.

Is the action complete?

—Verify repair—

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 1989 of 6000

6E–96

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0198 (Flash DTC 16)

Oil Temp Sensor High Voltage

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted in the oil rail. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine oil is cold, the

sensor (thermistor) resistance is high, therefore the ECM

will measure a high signal voltage. As the engine oil

warms, the sensor resistance becomes lower, and the OT

signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0198 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

OT display on the Tech 2 while moving connectors and

wiring harnesses related to the OT sensor. A change

in the OT display will indicate the location of the fault.

If DTC P0198 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Page 1990 of 6000

6E–97 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

3. If DTC P0198 can be repeated only by duplicating

the Failure Records conditions, refer to the

“Temperature vs. Resistance Value” table. The

table may be used to test the OT sensor at various

temperatures to evaluate the possibility of a

“shifted” sensor that may be shorted above or below

a certain temperature. If this is the case, replace

the OT sensor. If the OT sensor appears to be OK,

the fault is intermittent; refer to

Diagnostic Aids.

Engine Oil Temperature Sensor

CFOhms

Temperature vs. Resistance Values

(approximate)

80176332

25772796

15594450

DTC P0198 – OT Sensor High Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Observe the “Eng Oil Temp” display on the Tech 2.

Is the “Eng Oil Temp” below the specified value?

–39C

(–38

F)Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “ DTC” info for DTC

P0198.

Does the Tech 2 indicate DTC P0198 failed?

—

Refer to Te s t

Description

Refer to

Diagnostic

Aids

41. Disconnect the OT sensor electrical connector.

2. Jumper the OT signal circuit and the sensor ground

circuit together at the OT sensor harness

connector.

3. Observe the “Eng Oil Temp” display on the Tech 2.

Is the “Eng Oil Temp” at the specified value?

140C

(284

F)Go to Step 6Go to Step 5

51. Jumper the OT signal circuit at the OT sensor

harness connector to chassis ground.

2. Observe the “Eng Oil Temp” display on the Tech 2.

Is the “Eng Oil Temp” at the specified value?

140C

(284

F)Go to Step 7Go to Step 8

6Check for poor connections at the OT sensor and

replace terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 10

71. Ignition “OFF.”

2. Disconnect the ECM, and check the OT sensor

ground circuit for an open.

3. If the OT sensor ground circuit is open, repair it as

necessary.

Was the OT sensor ground circuit open?

—Verify repairGo to Step 9

Page 1991 of 6000

6E–98

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0198 – OT Sensor High Voltage

StepNo Ye s Va l u e ( s ) Action

81. Ignition “OFF.”

2. Disconnect the OT, and check the OT signal circuit

for an open.

3. If the OT sensor signal circuit is open, repair it as

necessary.

Was the OT signal circuit open?

—Verify repairGo to Step 9

9Check for a poor sensor ground or OT signal circuit

terminal connection at the ECM and replace

terminal(s) if necessary.

Did any of the terminals need to be replaced?

—Verify repairGo to Step 11

10Replace the ECT sensor.

Is the action complete?

—Verify repair—

11Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 1993 of 6000

6E–100

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0201 – Injector # 1 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0201 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0201 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0201 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 1995 of 6000

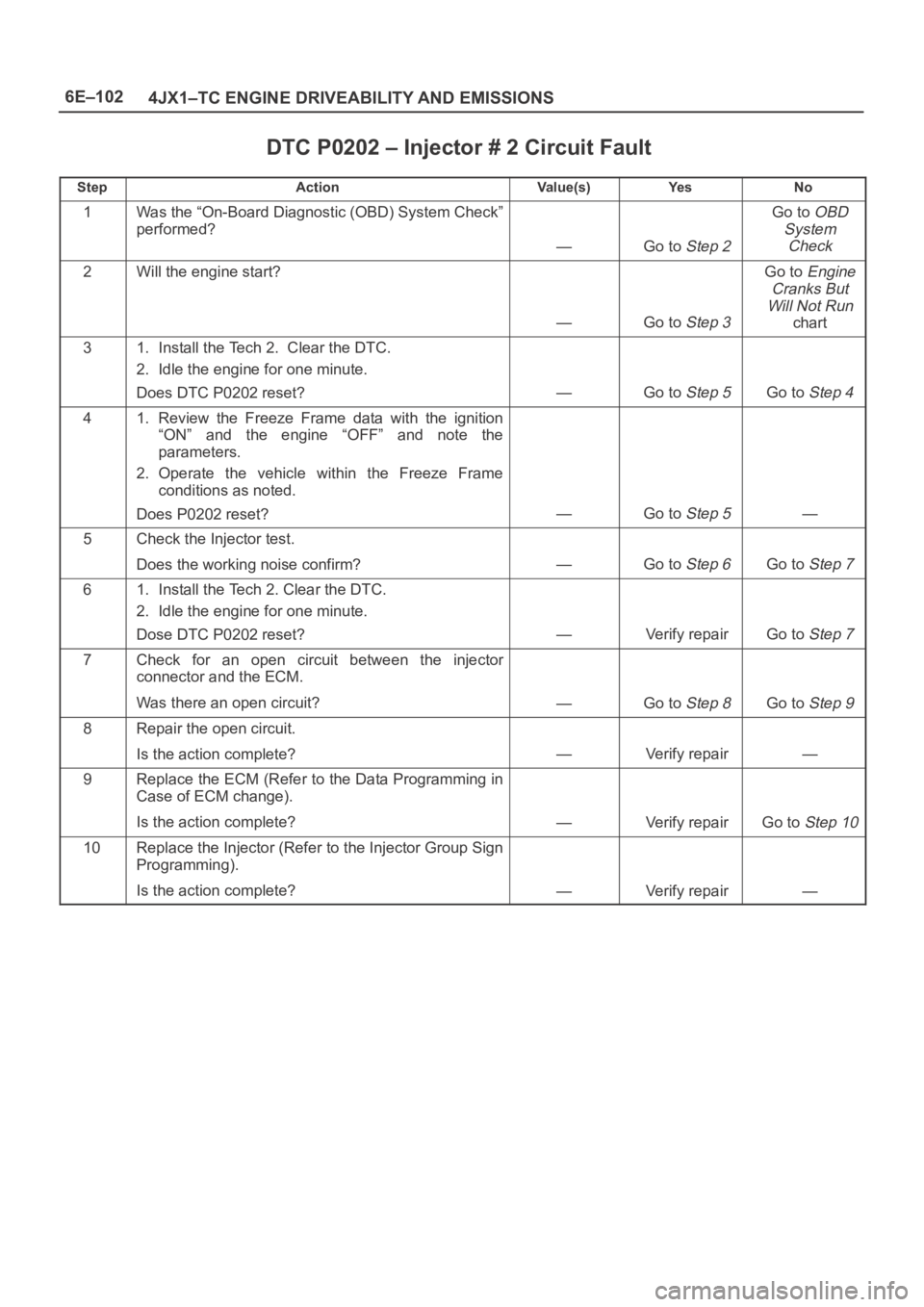

6E–102

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0202 – Injector # 2 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0202 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0202 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0202 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 1997 of 6000

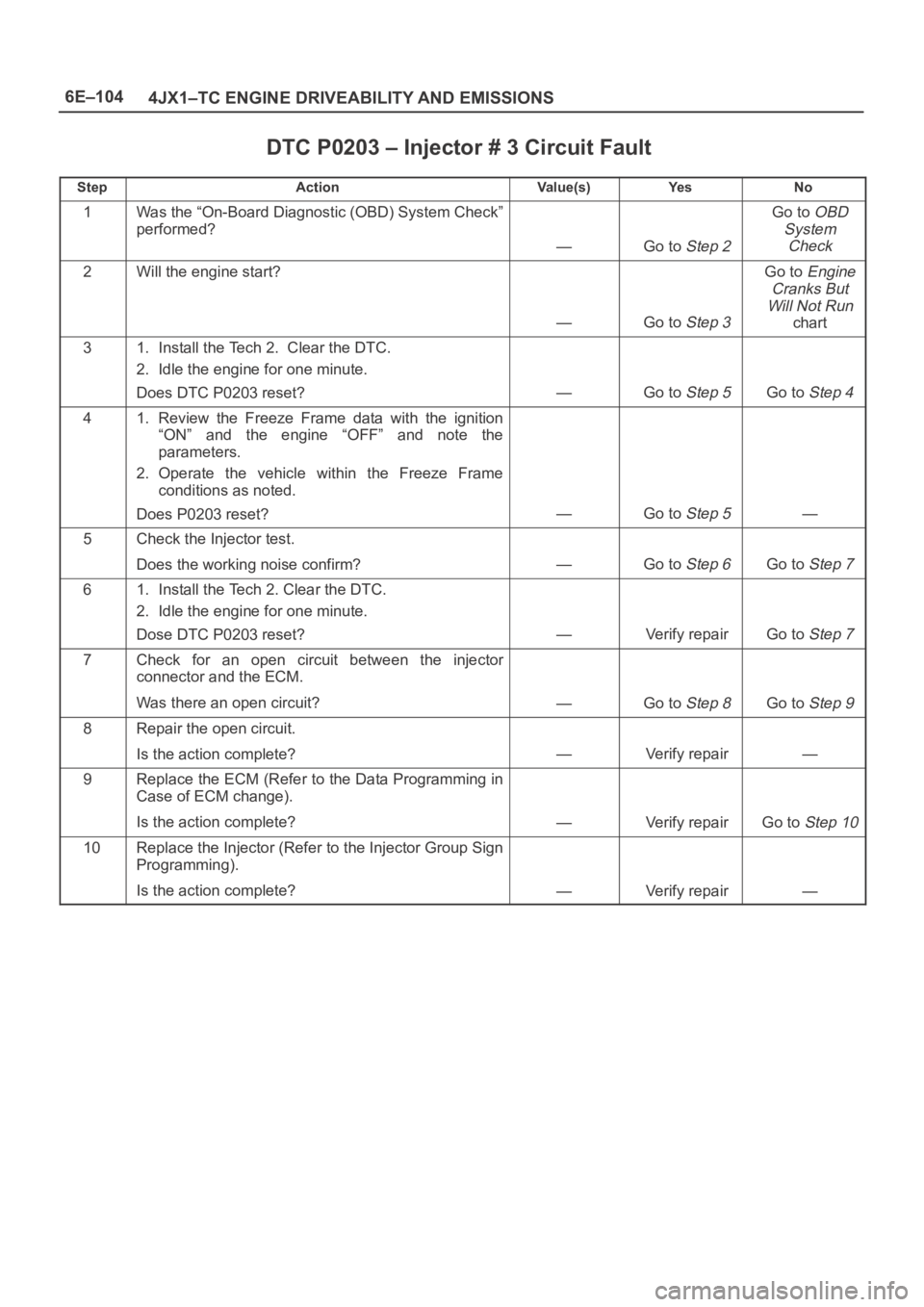

6E–104

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0203 – Injector # 3 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0203 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0203 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0203 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 1999 of 6000

6E–106

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0204 – Injector #4 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0204 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0204 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0204 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Is the action complete?—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—