service OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

1A HEATING AND VENTILATION

1B AIR CONDITIONING

1D COMPRESSOR OVERHAUL

HOME

00

1D

1B

1A

Page 5 of 6000

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

2A FRONT END ALIGNMENT

HOME

00

2A

Page 10 of 6000

PAGE BACK PAGE NEXT

4JG2

4JX1 SECTION No. CONTRNTS

00 SERVICE INFORMATION

6A ENGINE MECHANICAL

6A2 4JG2-NA / 4JG2-TURBO ENGINE

6B ENGINE COOLING

6C FUEL SYSTEM

6D ENGINE ELECTRICAL

6E -

6F EXHAUST

6G -

SECTION No. CONTRNTS

6A ENGINE MECHANICAL

6B ENGINE COOLING

6C ENGINE FUEL

6D ENGINE ELECTRICAL

6E ENGINE DRIVEABILITY AND EMISSIONS

6F ENGINE EXHAUST

6G ENGINE LUBRICATION

6H ENGINE SPEED CONTROL

6J INDUCTION

HOME

00

6A

6A2

6B

6C

6D

6E

6F

6G

6A

6B

6C

6D

6E

6F

6G

6H

6J

Page 15 of 6000

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners

or fasteners joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.

Page 28 of 6000

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners

or fasteners joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.

Page 262 of 6000

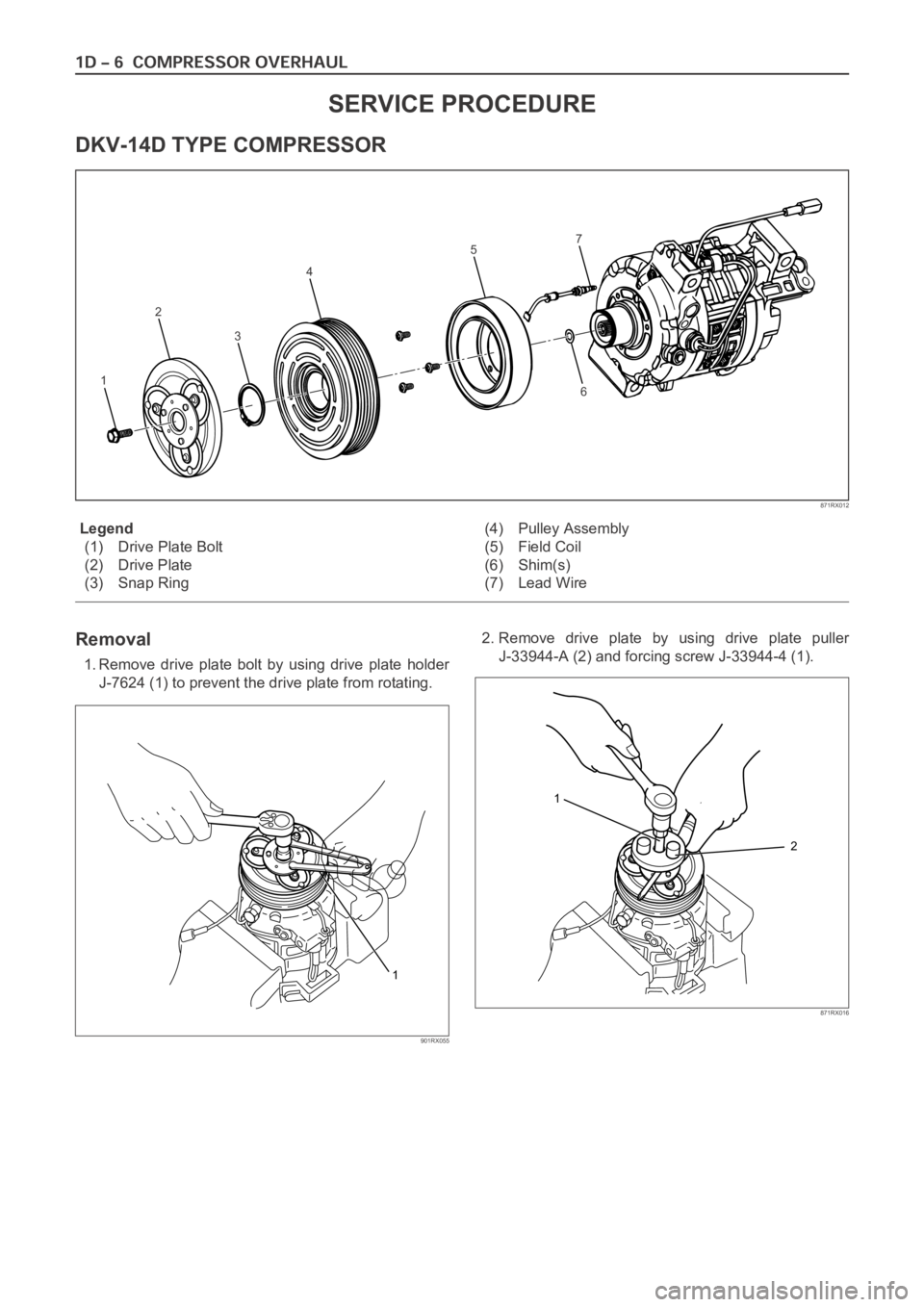

Legend

(1) Drive Plate Bolt

(2) Drive Plate

(3) Snap Ring(4) Pulley Assembly

(5) Field Coil

(6) Shim(s)

(7) Lead Wire

Removal

1. Remove drive plate bolt by using drive plate holder

J-7624 (1) to prevent the drive plate from rotating.2. Remove drive plate by using drive plate puller

J-33944-A (2) and forcing screw J-33944-4 (1).

SERVICE PROCEDURE

DKV-14D TYPE COMPRESSOR

1

2

3

4

5

67

871RX012

1

901RX055

1

2

871RX016

Page 278 of 6000

COMPRESSOR SHAFT SEAL

Service Precaution

When replacing the shaft seal assembly, pressure relief

valve or control switches, it will be necessary to recover

the refrigerant. Other than clutch repair procedures, the

same holds true for any disassembly of the compressor.

A clean workbench covered with a sheet of clean

paper, and a place (clean trays, etc) for all parts being

removed and replaced is important, as is the use of

proper clean service tools.

CAUTION: Any attempt to use makeshift or

inadequate service tools or equipment may result

in damage and/or improper compressor operation.

All parts required for servicing the internal compressor

are protected by a preservative process and packaged

in a manner which will eliminate the necessity of

cleaning, washing or flushing of the parts. The parts

can be used in the internal assembly just as they are

removed from the service package. Seals and

protective packaging should be left intact until just

prior to installation.

If the compressor rear head, front head or cylinder and

shaft assembly is to be serviced or replaced, the oil in

the compressor must be drained, measured, recorded

and replaced.

Legend

(1) Suction Port

(2) Discharge Port

(3) Mounting Boss

(4) Mounting Boss

(5) Pressure Relief Valve

(6) Mounting Boss

Seal Leak Detection

A shaft seal should not be changed because of small

amounts of oil found on an adjacent surface but only

after actual refrigerant leakage is found using an

approved leak detector.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Loosen and reposition compressor in mounting

brackets, if necessary.

3. Remove clutch plate and hub assembly from

compressor as described previously.

4. Remove the shaft seal retainer ring, using snap ring

pliers.

5. Thoroughly clean inside of compressor neck area

surrounding the shaft, the exposed portion of the

seal, the retainer ring groove and the shaft itself.

Any dirt or foreign material getting into compressor

may cause damage.

6. Fully engage the knurled tangs of Seal Remover-

Installer J-23128-A into the recessed portion of the

Seal (1) by turning the handle clockwise. Remove

the Seal from the compressor with a rotary-pulling

motion.

Discard the seal. The handle must be hand-

tightened securely. Do not use a wrench or pliers.

1

2

3

456

871RW006

J-23128-A1

901RW008

Page 279 of 6000

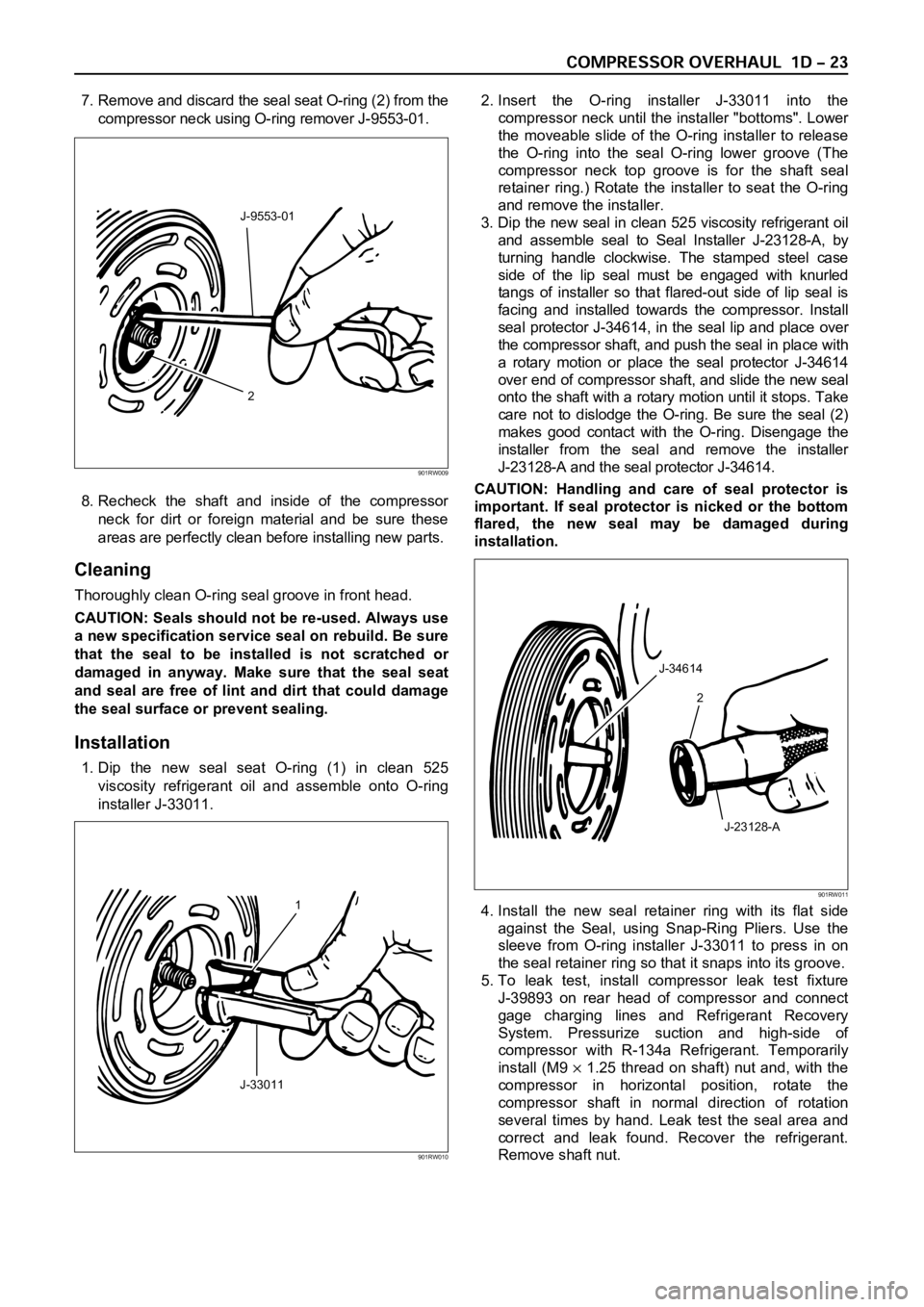

7. Remove and discard the seal seat O-ring (2) from the

compressor neck using O-ring remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck for dirt or foreign material and be sure these

areas are perfectly clean before installing new parts.

Cleaning

Thoroughly clean O-ring seal groove in front head.

CAUTION: Seals should not be re-used. Always use

a new specification service seal on rebuild. Be sure

that the seal to be installed is not scratched or

damaged in anyway. Make sure that the seal seat

and seal are free of lint and dirt that could damage

the seal surface or prevent sealing.

Installation

1. Dip the new seal seat O-ring (1) in clean 525

viscosity refrigerant oil and assemble onto O-ring

installer J-33011.2. Insert the O-ring installer J-33011 into the

compressor neck until the installer "bottoms". Lower

the moveable slide of the O-ring installer to release

the O-ring into the seal O-ring lower groove (The

compressor neck top groove is for the shaft seal

retainer ring.) Rotate the installer to seat the O-ring

and remove the installer.

3. Dip the new seal in clean 525 viscosity refrigerant oil

and assemble seal to Seal Installer J-23128-A, by

turning handle clockwise. The stamped steel case

side of the lip seal must be engaged with knurled

tangs of installer so that flared-out side of lip seal is

facing and installed towards the compressor. Install

seal protector J-34614, in the seal lip and place over

the compressor shaft, and push the seal in place with

a rotary motion or place the seal protector J-34614

over end of compressor shaft, and slide the new seal

onto the shaft with a rotary motion until it stops. Take

care not to dislodge the O-ring. Be sure the seal (2)

makes good contact with the O-ring. Disengage the

installer from the seal and remove the installer

J-23128-A and the seal protector J-34614.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

4. Install the new seal retainer ring with its flat side

against the Seal, using Snap-Ring Pliers. Use the

sleeve from O-ring installer J-33011 to press in on

the seal retainer ring so that it snaps into its groove.

5. To leak test, install compressor leak test fixture

J-39893 on rear head of compressor and connect

gage charging lines and Refrigerant Recovery

System. Pressurize suction and high-side of

compressor with R-134a Refrigerant. Temporarily

install (M9

1.25 thread on shaft) nut and, with the

compressor in horizontal position, rotate the

compressor shaft in normal direction of rotation

several times by hand. Leak test the seal area and

correct and leak found. Recover the refrigerant.

Remove shaft nut.

2 J-9553-01

901RW009

1

J-33011

901RW010

J-34614

2

J-23128-A

901RW011

Page 280 of 6000

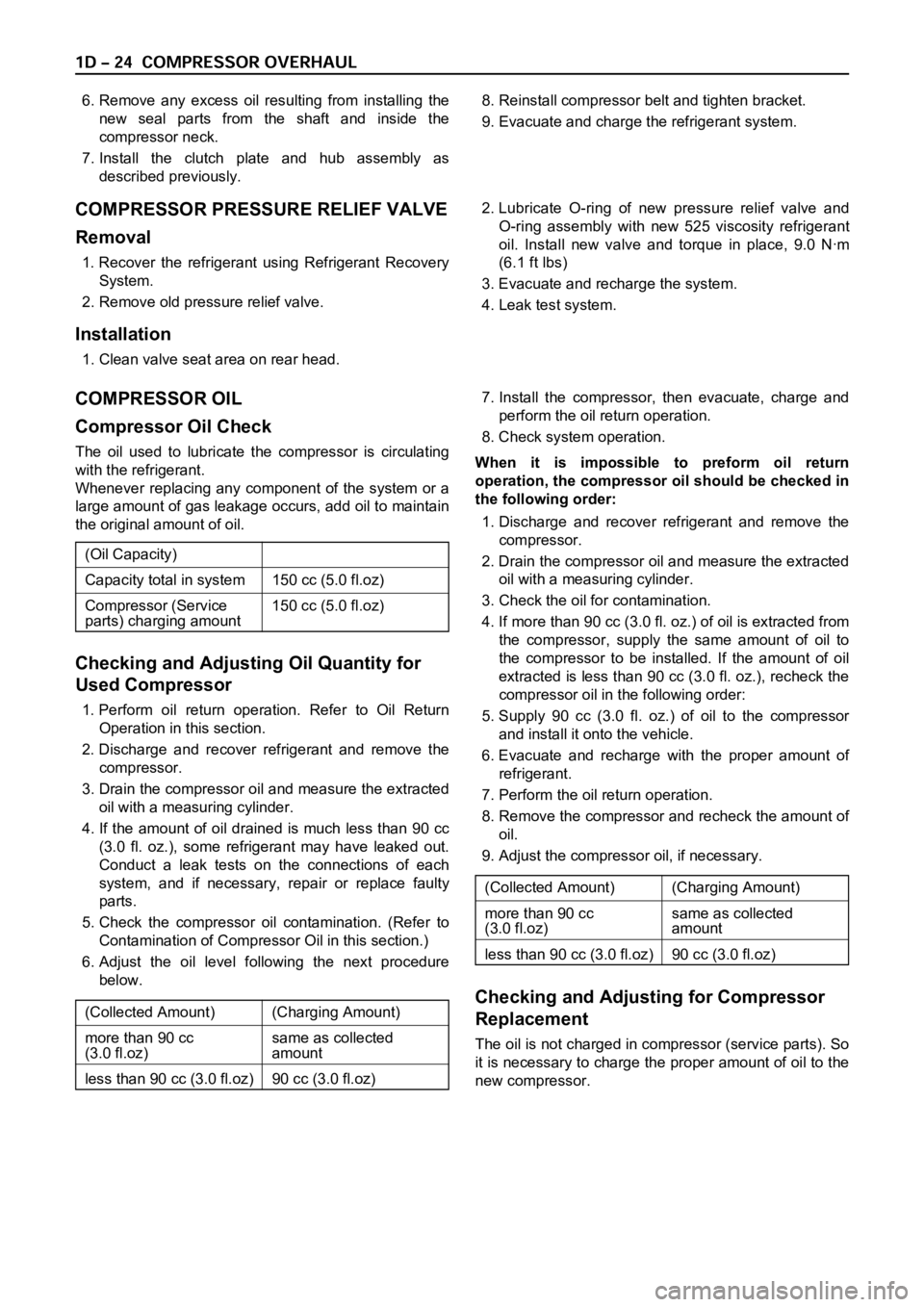

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 438 of 6000

4A1–1 DIFFERENTIAL (FRONT)

DRIVELINE/AXLE

CONTENTS

Differential (Front) 4A1. . . . . . . . . . . . . . . . . . . . . . .

Differential (Rear/220mm) 4A2A. . . . . . . . . . . . . . . .

Differential (Rear/244mm) 4A2B. . . . . . . . . . . . . . . .

Driveline Control System (Shift on the Fly) 4B1. . Driveline Control System (TOD) 4B2. . . . . . . . . . .

Driveshaft System 4C. . . . . . . . . . . . . . . . . . . . . . .

Transfer Case (Standard Type) 4D1. . . . . . . . . . .

Transfer Case (TOD) 4D2. . . . . . . . . . . . . . . . . . . .

DIFFERENTIAL (FRONT)

CONTENTS

Service Precaution 4A1–1. . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 4A1–2. . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal 4A1–3. . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal and Associated Parts 4A1–3

Removal 4A1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1–4. . . . . . . . . . . . . . . . . .

Installation 4A1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle Assembly 4A1–5. . . . . . . . . . . . . . .

Front Drive Axle Assembly and

Associated Parts 4A1–5. . . . . . . . . . . . . . . . . . . . . .

Removal 4A1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A1–9. . . . . . . . . . . . . . . . . . . .

Disassembled View 4A1–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A1–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A1–21. . . . . . . . . . . . . . .

Disassembled View 4A1–21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1–22. . . . . . . . . . . . . . . . . .

Reassembly 4A1–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A1–25. . . . . . . . . . .

Special Tools 4A1–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.