battery OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3456 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–19

NOTE: Ensure that the pigtail adapter is firmly seated into

the air bag assembly connector. Failure to fully seat the

connectors may leave the shorting bar located in the air

bag assembly connector functioning (shorting the

deployment circuit) and may result in non deployment of

the air bag assembly.

827RW054

3. Put a tire without wheel on another, put the tire on

which the air bag is fixing, put a tire without a

wheel, and finally put a tire with a wheel on top.

Bind the tires with a rope so that the tires pile may

not collapse.

827RW050

Legend

(A) 10 m (33 feet) or more

9. Notify all people in the immediate area of your

intention to deploy the passenger air bag assembly.

The deployment will be accompanied by a substantial

noise which may startle the uninformed.

WARNING: DEPLOYED HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A CONNECTING THE

DEPLOYMENT HARNESS TO THE POWER SOURCE

SHOULD ALWAYS BE THE LAST STEP IN THE AIR

BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED MAY RESULT IN PERSONAL

INJURY.

10. Connect the Supplemental Restraint System (SRS)

deployment harness wires to the power source to

immediately deploy the air bag assembly.

Recommended application : 12 volts minimum, 2

amps minimum. A vehicle battery is suggested.

827LW011

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED AIR BAG

ASSEMBLY. AFTER DEPLOYMENT, THE METAL

SURFACES OF THE AIR BAG ASSEMBLY WILL BE

VERY HOT. ALLOW THE AIR BAG ASSEMBLY TO

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED INFLATOR

MODULE NEAR ANY FLAMMABLE OBJECTS.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

I N F IR E O R PE RSO NAL IN JU RY. A FT ER A N A IR BAG

ASSEMBLY HAS BEEN DEPLOYED, THE METAL

CANISTER AND SURROUNDING AREAS OF THE AIR

BAG ASSEMBLY WILL BE HOT. DO NOT TOUCH THE

METAL AREAS OF THE AIR BAG ASSEMBLY FOR

ABOUT THIRTY MINUTES AFTER DEPLOYMENT. IF

THE DEPLOYED AIR BAG ASSEMBLY MUST BE

MOVED BEFORE IT IS COOL, WEAR GLOVES AND

HANDLE BY THE AIR BAG IT SELF.

11. Disconnect the pigtail adapter from the air bag

assembly as soon after deployment as possible to

avoid damage to the pigtail adapter or SRS

deployment harness from contacting the hot air bag

assembly canister. The pigtail adapter and SRS

deployment harness are designed to be reused. They

should, however, be inspected for damage after each

deployment and replaced if necessary.

12. Dispose of the deployed air bag assembly through

normal refuse channels after it has cooled for at least

30 minutes.

Page 3459 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–22

28. Connect the driver deployment harness wires to a

power source to immediately deploy the driver air bag

assembly. Recommended application: 12 volts

minimum, 2 amps minimum. A vehicle battery is

suggested.

29. Separate the two ends of the passenger deployment

harness wires.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE IS

CONNECTED TO IT. CONNECTING THE

DEPLOYMENT WIRES TO THE POWER SOURCE

SHOULD ALWAYS BE THE FINAL STEP IN THE AIR

BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED COULD RESULT IN PERSONAL

INJURY.

30. Connect the passenger deployment harness wires to

a power source to immediately deploy the passenger

air bag assembly. Recommended application: 12

volts minimum, 2 amps minimum. A vehicle battery is

suggested.(Driver air bag assembly) Put on a pair of

shop gloves and safety glasses to protect your hands

and eyes from possible irritation and heat when

handling the deployed air bag assembly. After the air

bag assembly has been deployed, the surface of the

air bag may contain solid particulate. This solid

particulate consists primarily of by products of the

chemical reaction, Potassium Chloride and copper

metal dust. Compounds of Potassium Borate,

Strontium Chloride, Copper Chloride, and

Ammonium Chloride may be found in amounts of

about 1 % (each) of the total particulate.

(Passenger air bag assembly)

Put on a pair of shop gloves and safety glasses to

protect your hands and eyes from possible irritation

and heat when handling the deployed air bag

assembly.

After the air bag assembly has been deployed, the

surface of the air bag may contain a powdery residue.

This powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by product of the

deployment reaction. The sodium hydroxide then

quickly reacts with atmospheric moisture and is

converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikely

that sodium hydroxide will be present after

deployment.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE

METAL SURFACES OF THE AIR BAG ASSEMBLY

WILL BE VERY HOT. ALLOW THE AIR BAG

ASSEMBLY TO COOL BEFORE HANDLING ANY

METAL PORTION OF IT. DO NOT PLACE THE HOT

DEPLOYED AIR BAG ASSEMBLY NEAR ANY

FLAMMABLE OBJECTS. FAILURE TO FOLLOWPROCEDURES COULD RESULT IN FIRE OR

PERSONAL INJURY.

After an air bag assembly has been deployed, the

metal canister and surrounding areas of the air bag

assembly will be very hot. Do not touch the metal

areas of the air bag assembly for about 30 minutes

after deployment. If the deployed air bag assembly

must be moved before it is cool, wear gloves and

handle by the air bag or trim cover.

31. Short the driver deployment harness wires by twisting

together one end from each. Repeat this procedure

for the passenger deployment harness.

32. Carefully remove drop cloth from vehicle and clean off

any fragments or discard drop cloth entirely.

33. Disconnect driver deployment harness and

passenger deployment harness from vehicle and

discard.

34. In the unlikely event that either or both of the air bag

assemblies did not deploy after following these

procedures, proceed immediately with Steps 36

through 37. If the air bag assembly deployed, proceed

to step 35.

35. With both air bags deployed, the vehicle may be

scrapped in the same manner as a non–SRS

equipped vehicle.

NOTE: The remaining steps are to be followed in the

unlikely event that the air bag assembly did not deploy

after following these procedures.

36. Remove the undeployed air bag assembly (s) from

the vehicle. For driver air bag assembly refer to in the

“Passenger Air Bag Assembly Removal” in this

manual.

WARNING: W H E N S T O R I N G A L I V E A I R B A G

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR OTHER

SURFACE, ALWAYS FACE THE BAG AND TRIM

COVER UP, AWAY FROM THE SURFACE. THIS IS

NECESSARY SO THAT A FREE SPACE IS PROVIDED

TO ALLOW THE AIR BAG TO EXPAND IN THE

UNLIKELY EVENT OF ACCIDENTAL DEPLOYMENT.

FAILURE TO FOLLOW PROCEDURES COULD

RESULT IN PERSONAL INJURY.

37. Temporarily store the air bag assembly with the air

bag opening facing up, away from the surface upon

which it rests.

Deployed Air Bag Assembly Handling

Put on a pair of shop gloves and safety glasses to protect

your hands and eyes from possible irritation and heat

when handling the deployed air bag assembly.

After the air bag assembly has been deployed, the

surface of the air bag may contain a powdery residue.

(Passenger air bag assembly)

After the air bag assembly has been deployed, the

surface of the air bag may contain a powdery residue.

This powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by products of the

chemical reaction. Sodium hydroxide dust (similar to lye

soap) is produced as a by product of the deployment

reaction. The sodium hydroxide then quickly reacts with

atmospheric moisture and is converted to sodium

Page 3460 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–23

carbonate and sodium bicarbonate (baking soda).

Therefore, it is unlikely that sodium hydroxide will be

present after deployment.

(Driver air bag assembly)

After the air bag assembly has been deployed, the

surface of the air bag may contain solid particulate. This

solid particulate consists primarily of by products of the

chemical reaction, Potassium Chloride and copper metal

dust. Compounds of Potassium Borate, Strontium

Chloride, Copper Chloride, and Ammonium Chloride may

be found in amounts of about 1 % (each) of the total

particulate.

Deployment Outside Vehicle (Pretensioner

Seat Belt Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

pretensioner seat belt assembly is replaced. Deployment

and disposal of a malfunctioning pretensioner seat belt

assembly is, of course, subject to any required retention

period.

For deployment of a live (undeployed) pretensioner seat

belt assembly outside the vehicle, the deployment

procedure must be followed exactly. Always wear gloves

and safety glasses during this deployment procedure until

a deployed pretensioner seat belt assembly is scrapped

or until an undeployed pretensioner seat belt assembly is

shipped. Before performing the procedures you should

be familiar with servicing the system and with proper

handling of the pretensioner seat belt assembly.

Procedures should be read fully before they are

performed.

The following procedure requires use of SRS deployment

harness with appropriate pigtail adapter. Do not attempt

procedure without adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

PRETENSIONER SEAT BELT ASSEMBLY.

DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT ASSEMBLY WILL IMMEDIATELY DEPLOY THE

PRETENSIONER SEAT BELT WHEN A POWER

SOURCE IS CONNECTED TO IT. WEAR GLOVES

AND SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

1. Turn ignition switch to “LOCK”, remove key.

2. Remove the pretensioner seat belt assembly from

vehicle. Refer to “Pretensioner Seat Belt Removal” in

this manual.

3. Prepare SRS deployment harness.

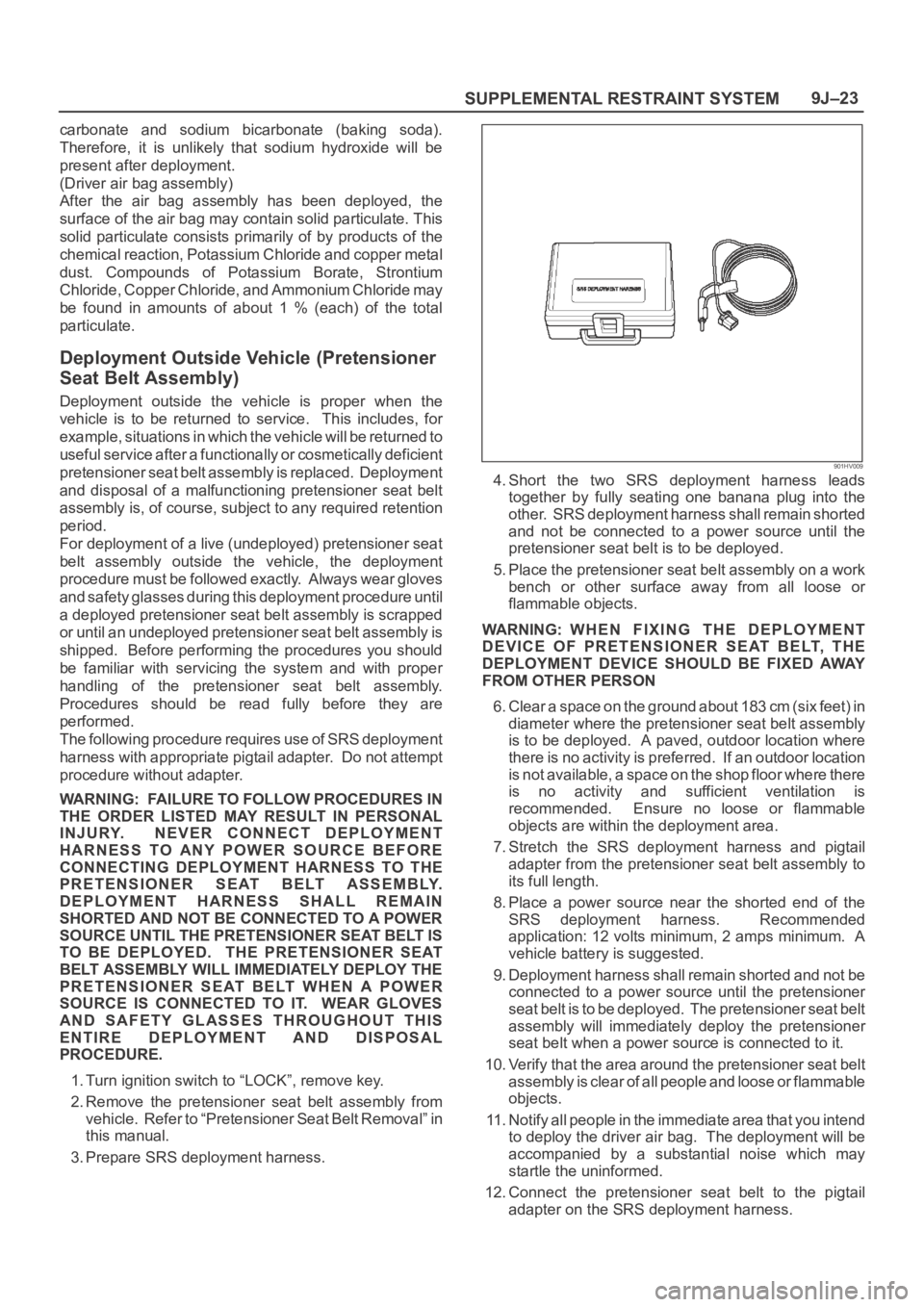

901HV009

4. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the

pretensioner seat belt is to be deployed.

5. Place the pretensioner seat belt assembly on a work

bench or other surface away from all loose or

flammable objects.

WARNING: WHEN FIXING THE DEPLOYMENT

DEVICE OF PRETENSIONER SEAT BELT, THE

DEPLOYMENT DEVICE SHOULD BE FIXED AWAY

FROM OTHER PERSON

6. Clear a space on the ground about 183 cm (six feet) in

diameter where the pretensioner seat belt assembly

is to be deployed. A paved, outdoor location where

there is no activity is preferred. If an outdoor location

is not available, a space on the shop floor where there

is no activity and sufficient ventilation is

recommended. Ensure no loose or flammable

objects are within the deployment area.

7. Stretch the SRS deployment harness and pigtail

adapter from the pretensioner seat belt assembly to

its full length.

8. Place a power source near the shorted end of the

SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps minimum. A

vehicle battery is suggested.

9. Deployment harness shall remain shorted and not be

connected to a power source until the pretensioner

seat belt is to be deployed. The pretensioner seat belt

assembly will immediately deploy the pretensioner

seat belt when a power source is connected to it.

10. Verify that the area around the pretensioner seat belt

assembly is clear of all people and loose or flammable

objects.

11. Notify all people in the immediate area that you intend

to deploy the driver air bag. The deployment will be

accompanied by a substantial noise which may

startle the uninformed.

12. Connect the pretensioner seat belt to the pigtail

adapter on the SRS deployment harness.

Page 3461 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–24

NOTE: Ensure that the pigtail adapter is firmly seated into

the pretensioner seat belt assembly connector. Failure to

fully seat the connectors may leave the shorting bar

located in the pretensioner seat belt assembly connector

functioning (shorted) and may result in nondeployment of

the pretensioner seat belt assembly.

13. Separate the two banana plugs on the SRS

deployment harness.

NOTE: When the pretensioner seat belt deploys, the

rapid gas expansion will create a substantial noise. Notify

all people in the immediate area that you intend to deploy

the pretensioner seat belt.

WARNING: DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO A

POWER SOURCE UNTIL THE PRETENSIONER SEAT

BELT IS TO BE DEPLOYED. THE PRETENSIONER

SEAT BELT ASSEMBLY WILL IMMEDIATELY

DEPLOY THE PRETENSIONER SEAT BELT WHEN A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT HARNESS TO

THE POWER SOURCE SHOULD ALWAYS BE THE

LAST STEP IN THE PRETENSIONER SEAT BELT

ASSEMBLY DEPLOYMENT PROCEDURE. FAILURE

TO FOLLOW PROCEDURES IN THE ORDER LISTED

MAY RESULT IN PERSONAL INJURY.

14. Connect the SRS deployment harness wires to the

power source to immediately deploy the pretensioner

seat belt. Recommended application: 12 volts

minimum, 2 amps minimum. A vehicle battery is

suggested.

15. Disconnect the SRS deployment harness from the

power source.

16. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other.

17. In the unlikely event that the pretensioner seat belt

assembly did not deploy after following these

procedures, proceed immediately with Steps 21

through 24. If the pretensioner seat belt assembly did

deploy, proceed with Steps 15 through 20.

18.

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED

PRETENSIONER SEAT BELT ASSEMBLY. AFTER

DEPLOYMENT, THE METAL SURFACES OF THE

PRETENSIONER SEAT BELT ASSEMBLY WILL BE

VERY HOT. ALLOW THE INFLATOR MODULE TO

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED

PRETENSIONER SEAT BELT ASSEMBLY NEAR ANY

FLAMMABLE OBJECTS. FAILURE TO FOLLOW

PROCEDURES MAY RESULT IN FIRE OR PERSONAL

INJURY.

AFTER A DRIVER PRETENSIONER SEAT BELT

ASSEMBLY HAS BEEN DEPLOYED, THE METAL

CANISTER AND SURROUNDING AREAS OF THE

DRIVER PRETENSIONER SEAT BELT ASSEMBLY

WILL BE VERY HOT. DO NOT TOUCH THE METAL

AREAS OF THE PRETENSIONER SEAT BELT

ASSEMBLY FOR ABOUT TEN MINUTES AFTER

DEPLOYMENT. IF THE DEPLOYED PRETENSIONERSEAT BELT ASSEMBLY MUST BE MOVED BEFORE

IT IS COOL, WEAR GLOVES AND HANDLE BY THE

PRETENSIONER SEAT BELT OR TRIM COVER.

19. Disconnect the pigtail adapter from the pretensioner

seat belt assembly as soon after deployment as

possible. This will prevent damage to the pigtail

adapter or SRS deployment harness due to possible

contact with the hot pretensioner seat belt assembly

canister. The pigtail adapter can be reused. They

should, however, be inspected for damage after each

deployment and replaced if necessary.

20. Dispose of the deployed pretensioner seat belt

assembly through normal refuse channels after it has

cooled for at least 30 minutes.

21. Wash your hands with mild soap and water afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the pretensioner seat belt assembly

did not deploy after following these procedures.

22. Ensure that the SRS deployment harness has been

disconnected from the power source and that its two

banana plugs have been shorted together by fully

seating one banana plug into the other.

23. Disconnect the pigtail adapter from the pretensioner

seat belt assembly.

24. Remove the undeployed pretensioner seat belt from

the special tool.

WARNING: W H E N S TO R I N G A L I V E

PRETENSIONER SEAT BELT ASSEMBLY OR WHEN

LEAVING A LIVE INFLATOR MODULE UNATTENDED

ON A BENCH OR OTHER SURFACE, ALWAYS PUT

THE PRETENSIONER SEAT BELT HORIZONTAL

PLACE. THIS IS NECESSARY SO THAT A FREE

SPACE IS PROVIDED TO ALLOW THE

PRETENSIONER SEAT BELT TO SHRINK IN THE

UNLIKELY EVENT OF ACCIDENTAL DEPLOYMENT.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

IN PERSONAL INJURY.

25.Temporarily store the pretensioner seat belt

assembly with its deployment device facing up, away

from the surface upon which it rests.

Deployment Inside Vehicle (Pretensioner

Seat Belt Vehicle Scrapping Procedure)

Deployment inside vehicle is proper when the vehicle is to

be destroyed. This includes, but is not limited to, the

following situations:

1. The vehicle has completed its useful life.

2. The vehicle has been damaged beyond repair in a

nondeployment type accident.

3. The vehicle has been stripped or damaged beyond

repair in a theft.

NOTE: The vehicle will be salvaged for component parts

to be used on a vehicle with a different Vehicle

Identification Number (VIN) as opposed to being rebuilt

as same VIN. Never use pretensioner seat belt

components from another vehicle.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED COULD RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT WIRES

Page 3462 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–25

TO ANY POWER SOURCE BEFORE CONNECTING

DEPLOYMENT WIRES TO THE PRETENSIONER

SEAT BELT ASSEMBLY LEADS. DEPLOYMENT

WIRES SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE

PRETENSIONER SEAT BELT IS TO BE DEPLOYED.

THE PRETENSIONER SEAT BELT ASSEMBLY WILL

IMMEDIATELY DEPLOY THE PRETENSIONER SEAT

BELT WHEN A POWER SOURCE IS CONNECTED TO

IT. WEAR SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

1. Turn ignition switch to “LOCK,” remove key and put

on safety glasses.

2. Remove all loose objects from front seats.

3. Disconnect pretensioner seat belt assembly, yellow

2–pin connector located at the base of the seat.

4. Prepare SRS deployment harness.

5. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other.

6. Deployment harness shall remain shorted and not be

connected to a power source until the pretensioner

seat belt is to be deployed.

7. Route deployment harness out the driver side of the

vehicle.

8. Verify that the inside of the vehicle and the area

surrounding the vehicle are clear of all people and

loose or flammable objects.

9. Stretch the SRS deployment harness to their full

length.

10. Connect the deployment harness to the pretensioner

seat belt assembly, yellow 2-pin connector at the

base of the seat.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT ASSEMBLY WILL IMMEDIATELY DEPLOY THE

PRETENSIONER SEAT BELT WHEN A POWER

SOURCE IS CONNECTED TO IT. CONNECTING THE

DEPLOYMENT WIRES TO THE POWER SOURCE

SHOULD ALWAYS BE THE FINAL STEP IN THE

PRETENSIONER SEAT BELT ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO FOLLOW

PROCEDURES IN THE ORDER LISTED COULD

RESULT IN PERSONAL INJURY.

11. Notify all people in the immediate area that you intend

to deploy the pretensioner seat belt. The deployment

will be accompanied by a substantial noise which may

startle the uninformed.

12. Separate the two banana plugs on the SRS

deployment harness.

NOTE: When the pretensioner seat belt deploys, the

rapid gas expansion will create a substantial noise. Notify

all people in the immediate area that you intend to deploy

the pretensioner seat belt.13. Connect the SRS deployment harness wires to a

power source to immediately deploy the pretensioner

seat belt assembly. Recommended application: 12

volts minimum, 2 amps minimum. A vehicle battery is

suggested.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO IS TO BE DEPLOYED. THE PRETENSIONER

SEAT BELT ASSEMBLY WILL IMMEDIATELY

DEPLOY THE PRETENSIONER SEAT BELT WHEN A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT WIRES SHOULD

ALWAYS BE THE FINAL STEP IN THE

PRETENSIONER SEAT BELT ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO FOLLOW

PROCEDURES IN THE ORDER LISTED COULD

RESULT IN PERSONAL INJURY.

14. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other.

15. Disconnect the deployment harness to the

pretensioner seat belt assembly, yellow 2-pin

connector at the base of the seat.

16. In the unlikely event that the pretensioner seat belt

assembly did not deploy after following these

procedures, proceed immediately with Steps 18

through 19. If the pretensioner seat belt assembly

deployed as intended, proceed with Steps 14 through

17.

17. With both air bags and pretensioner seat belt

deployed, the vehicle may be scrapped in the same

manner as a non–SRS equipped vehicle.

NOTE: The remaining steps are to be followed in the

unlikely event that the pretensioner seat belt assembly

did not deploy after following these procedures.

18. Remove the undeployed pretensioner seat belt

assembly (s) from the vehicle. For pretensioner seat

belt assembly refer to in the “Pretensioner Seat Belt

Assembly Removal” in this manual.

19.Temporarily store the pretensioner seat belt

assembly with the deployment device facing up, away

from the surface upon which it rests.

Page 3463 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–26

Special Tools

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A

NONPOWERED PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

5–8840–2421–0 SRS Driver/Passenger

Load Tool

901RS146The SRS Driver/Passenger Load Tool 5–8840–2421–0 is

used only when called for in this section. It is used as a

diagnostic aid and safety device to prevent inadvertent air

bag assembly deployment.

The load tool has three yellow connectors attached to its

case.

The three small connectors are electrically functional and

serve as resistive load substitutions.

No more than two connectors are used at any time. One

of the small connectors is used to substitute for the load of

the driver air bag assembly when it is connected at the top

of the column to the SRS coil assembly. Another small

connector is used to substitute for the load of the driver air

bag assembly and the SRS coil assembly when it is

connected at the base of the column to the SRS wiring

harness. The third small connector is used to substitute

for the load of the passenger air bag assembly and

pretensioner seat belt assembly when connected to the

passenger air bag assembly and pretensioner seat belt

assembly harness connector.

By substituting the resistance of the load tool when called

for, a determination can be made as to whether an inflator

circuit component is causing system malfunction and

which component is causing the malfunction. The loadtool should be used only when specifically called for in the

diagnostic procedures.

NOTE: If comand to use 5–8840–2421–0 load tool when

repair the pretensioner seat belt, connect load tool

connector to use for driver air bag and/or passenger air

bag connector.

5–8840–0285–0 DVM

901RS153The 5–8840–0285–0 DVM is the preferred DVM for use in

SRS diagnosis and repair. However, 5–8840–0366–0

may be used if 5–8840–0285–0 is not available. No other

DVMs are approved for SRS diagnosis and repair.

Scan Tool

901RW176The Tech 2 is used to read and clear SRS Diagnostic

Trouble Codes (DTCs). Refer to the Tech 2 Operators,

Manual for specific information on how to use the Tech 2.

Page 3467 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–30

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle’s wheels are pointing straight

ahead.

1. Remove SRS fuse “C–21” from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3 . R e m o v e g l o v e b o x a s s e m b l y ; R e f e r t o “ P a s s e n g e r a i r

bag assembly replacement” in this section.

4. Disconnect passenger air bag assembly yellow 2–pin

connector behind the glove box assembly.

CAUTION: W i t h t h e “ C – 2 1 ” f u s e r e m o v e d a n d

ignition switch “ON,” the “AIR BAG” warning lamp

will be “ON.” This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.2. Install glove box assembly. Refer to “Passenger Air

Bag Assembly Replacement” in this section.

3. Connect yellow 2–pin connector at the base of the

steering column.

4. Install “AIR BAG” fuse “C–21” to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 93

C (200F).

2. Air bag assembly, and SDM should not be used if they

have been dropped from a height of 100 centimeters

(3.28 feet) or more.

3. When a SDM is replaced, it must be oriented with the

arrow on the SDM pointing toward the front of the

vehicle. It is very important for the SDM to be located

flat on the mounting surface, parallel to the vehicle

datum line. It is important that the SDM mounting

surface is free of any dirt or other foreign material.

4. Do not apply power to the SRS unless all components

are connected or a diagnostic chart requests it, as

this will set a diagnostic trouble code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “AIR

BAG” warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

Inspections Required After An Accident

CAUTION: C e r t a i n S R S c o m p o n e n t s m u s t b e

replaced after a frontal crash involving air bag

deployment.

In all types of accidents regardless of “Air Bag”

deployment, visually inspect all of the following

components and replace as required:

— Driver air bag assembly

— Passenger air bag assembly

— Driver pretensioner assembly

— Passenger pretensioner assembly

— Steering wheel

— SRS coil assembly

— Steering column

— Knee bolster and instrument panel mounting

attachments

— Driver seat and belt

— Passenger seat and belt

—SDM

SDM always should be checked according to “SDM

Replacement Guidelines.”

Page 3489 of 6000

RESTRAINT CONTROL SYSTEM 9J1–2

Diagnostic Information

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. if a fastener needs to be replaced, use

the correct part number fastener for that application.

if the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. the correct torque value must be used when

installing fasteners that require it. if the above

conditions are not followed, parts or system damage

could result.

Diagnostic Procedures

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY–POWERED OR AC–POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED, PROBE–TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

The diagnostic procedures used in this section are

designed to aid in finding and repairing SRS problems.

Outlined below are the steps to find and repair SRS

problems quickly and effectively. Failure to carefully

follow these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect parts

replacement.

1.Perform The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” should always

be the starting point of any SRS diagnostics. The

“SRS Diagnostic System Check” checks for proper

“AIR BAG” warning lamp operation and checks for

SRS trouble codes using both “Flash Code” and

“Scan Tool” Methods.

2.Refer To The Proper Diagnostic Chart As Directed

By The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” will lead you to

the correct chart to diagnose any SRS problems.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

3.Repeat The “SRS Diagnostic System Check”

After Any Repair Or Diagnostic Procedures Have

Been Performed.

Preforming the “SRS Diagnostic System Check” after

all repair or diagnostic procedures will assure that the

repair has been made correctly and that no other

conditions exist.

Diagnostic Codes

The Sensing and Diagnostic Module (SDM) maintains a

history record of all diagnostic codes that have beendetected since the SRS codes were last cleared during

service.

1. Active Codes — Faults that are presently detected

this ignition cycle. Active codes are stored in RAM

(Random Access Memory).

2. History Codes — All faults detected since the last

time the history fault memory was cleared. History

codes are stored in EEPROM. (Electronically

Erasable Programmable Read only Memory)

How To Read Trouble Codes

All codes (Active and history) can be read (or cleared) by

using a scan tool or equivalent.

If a PDT is not available, have the vehicle serviced by

ISUZU dealer.

How To Clear Trouble Codes

Trouble codes can only be cleared by using a Scan Tool.

If a “scan tool” is not available then inform the owner of the

stored codes and suggest that the codes are cleared

upon the next visit to an Isuzu dealership.

Scan Tool Diagnostics

A scan tool can be used to read current and history codes

and to clear all history codes after a repair is complete.

The scan tool must be updated to communicate with the

SRS through a memory card or a manufacturer’s update

before it can be used for SRS diagnostics. To use the

scan tool, connect it to the DLC connector and turn the

ignition switch “ON”. Then follow the manufacturer’s

directions for communication with the SRS. The scan tool

reads serial data from the SDM “Serial Data” output

(terminal 24) to the DLC connector (terminal 9).

Basic Knowledge Required

Before using this section of the Service Manual, there is

some basic knowledge which will be required. Without

this knowledge, you will have trouble using the diagnostic

procedures in this section. Use care to prevent harm or

unwanted deployment. Read all cautions in the service

manual and on warning labels attached to SRS

components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand the

voltage drops across series resistors. You should know

the meaning of voltage (volts), current (amps), and

resistance (ohms). You should understand what happens

in a circuit with an open or a shorted wire. You should be

able to read and understand a wiring diagram.

“Flash Code” Diagnostics

Flash code diagnostics can be used to read active codes

and to determine if history codes are present but cannot

be used to clear codes or read history codes. Flash code

diagnostics is enabled by grounding by terminal 4

shorting to terminal 13 of the DLC connector with the

ignition switch “ON”. Grounding terminal 4 of the DLC

connector pulls the “Diagnostics Request” input (Terminal

1) of the SDM low and signals the SDM to enter the flash

code diagnostic display mode.

Page 3526 of 6000

9J1–39

RESTRAINT CONTROL SYSTEM

DTC 61 Warning Lamp Circuit Failure

D09RW014

Circuit Description:

When the ignition switch is turned “ON”, battery voltage is

applied to the “AIR BAG” warning lamp and to the “Ignition

1” input terminal “12”. The SDM responds by turning on

the “AIR BAG” warning lamp 3.5 seconds. The SDM

monitors the lamp driver output by comparing the output

state at “SRS Warning Lamp” terminal “7” to the

microprocessor commanded state. When “Ignition 1” is in

the specified value, and the output state does not match

the commanded state of the lamp driver for 500

milliseconds, DTC 61 is set.

DTC Will Set When:

“Ignition 1” voltage is in the specified value and the output

state at the “SRS Warning Lamp” terminal does not matchthe commanded state of the lamp driver for 500

milliseconds. This test is run every 100 milliseconds

during “Continuous Monitoring” tests and once per each

ignition cycle at the beginning.

Action Taken:

SDM attempts to turn “ON” the “AIR BAG” warning lamp

and sets a diagnostic trouble code.

DTC Will Clear When:

The ignition switch is turned “OFF.”

Diagnostic Aids:

Refer to Charts B and C to diagnose warning lamp circuit

malfunctions.

Page 3552 of 6000

10A–1

CRUISE CONTROL SYSTEM

CONTROL SYSTEM

CRUISE CONTROL SYSTEM

CONTENTS

Service Precaution 10A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 10A–1. . . . . . . . . . . . . . . . . . . . .

Diagnosis 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Switch 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Switch 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–3. . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Switch 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Main Switch 10A–5. . . . . . . . . . . . . . . Removal 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Switch (Combination Switch) 10A–5

Removal and Installation 10A–5. . . . . . . . . . . . . . .

Cruise Control Unit 10A–6. . . . . . . . . . . . . . . . . . . . . .

Removal 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Actuator 10A–7. . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Cable Diagram (LHD) 10A–7. . . . . . . . . .

Actuator Cable Diagram (RHD) 10A–7. . . . . . . . . .

Removal 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–8. . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The cruise control keeps the vehicle running at a fixed

speed until a signal canceling this fixed speed is received .

When the main switch “AUTO CRUISE” is turned on with

the vehicle in the running mode, the battery voltage is

applied to the control unit. When a signal from the control

switch is input to the control unit while the vehicle is in this

state, the cruise control actuator is activated to operate

the system. Also, while the system is operating, the

“AUTO CRUISE” indicator light in the meter assembly

lights up.

1. SET/COAST Switch Function

1.Set Function: When the SET/COAST switch is

pressed and released with the main switch on, the

speed at which the vehicle is running at that moment

is stored in the memory, and the vehicle automatically

runs at the stored speed.

2.Coast-down Function: When the SET/COAST

switch is kept on while the vehicle in running, the

vehicle decelerates during that time. The speed at

which vehicle is running when the control switch is

turned off is stored in the memory, and the vehicle

automatically returns to the stored speed.

3.Tap-down Function: When the SET/COAST switch

is turned on and off instantaneously while the vehicle

is running, the vehicle decelerates a mile for each

on/off operation. The vehicle speed at which the

vehicle was running when the SET/COAST was

turned off last is stored in the memory, and the vehicle

automatically returns to this stored speed.