oil level OPEL FRONTERA 1998 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5006 of 6000

6E–349 ENGINE DRIVEABILITY AND EMISSIONS

Damage during re-gapping can happen if the gapping

tool is pushed against the center electrode or the

insulator around it, causing the insulator to crack.

When re-gapping a spark plug, make the adjustment

by bending only the ground side terminal, keeping the

tool clear of other parts.

”Heat shock” breakage in the lower insulator tip

generally occurs during several engine operating

conditions (high speeds or heavy loading) and may be

caused by over-advanced timing or low grade fuels.

Heat shock refers to a rapid increase in the tip

temperature that causes the insulator material to

crack.

Spark plugs with less than the recommended amount of

service can sometimes be cleaned and re-gapped , then

returned to service. However, if there is any doubt about

the serviceability of a spark plug, replace it. Spark plugs

with cracked or broken insulators should always be

replaced.

A/C Clutch Diagnosis

A/C Clutch Circuit Operation

A 12-volt signal is supplied to the A/C request input of the

PCM when the A/C is selected through the A/C control

switch.

The A/C compressor clutch relay is controlled through the

PCM. This allows the PCM to modify the idle air control

position prior to the A/C clutch engagement for better idle

quality. If the engine operating conditions are within their

specified calibrated acceptable ranges, the PCM will

enable the A/C compressor relay. This is done by

providing a ground path for the A/C relay coil within the

PCM. When the A/C compressor relay is enabled,

battery voltage is supplied to the compressor clutch coil.

The PCM will enable the A/C compressor clutch

whenever the engine is running and the A/C has been

requested. The PCM will not enable the A/C compressor

clutch if any of the following conditions are met:

The throttle is greater than 90%.

The engine speed is greater than 6315 RPM.

The ECT is greater than 119C (246F).

The IAT is less than 5C (41F).

The throttle is more than 80% open.

A/C Clutch Circuit Purpose

The A/C compressor operation is controlled by the

powertrain control module (PCM) for the following

reasons:

It improvises idle quality during compressor clutch

engagement.

It improvises wide open throttle (WOT) performance.

It provides A/C compressor protection from operation

with incorrect refrigerant pressures.

The A/C electrical system consists of the following

components:

The A/C control head.

The A/C refrigerant pressure switches.

The A/C compressor clutch.

The A/C compressor clutch relay.

The PCM.

A/C Request Signal

This signal tells the PCM when the A/C mode is selected

at the A/C control head. The PCM uses this to adjust the

idle speed before turning on the A/C clutch. The A/C

compressor will be inoperative if this signal is not

available to the PCM.

Refer to

A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for A/C electrical system.

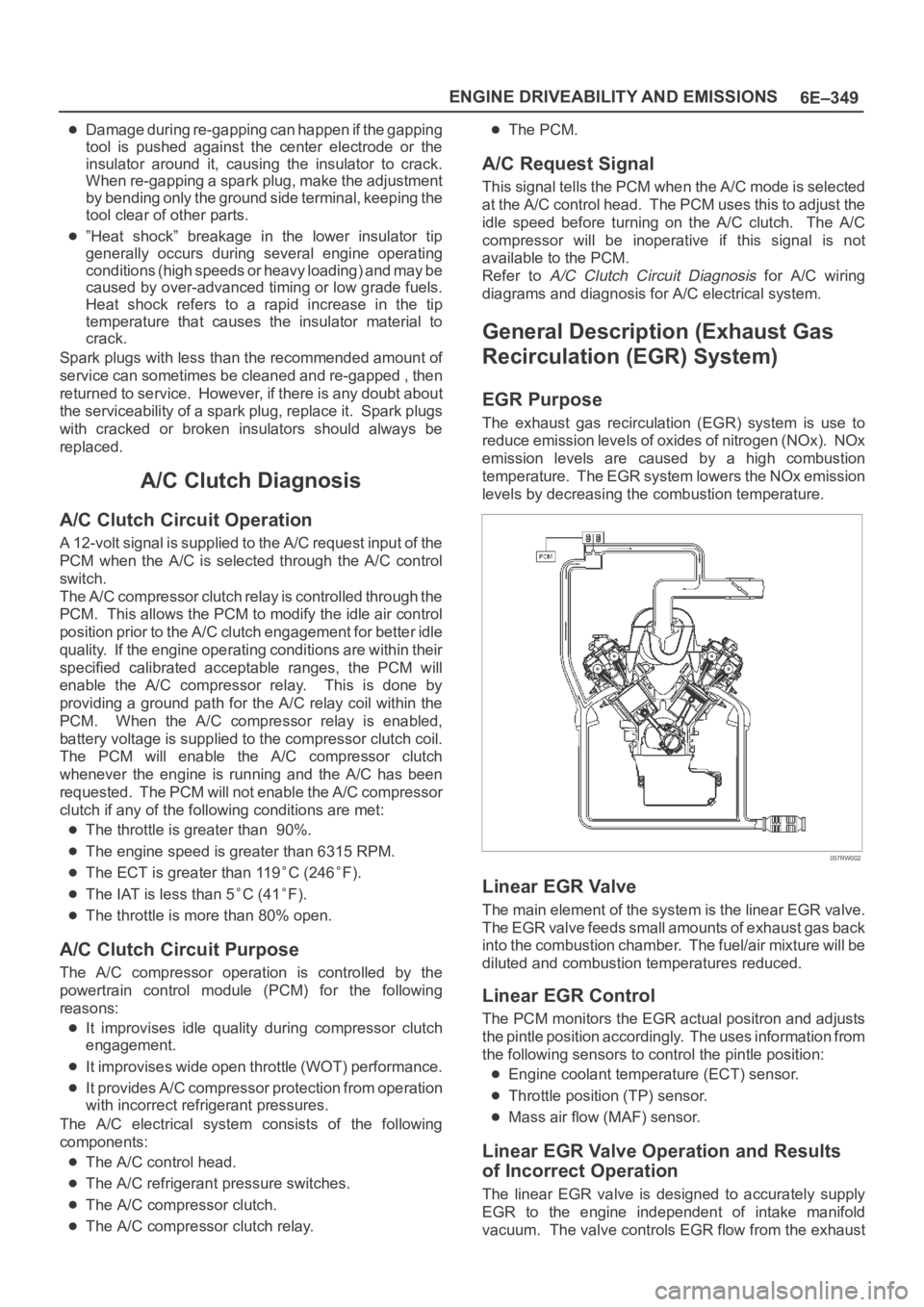

General Description (Exhaust Gas

Recirculation (EGR) System)

EGR Purpose

The exhaust gas recirculation (EGR) system is use to

reduce emission levels of oxides of nitrogen (NOx). NOx

emission levels are caused by a high combustion

temperature. The EGR system lowers the NOx emission

levels by decreasing the combustion temperature.

057RW002

Linear EGR Valve

The main element of the system is the linear EGR valve.

The EGR valve feeds small amounts of exhaust gas back

into the combustion chamber. The fuel/air mixture will be

diluted and combustion temperatures reduced.

Linear EGR Control

The PCM monitors the EGR actual positron and adjusts

the pintle position accordingly. The uses information from

the following sensors to control the pintle position:

Engine coolant temperature (ECT) sensor.

Throttle position (TP) sensor.

Mass air flow (MAF) sensor.

Linear EGR Valve Operation and Results

of Incorrect Operation

The linear EGR valve is designed to accurately supply

EGR to the engine independent of intake manifold

vacuum. The valve controls EGR flow from the exhaust

Page 5026 of 6000

6G–7 ENGINE LUBRICATION

Oil Pan and Crankcase

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Lift vehicle by supporting the frame.

4. Remove front wheels.

5. Remove oil level dipstick from level gauge tube.

6. Remove stone guard.

7. Remove radiator under fan shroud.

8. Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9. Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10. Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11. Remove oil pan fixing bolts.

12. Remove oil pan, using 5–8840–2153–0 sealer cutter,

remove oil pan.

013RS003

13. Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1. Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

The crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

013RW010

Page 5028 of 6000

6G–9 ENGINE LUBRICATION

6. Install suspension cross member and tighten fixing

bolts to the specified torque.

Torque : 78 Nꞏm (8.0 Kgꞏm/58 lb ft)

013RW007

7. Install radiator under fan shroud.

8. Install stone guard.

9. Install engine oil level dipstick.

10. Fill engine oil until full level on engine oil gauge

dipstick.

Page 5030 of 6000

6G–11 ENGINE LUBRICATION

4. Install oil filter assembly and tighten bolts to the

specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Oil Filter

(5) To Oil Filter

5. Install timing pulley on crankshaft.

Install timing belt.

Refer to installation procedure for Timing Belt in this

manual.

6. Install crankshaft pulley.

Refer to install procedure for Crankshaft Pulley in

this manual.

7. Install crankcase assembly.

Refer to installation procedure for Oil Pan and

Crankcase in this manual.

8. Refill engine oil until full level on engine oil dipstick.

Page 5031 of 6000

6G–12

ENGINE LUBRICATION

Oil Pump Oil Seal

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Remove crankshaft pulley.

Refer to removal procedure for Crankshaft Pulley in

this manual.

4. Remove timing belt.

Refer to removal procedure for Timing Belt in this

manual.

5. Remove timing pulley from crankshaft.

6. Remove oil pump oil seal using a sealer puller.

NOTE: Take care not to damage sealing surfaces of oil

pump and crankshaft when removing oil seal.

Installation

1. Install oil pump oil seal, apply engine oil to oil seal lip,

then install oil seal using 5–8840–2287–0 installer.

015RS001

2. Install timing pulley to crankshaft.

3. Install timing belt.

Refer to installation procedure for Timing Belt in this

manual.

4. Install crankshaft pulley.

Refer to installation procedure for Crankshaft

Pulley in this manual.

5. Refill engine oil until full level.

Page 5032 of 6000

6G–13 ENGINE LUBRICATION

Oil Filter

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Remove oil filter using 5-8840-0203-0 filter wrench.

Installation

1. Clean filter fitting surface and apply small amount of

engine oil to sealing surface.

2. Install oil filter cartridge by hand until it comes in

contact with sealing surface then rotate additional 2/3

turn to tighten using 5-8840-0203-0 filter wrench.

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Filter

(5) To Filter

3. Fill engine oil until full level on dipstick.

4. Reconnect battery ground cable.

Page 5283 of 6000

6A – 10 ENGINE MECHANICAL

8. Check the engine oil level and replenish to the

specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

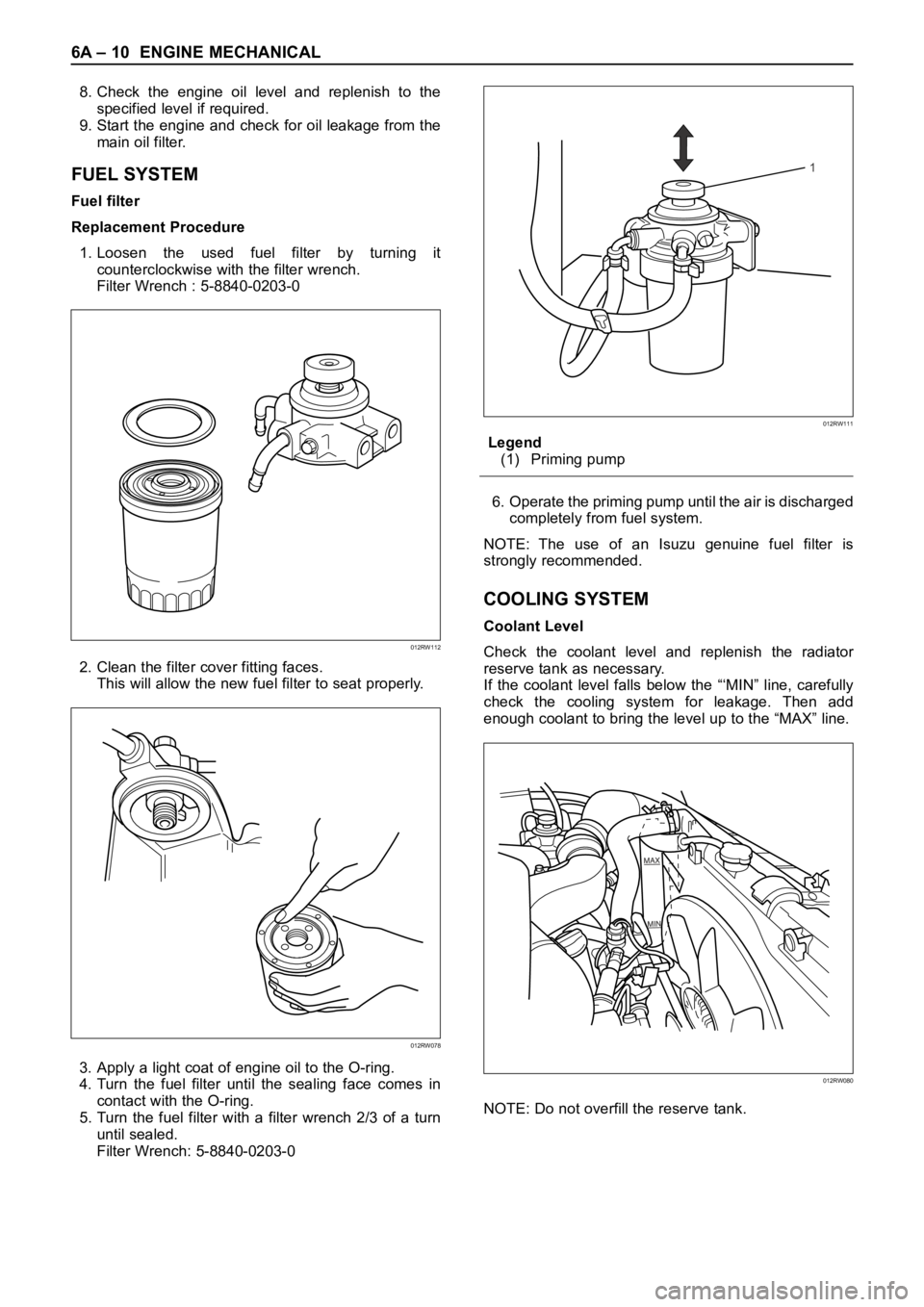

FUEL SYSTEM

Fuel filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench : 5-8840-0203-0

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn the fuel filter with a filter wrench 2/3 of a turn

until sealed.

Filter Wrench: 5-8840-0203-0Legend

(1) Priming pump

6. Operate the priming pump until the air is discharged

completely from fuel system.

NOTE: The use of an Isuzu genuine fuel filter is

strongly recommended.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator

reserve tank as necessary.

If the coolant level falls below the “‘MIN” line, carefully

check the cooling system for leakage. Then add

enough coolant to bring the level up to the “MAX” line.

NOTE: Do not overfill the reserve tank.

012RW112

012RW078

1

012RW111

012RW080

Page 5306 of 6000

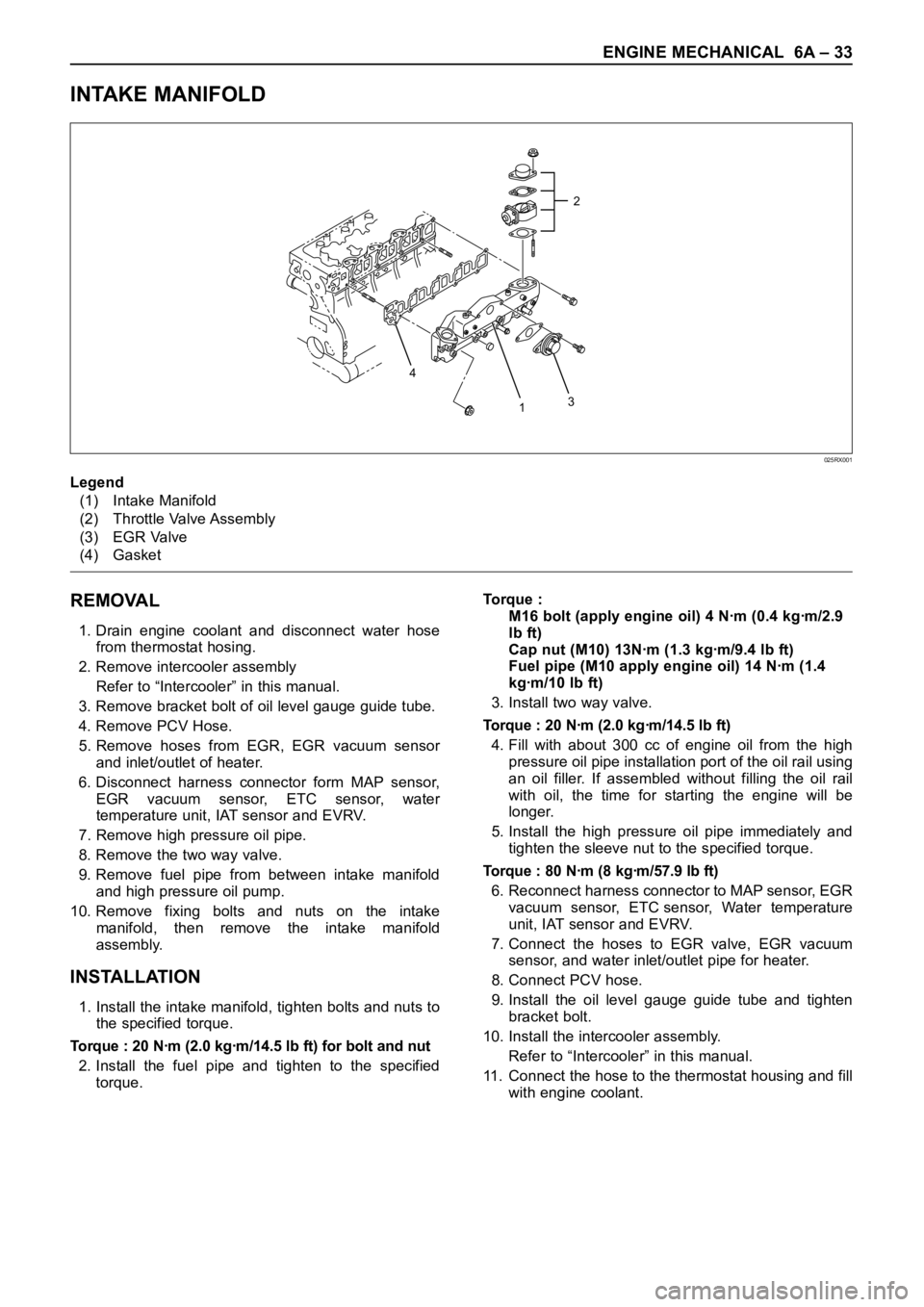

ENGINE MECHANICAL 6A – 33

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and disconnect water hose

from thermostat hosing.

2. Remove intercooler assembly

Refer to “Intercooler” in this manual.

3. Remove bracket bolt of oil level gauge guide tube.

4. Remove PCV Hose.

5. Remove hoses from EGR, EGR vacuum sensor

and inlet/outlet of heater.

6. Disconnect harness connector form MAP sensor,

EGR vacuum sensor, ETC sensor, water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove the two way valve.

9. Remove fuel pipe from between intake manifold

and high pressure oil pump.

10. Remove fixing bolts and nuts on the intake

manifold, then remove the intake manifold

assembly.

INSTALLATION

1. Install the intake manifold, tighten bolts and nuts to

the specified torque.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for bolt and nut

2. Install the fuel pipe and tighten to the specified

torque.To r q u e :

M16 bolt (apply engine oil) 4 Nꞏm (0.4 kgꞏm/2.9

lb ft)

Cap nut (M10) 13Nꞏm (1.3 kgꞏm/9.4 lb ft)

Fuel pipe (M10 apply engine oil) 14 Nꞏm (1.4

kgꞏm/10 lb ft)

3. Install two way valve.

Torque : 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler. If assembled without filling the oil rail

with oil, the time for starting the engine will be

longer.

5. Install the high pressure oil pipe immediately and

tighten the sleeve nut to the specified torque.

Torque : 80 Nꞏm (8 kgꞏm/57.9 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water temperature

unit, IAT sensor and EVRV.

7. Connect the hoses to EGR valve, EGR vacuum

sensor, and water inlet/outlet pipe for heater.

8. Connect PCV hose.

9. Install the oil level gauge guide tube and tighten

bracket bolt.

10. Install the intercooler assembly.

Refer to “Intercooler” in this manual.

11. Connect the hose to the thermostat housing and fill

with engine coolant.

2

3

4

1

025RX001

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

Page 5313 of 6000

6A – 40 ENGINE MECHANICAL

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove air cleaner and air duct.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Remove PCV hose.

7. Remove EGR vacuum hose.

8. Disconnect harness connector around the cylinder

head.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out fan belt.

12. Remove heat protector and remove valve

assembly.

13. Remove water hose and oil pipe from turbocharger.

14. Remove turbocharger assembly.

15. Remove water hose between thermostat and

radiator.

16. Remove cylinder head noise insulator cover.

NOTE: Do not make damage to the harness.

17. Remove high pressure pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner and remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove water pipe between cylinder head and

water pump.

24. Remove fuel pipe between fuel pump and intake

manifold.

25. Remove fuel return pipe.

26. Remove intake manifold assembly.

27. Disconnect glow plug wiring and remove glow plug.

28. Remove cylinder head cover.

29. Drain oil from oil rail.

30. Disconnect injector harness connector.

31. Disconnect harness connector from oil pressure

sensor and oil temperature sensor on the oil rail.

32. Disconnect injector harness assembly.

33. Remove injector clamp.

34. Remove injector spacer.

35. Remove injector assembly.

36. Remove oil rail assembly.

37. Remove camshaft carrier.

38. Remove cylinder head assembly.

39. Remove cylinder gasket.

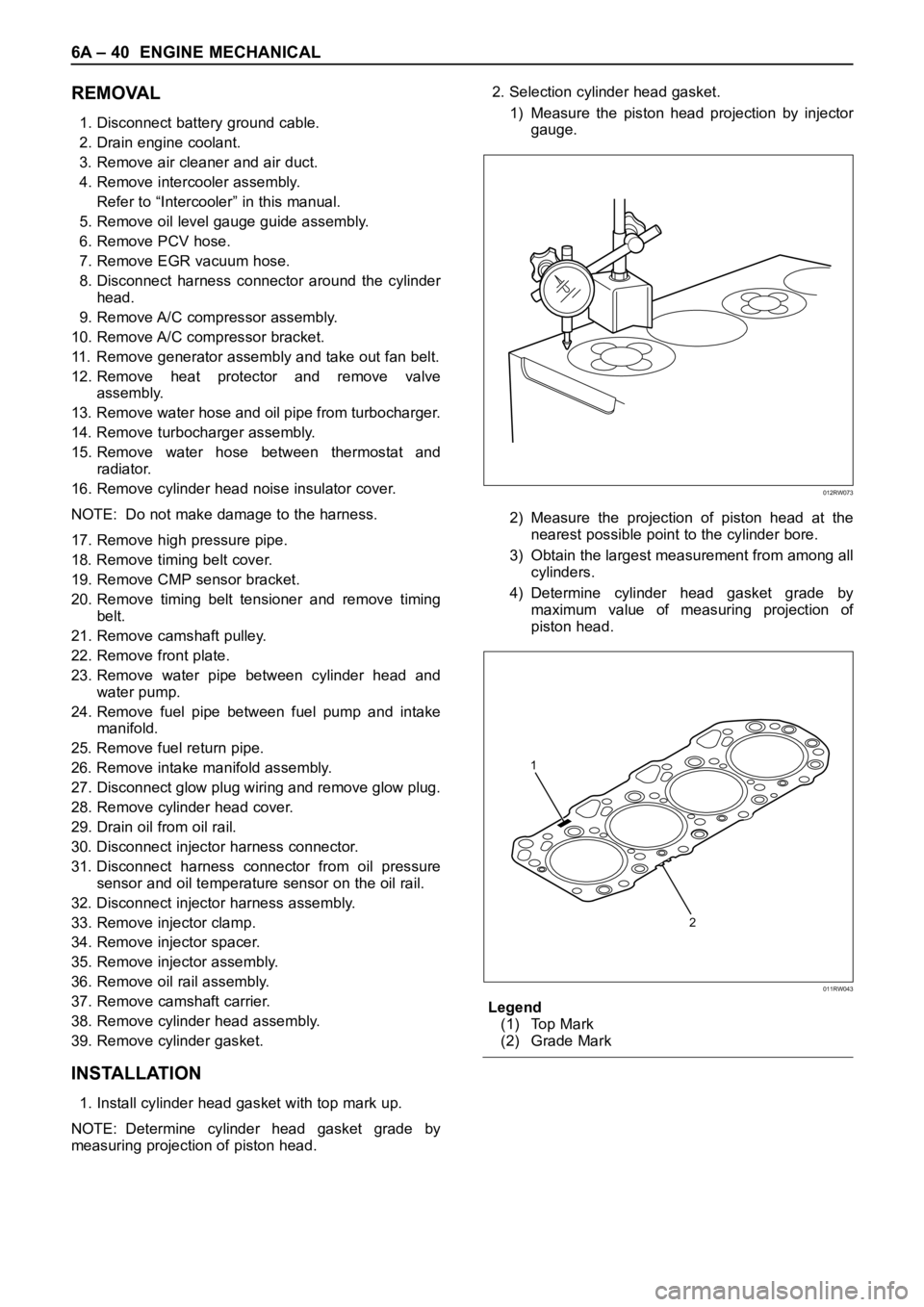

INSTALLATION

1. Install cylinder head gasket with top mark up.

NOTE: Determine cylinder head gasket grade by

measuring projection of piston head.2. Selection cylinder head gasket.

1) Measure the piston head projection by injector

gauge.

2) Measure the projection of piston head at the

nearest possible point to the cylinder bore.

3) Obtain the largest measurement from among all

cylinders.

4) Determine cylinder head gasket grade by

maximum value of measuring projection of

piston head.

Legend

(1) Top Mark

(2) Grade Mark

012RW073

2 1

011RW043

Page 5315 of 6000

6A – 42 ENGINE MECHANICAL

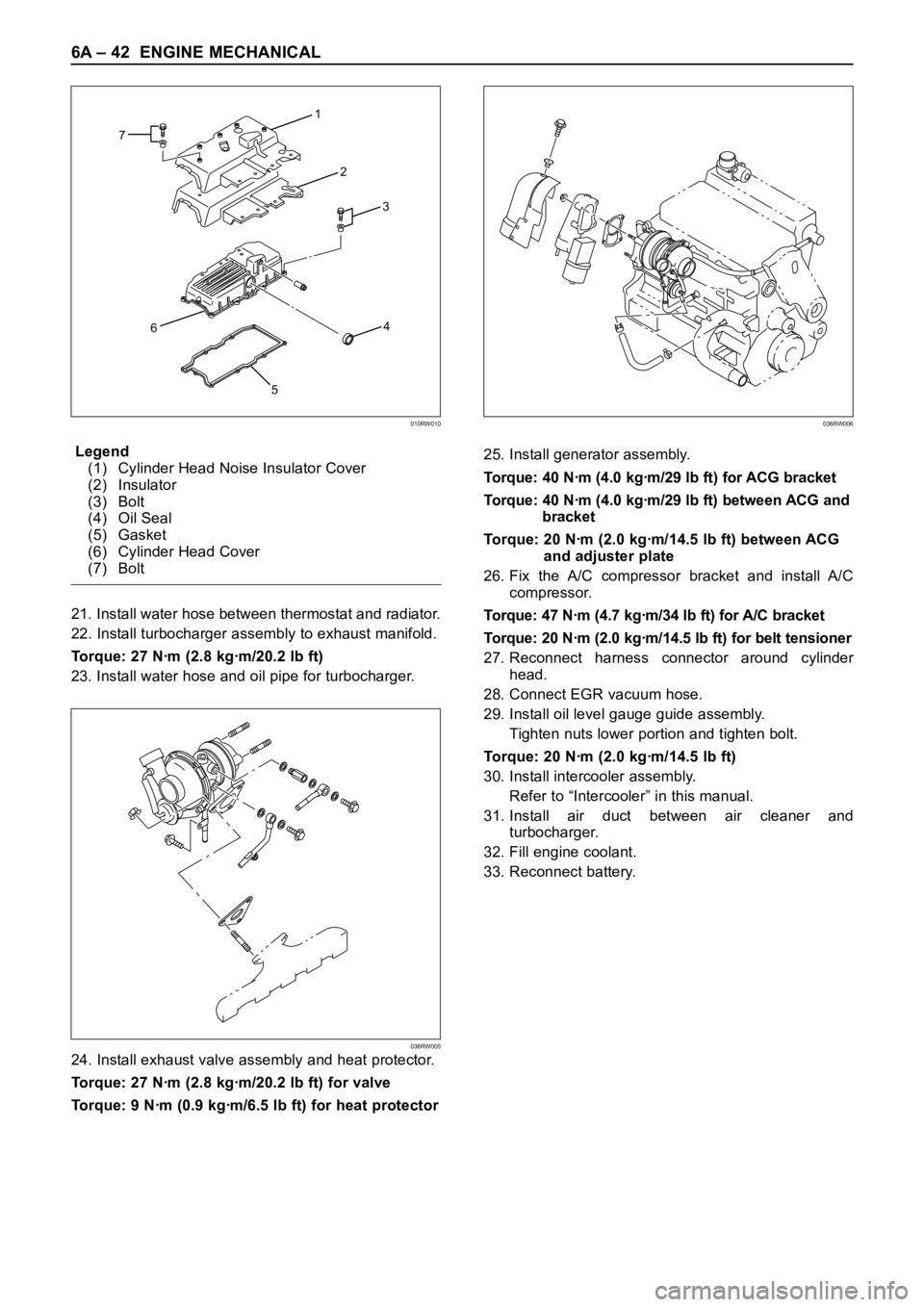

Legend

(1) Cylinder Head Noise Insulator Cover

(2) Insulator

(3) Bolt

(4) Oil Seal

(5) Gasket

(6) Cylinder Head Cover

(7) Bolt

21. Install water hose between thermostat and radiator.

22. Install turbocharger assembly to exhaust manifold.

Torque: 27 Nꞏm (2.8 kgꞏm/20.2 lb ft)

23. Install water hose and oil pipe for turbocharger.

24. Install exhaust valve assembly and heat protector.

Torque: 27 Nꞏm (2.8 kgꞏm/20.2 lb ft) for valve

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft) for heat protector25. Install generator assembly.

Torque: 40 Nꞏm (4.0 kgꞏm/29 lb ft) for ACG bracket

Torque: 40 Nꞏm (4.0 kgꞏm/29 lb ft) between ACG and

bracket

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) between ACG

and adjuster plate

26.Fix the A/C compressor bracket and install A/C

compressor.

Torque: 47 Nꞏm (4.7 kgꞏm/34 lb ft) for A/C bracket

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for belt tensioner

27. Reconnect harness connector around cylinder

head.

28. Connect EGR vacuum hose.

29. Install oil level gauge guide assembly.

Tighten nuts lower portion and tighten bolt.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

30. Install intercooler assembly.

Refer to “Intercooler” in this manual.

31. Install air duct between air cleaner and

turbocharger.

32. Fill engine coolant.

33. Reconnect battery.

036RW005

036RW006

1

2

3 7

4

5 6

010RW010