radiator OPEL FRONTERA 1998 Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4949 of 6000

6E–292

ENGINE DRIVEABILITY AND EMISSIONS

Crankshaft Position (CKP)

Sensor

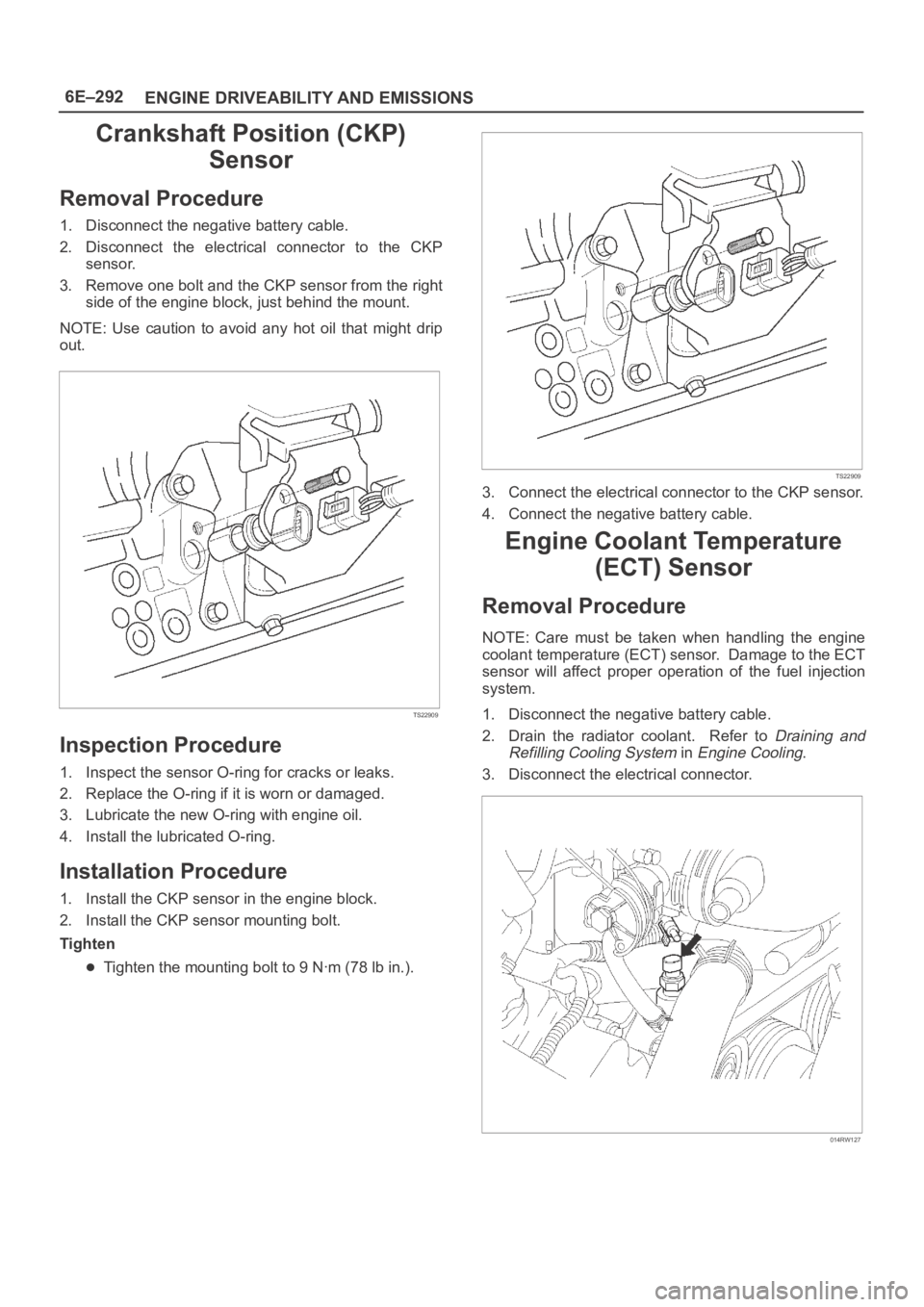

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector to the CKP

sensor.

3. Remove one bolt and the CKP sensor from the right

side of the engine block, just behind the mount.

NOTE: Use caution to avoid any hot oil that might drip

out.

TS22909

Inspection Procedure

1. Inspect the sensor O-ring for cracks or leaks.

2. Replace the O-ring if it is worn or damaged.

3. Lubricate the new O-ring with engine oil.

4. Install the lubricated O-ring.

Installation Procedure

1. Install the CKP sensor in the engine block.

2. Install the CKP sensor mounting bolt.

Tighten

Tighten the mounting bolt to 9 Nꞏm (78 lb in.).

TS22909

3. Connect the electrical connector to the CKP sensor.

4. Connect the negative battery cable.

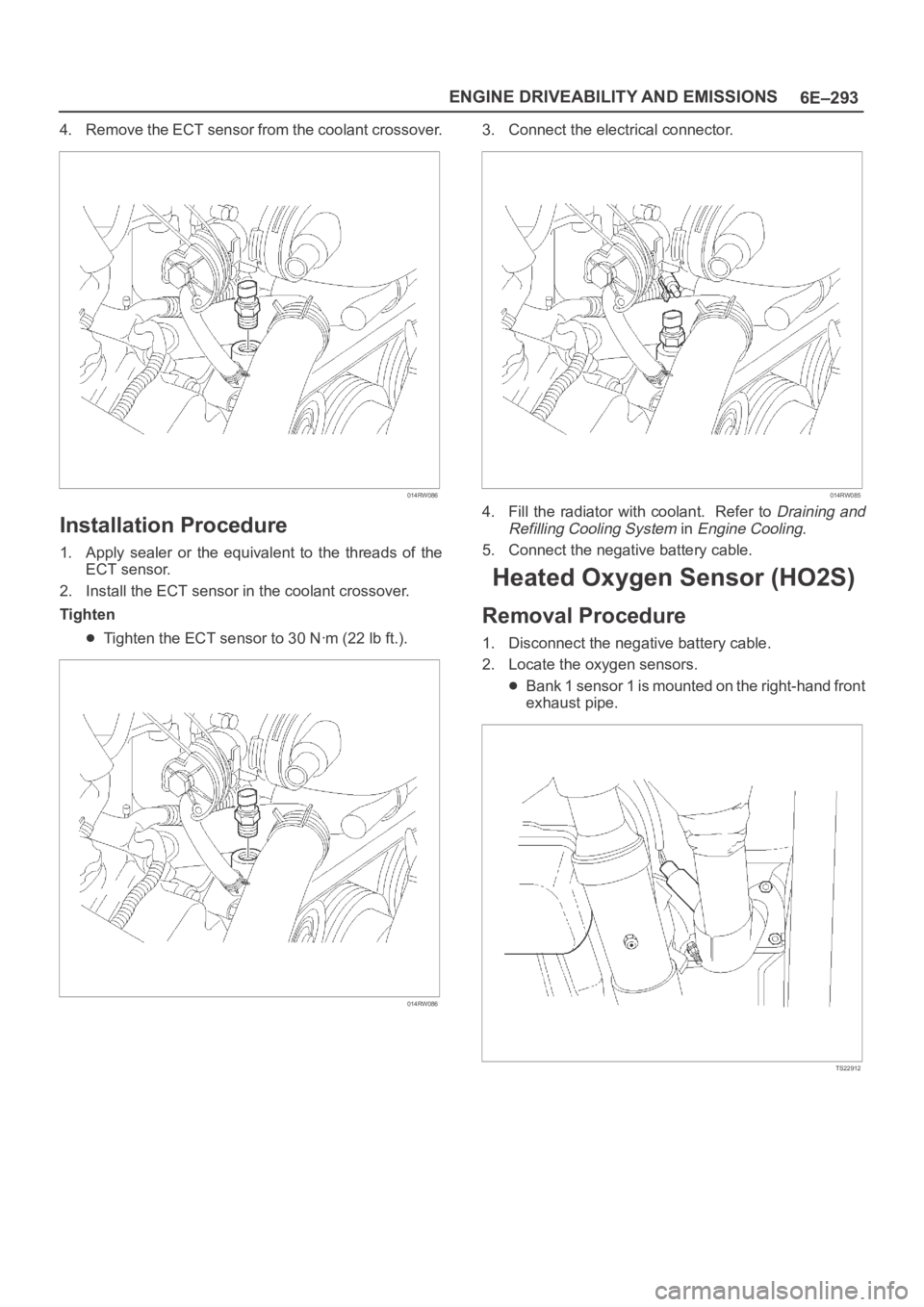

Engine Coolant Temperature

(ECT) Sensor

Removal Procedure

NOTE: Care must be taken when handling the engine

coolant temperature (ECT) sensor. Damage to the ECT

sensor will affect proper operation of the fuel injection

system.

1. Disconnect the negative battery cable.

2. Drain the radiator coolant. Refer to

Draining and

Refilling Cooling System

in Engine Cooling.

3. Disconnect the electrical connector.

014RW127

Page 4950 of 6000

6E–293 ENGINE DRIVEABILITY AND EMISSIONS

4. Remove the ECT sensor from the coolant crossover.

014RW086

Installation Procedure

1. Apply sealer or the equivalent to the threads of the

ECT sensor.

2. Install the ECT sensor in the coolant crossover.

Tighten

Tighten the ECT sensor to 30 Nꞏm (22 lb ft.).

014RW086

3. Connect the electrical connector.

014RW085

4. Fill the radiator with coolant. Refer to Draining and

Refilling Cooling System

in Engine Cooling.

5. Connect the negative battery cable.

Heated Oxygen Sensor (HO2S)

Removal Procedure

1. Disconnect the negative battery cable.

2. Locate the oxygen sensors.

Bank 1 sensor 1 is mounted on the right-hand front

exhaust pipe.

TS22912

Page 5026 of 6000

6G–7 ENGINE LUBRICATION

Oil Pan and Crankcase

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Lift vehicle by supporting the frame.

4. Remove front wheels.

5. Remove oil level dipstick from level gauge tube.

6. Remove stone guard.

7. Remove radiator under fan shroud.

8. Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9. Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10. Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11. Remove oil pan fixing bolts.

12. Remove oil pan, using 5–8840–2153–0 sealer cutter,

remove oil pan.

013RS003

13. Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1. Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

The crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

013RW010

Page 5028 of 6000

6G–9 ENGINE LUBRICATION

6. Install suspension cross member and tighten fixing

bolts to the specified torque.

Torque : 78 Nꞏm (8.0 Kgꞏm/58 lb ft)

013RW007

7. Install radiator under fan shroud.

8. Install stone guard.

9. Install engine oil level dipstick.

10. Fill engine oil until full level on engine oil gauge

dipstick.

Page 5277 of 6000

6A – 4 ENGINE MECHANICAL

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Voltage V 12

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 5281 of 6000

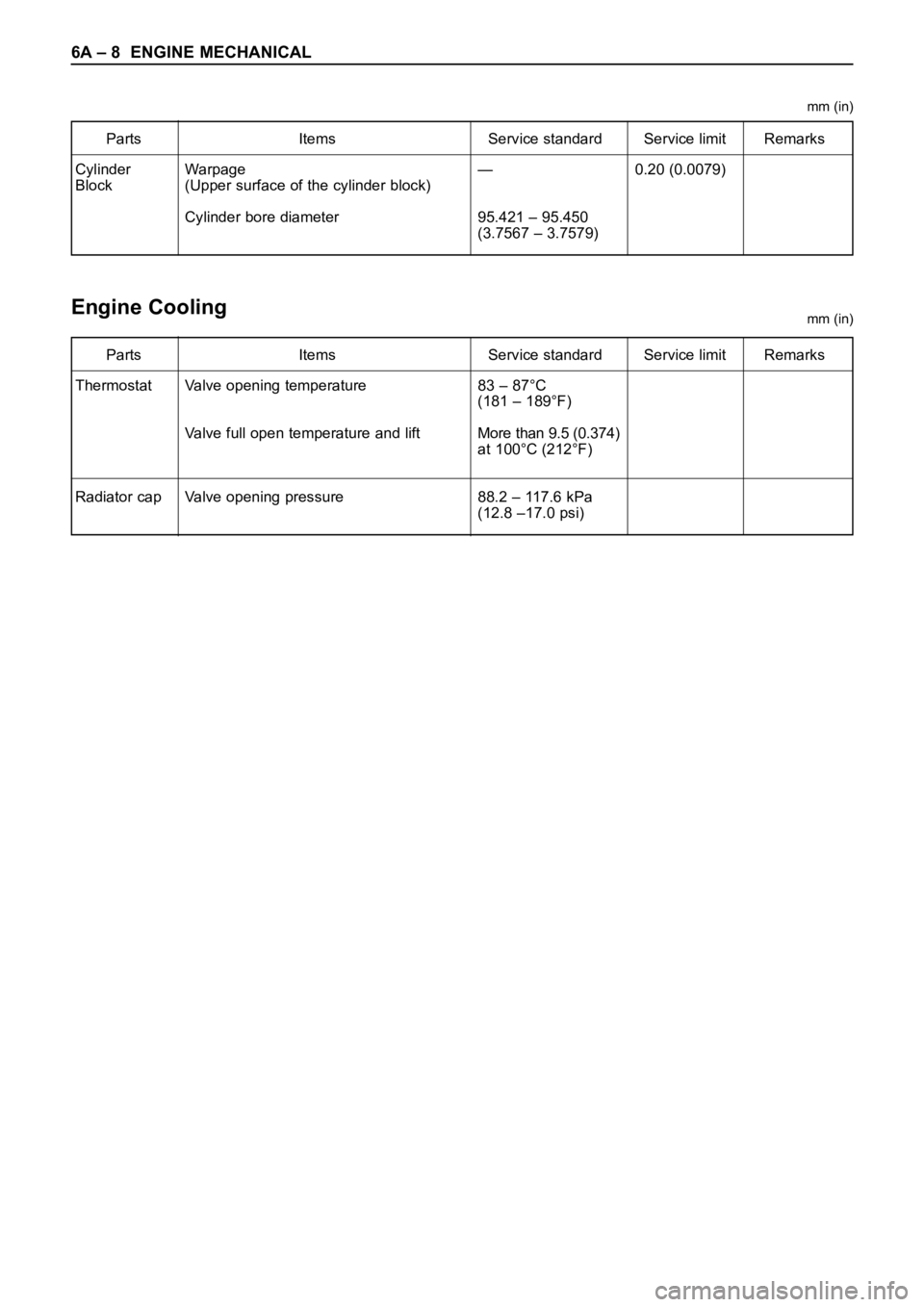

6A – 8 ENGINE MECHANICAL

Parts Items Service standard Service limit Remarks

Cylinder

Block—

95.421 – 95.450

(3.7567 – 3.7579)0.20 (0.0079) Warpage

(Upper surface of the cylinder block)

Cylinder bore diameter

Parts Items Service standard Service limit Remarks

Thermostat

Radiator cap83 – 87°C

(181 – 189°F)

More than 9.5 (0.374)

at 100°C (212°F)

88.2 – 117.6 kPa

(12.8 –17.0 psi) Valve opening temperature

Valve full open temperature and lift

Valve opening pressure

Engine Coolingmm (in) mm (in)

Page 5283 of 6000

6A – 10 ENGINE MECHANICAL

8. Check the engine oil level and replenish to the

specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

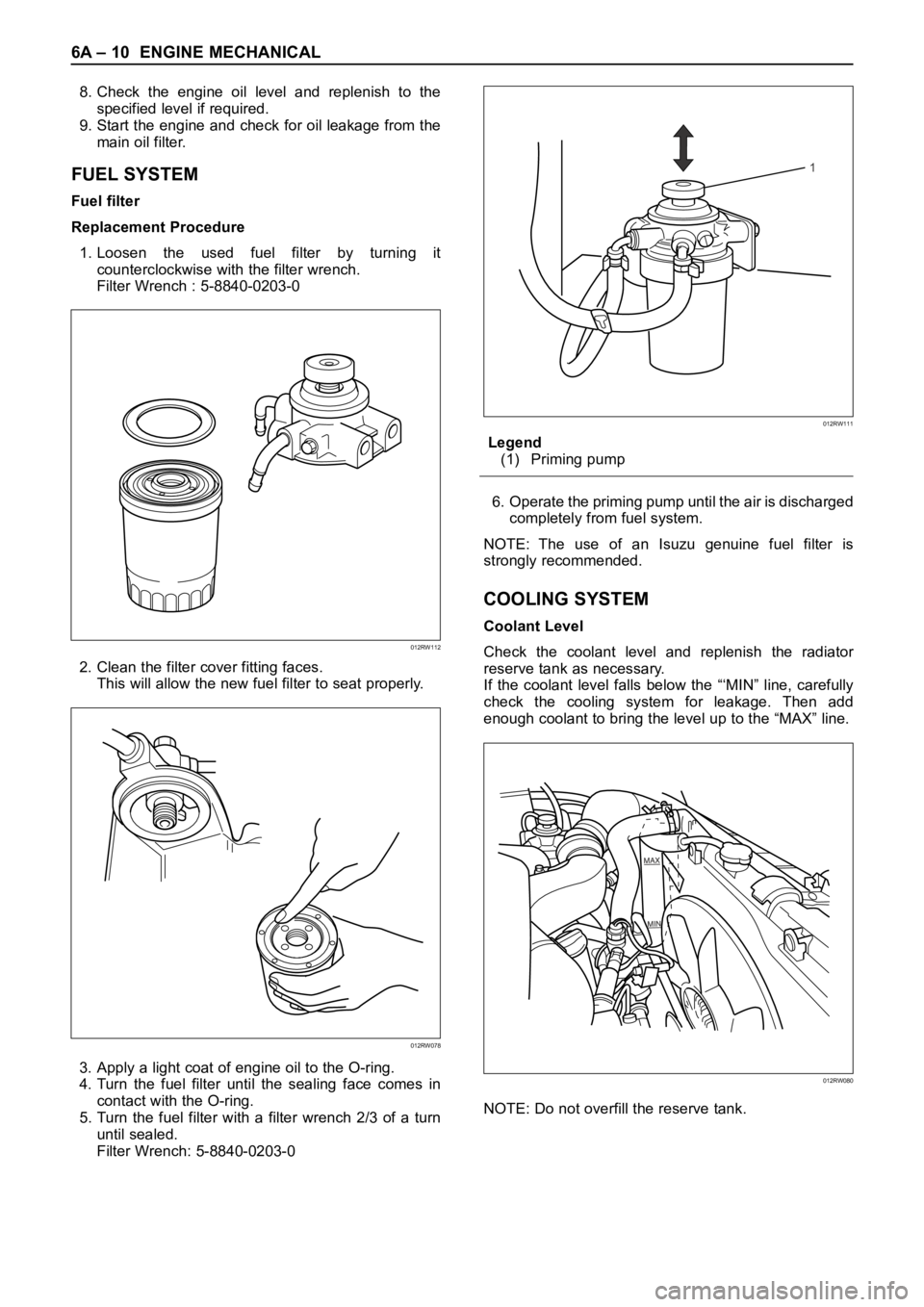

FUEL SYSTEM

Fuel filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench : 5-8840-0203-0

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn the fuel filter with a filter wrench 2/3 of a turn

until sealed.

Filter Wrench: 5-8840-0203-0Legend

(1) Priming pump

6. Operate the priming pump until the air is discharged

completely from fuel system.

NOTE: The use of an Isuzu genuine fuel filter is

strongly recommended.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator

reserve tank as necessary.

If the coolant level falls below the “‘MIN” line, carefully

check the cooling system for leakage. Then add

enough coolant to bring the level up to the “MAX” line.

NOTE: Do not overfill the reserve tank.

012RW112

012RW078

1

012RW111

012RW080

Page 5284 of 6000

ENGINE MECHANICAL 6A – 11

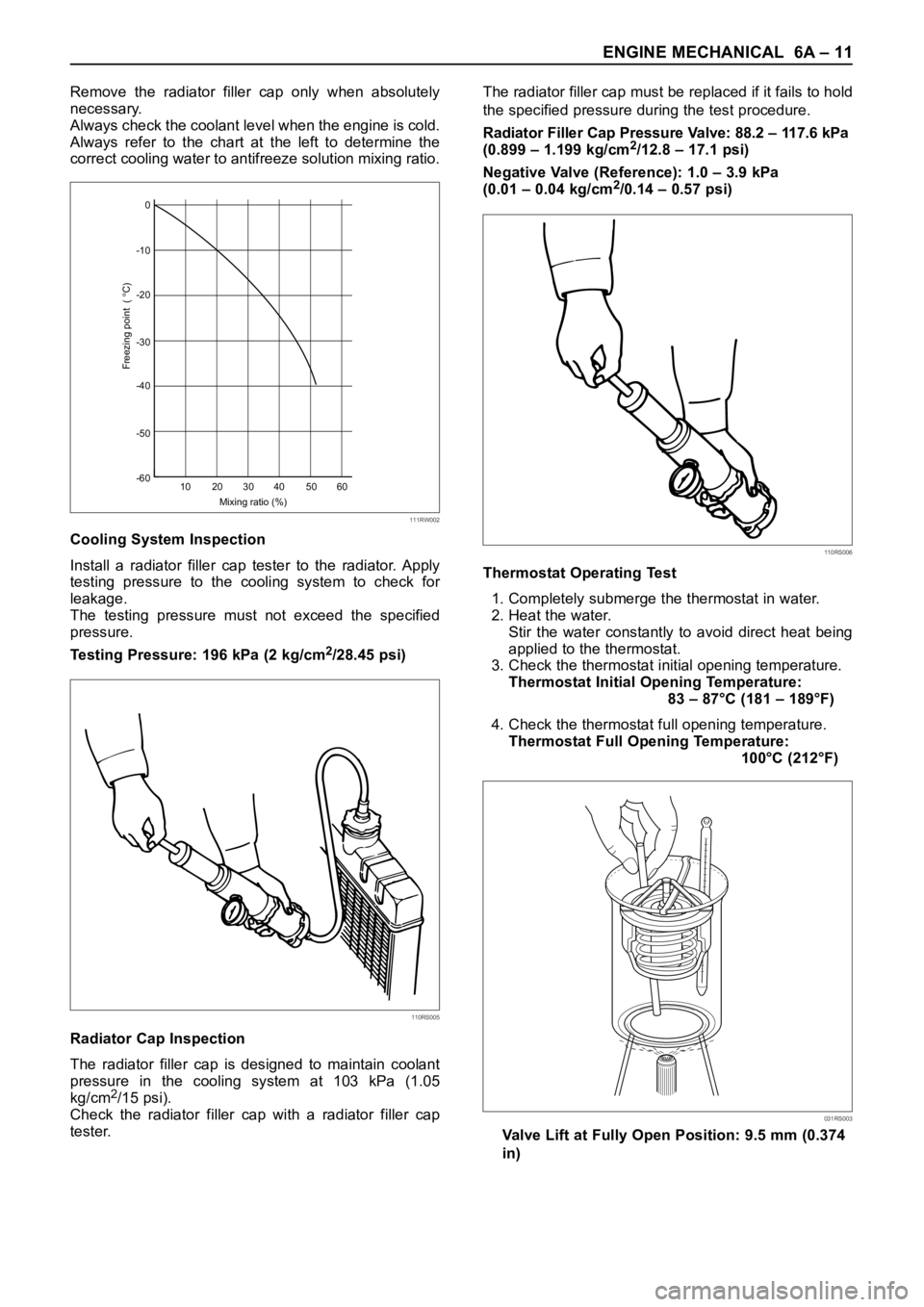

Remove the radiator filler cap only when absolutely

necessary.

Always check the coolant level when the engine is cold.

Always refer to the chart at the left to determine the

correct cooling water to antifreeze solution mixing ratio.

Cooling System Inspection

Install a radiator filler cap tester to the radiator. Apply

testing pressure to the cooling system to check for

leakage.

The testing pressure must not exceed the specified

pressure.

Testing Pressure: 196 kPa (2 kg/cm

2/28.45 psi)

Radiator Cap Inspection

The radiator filler cap is designed to maintain coolant

pressure in the cooling system at 103 kPa (1.05

kg/cm

2/15 psi).

Check the radiator filler cap with a radiator filler cap

tester.The radiator filler cap must be replaced if it fails to hold

the specified pressure during the test procedure.

Radiator Filler Cap Pressure Valve: 88.2 – 117.6 kPa

(0.899 – 1.199 kg/cm

2/12.8 – 17.1 psi)

Negative Valve (Reference): 1.0 – 3.9 kPa

(0.01 – 0.04 kg/cm

2/0.14 – 0.57 psi)

Thermostat Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature:

83 – 87°C (181 – 189°F)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature:

100°C (212°F)

Valve Lift at Fully Open Position: 9.5 mm (0.374

in)0

-10

-20

-30

-40

-50

-60

10 20 30

Mixing ratio (%)

Freezing point (

C)

40 50 60

111RW002

110RS005

110RS006

031RS003

Page 5299 of 6000

6A – 26 ENGINE MECHANICAL

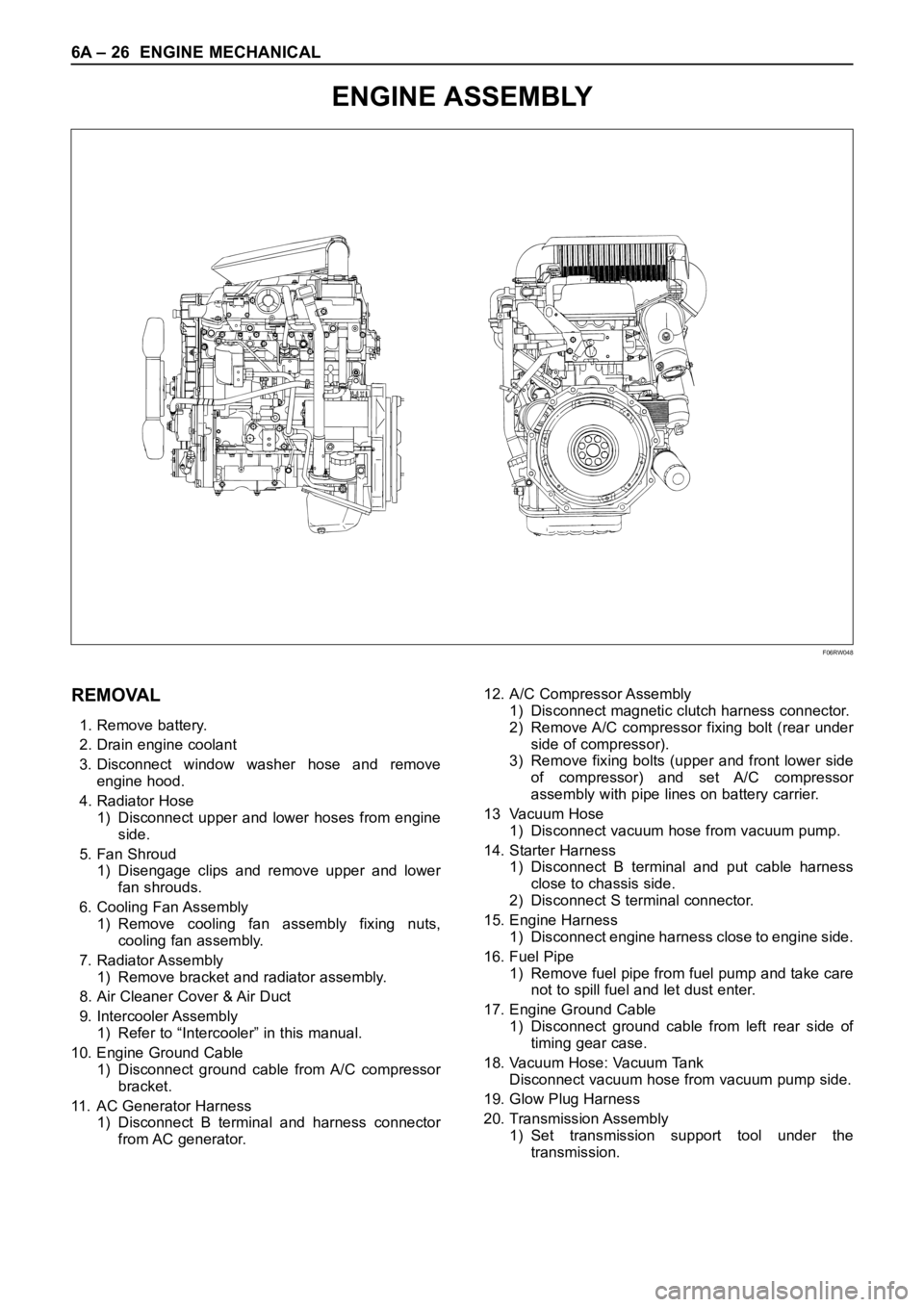

ENGINE ASSEMBLY

F06RW048

REMOVAL

1. Remove battery.

2. Drain engine coolant

3. Disconnect window washer hose and remove

engine hood.

4. Radiator Hose

1) Disconnect upper and lower hoses from engine

side.

5. Fan Shroud

1) Disengage clips and remove upper and lower

fan shrouds.

6. Cooling Fan Assembly

1) Remove cooling fan assembly fixing nuts,

cooling fan assembly.

7. Radiator Assembly

1) Remove bracket and radiator assembly.

8. Air Cleaner Cover & Air Duct

9. Intercooler Assembly

1) Refer to “Intercooler” in this manual.

10. Engine Ground Cable

1) Disconnect ground cable from A/C compressor

bracket.

11. AC Generator Harness

1) Disconnect B terminal and harness connector

from AC generator.12. A/C Compressor Assembly

1) Disconnect magnetic clutch harness connector.

2) Remove A/C compressor fixing bolt (rear under

side of compressor).

3) Remove fixing bolts (upper and front lower side

of compressor) and set A/C compressor

assembly with pipe lines on battery carrier.

13 Vacuum Hose

1) Disconnect vacuum hose from vacuum pump.

14. Starter Harness

1) Disconnect B terminal and put cable harness

close to chassis side.

2) Disconnect S terminal connector.

15. Engine Harness

1) Disconnect engine harness close to engine side.

16. Fuel Pipe

1) Remove fuel pipe from fuel pump and take care

not to spill fuel and let dust enter.

17. Engine Ground Cable

1) Disconnect ground cable from left rear side of

timing gear case.

18. Vacuum Hose: Vacuum Tank

Disconnect vacuum hose from vacuum pump side.

19. Glow Plug Harness

20. Transmission Assembly

1) Set transmission support tool under the

transmission.

Page 5300 of 6000

ENGINE MECHANICAL 6A – 27

2) Remove transmission rear mount.

3) Remove transmission fixing bolt from rear of

engine assembly except two bolts.

4) Carefully hang up engine assembly with a hoist.

5) Remove remaining two transmission fixing bolts.

6) Remove transmission assembly.

7) Remove heater hose.

8) Disconnect wire harness connector for shift on

the fly.

9) Remove vacuum hose.

21. Prepare Engine Stand

22. Engine Assembly

1) Remove engine mount fixing bolts.

2) Carefully hang up the engine assembly.

3) Take out the engine assembly making sure not

to damage the brake oil pipe and other pipe etc.

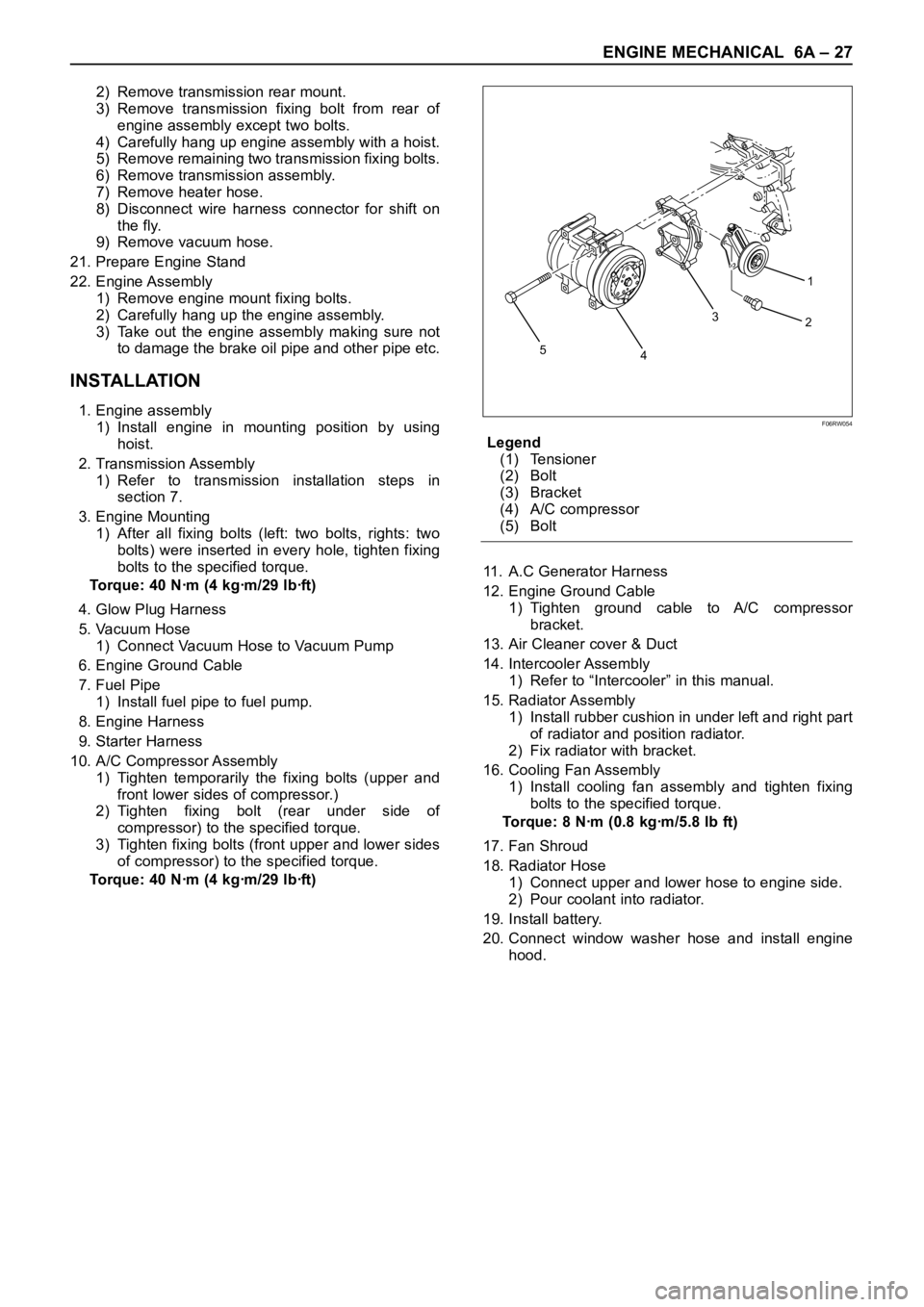

INSTALLATION

1. Engine assembly

1) Install engine in mounting position by using

hoist.

2. Transmission Assembly

1) Refer to transmission installation steps in

section 7.

3. Engine Mounting

1) After all fixing bolts (left: two bolts, rights: two

bolts) were inserted in every hole, tighten fixing

bolts to the specified torque.

Torque: 40 Nꞏm (4 kgꞏm/29 lbꞏft)

4. Glow Plug Harness

5. Vacuum Hose

1) Connect Vacuum Hose to Vacuum Pump

6. Engine Ground Cable

7. Fuel Pipe

1) Install fuel pipe to fuel pump.

8. Engine Harness

9. Starter Harness

10. A/C Compressor Assembly

1) Tighten temporarily the fixing bolts (upper and

front lower sides of compressor.)

2) Tighten fixing bolt (rear under side of

compressor) to the specified torque.

3) Tighten fixing bolts (front upper and lower sides

of compressor) to the specified torque.

Torque: 40 Nꞏm (4 kgꞏm/29 lbꞏft)Legend

(1) Tensioner

(2) Bolt

(3) Bracket

(4) A/C compressor

(5) Bolt

11. A.C Generator Harness

12. Engine Ground Cable

1) Tighten ground cable to A/C compressor

bracket.

13. Air Cleaner cover & Duct

14. Intercooler Assembly

1) Refer to “Intercooler” in this manual.

15. Radiator Assembly

1) Install rubber cushion in under left and right part

of radiator and position radiator.

2) Fix radiator with bracket.

16. Cooling Fan Assembly

1) Install cooling fan assembly and tighten fixing

bolts to the specified torque.

Torque: 8 Nꞏm (0.8 kgꞏm/5.8 lb ft)

17. Fan Shroud

18. Radiator Hose

1) Connect upper and lower hose to engine side.

2) Pour coolant into radiator.

19. Install battery.

20. Connect window washer hose and install engine

hood.

1

2

3

4

5

F06RW054