change key battery OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1232 of 6000

6E–115 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0108 MAP Sensor Circuit High Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the key “ON,” engine not

running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the linear EGR flow test diagnostic is being

run (refer to

DTC P0401), to determine engine vacuum

level for some other diagnostics and to determine

barometric pressure (BARO). The PCM monitors the

MAP signals for voltages outside the normal range of the

MAP sensor. If the PCM detects a MAP signal voltage

that is excessively high, DTC P0108 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running for more than 10 seconds.

Throttle position is below 3% if engine speed is below

1000 RPM.

Throttle position is below 10% if engine speed is above

1000 RPM.

The MAP sensor indicates an intermittent manifold

absolute pressure above 80kPa for a total of

approximately 10 seconds over a 16-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently,

performing the DTC P1108 Diagnostic Chart may isolate

the cause of the fault.

Page 1253 of 6000

6E–136

ENGINE DRIVEABILITY AND EMISSIONS

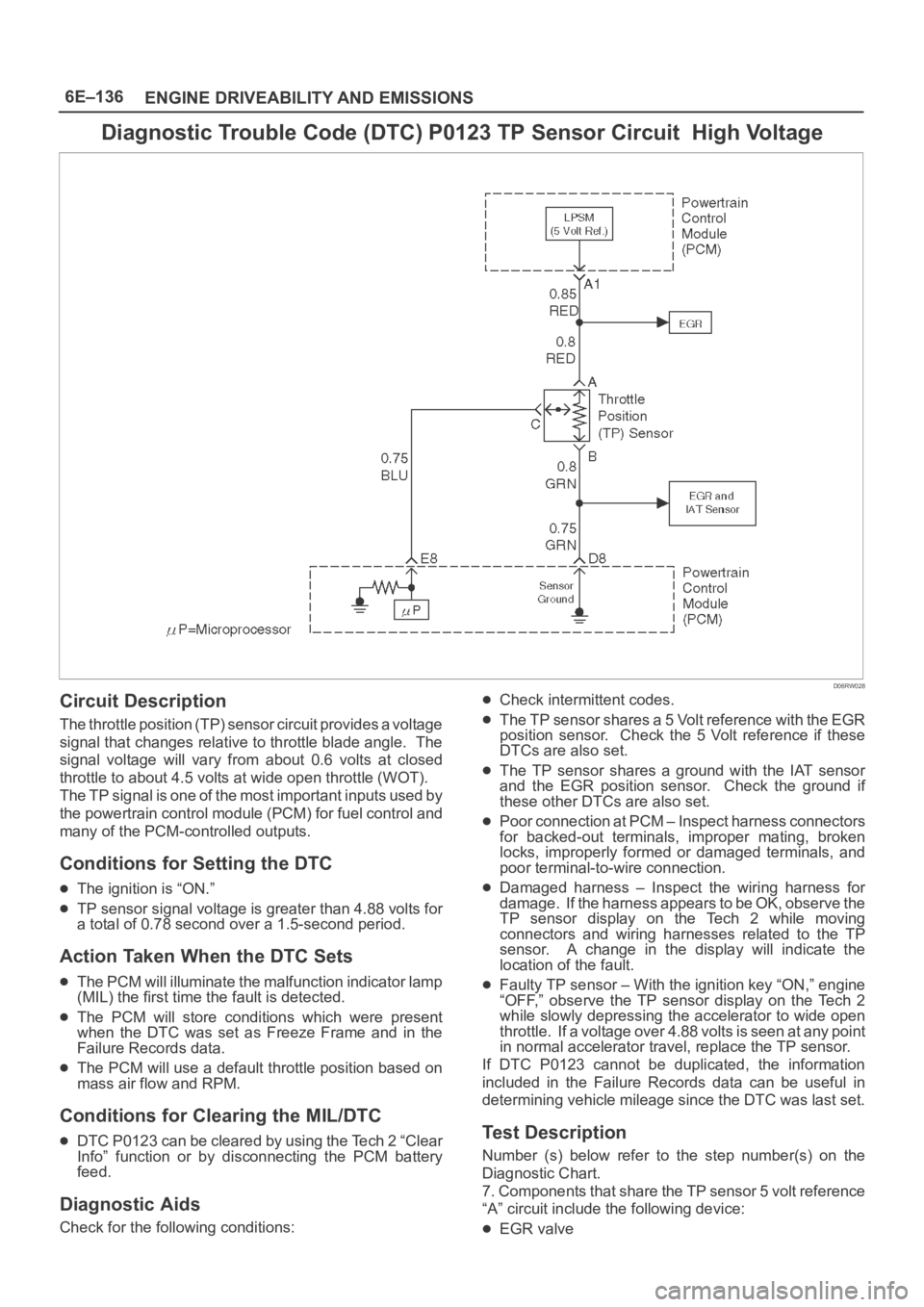

Diagnostic Trouble Code (DTC) P0123 TP Sensor Circuit High Voltage

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from about 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is one of the most important inputs used by

the powertrain control module (PCM) for fuel control and

many of the PCM-controlled outputs.

Conditions for Setting the DTC

The ignition is “ON.”

TP sensor signal voltage is greater than 4.88 volts for

a total of 0.78 second over a 1.5-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0123 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check intermittent codes.

The TP sensor shares a 5 Volt reference with the EGR

position sensor. Check the 5 Volt reference if these

DTCs are also set.

The TP sensor shares a ground with the IAT sensor

and the EGR position sensor. Check the ground if

these other DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

TP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty TP sensor – With the ignition key “ON,” engine

“OFF,” observe the TP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle. If a voltage over 4.88 volts is seen at any point

in normal accelerator travel, replace the TP sensor.

If DTC P0123 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number (s) below refer to the step number(s) on the

Diagnostic Chart.

7. Components that share the TP sensor 5 volt reference

“A” circuit include the following device:

EGR valve

Page 1460 of 6000

6E–343 ENGINE DRIVEABILITY AND EMISSIONS

constant measuring and adjusting of the air/fuel ratio, the

fuel injection system is called a “closed loop” system.

The PCM monitors signals from several sensors in order

to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called “modes.”

All modes are controlled by the PCM.

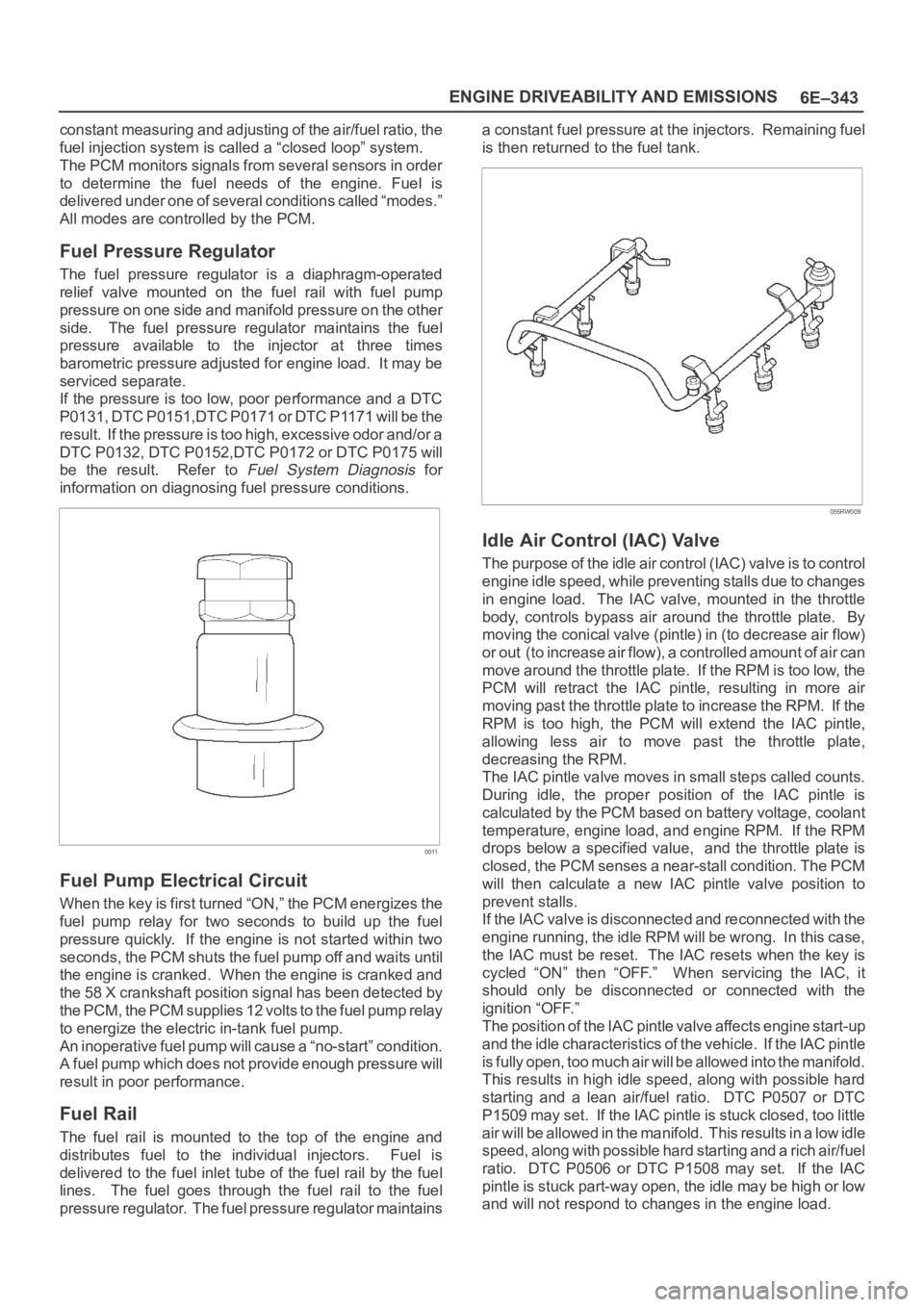

Fuel Pressure Regulator

The fuel pressure regulator is a diaphragm-operated

relief valve mounted on the fuel rail with fuel pump

pressure on one side and manifold pressure on the other

side. The fuel pressure regulator maintains the fuel

pressure available to the injector at three times

barometric pressure adjusted for engine load. It may be

serviced separate.

If the pressure is too low, poor performance and a DTC

P0131, DTC P0151,DTC P0171 or DTC P1171 will be the

result. If the pressure is too high, excessive odor and/or a

DTC P0132, DTC P0152,DTC P0172 or DTC P0175 will

be the result. Refer to

Fuel System Diagnosis for

information on diagnosing fuel pressure conditions.

0011

Fuel Pump Electrical Circuit

When the key is first turned “ON,” the PCM energizes the

fuel pump relay for two seconds to build up the fuel

pressure quickly. If the engine is not started within two

seconds, the PCM shuts the fuel pump off and waits until

the engine is cranked. When the engine is cranked and

the 58 X crankshaft position signal has been detected by

the PCM, the PCM supplies 12 volts to the fuel pump relay

to energize the electric in-tank fuel pump.

An inoperative fuel pump will cause a “no-start” condition.

A fuel pump which does not provide enough pressure will

result in poor performance.

Fuel Rail

The fuel rail is mounted to the top of the engine and

distributes fuel to the individual injectors. Fuel is

delivered to the fuel inlet tube of the fuel rail by the fuel

lines. The fuel goes through the fuel rail to the fuel

pressure regulator. The fuel pressure regulator maintainsa constant fuel pressure at the injectors. Remaining fuel

is then returned to the fuel tank.

055RW009

Idle Air Control (IAC) Valve

The purpose of the idle air control (IAC) valve is to control

engine idle speed, while preventing stalls due to changes

in engine load. The IAC valve, mounted in the throttle

body, controls bypass air around the throttle plate. By

moving the conical valve (pintle) in (to decrease air flow)

or out (to increase air flow), a controlled amount of air can

move around the throttle plate. If the RPM is too low, the

PCM will retract the IAC pintle, resulting in more air

moving past the throttle plate to increase the RPM. If the

RPM is too high, the PCM will extend the IAC pintle,

allowing less air to move past the throttle plate,

decreasing the RPM.

The IAC pintle valve moves in small steps called counts.

During idle, the proper position of the IAC pintle is

calculated by the PCM based on battery voltage, coolant

temperature, engine load, and engine RPM. If the RPM

drops below a specified value, and the throttle plate is

closed, the PCM senses a near-stall condition. The PCM

will then calculate a new IAC pintle valve position to

prevent stalls.

If the IAC valve is disconnected and reconnected with the

engine running, the idle RPM will be wrong. In this case,

the IAC must be reset. The IAC resets when the key is

cycled “ON” then “OFF.” When servicing the IAC, it

should only be disconnected or connected with the

ignition “OFF.”

The position of the IAC pintle valve affects engine start-up

and the idle characteristics of the vehicle. If the IAC pintle

is fully open, too much air will be allowed into the manifold.

This results in high idle speed, along with possible hard

starting and a lean air/fuel ratio. DTC P0507 or DTC

P1509 may set. If the IAC pintle is stuck closed, too little

air will be allowed in the manifold. This results in a low idle

speed, along with possible hard starting and a rich air/fuel

ratio. DTC P0506 or DTC P1508 may set. If the IAC

pintle is stuck part-way open, the idle may be high or low

and will not respond to changes in the engine load.

Page 1968 of 6000

6E–75 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0123 (Flash DTC 21)

AP Sensor High Voltage

060RW134

Circuit Description

The accelerator position (AP) sensor circuit provides a

voltage signal that changes relative to throttle blade

angle.

The TP signal is one of the most important inputs used by

the Engine Control Module ECM for fuel volume control

and many of the ECM-controlled outputs.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0123 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, brokenlocks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

AP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty AP sensor – With the ignition key “ON,” engine

“OFF,” observe the AP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle. If a voltage over 4.88 volts is seen at any point

in normal accelerator travel, replace the AP sensor.

If DTC P0123 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number (s) below refer to the step number(s) on the

Diagnostic Chart.

8. Components that share the AP sensor 5 volt reference

“A” circuit include the following device:

Page 2039 of 6000

6E–146

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1486 (Flash DTC 74)

ITP (Intake Throttle Position) Sensor High Voltage

060RW134

Circuit Description

The intake throttle position (ITP) sensor circuit provides a

voltage signal that changes relative to throttle blade

angle.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1486 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ITP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty TP sensor – With the ignition key “ON,” engine

“OFF,” observe the TP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle.

If DTC P1486 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 2992 of 6000

WIRING SYSTEM 8D–399

1. Check to see if the battery voltage is normal.

2. Check to see if the fuse is normal.

3. Replace the anti–theft & keyless entry control unit with one reserved for test. If a trouble recurs even after replacing

the control unit, find out the cause of the trouble by referring to “System check procedure” and the following list.

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

ANTI–THEFT

indicator light

does not flash

ANTI–THEFT

indicator light

does not turn off.

(Steadily on)

When door is

opened by pulling

up locking knob,

alarm does not

operate

Alarm does not

stop. Indicator light

does not change

to fully ON

condition, or does

not come on at

all.Burnt out indicator

light bulb possible.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of door switch,

or open circuit in door switch

wiring.

Short circuit in the detect switch.

Engine hood, doors and tailgate

are not fully closed and locked.

Defective door switch, or short

circuit in switch wiring.

Defective tamper switch, or short

circuit in wiring.

Defective lock switch, or short

circuit in wiring.

Defective engine hood switch, or

short circuit in wiring.

Defective tailgate switch, or short

circuit in wiring.

Defective control unit.

Poor contact of lock switch, or

open circuit in wiring.

Broken wire in wiring to headlight

and horn, or a blown fuse.

Defective contact of detect

switch, or damaged switch wiring.With door open, dome light and

courtesy light do not come on.

Check the control unit connector.

Check to see if doors are closed

and locked.

Dome light and courtesy light

remain lit on after closing doors.

Check the control unit connector.

Check the control unit connector.

Check the control unit connector.

Luggage room light remains lit

after closing tailgate.

Check alarm operation (See No.

46 of “System check procedure”),

possible cause is a poor contact

of lock switch of an open circuit in

wiring.

Check to see if headlights go out.

Check the control unit connector.

Check the control unit connector. A

C

D

E B

Page 3366 of 6000

SECURITY AND LOCKS8H–27

StepNo Ye s Action

41. Lock the door and unlock it three times.

2. Close the door and then open it.

NOTE: This step must be performed within ten seconds after step

3.

Is the action complete?

Go to Step 5Finished

5Answer back mode changes.

Is this step complete?

Go to Step 6Go to Step 7

6The control unit makes lock/unlock response once with interval of

one second.

Is the response complete?

Finished—

7The control unit makes lock/unlock response three times with

interval of one second.

Is the response complete?

Finished—

Anti–theft & Keyless Entry Control

Unit/Transmitter Replacement

Anti–theft & Keyless Entry Control Unit

Replacement

1. Remove and install the control unit.

Refer to Anti–theft & Keyless Entry Control Unit

Removal and Installation in this section.

2. Register ID code.

Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Transmitter Replacement

1. Prepare a new transmitter.

2. Regiter ID code.

Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Transmitter Battery Replacement

1. Remove a screw to remove the cover.

2. Remove the batteries.

3. Set the new batteries into the transmitter.

4. Install the cover to the transmitter.

5. Check that the keyless entry system works normally.

Page 4772 of 6000

6E–115 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0108 MAP Sensor Circuit High Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the key “ON,” engine not

running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the linear EGR flow test diagnostic is being

run (refer to

DTC P0401), to determine engine vacuum

level for some other diagnostics and to determine

barometric pressure (BARO). The PCM monitors the

MAP signals for voltages outside the normal range of the

MAP sensor. If the PCM detects a MAP signal voltage

that is excessively high, DTC P0108 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running for more than 10 seconds.

Throttle position is below 3% if engine speed is below

1000 RPM.

Throttle position is below 10% if engine speed is above

1000 RPM.

The MAP sensor indicates an intermittent manifold

absolute pressure above 80kPa for a total of

approximately 10 seconds over a 16-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently,

performing the DTC P1108 Diagnostic Chart may isolate

the cause of the fault.

Page 4793 of 6000

6E–136

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0123 TP Sensor Circuit High Voltage

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from about 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is one of the most important inputs used by

the powertrain control module (PCM) for fuel control and

many of the PCM-controlled outputs.

Conditions for Setting the DTC

The ignition is “ON.”

TP sensor signal voltage is greater than 4.88 volts for

a total of 0.78 second over a 1.5-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0123 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check intermittent codes.

The TP sensor shares a 5 Volt reference with the EGR

position sensor. Check the 5 Volt reference if these

DTCs are also set.

The TP sensor shares a ground with the IAT sensor

and the EGR position sensor. Check the ground if

these other DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

TP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty TP sensor – With the ignition key “ON,” engine

“OFF,” observe the TP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle. If a voltage over 4.88 volts is seen at any point

in normal accelerator travel, replace the TP sensor.

If DTC P0123 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number (s) below refer to the step number(s) on the

Diagnostic Chart.

7. Components that share the TP sensor 5 volt reference

“A” circuit include the following device:

EGR valve

Page 5000 of 6000

6E–343 ENGINE DRIVEABILITY AND EMISSIONS

constant measuring and adjusting of the air/fuel ratio, the

fuel injection system is called a “closed loop” system.

The PCM monitors signals from several sensors in order

to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called “modes.”

All modes are controlled by the PCM.

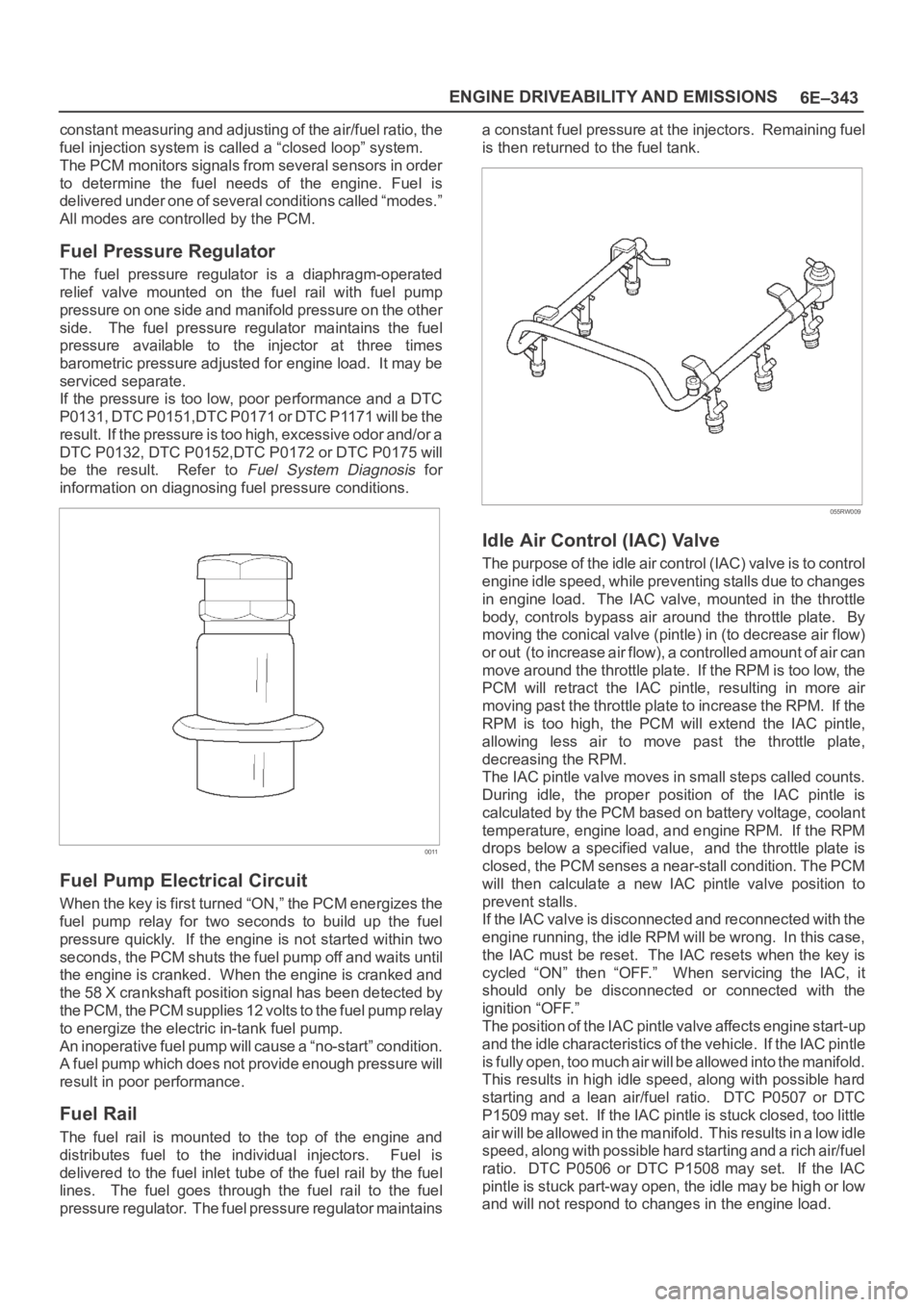

Fuel Pressure Regulator

The fuel pressure regulator is a diaphragm-operated

relief valve mounted on the fuel rail with fuel pump

pressure on one side and manifold pressure on the other

side. The fuel pressure regulator maintains the fuel

pressure available to the injector at three times

barometric pressure adjusted for engine load. It may be

serviced separate.

If the pressure is too low, poor performance and a DTC

P0131, DTC P0151,DTC P0171 or DTC P1171 will be the

result. If the pressure is too high, excessive odor and/or a

DTC P0132, DTC P0152,DTC P0172 or DTC P0175 will

be the result. Refer to

Fuel System Diagnosis for

information on diagnosing fuel pressure conditions.

0011

Fuel Pump Electrical Circuit

When the key is first turned “ON,” the PCM energizes the

fuel pump relay for two seconds to build up the fuel

pressure quickly. If the engine is not started within two

seconds, the PCM shuts the fuel pump off and waits until

the engine is cranked. When the engine is cranked and

the 58 X crankshaft position signal has been detected by

the PCM, the PCM supplies 12 volts to the fuel pump relay

to energize the electric in-tank fuel pump.

An inoperative fuel pump will cause a “no-start” condition.

A fuel pump which does not provide enough pressure will

result in poor performance.

Fuel Rail

The fuel rail is mounted to the top of the engine and

distributes fuel to the individual injectors. Fuel is

delivered to the fuel inlet tube of the fuel rail by the fuel

lines. The fuel goes through the fuel rail to the fuel

pressure regulator. The fuel pressure regulator maintainsa constant fuel pressure at the injectors. Remaining fuel

is then returned to the fuel tank.

055RW009

Idle Air Control (IAC) Valve

The purpose of the idle air control (IAC) valve is to control

engine idle speed, while preventing stalls due to changes

in engine load. The IAC valve, mounted in the throttle

body, controls bypass air around the throttle plate. By

moving the conical valve (pintle) in (to decrease air flow)

or out (to increase air flow), a controlled amount of air can

move around the throttle plate. If the RPM is too low, the

PCM will retract the IAC pintle, resulting in more air

moving past the throttle plate to increase the RPM. If the

RPM is too high, the PCM will extend the IAC pintle,

allowing less air to move past the throttle plate,

decreasing the RPM.

The IAC pintle valve moves in small steps called counts.

During idle, the proper position of the IAC pintle is

calculated by the PCM based on battery voltage, coolant

temperature, engine load, and engine RPM. If the RPM

drops below a specified value, and the throttle plate is

closed, the PCM senses a near-stall condition. The PCM

will then calculate a new IAC pintle valve position to

prevent stalls.

If the IAC valve is disconnected and reconnected with the

engine running, the idle RPM will be wrong. In this case,

the IAC must be reset. The IAC resets when the key is

cycled “ON” then “OFF.” When servicing the IAC, it

should only be disconnected or connected with the

ignition “OFF.”

The position of the IAC pintle valve affects engine start-up

and the idle characteristics of the vehicle. If the IAC pintle

is fully open, too much air will be allowed into the manifold.

This results in high idle speed, along with possible hard

starting and a lean air/fuel ratio. DTC P0507 or DTC

P1509 may set. If the IAC pintle is stuck closed, too little

air will be allowed in the manifold. This results in a low idle

speed, along with possible hard starting and a rich air/fuel

ratio. DTC P0506 or DTC P1508 may set. If the IAC

pintle is stuck part-way open, the idle may be high or low

and will not respond to changes in the engine load.