wheel alignment OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 439 of 6000

DIFFERENTIAL (FRONT) 4A1–2

Front Drive Axle

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 669 of 6000

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 679 of 6000

4C–13 DRIVE SHAFT SYSTEM

9. Install lock washer and lock screw in the following

manner.

Turn the side with larger diameter of the tapered

bore to the vehicle outer side, then attach the

washer.

If the bolt holes in the lock plate are not aligned with

the corresponding holes in the nut, reverse the lock

plate.

If the bolt holes are still out of alignment, turn in the

nut just enough to obtain alignment.

Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

10. Apply adhesive (LOCTITE 515 or equivalent) to both

joining flange faces then install hub flange.

11. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance: 0 mm–0.3 mm (0 in–0.012 in)

Shims Available: 0.2 mm, 0.3 mm, 0.5 mm,

1.0 mm (0.008 in, 0.012 in, 0.020 in, 0.039 in)

411RW002

12. Install hub cap.

13. Tighten the bolts to the specified torque.

Torque: 59 Nꞏm (6.0 kgꞏm/43 lb ft)

Page 685 of 6000

4C–19 DRIVE SHAFT SYSTEM

21. Install lock washer and lock screw in the following

manner.

Turn the side with larger diameter of the tapered

bore to the vehicle outer side, and attach the

washer.

If the bolt holes in the lock plate are not aligned with

the corresponding holes in the nut, reverse the lock

plate.

If the bolt holes are still out of alignment, trun in the

nut just enough to obtain alignment.

Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

22. Install body assembly.

Apply adhesive (LOCTITE 515 or equivalent) to

both joining faces.

Tighten the bolts to the specified torque.

Torque:59Nꞏm (6.0kgꞏm/43lbft)

23. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance:

0-0.3mm (0-0.012in)

Shims Available:

0.2mm, 0.3mm, 0.5mm, 1.0mm, (0.008in, 0.012in,

0.020in, 0.039in)

411RW002

24. Install cover assembly.

Align stopper nails (1) to grooves of body (2).

411RW019

25. Tighten the cover bolts to the specified torque.

Torque:12Nꞏm (1.2kgꞏm/104lbin)

Page 1004 of 6000

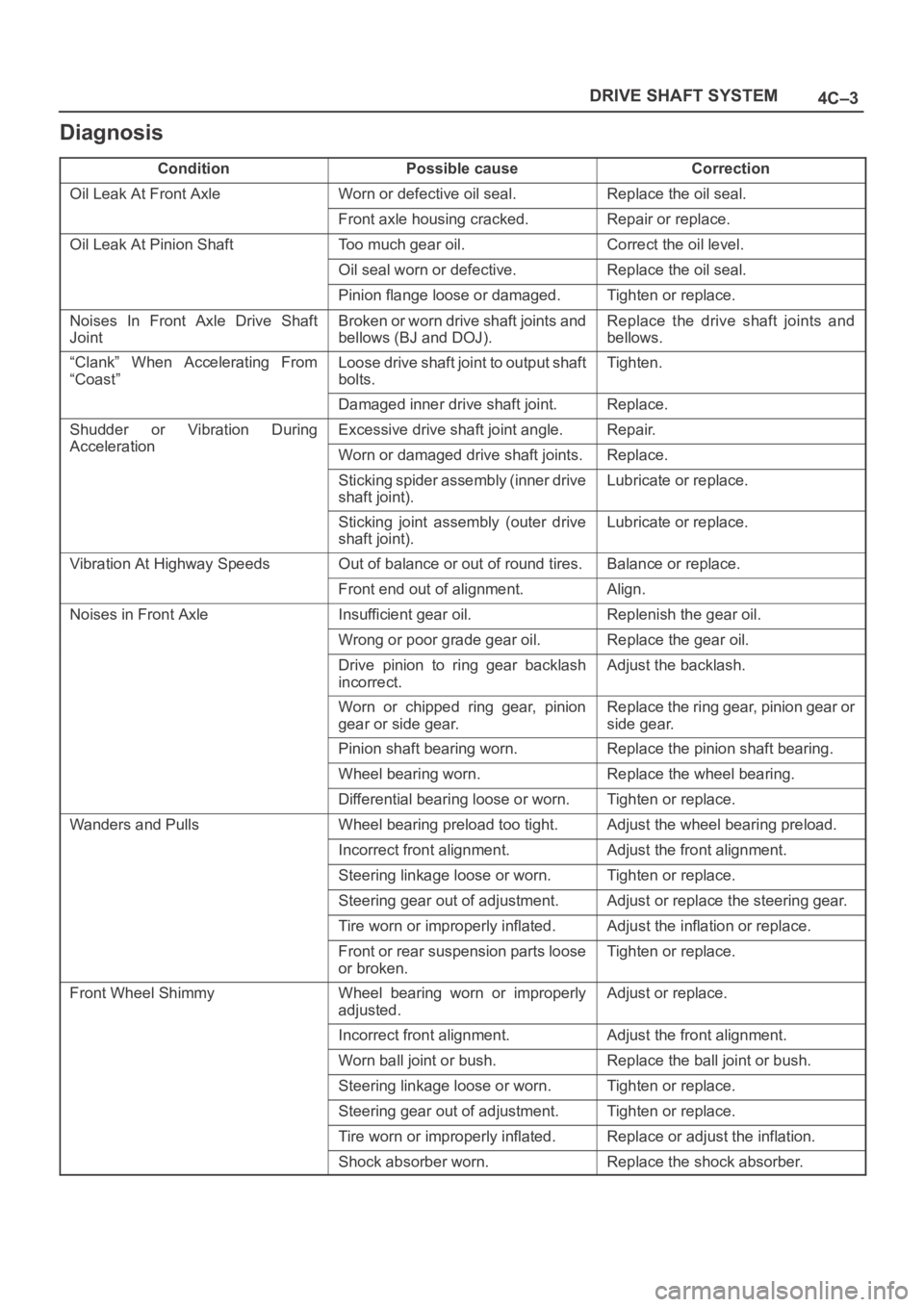

6A–48

ENGINE MECHANICAL

Engine Assembly

Removal

035RW027

1. Disconnect battery ground and positive cable.

2. Remove battery.

3. Make alignment mark on the engine hood and hinges

before removal in order to return the hood to original

position exactly.

4. Remove engine hood.

5. Drain radiator coolant.

6. Disconnect accelerator cable and automatic cruise

control cable from throttle valve on common

chamber.

7. Disconnect air duct with air cleaner cover.

8. Remove air cleaner assembly.

9. Disconnect canister vacuum hose.

10. Disconnect vacuum booster hose.

11. Disconnect three engine harness connectors.

12. Disconnect harness connector to transmission (left

front side of engine compartment), disconnect shift

on the fly harness connector from front side of front

axle and remove transmission harness bracket from

engine left side.

13. Disconnect ground cable between engine and frame.

14. Disconnect bonding cable connector on the back of

right dash panel.

15. Disconnect bonding cable terminal on the left bank.

16. Disconnect starter harness connector from starter.

17. Disconnect generator harness connector from

generator.

18. Disconnect coolant reserve tank hose from radiator.

19. Remove radiator upper and lower hoses.

20. Remove upper fan shroud.

21. Remove cooling fan assembly four fixing nuts, then

the cooling fan assembly.

22. Move drive belt tensioner to loose side using wrench

then remove drive belt.23. Remove power steering pump fixing bolts, then

power steering pump. Place the power steering pump

along with piping on the body side.

24. Remove air conditioning compressor fixing bolts from

bracket and place the compressor along with piping

on the body side.

25. Remove O

2 sensor harness connectors from exhaust

front pipe.

26. Remove three exhaust pipe fixing nuts from each

bank.

27. Remove two exhaust pipe fixing nuts from each

exhaust pipe, then move exhaust pipe to rear side of

vehicle.

28. Remove flywheel dust covers.

29. Disconnect two heater hoses from engine.

30. Disconnect fuel hoses from right side of transmission.

CAUTION: Plug fuel pipes on engine side and fuel

hoses from fuel tank.

31. Remove transmission assembly. Refer to

Transmission section in this manual.

32. Support the engine by engine hoist.

33. Remove two left side engine mount fixing bolts from

engine mount on chassis side.

34. Remove two right side engine mount fixing bolts from

engine mount on chassis side.

35. Remove engine assembly.

Installation

CAUTION: W h e n a s s e m b l i n g t h e e n g i n e a n d

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side. Take care that dowel positions are different

between the manual transmission and the automatic

transmission.

Page 2291 of 6000

7A1–46

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0722 Transmission Output Speed Sensor (OSS) Low Input

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Raise the drive wheels.

5. Start the engine.

6. Place the transmission in any drive range.

With the drive wheels rotating, does the “Trans Output Speed”

increase with the drive wheel speed?

Go to Diagnostic

Aids

Go to Step 2

2Does the speedometer work?Go to Step 3Go to Step 4

3Check for the most current and/or incorrect calibration.

Is the calibration current?

Go to Step 16Go to Step 4

41. Turn the ignition “off”.

2. Disconnect the J3 (BLUE) PCM connector.

3. Using the J39200 DVOM, measure the resistance between

harness connector terminals J3–E1 and J3–E2.

Is the reading 3,000 ohms?

Go to Step 5Go to Step 6

51. Select AC volts.

2. Rotate the rear wheels, ensuring the driveshaft is turning.

Is the voltage greater than 0.5 volts?

Go to Step 7Go to Step 8

6Inspect circuits RED and WHT for a poor connection or an open

circuit.

Was a problem found?

Go to Step 17Go to Step 8

71. Reconnect the J3 (BLUE) PCM connector.

2. Disconnect the OSS harness from the OSS.

3. With the engine “off”, turn the ignition “on”.

4. Using the J 39200 DVOM, measure the voltage at the OSS

harness connector terminals M15–1 and M15–2.

Is the reading between 4.0 to 5.1 volts?

Go to Step 16Go to Step 10

81. Remove the OSS.

2. Check the output shaft speed sensor rotor for damage or

misalignment. Refer to Speed Sensor (Extension Housing) in

Automatic Transmission (4L30–E) section.

Was a problem found?

Go to Step 17Go to Step 9

9Replace the OSS.

Is the replacement complete?

Go to Step 17—

10Was the reading in step 8 less than 4.0 volts?Go to Step 12Go to Step 11

11Was the reading in Step 8 greater than 5.1 volts?Go to Step 15—

12Using the J 39200 DVOM to chassis ground, measure the voltage

on circuit RED.

Is the reading between 4.0 to 5.1 volts?

Go to Step 13Go to Step 14

13Repair the open in circuit WHT.

Is the repair complete?

Go to Step 17—

14Check circuit RED for a short to ground or open.

Was a problem found and corrected?

Go to Step 17Go to Step 16

Page 2294 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–49

DTC P0723 Transmission Output Speed Sensor (OSS) Intermittent

StepActionYe sNo

11. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Failure Records”.

4. Raise the drive wheels.

5. Start the engine.

6. Place the transmission in any drive range.

With the drive wheels rotating, does the “Trans Output Speed”

increase with the drive wheel speed?

Go to Diagnostic

Aids

Go to Step 2

2Does the speedometer work?Go to Step 3Go to Step 4

3Check for the most current and/or incorrect calibration.

Is the calibration current?

Go to Step 16Go to Step 4

41. Turn the ignition “off”.

2. Disconnect the J3 (BLUE) PCM connector.

3. Using the J39200 DVOM, measure the resistance between

harness connector terminals J3–E1 and J3–E2.

Is the reading 3,000 ohms?

Go to Step 5Go to Step 6

51. Select AC volts.

2. Rotate the rear wheels, ensuring the driveshaft is turning.

Is the voltage greater than 0.5 volts?

Go to Step 7Go to Step 8

6Inspect circuits RED and WHT for a poor connection or an open

circuit.

Was a problem found?

Go to Step 17Go to Step 8

71. Reconnect the J3 (BLUE) PCM connector.

2. Disconnect the OSS harness from the OSS.

3. With the engine “off”, turn the ignition “on”.

4. Using the J 39200 DVOM, measure the voltage at the OSS

harness connector terminals M15–1 and M15–2.

Is the reading between 4.0 to 5.1 volts?

Go to Step 16Go to Step 10

81. Remove the OSS.

2. Check the output shaft speed sensor rotor for damage or

misalignment. Refer to Speed Sensor (Extension Housing) in

Automatic Transmission (4L30–E) section.

Was a problem found?

Go to Step 17Go to Step 9

9Replace the OSS.

Is the replacement complete?

Go to Step 17—

10Was the reading in step 8 less than 4.0 volts?Go to Step 12Go to Step 11

11Was the reading in Step 8 greater than 5.1 volts?Go to Step 15—

12Using the J 39200 DVOM to chassis ground, measure the voltage

on circuit RED.

Is the reading between 4.0 to 5.1 volts?

Go to Step 13Go to Step 14

13Repair the open in circuit WHT.

Is the repair complete?

Go to Step 17—

14Check circuit RED for a short to ground or open.

Was a problem found and corrected?

Go to Step 17Go to Step 16

Page 2518 of 6000

CLUTCH7C–9

Clutch Assembly

Clutch Assembly and Associated Parts

201RW029

Legend

(1) Flywheel Assembly and Crankshaft Bearing

(2) Driven Plate Assembly (6VE1)

(3) Driven Plate Assembly (4JX1)

(4) Pressure Plate Assembly (5) Transmission Assembly

(6) Front Cover

(7) Shift Fork

(8) Release Bearing

Removal

1. Remove transmission assembly, refer to ”MANUAL

TRANSMISSION” of Section 7B for ”Removal AND

INSTALLATION” procedure.

2. Mark the flywheel, clutch cover and pressure plate lug

for alignment when installing.

3. Remove pressure plate assembly (3).

4. Remove driven plate assembly (1) or (2). Use the pilot

aligner 5-85253-001-0 (J-24547) to prevent the

driven plate assembly from falling free.

201RW031

Page 2519 of 6000

7C–10CLUTCH

5. Mark the flywheel, clutch cover and pressure plate lug

for alignment when installing.

6. Remove the release bearing (3) from the

transmission case .

7. Remove the shift fork snap pin.

8. Remove the shift fork pin and shift fork (4) from the

front cover.

9. Remove the front cover bolts.

10. Remove the front cover (5) from the transmission

case.

220RW088

11. Remove flywheel assembly and crankshaft bearing.

Do not remove except for replacement.

12. Use the remover 5–8840–2000–0 (J–5822) and

sliding hammer 5–8840–0019–0 (J–23907) to

remove the crankshaft bearing

015RW053

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, or any other abnormal condition are found

through inspection.

Pressure Plate Assembly

201RS002

1. Visually check the pressure plate friction surface for

excessive wear and heat cracks.

2. If excessive wear or deep heat cracks are present,

the pressure plate must be replaced.

Pressure Plate Warpage

201RS003

Page 2557 of 6000

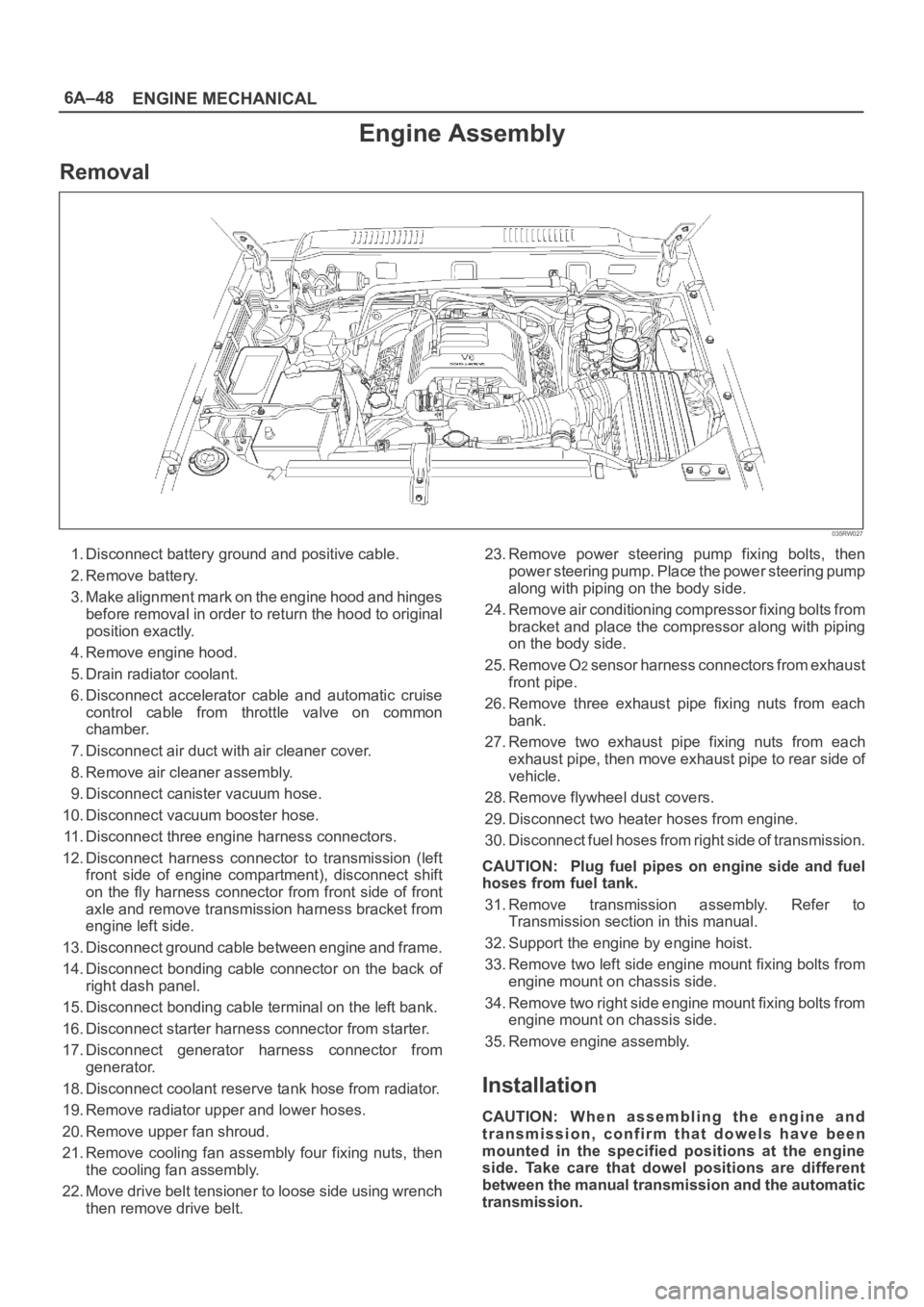

8A–18LIGHTING SYSTEM

Lighting Switch (Combination Switch)

Removal

1. Disconnect the battery ground cable.

2. Remove the instrument panel driver lower cover(5).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove seven screws to remove the steering

cowl(4).

4. Disconnect the SDM (air bag controller) connector

located at lower of the instrument panel driver lower

cover.

5. Remove four fixing screws and disconnect the driver

inflator module connector to remove the driver inflator

module(3).

CAUTION: When carrying a live inflator module,

make sure the bag opening is pointed away from

y o u . I n c a s e o f a n a c c i d e n t a l d e p l o y m e n t , t h e b a g w i l l

then deploy with minimal chance of injury. Never

carry the inflator module by the wires or connector

on the underside of the module.

When placing a live inflator module on a bench or

other surface, always face the bag and trim cover up,

away from the surface. This is necessary so that a

free space is provided to allow the air bag to expand

in the unlikely event of accidental deployment.

6. Remove the steering wheel(2).

Refer to the Steering Wheel in Steering section.

7. Disconnect the SRS coil assembly connector,

remove four fixing screws to remove the SRS coil

assembly(1).

8. Disconnect the lighting switch connector, remove four

fixing screws to remove the lighting switch(6).

825RS039

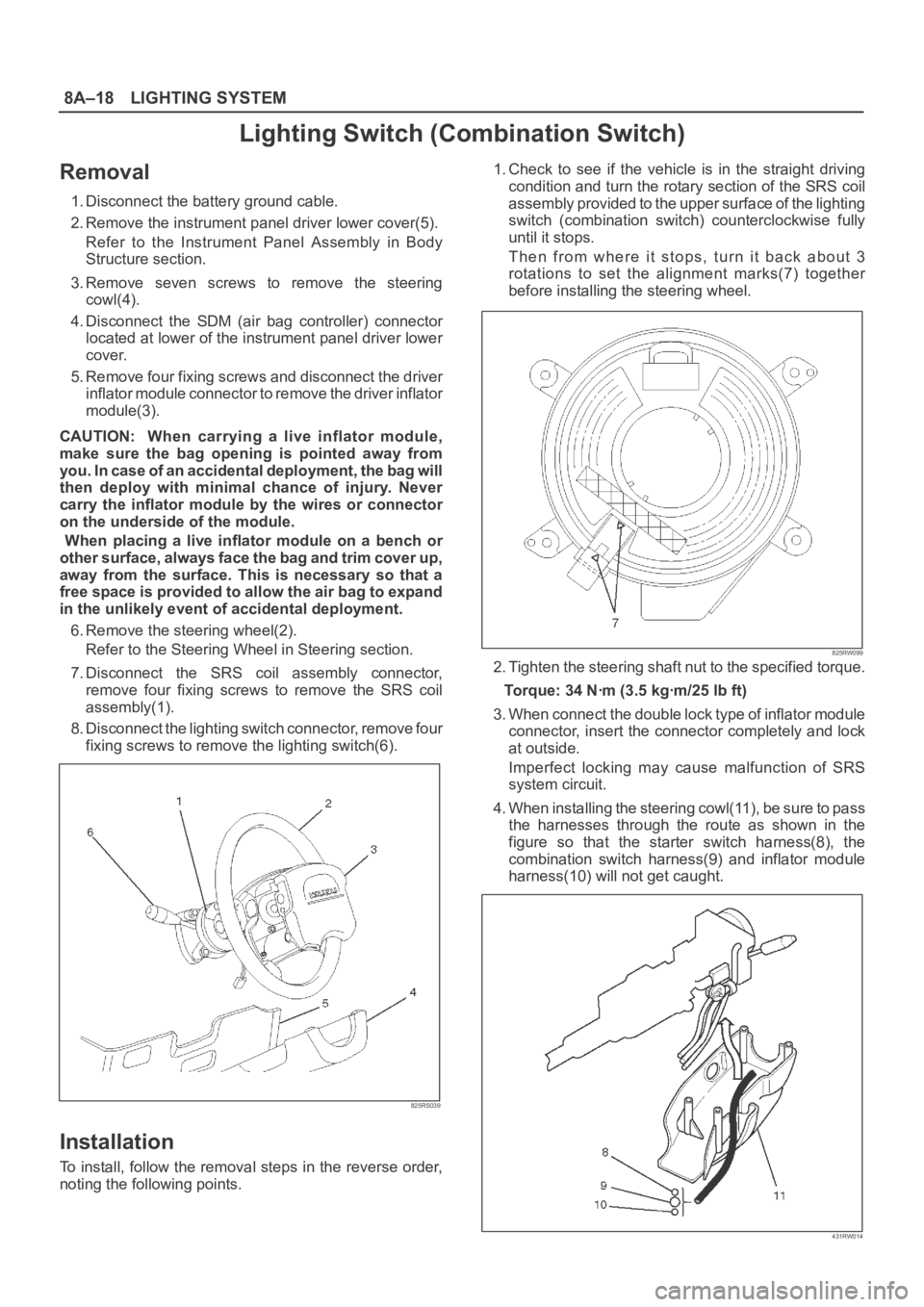

Installation

To install, follow the removal steps in the reverse order,

noting the following points.1. Check to see if the vehicle is in the straight driving

condition and turn the rotary section of the SRS coil

assembly provided to the upper surface of the lighting

switch (combination switch) counterclockwise fully

until it stops.

Then from where it stops, turn it back about 3

rotations to set the alignment marks(7) together

before installing the steering wheel.

825RW099

2. Tighten the steering shaft nut to the specified torque.

Torque: 34 Nꞏm (3.5 kgꞏm/25 lb ft)

3. When connect the double lock type of inflator module

connector, insert the connector completely and lock

at outside.

Imperfect locking may cause malfunction of SRS

system circuit.

4. When installing the steering cowl(11), be sure to pass

the harnesses through the route as shown in the

figure so that the starter switch harness(8), the

combination switch harness(9) and inflator module

harness(10) will not get caught.

431RW014