oil type OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 262 of 6000

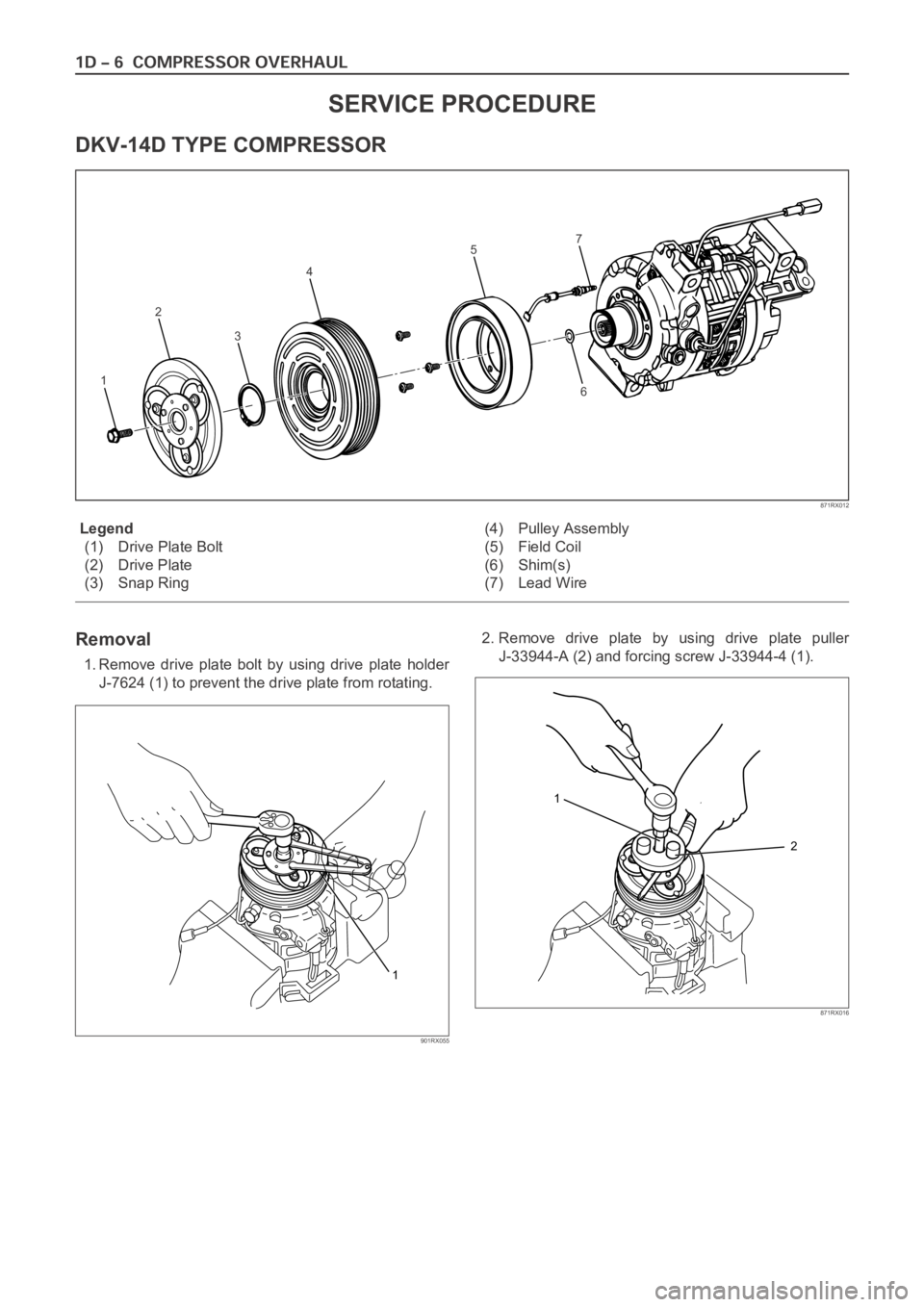

Legend

(1) Drive Plate Bolt

(2) Drive Plate

(3) Snap Ring(4) Pulley Assembly

(5) Field Coil

(6) Shim(s)

(7) Lead Wire

Removal

1. Remove drive plate bolt by using drive plate holder

J-7624 (1) to prevent the drive plate from rotating.2. Remove drive plate by using drive plate puller

J-33944-A (2) and forcing screw J-33944-4 (1).

SERVICE PROCEDURE

DKV-14D TYPE COMPRESSOR

1

2

3

4

5

67

871RX012

1

901RX055

1

2

871RX016

Page 266 of 6000

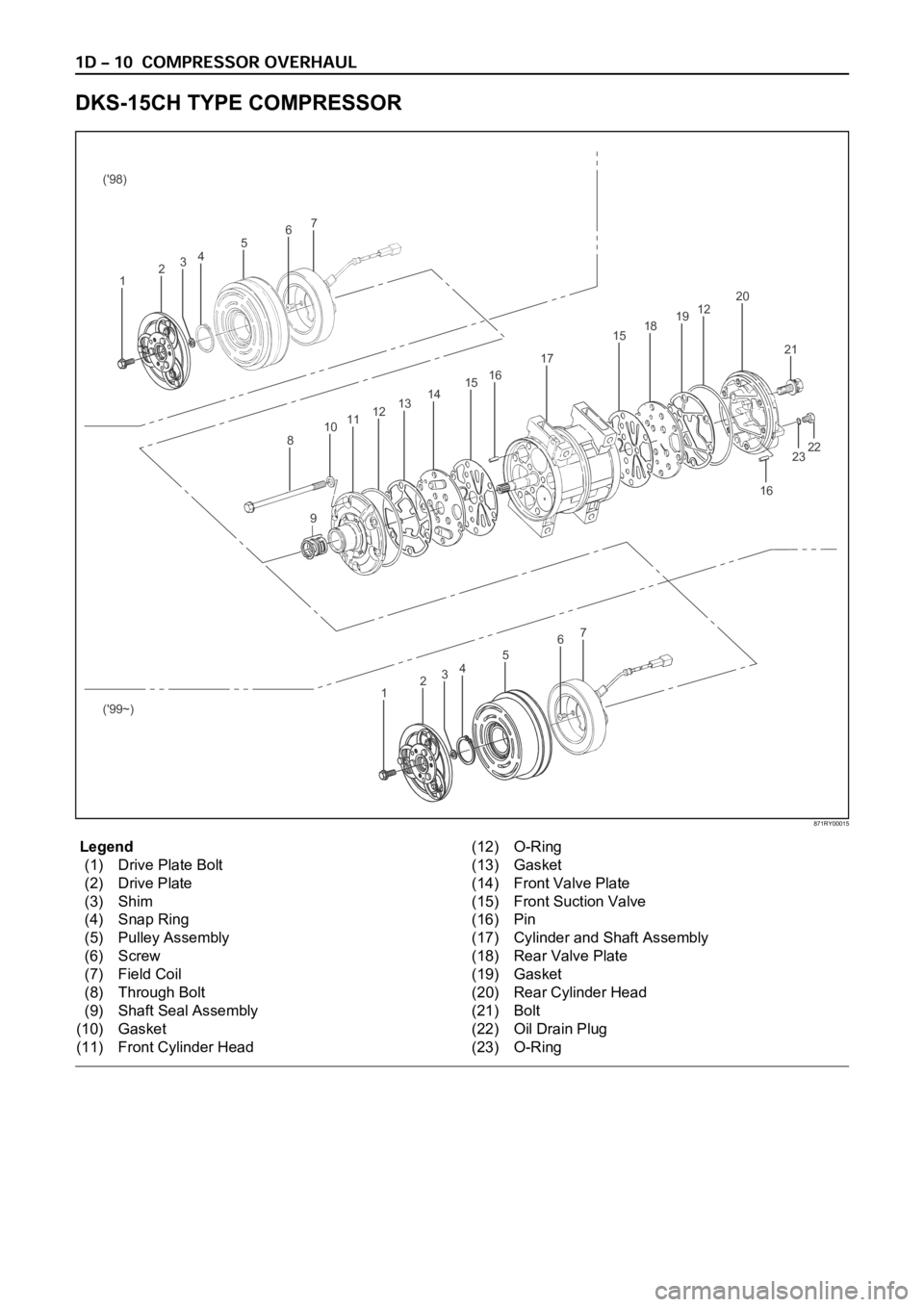

Legend

(1) Drive Plate Bolt

(2) Drive Plate

(3) Shim

(4) Snap Ring

(5) Pulley Assembly

(6) Screw

(7) Field Coil

(8) Through Bolt

(9) Shaft Seal Assembly

(10) Gasket

(11) Front Cylinder Head(12) O-Ring

(13) Gasket

(14) Front Valve Plate

(15) Front Suction Valve

(16) Pin

(17) Cylinder and Shaft Assembly

(18) Rear Valve Plate

(19) Gasket

(20) Rear Cylinder Head

(21) Bolt

(22) Oil Drain Plug

(23) O-Ring

DKS-15CH TYPE COMPRESSOR

16

23 2122 6

7

45

321 ('98)

('99~)

67

45

321

8

910111213141516

17

1518191220

871RY00015

Page 438 of 6000

4A1–1 DIFFERENTIAL (FRONT)

DRIVELINE/AXLE

CONTENTS

Differential (Front) 4A1. . . . . . . . . . . . . . . . . . . . . . .

Differential (Rear/220mm) 4A2A. . . . . . . . . . . . . . . .

Differential (Rear/244mm) 4A2B. . . . . . . . . . . . . . . .

Driveline Control System (Shift on the Fly) 4B1. . Driveline Control System (TOD) 4B2. . . . . . . . . . .

Driveshaft System 4C. . . . . . . . . . . . . . . . . . . . . . .

Transfer Case (Standard Type) 4D1. . . . . . . . . . .

Transfer Case (TOD) 4D2. . . . . . . . . . . . . . . . . . . .

DIFFERENTIAL (FRONT)

CONTENTS

Service Precaution 4A1–1. . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 4A1–2. . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal 4A1–3. . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal and Associated Parts 4A1–3

Removal 4A1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1–4. . . . . . . . . . . . . . . . . .

Installation 4A1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle Assembly 4A1–5. . . . . . . . . . . . . . .

Front Drive Axle Assembly and

Associated Parts 4A1–5. . . . . . . . . . . . . . . . . . . . . .

Removal 4A1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A1–9. . . . . . . . . . . . . . . . . . . .

Disassembled View 4A1–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A1–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A1–21. . . . . . . . . . . . . . .

Disassembled View 4A1–21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1–22. . . . . . . . . . . . . . . . . .

Reassembly 4A1–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A1–25. . . . . . . . . . .

Special Tools 4A1–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 462 of 6000

4A1–25 DIFFERENTIAL (FRONT)

Main Data and Specifications

General Specifications

Axle tube TypeIt consists of the duct, a cast iron housing and the axle

tube.

Gear typeHypoid

Gear ratio(to 1)4.100(6VE1)

4.300(4JX1, 6VE1)

4.555(4JG2–TC, 6VD1)

4.777(4JG2)

Differential typeTwo pinion

Oil capacityliter

(Imp qt/US qt)1.4 (1.2/1.5) (Differential)

0.12 (0.11/0.13) (Actuator Housing: Shift on the fly)

Type of lubricant75W–90 GL–5 (Multi grade type)

Refer to General Information

Axle shaft typeConstant velocity joint

(Birfield joint type and double offset joint)

Page 577 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–6

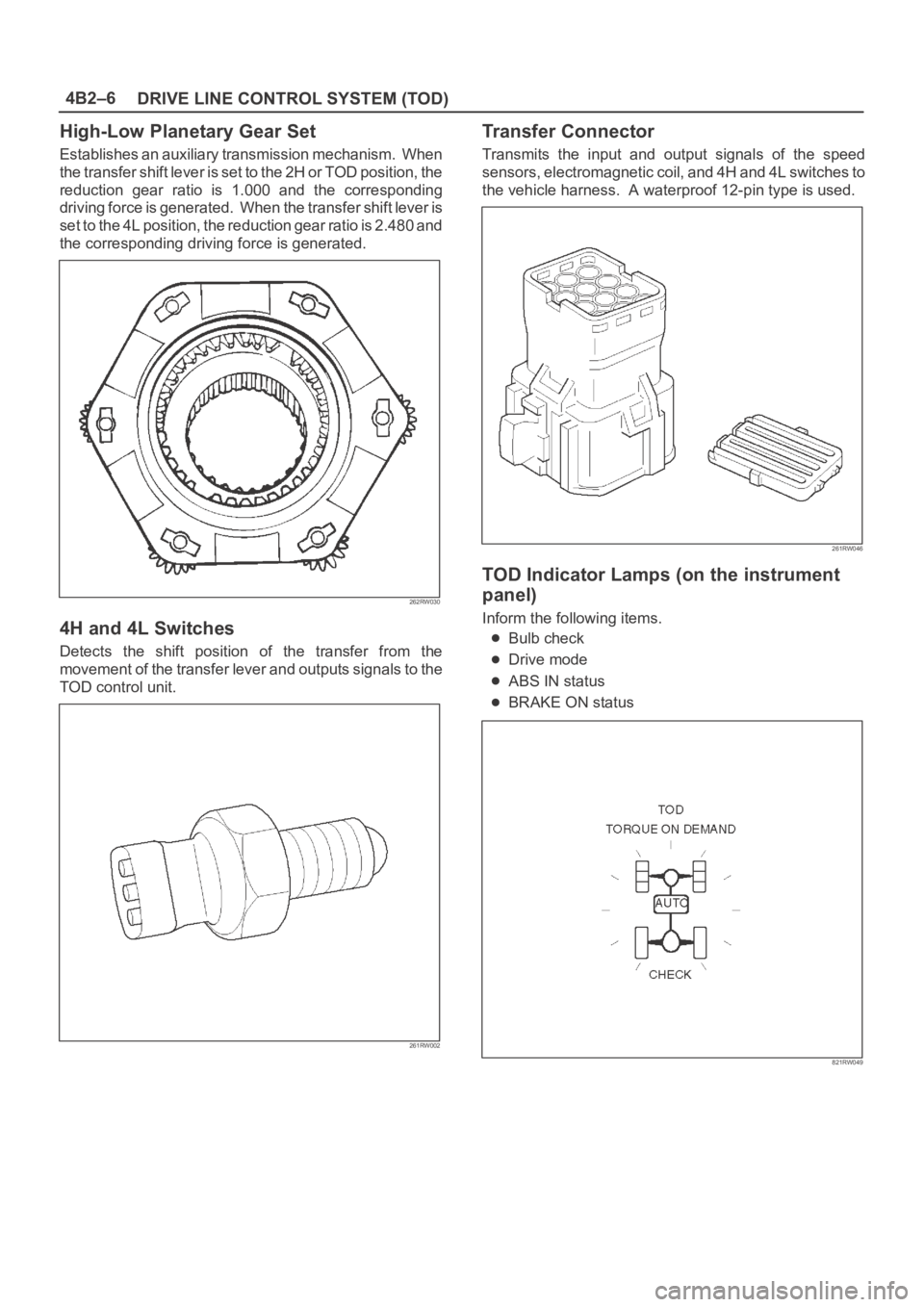

High-Low Planetary Gear Set

Establishes an auxiliary transmission mechanism. When

the transfer shift lever is set to the 2H or TOD position, the

reduction gear ratio is 1.000 and the corresponding

driving force is generated. When the transfer shift lever is

set to the 4L position, the reduction gear ratio is 2.480 and

the corresponding driving force is generated.

262RW030

4H and 4L Switches

Detects the shift position of the transfer from the

movement of the transfer lever and outputs signals to the

TOD control unit.

261RW002

Transfer Connector

Transmits the input and output signals of the speed

sensors, electromagnetic coil, and 4H and 4L switches to

the vehicle harness. A waterproof 12-pin type is used.

261RW046

TOD Indicator Lamps (on the instrument

panel)

Inform the following items.

Bulb check

Drive mode

ABS IN status

BRAKE ON status

821RW049

Page 601 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–30

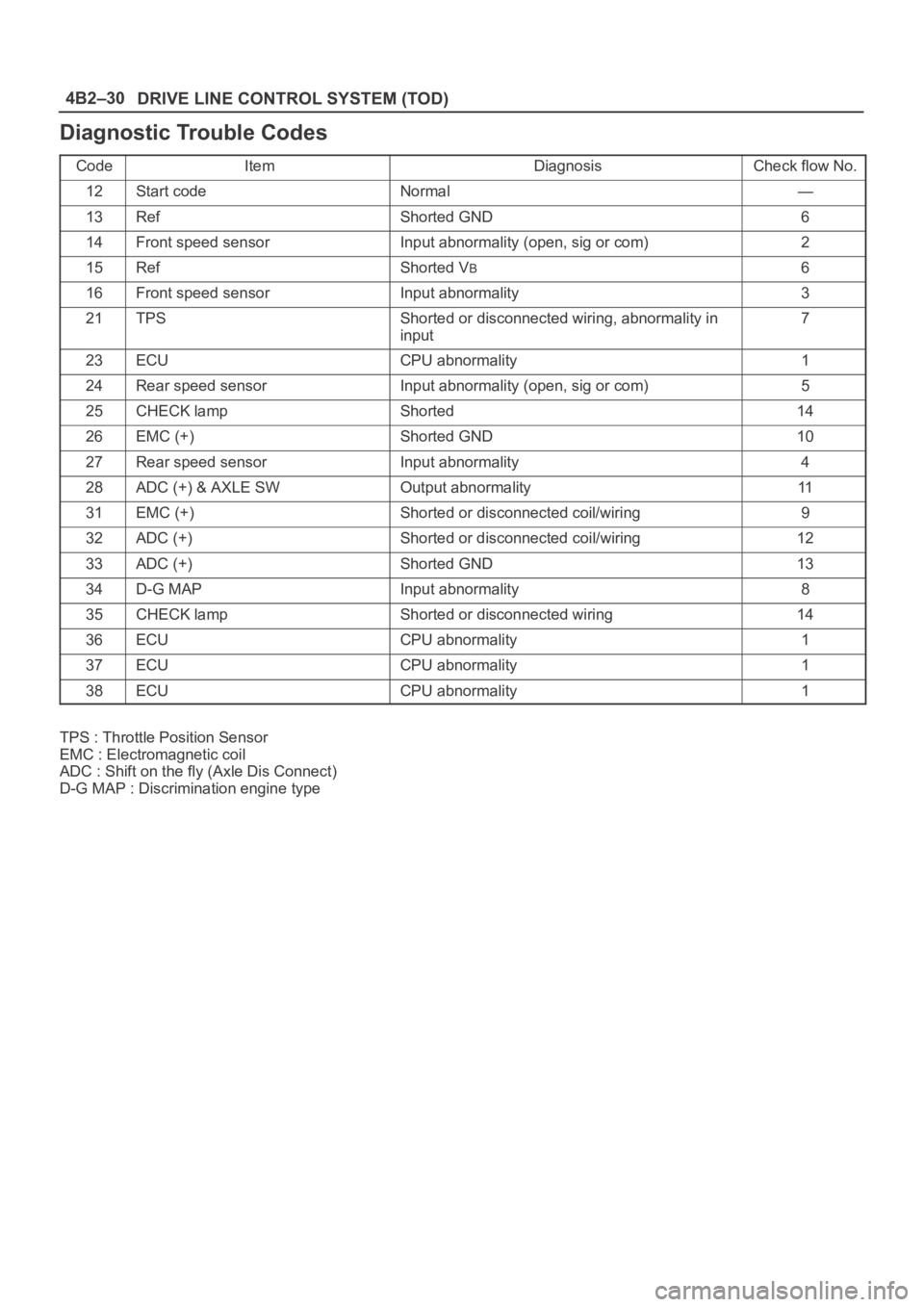

Diagnostic Trouble Codes

CodeItemDiagnosisCheck flow No.

12Start codeNormal—

13RefShorted GND6

14Front speed sensorInput abnormality (open, sig or com)2

15RefShorted VB6

16Front speed sensorInput abnormality3

21TPSShorted or disconnected wiring, abnormality in

input7

23ECUCPU abnormality1

24Rear speed sensorInput abnormality (open, sig or com)5

25CHECK lampShorted14

26EMC (+)Shorted GND10

27Rear speed sensorInput abnormality4

28ADC (+) & AXLE SWOutput abnormality11

31EMC (+)Shorted or disconnected coil/wiring9

32ADC (+)Shorted or disconnected coil/wiring12

33ADC (+)Shorted GND13

34D-G MAPInput abnormality8

35CHECK lampShorted or disconnected wiring14

36ECUCPU abnormality1

37ECUCPU abnormality1

38ECUCPU abnormality1

TPS : Throttle Position Sensor

EMC : Electromagnetic coil

ADC : Shift on the fly (Axle Dis Connect)

D-G MAP : Discrimination engine type

Page 659 of 6000

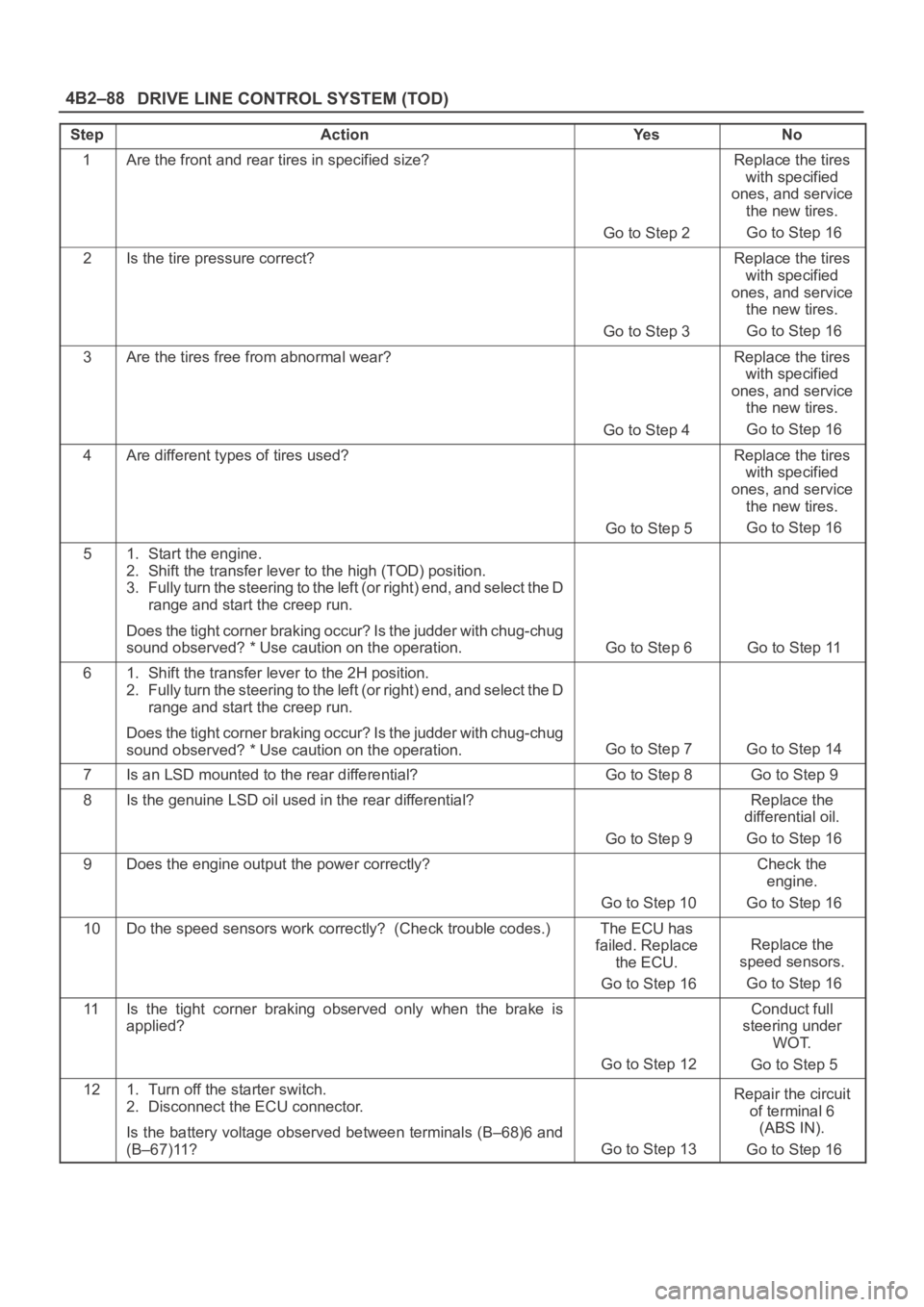

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 678 of 6000

4C–12

DRIVE SHAFT SYSTEM

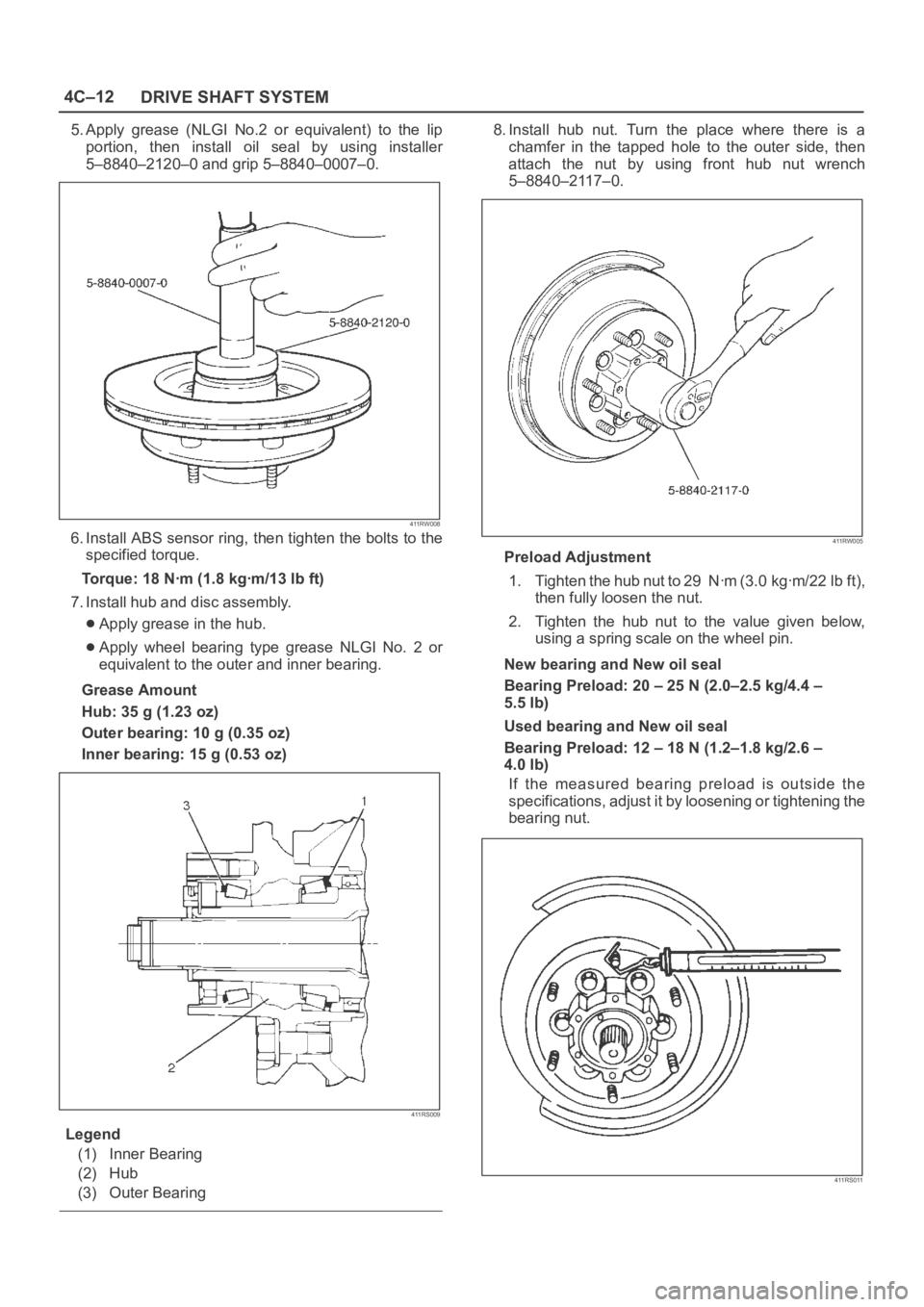

5. Apply grease (NLGI No.2 or equivalent) to the lip

portion, then install oil seal by using installer

5–8840–2120–0 and grip 5–8840–0007–0.

411RW008

6. Install ABS sensor ring, then tighten the bolts to the

specified torque.

Torque: 18 Nꞏm (1.8 kgꞏm/13 lb ft)

7. Install hub and disc assembly.

Apply grease in the hub.

Apply wheel bearing type grease NLGI No. 2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23 oz)

Outer bearing: 10 g (0.35 oz)

Inner bearing: 15 g (0.53 oz)

411RS009

Legend

(1) Inner Bearing

(2) Hub

(3) Outer Bearing

8. Install hub nut. Turn the place where there is a

chamfer in the tapped hole to the outer side, then

attach the nut by using front hub nut wrench

5–8840–2117–0.

411RW005

Preload Adjustment

1. Tighten the hub nut to 29 Nꞏm (3.0 kgꞏm/22 lb ft),

then fully loosen the nut.

2. Tighten the hub nut to the value given below,

using a spring scale on the wheel pin.

New bearing and New oil seal

Bearing Preload: 20 – 25 N (2.0–2.5 kg/4.4 –

5.5 lb)

Used bearing and New oil seal

Bearing Preload: 12 – 18 N (1.2–1.8 kg/2.6 –

4.0 lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening the

bearing nut.

411RS011

Page 684 of 6000

4C–18

DRIVE SHAFT SYSTEM

17. Install oil seal by using installer 5–8840–2120–0 and

grip 5–8840–0007–0.

Apply grease (NLGI No.2 or equivalent) to the lip

portion.

411RW008

18. Install ABS sensor ring (if so equipped).

Tighten the bolts to the specified torque.

Torque:18Nꞏm (1.8kgꞏm/13lbft)

19. Install hub and disc assembly.

1. Apply grease in the hub.

2. Apply wheel bearing type grease NLGI No.2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23 oz)

Outer bearing: 10 g (0.35 oz)

Inner bearing: 15 g (0.53 oz)

20. Install hub nut.

1. Turn the place where there is a chamfer in the

tapped hole to the outer side, and attach the nut

by using wrench 5–8840–2117–0.

411RW005

Preload Adjustment

Tighten the hub nut to 29 Nꞏm (3.0 kgꞏm/22 lbꞏft),

then fully loosen the nut.

Tighten the hub nut to the value given below, using

a spring scale on the wheel pin.

Bearing Preload

New bearing and New oil seal:

20-25N (2-2.5 kg/4.4-5.5 lb)

Used bearing and New oil seal:

12-18N (1.2-1.8 kg/2.6-4.0 lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening

the bearing nut.

411RS011

Page 701 of 6000

4C–35 DRIVE SHAFT SYSTEM

Main Data and Specifications

General Specifications

Front drive axle oil capacity1.4 liter (1.23 Imp qt/1.48 US qt)(Differential)

0.12 liter (0.10 Imp qt/0.13 US qt)(Actuator Housing:Shift on the fly)

Type of lubricantGL–5 (Multi grade type) Refer to chart in General Information

Axle shaft typeConstant velocity joint(Birfield joint type and double offset joint)

Torque Specifications

E04RW020