fold seats OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1009 of 6000

6A–53

ENGINE MECHANICAL

2. Remove camshaft bracket fixing bolt (5), camshaft

bracket (6), then camshaft exhaust (7), and intake

side (8).

3. Remove tappet with shim (11).

4. Use the 5–8840–2446–0 valve spring compressor

and 5–8840–2547–0 valve spring compressor

adapter to remove the split collar (12), valve spring

with upper seat (13) and valve (14).

014RW042

5. Remove spark plug (1).

CAUTION: Do not remove the spark plugs when the

head and plugs are hot. Clean dirt and debris from

spark plug recess areas before removal.

Clean

Cylinder head

Carefully remove all varnish, soot and carbon from the

bare metal. Do not use a motorized wire brush on any

gasket sealing surface.

Inspection and Repair

1. Cylinder head gasket and mating surfaces for leaks,

corrosion and blow–by. If the gasket has failed,

determine the cause.

– Insufficient torque on head bolts.

– Improper installation

– Loose or warped cylinder head

– Missing dowel pins

– Warped case surface

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION:

Do not attempt to weld the cylinder head. Replace

it.

Do not reuse cylinder head bolts.

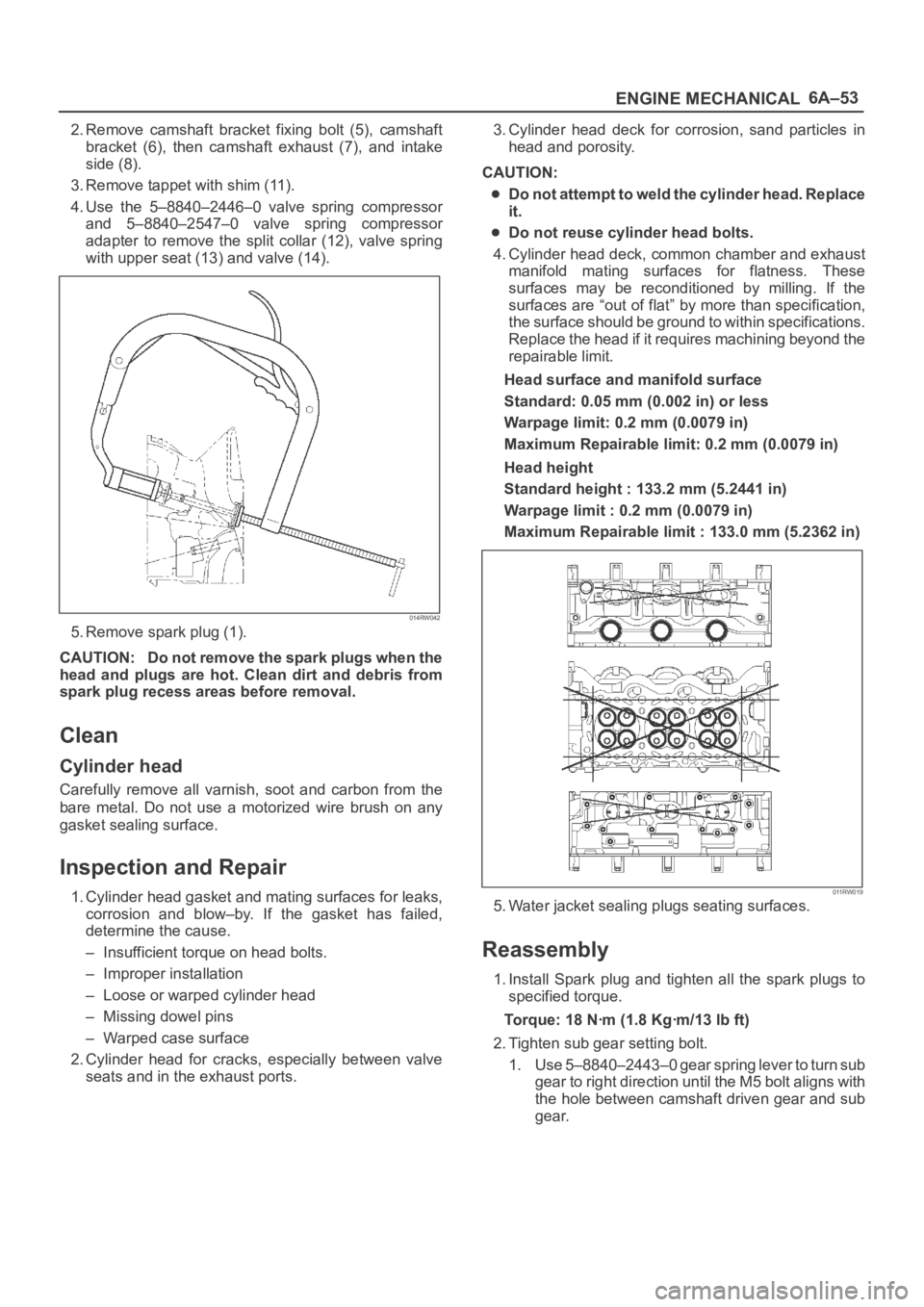

4. Cylinder head deck, common chamber and exhaust

manifold mating surfaces for flatness. These

surfaces may be reconditioned by milling. If the

surfaces are “out of flat” by more than specification,

the surface should be ground to within specifications.

Replace the head if it requires machining beyond the

repairable limit.

Head surface and manifold surface

Standard: 0.05 mm (0.002 in) or less

Warpage limit: 0.2 mm (0.0079 in)

Maximum Repairable limit: 0.2 mm (0.0079 in)

Head height

Standard height : 133.2 mm (5.2441 in)

Warpage limit : 0.2 mm (0.0079 in)

Maximum Repairable limit : 133.0 mm (5.2362 in)

011RW019

5. Water jacket sealing plugs seating surfaces.

Reassembly

1. Install Spark plug and tighten all the spark plugs to

specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

2. Tighten sub gear setting bolt.

1. Use 5–8840–2443–0 gear spring lever to turn sub

gear to right direction until the M5 bolt aligns with

the hole between camshaft driven gear and sub

gear.

Page 1775 of 6000

6A – 42 ENGINE MECHANICAL

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.

3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

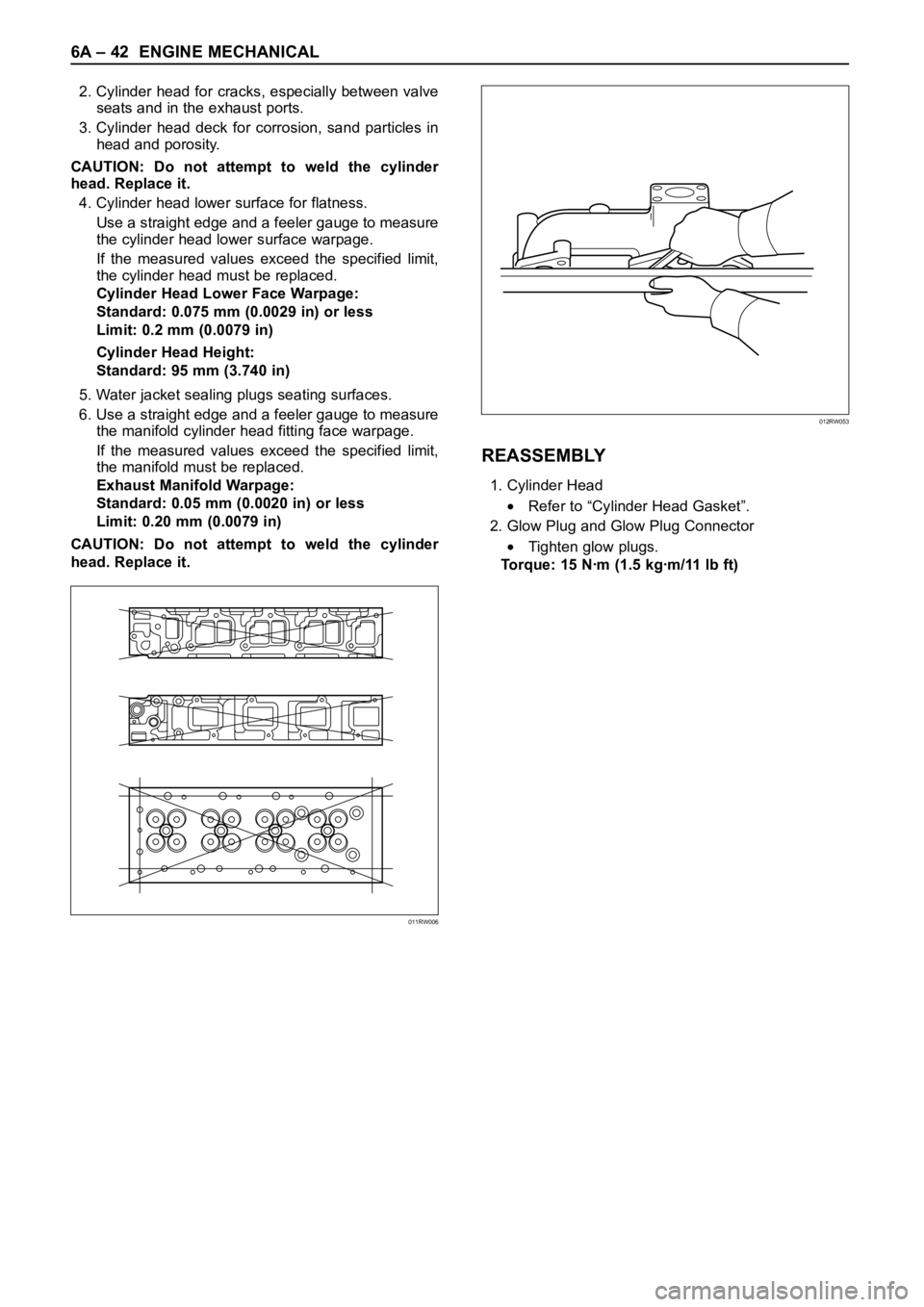

4. Cylinder head lower surface for flatness.

Use a straight edge and a feeler gauge to measure

the cylinder head lower surface warpage.

If the measured values exceed the specified limit,

the cylinder head must be replaced.

Cylinder Head Lower Face Warpage:

Standard: 0.075 mm (0.0029 in) or less

Limit: 0.2 mm (0.0079 in)

Cylinder Head Height:

Standard: 95 mm (3.740 in)

5. Water jacket sealing plugs seating surfaces.

6. Use a straight edge and a feeler gauge to measure

the manifold cylinder head fitting face warpage.

If the measured values exceed the specified limit,

the manifold must be replaced.

Exhaust Manifold Warpage:

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.20 mm (0.0079 in)

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

REASSEMBLY

1. Cylinder Head

Refer to “Cylinder Head Gasket”.

2. Glow Plug and Glow Plug Connector

Tighten glow plugs.

Torque: 15 Nꞏm (1.5 kgꞏm/11 lb ft)

011RW006

012RW053

Page 4549 of 6000

6A–53

ENGINE MECHANICAL

2. Remove camshaft bracket fixing bolt (5), camshaft

bracket (6), then camshaft exhaust (7), and intake

side (8).

3. Remove tappet with shim (11).

4. Use the 5–8840–2446–0 valve spring compressor

and 5–8840–2547–0 valve spring compressor

adapter to remove the split collar (12), valve spring

with upper seat (13) and valve (14).

014RW042

5. Remove spark plug (1).

CAUTION: Do not remove the spark plugs when the

head and plugs are hot. Clean dirt and debris from

spark plug recess areas before removal.

Clean

Cylinder head

Carefully remove all varnish, soot and carbon from the

bare metal. Do not use a motorized wire brush on any

gasket sealing surface.

Inspection and Repair

1. Cylinder head gasket and mating surfaces for leaks,

corrosion and blow–by. If the gasket has failed,

determine the cause.

– Insufficient torque on head bolts.

– Improper installation

– Loose or warped cylinder head

– Missing dowel pins

– Warped case surface

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION:

Do not attempt to weld the cylinder head. Replace

it.

Do not reuse cylinder head bolts.

4. Cylinder head deck, common chamber and exhaust

manifold mating surfaces for flatness. These

surfaces may be reconditioned by milling. If the

surfaces are “out of flat” by more than specification,

the surface should be ground to within specifications.

Replace the head if it requires machining beyond the

repairable limit.

Head surface and manifold surface

Standard: 0.05 mm (0.002 in) or less

Warpage limit: 0.2 mm (0.0079 in)

Maximum Repairable limit: 0.2 mm (0.0079 in)

Head height

Standard height : 133.2 mm (5.2441 in)

Warpage limit : 0.2 mm (0.0079 in)

Maximum Repairable limit : 133.0 mm (5.2362 in)

011RW019

5. Water jacket sealing plugs seating surfaces.

Reassembly

1. Install Spark plug and tighten all the spark plugs to

specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

2. Tighten sub gear setting bolt.

1. Use 5–8840–2443–0 gear spring lever to turn sub

gear to right direction until the M5 bolt aligns with

the hole between camshaft driven gear and sub

gear.

Page 5311 of 6000

6A – 38 ENGINE MECHANICAL

1. Cylinder head bolts for damaged threads or

stretching and damaged heads caused by improper

use of tools.

CAUTION: Suspected bolts must be replaced.

2. Cylinder head for cracks, especially between valve

seats and in the exhaust ports.

3. Cylinder head deck for corrosion, sand particles in

head and porosity.

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

4. Cylinder head lower surface for flatness.

Use a straight edge and a feeler gauge to measure

the cylinder head lower surface warpage.

If the measured values exceed the specified limit,

the cylinder head must be replaced.

Cylinder Head Lower Face Warpage:

Standard: 0.075 mm (0.0029 in) or less

Limit: 0.50 mm (0.0197 in)

Cylinder Head Height:

Standard: 95 mm (3.740 in)

5. Water jacket sealing plugs seating surfaces.

6. Use a straight edge and a feeler gauge to measure

the manifold cylinder head fitting face warpage.

If the measured values exceed the specified limit,

the manifold must be replaced.

Exhaust Manifold Warpage:

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.20 mm (0.0079 in)

CAUTION: Do not attempt to weld the cylinder

head. Replace it.

REASSEMBLY

1. Cylinder Head

Refer to “Cylinder head”.

2. Glow Plug and Glow Plug Connector

Tighten glow plugs.

Torque: 15 Nꞏm (1.5 kgꞏm/11 lb ft)

011RW006

012RW053