headlights OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 960 of 6000

6A–4

ENGINE MECHANICAL

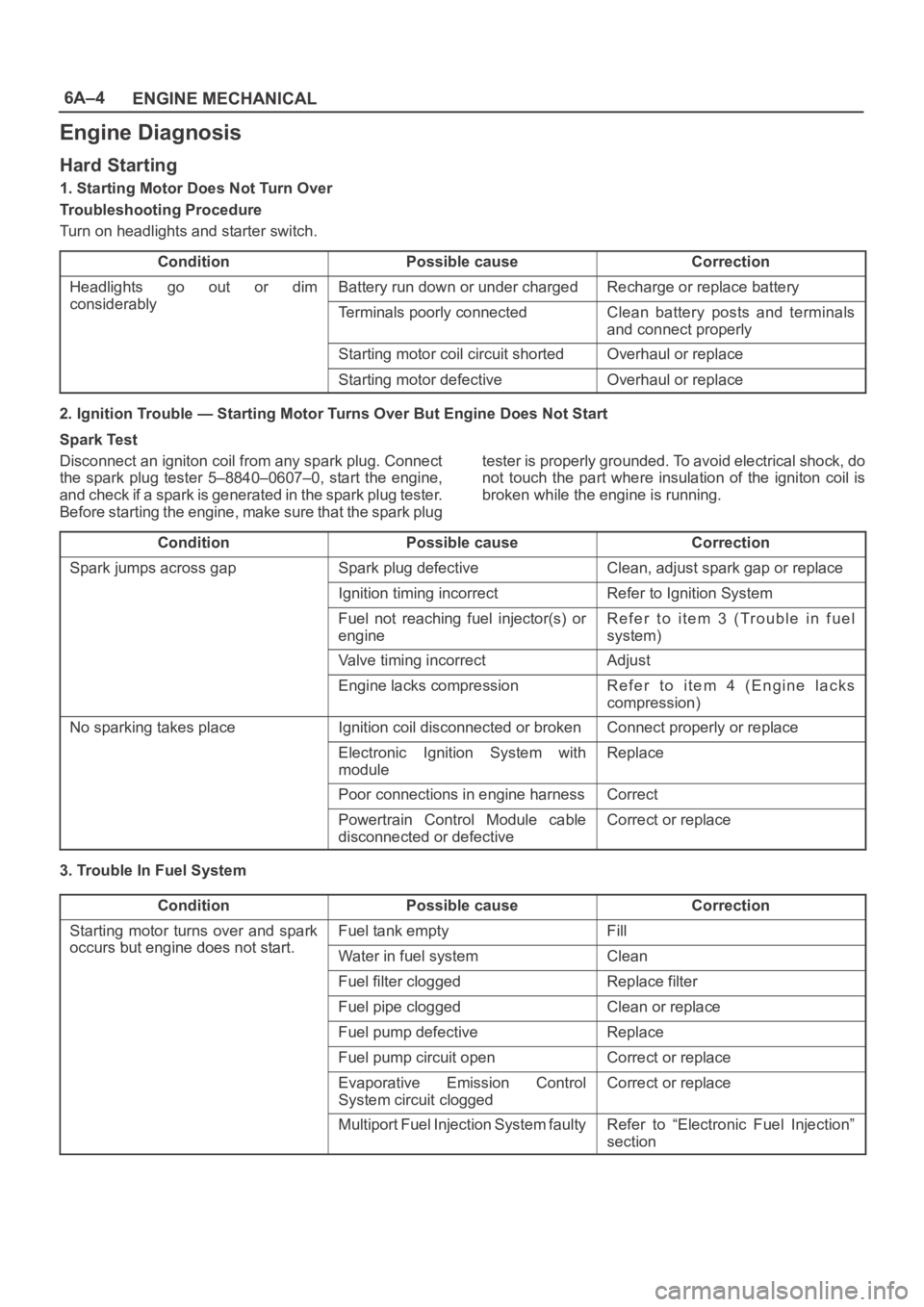

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

a n d c h e c k i f a s p a r k i s g e n e r a t e d in t h e s p a r k p l u g t e s t e r.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to “Electronic Fuel Injection”

section

Page 1355 of 6000

6E–238

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0562 – System Voltage Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Using a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/Char

ging

41. Ignition “OFF.”

2. Disconnect the PCM connector at the PCM.

3. Using a DVM, measure the battery voltage at the

PCM connector A-4.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the PCM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the PCM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 2052 of 6000

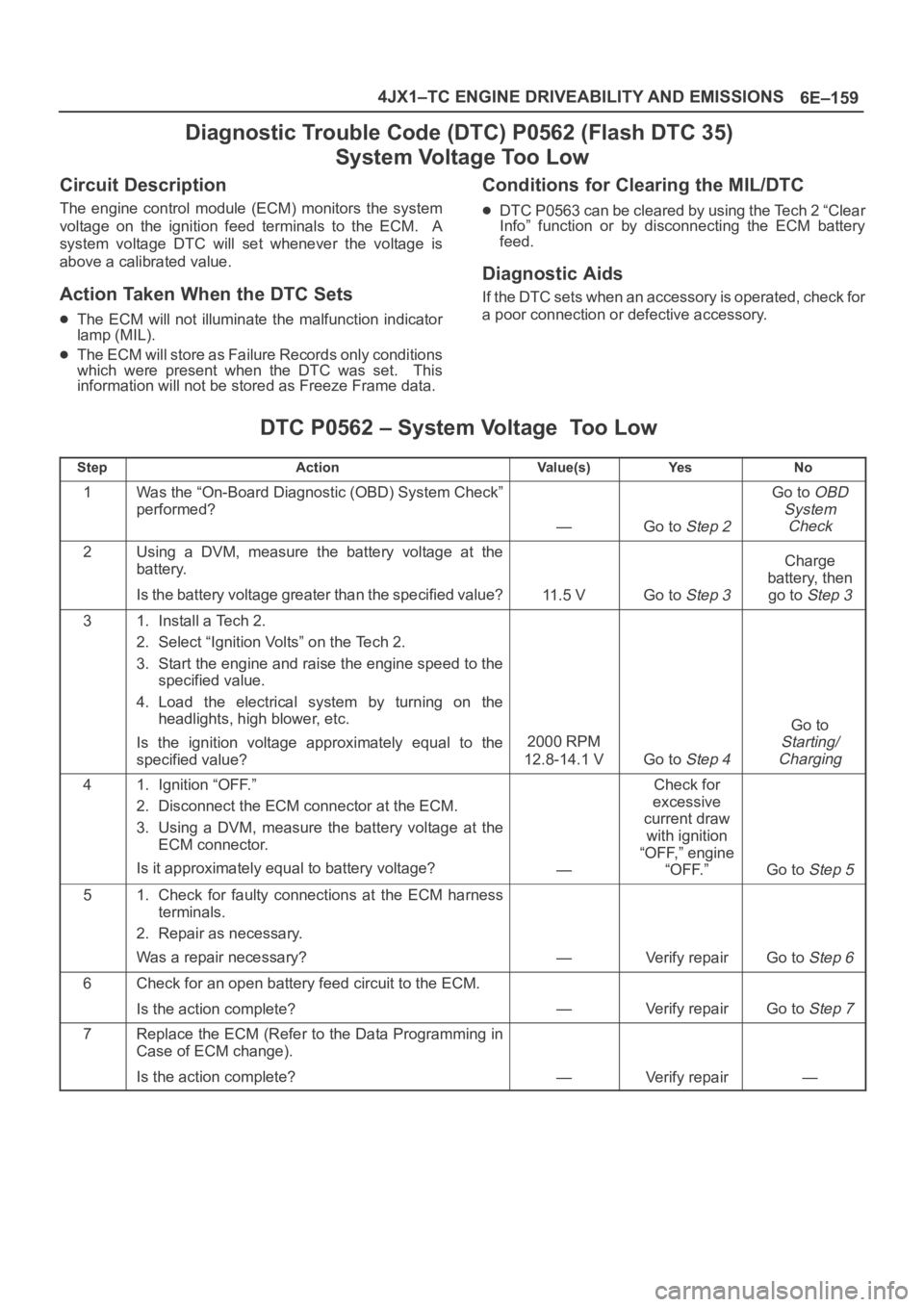

6E–159 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0562 (Flash DTC 35)

System Voltage Too Low

Circuit Description

The engine control module (ECM) monitors the system

voltage on the ignition feed terminals to the ECM. A

system voltage DTC will set whenever the voltage is

above a calibrated value.

Action Taken When the DTC Sets

The ECM will not illuminate the malfunction indicator

lamp (MIL).

The ECM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or defective accessory.

DTC P0562 – System Voltage Too Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a DVM, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Install a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/

Charging

41. Ignition “OFF.”

2. Disconnect the ECM connector at the ECM.

3. Using a DVM, measure the battery voltage at the

ECM connector.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the ECM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the ECM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—

Page 2992 of 6000

WIRING SYSTEM 8D–399

1. Check to see if the battery voltage is normal.

2. Check to see if the fuse is normal.

3. Replace the anti–theft & keyless entry control unit with one reserved for test. If a trouble recurs even after replacing

the control unit, find out the cause of the trouble by referring to “System check procedure” and the following list.

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

ANTI–THEFT

indicator light

does not flash

ANTI–THEFT

indicator light

does not turn off.

(Steadily on)

When door is

opened by pulling

up locking knob,

alarm does not

operate

Alarm does not

stop. Indicator light

does not change

to fully ON

condition, or does

not come on at

all.Burnt out indicator

light bulb possible.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of door switch,

or open circuit in door switch

wiring.

Short circuit in the detect switch.

Engine hood, doors and tailgate

are not fully closed and locked.

Defective door switch, or short

circuit in switch wiring.

Defective tamper switch, or short

circuit in wiring.

Defective lock switch, or short

circuit in wiring.

Defective engine hood switch, or

short circuit in wiring.

Defective tailgate switch, or short

circuit in wiring.

Defective control unit.

Poor contact of lock switch, or

open circuit in wiring.

Broken wire in wiring to headlight

and horn, or a blown fuse.

Defective contact of detect

switch, or damaged switch wiring.With door open, dome light and

courtesy light do not come on.

Check the control unit connector.

Check to see if doors are closed

and locked.

Dome light and courtesy light

remain lit on after closing doors.

Check the control unit connector.

Check the control unit connector.

Check the control unit connector.

Luggage room light remains lit

after closing tailgate.

Check alarm operation (See No.

46 of “System check procedure”),

possible cause is a poor contact

of lock switch of an open circuit in

wiring.

Check to see if headlights go out.

Check the control unit connector.

Check the control unit connector. A

C

D

E B

Page 3361 of 6000

8H–22SECURITY AND LOCKS

Anti-theft System

General Description

The circuit consists of the starter switch, anti-theft &

keyless entry control unit, anti-theft horn, front door and

tailgate key switch (detect and tamper switch), door lock

(& power window) switch, door lock actuator for each

door, engine hood switch, clutch start switch (M/T),

ANTI-THEFT indicator light and mode switch (A/T).

The system operates as follows: After locking the starter

switch and removing the starter key (this sets the alarm),

if the door is unlocked in any way other than with the

proper key, the headlights start flashing, the horn sounds,

and the starter circuit is disabled. (However, the engine

hood and all the doors must be locked and closed.)

Once the system has been placed in the warning or alarm

condition, it can be released only when the starter switch

is shifted from “OFF” to “ACC” by the starter key, or when

the lock of the front door or the tailgate is released (to

activate the detect switch) by the starter key.

Anti-theft & Keyless Entry Control

Unit Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Disconnect the connector(2).

5. Remove four screws to remove the anti-theft &

keyless entry control unit with bracket(1).

825RW029

6. Remove two nuts from the anti-theft & keyless entry

control unit with bracket(3) to remove the anti-theft &

keyless entry controller(4).

825RW028

Anti-theft & Keyless Entry Control

Unit Installation

To install, follow the removal steps in the reverse order.

Anti-theft Indicator Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover

assembly(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

Page 4500 of 6000

6A–4

ENGINE MECHANICAL

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5–8840–0607–0, start the engine,

a n d c h e c k i f a s p a r k i s g e n e r a t e d in t h e s p a r k p l u g t e s t e r.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to “Electronic Fuel Injection”

section

Page 4895 of 6000

6E–238

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0562 – System Voltage Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Using a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/Char

ging

41. Ignition “OFF.”

2. Disconnect the PCM connector at the PCM.

3. Using a DVM, measure the battery voltage at the

PCM connector A-4.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the PCM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the PCM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 5588 of 6000

6E–159 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0562 (Flash DTC 35)

System Voltage Too Low

Circuit Description

The engine control module (ECM) monitors the system

voltage on the ignition feed terminals to the ECM. A

system voltage DTC will set whenever the voltage is

above a calibrated value.

Action Taken When the DTC Sets

The ECM will not illuminate the malfunction indicator

lamp (MIL).

The ECM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or defective accessory.

DTC P0562 – System Voltage Too Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a DVM, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Install a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/

Charging

41. Ignition “OFF.”

2. Disconnect the ECM connector at the ECM.

3. Using a DVM, measure the battery voltage at the

ECM connector.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the ECM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the ECM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repair—