mileage OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1224 of 6000

6E–107 ENGINE DRIVEABILITY AND EMISSIONS

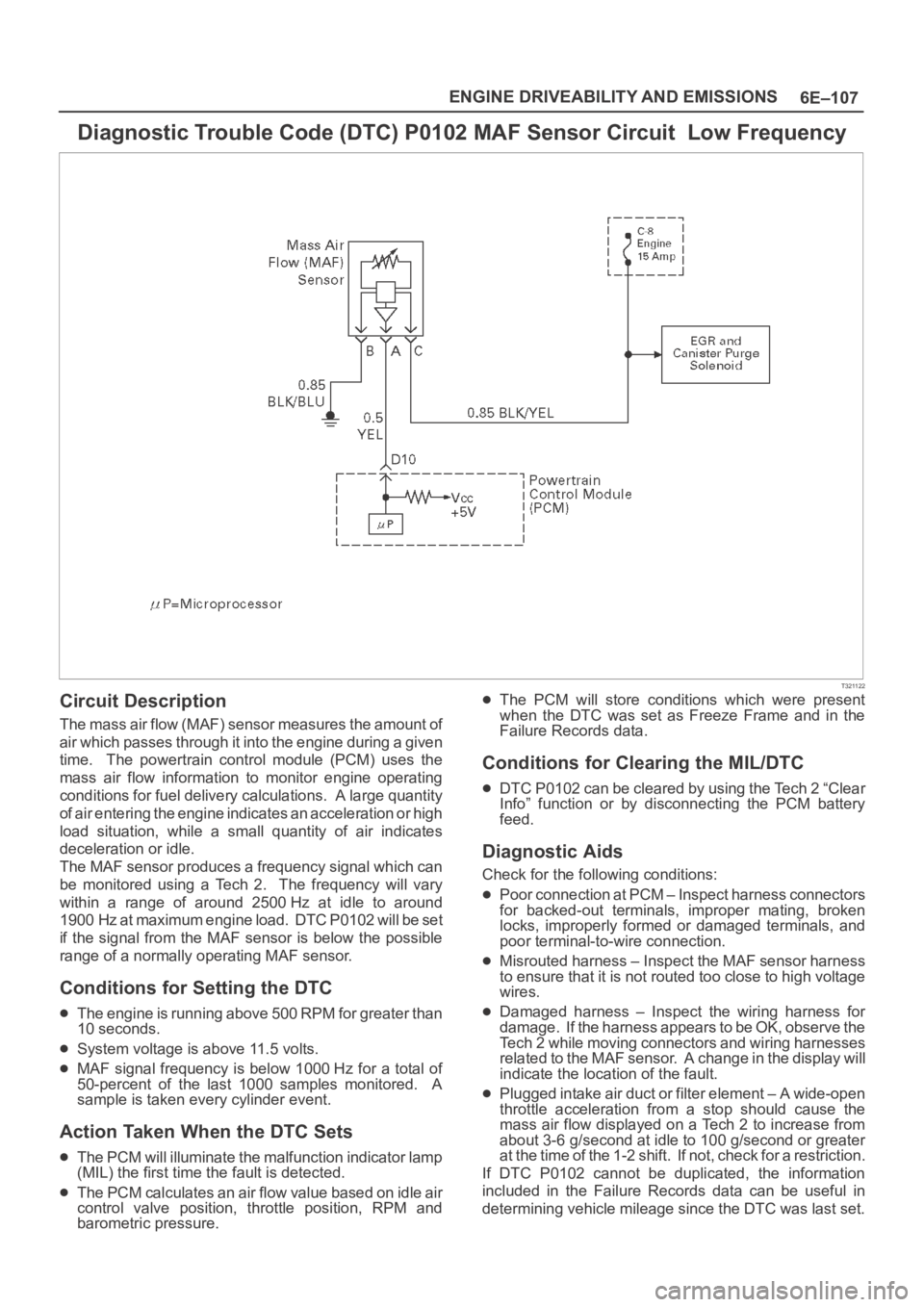

Diagnostic Trouble Code (DTC) P0102 MAF Sensor Circuit Low Frequency

T321122

Circuit Description

The mass air flow (MAF) sensor measures the amount of

air which passes through it into the engine during a given

time. The powertrain control module (PCM) uses the

mass air flow information to monitor engine operating

conditions for fuel delivery calculations. A large quantity

of air entering the engine indicates an acceleration or high

load situation, while a small quantity of air indicates

deceleration or idle.

The MAF sensor produces a frequency signal which can

be monitored using a Tech 2. The frequency will vary

within a range of around 2500 Hz at idle to around

1900 Hz at maximum engine load. DTC P0102 will be set

if the signal from the MAF sensor is below the possible

range of a normally operating MAF sensor.

Conditions for Setting the DTC

The engine is running above 500 RPM for greater than

10 seconds.

System voltage is above 11.5 volts.

MAF signal frequency is below 1000 Hz for a total of

50-percent of the last 1000 samples monitored. A

sample is taken every cylinder event.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM calculates an air flow value based on idle air

control valve position, throttle position, RPM and

barometric pressure.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0102 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Misrouted harness – Inspect the MAF sensor harness

to ensure that it is not routed too close to high voltage

wires.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 while moving connectors and wiring harnesses

related to the MAF sensor. A change in the display will

indicate the location of the fault.

Plugged intake air duct or filter element – A wide-open

throttle acceleration from a stop should cause the

mass air flow displayed on a Tech 2 to increase from

about 3-6 g/second at idle to 100 g/second or greater

at the time of the 1-2 shift. If not, check for a restriction.

If DTC P0102 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1227 of 6000

6E–110

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0103 MAF Sensor Circuit High Frequency

T321122

Circuit Description

The mass air flow (MAF) sensor measures the amount of

air which passes through it into the engine during a given

time. The powertrain control module (PCM) uses the

mass air flow information to monitor engine operating

conditions for fuel delivery calculations. A large quantity

of air entering the engine indicates an acceleration or high

load situation, while a small quantity of air indicates

deceleration or idle.

The MAF sensor produces a frequency signal which can

be monitored using a Tech 2. The frequency will vary

within a range of around 2500 Hz at idle to around

9000 Hz at maximum engine load. DTC P0103 will be set

if the signal from the MAF sensor is above the possible

range of a normally operating MAF sensor.

Conditions for Setting the DTC

The engine is running above 500 RPM for more than

10 seconds.

System voltage is above 11.5 volts.

MAF signal frequency is above 10,000 Hz (10.0 kHz)

for a total of 50 percent of the last 200 samples

monitored. A sample is taken every cylinder event.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM calculates an airflow value based on idle air

control valve position, throttle position, RPM and

barometric pressure.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for clearing the MIL/DTC

DTC P0103 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If DTC P0103 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. This step verifies that the problem is present at idle.

4. A frequency reading with the MAF sensor connector

disconnected indicates an electromagnetic

interfernce (EMI) related fault.

Page 1230 of 6000

6E–113 ENGINE DRIVEABILITY AND EMISSIONS

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0107 cannot be duplicated, the information

included in the Failure Records data can be useful indetermining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P0107 Diagnostic Chart may isolate

the cause of the fault.

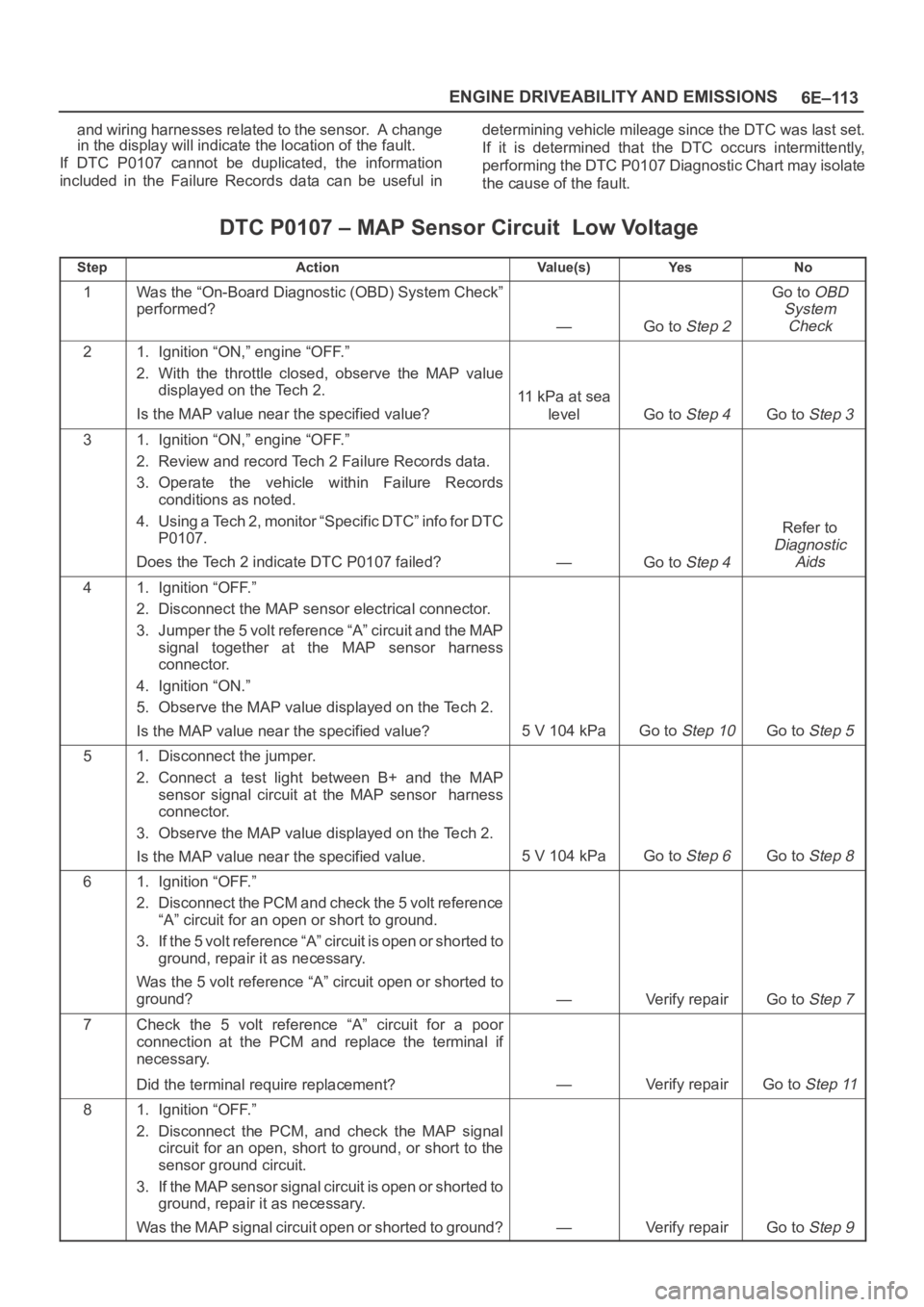

DTC P0107 – MAP Sensor Circuit Low Voltage

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. With the throttle closed, observe the MAP value

displayed on the Tech 2.

Is the MAP value near the specified value?

11 kPa at sea

level

Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “Specific DTC” info for DTC

P0107.

Does the Tech 2 indicate DTC P0107 failed?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Ignition “OFF.”

2. Disconnect the MAP sensor electrical connector.

3. Jumper the 5 volt reference “A” circuit and the MAP

signal together at the MAP sensor harness

connector.

4. Ignition “ON.”

5. Observe the MAP value displayed on the Tech 2.

Is the MAP value near the specified value?

5 V 104 kPaGo to Step 10Go to Step 5

51. Disconnect the jumper.

2. Connect a test light between B+ and the MAP

sensor signal circuit at the MAP sensor harness

connector.

3. Observe the MAP value displayed on the Tech 2.

Is the MAP value near the specified value.

5 V 104 kPaGo to Step 6Go to Step 8

61. Ignition “OFF.”

2. Disconnect the PCM and check the 5 volt reference

“A” circuit for an open or short to ground.

3. If the 5 volt reference “A” circuit is open or shorted to

ground, repair it as necessary.

Was the 5 volt reference “A” circuit open or shorted to

ground?

—Verify repairGo to Step 7

7Check the 5 volt reference “A” circuit for a poor

connection at the PCM and replace the terminal if

necessary.

Did the terminal require replacement?

—Verify repairGo to Step 11

81. Ignition “OFF.”

2. Disconnect the PCM, and check the MAP signal

circuit for an open, short to ground, or short to the

sensor ground circuit.

3. If the MAP sensor signal circuit is open or shorted to

ground, repair it as necessary.

Was the MAP signal circuit open or shorted to ground?

—Verify repairGo to Step 9

Page 1232 of 6000

6E–115 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0108 MAP Sensor Circuit High Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the key “ON,” engine not

running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the linear EGR flow test diagnostic is being

run (refer to

DTC P0401), to determine engine vacuum

level for some other diagnostics and to determine

barometric pressure (BARO). The PCM monitors the

MAP signals for voltages outside the normal range of the

MAP sensor. If the PCM detects a MAP signal voltage

that is excessively high, DTC P0108 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running for more than 10 seconds.

Throttle position is below 3% if engine speed is below

1000 RPM.

Throttle position is below 10% if engine speed is above

1000 RPM.

The MAP sensor indicates an intermittent manifold

absolute pressure above 80kPa for a total of

approximately 10 seconds over a 16-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently,

performing the DTC P1108 Diagnostic Chart may isolate

the cause of the fault.

Page 1235 of 6000

6E–118

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0112 IAT Sensor Circuit Low Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower, causing the PCM to monitor a lower voltage. DTC

P0112 will set when the PCM detects an excessively low

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 2 minutes.

Vehicle speed is greater than 30 mph (48 km/h) .

IAT signal voltage indicates and intake air temperature

greater than 148C (298F) (about 5 volts) for a total

of 12.5 seconds over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0112 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-bout terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0112 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1238 of 6000

6E–121 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0113 IAT Sensor Circuit High Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower causing the PCM to monitor a lower voltage. DTC

P0113 will set when the PCM detects an excessively high

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 4 minutes.

Vehicle speed is less than 20 mph (32 km/h).

ECT signal temperature is above 60C (140F).

Mass air flow is less then 20 g/second.

IAT signal voltage indicates an intake air temperature

less than –39C (–38F) for total of 12.5 seconds over

a 25-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0113 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The IAT sensor shares a ground with the EGR position

sensor and the TP sensor. Check the ground if these

DTC’s are set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0113 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1241 of 6000

6E–124

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0117 ECT Sensor Circuit Low Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes lower,

and the ECT signal voltage measured at the PCM drops.

With a fully warmed-up engine, the ECT signal voltage

should measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than one minute.

The ECT sensor signal indicates an engine coolant

temperature greater than 150C (302F) (about 0.10

V) for a total of 50 seconds over a 100–second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0117 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0117 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

Page 1244 of 6000

6E–127 ENGINE DRIVEABILITY AND EMISSIONS

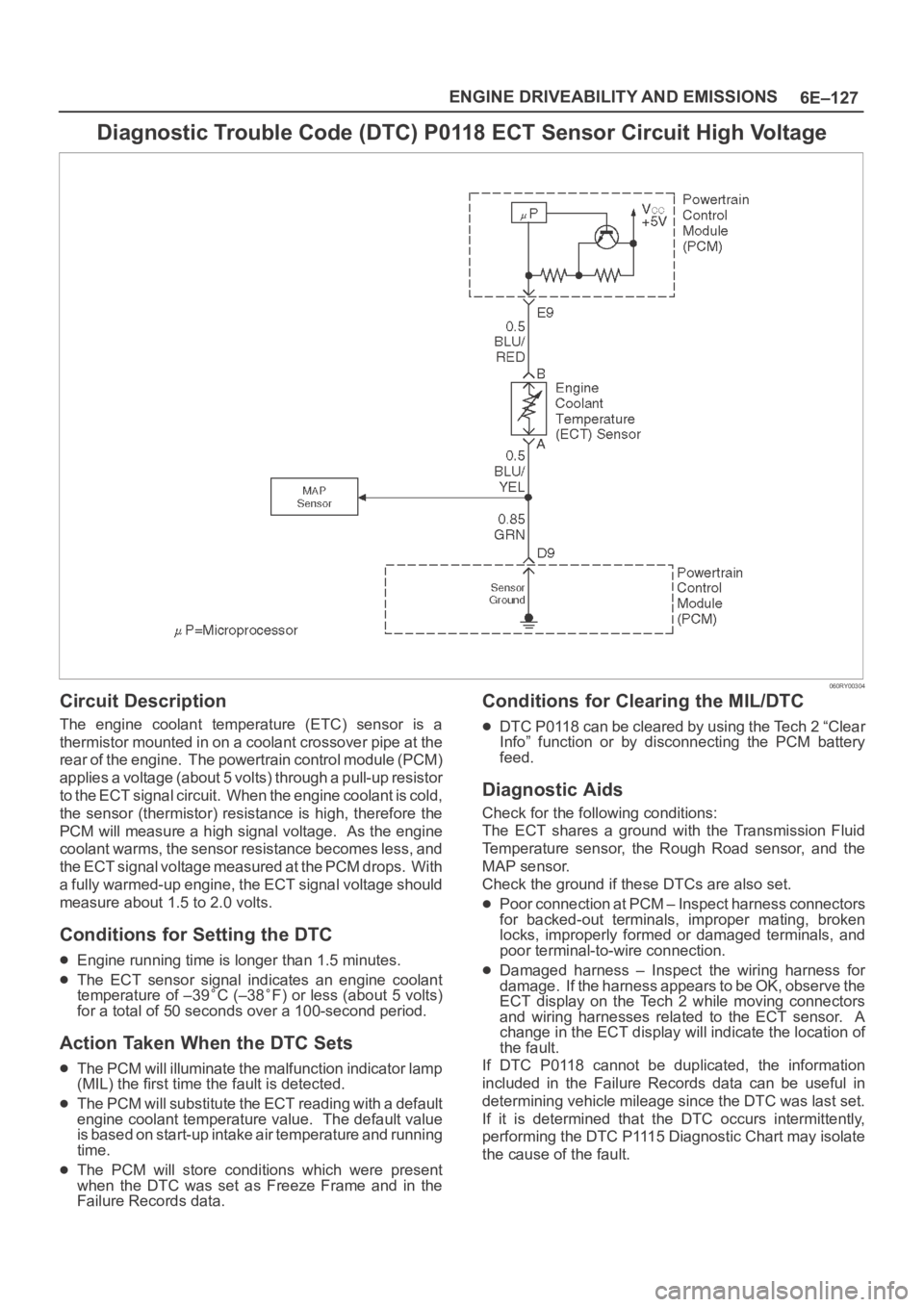

Diagnostic Trouble Code (DTC) P0118 ECT Sensor Circuit High Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted in on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes less, and

the ECT signal voltage measured at the PCM drops. With

a fully warmed-up engine, the ECT signal voltage should

measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than 1.5 minutes.

The ECT sensor signal indicates an engine coolant

temperature of –39C (–38F) or less (about 5 volts)

for a total of 50 seconds over a 100-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0118 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The ECT shares a ground with the Transmission Fluid

Temperature sensor, the Rough Road sensor, and the

MAP sensor.

Check the ground if these DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0118 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1115 Diagnostic Chart may isolate

the cause of the fault.

Page 1247 of 6000

6E–130

ENGINE DRIVEABILITY AND EMISSIONS

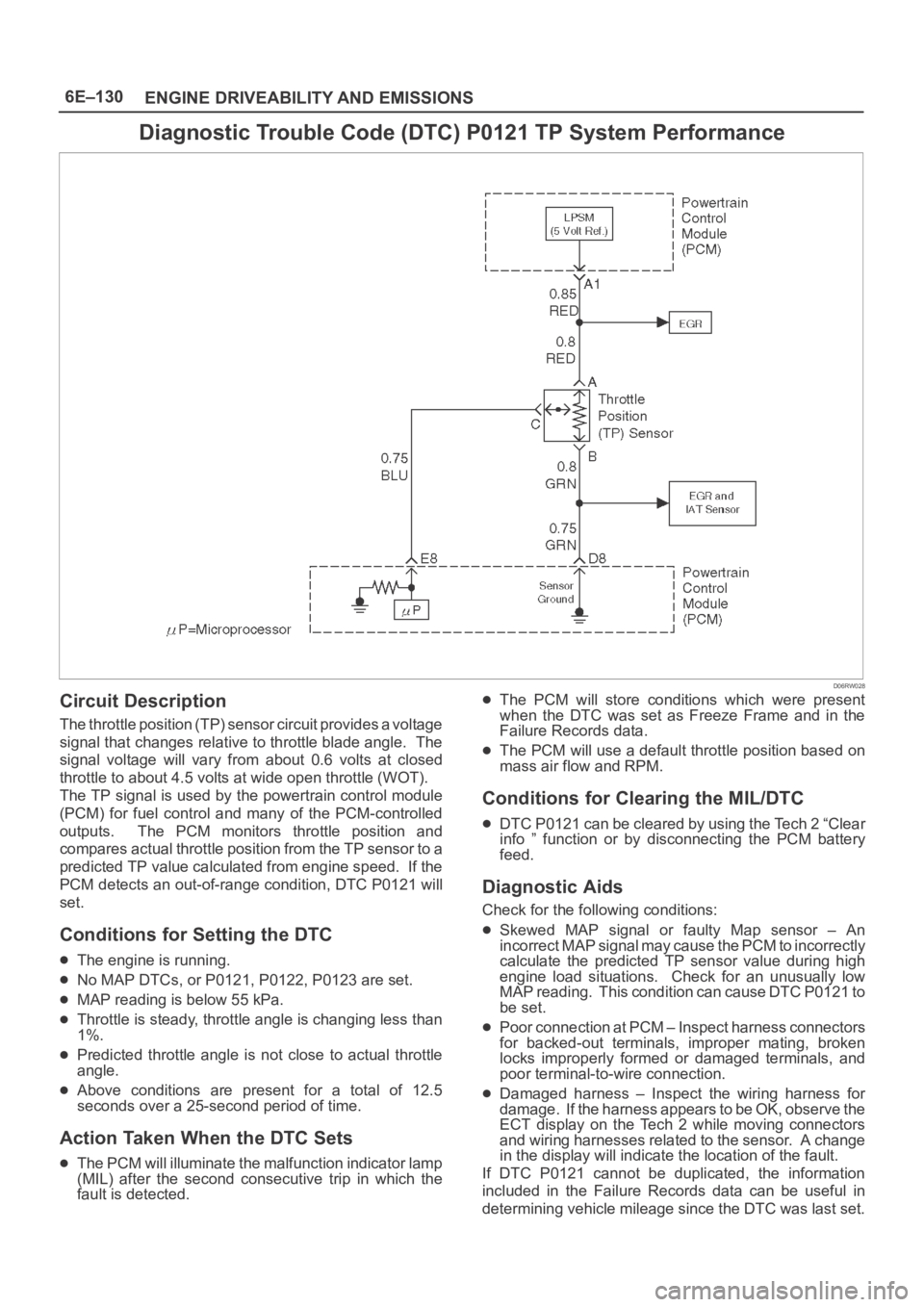

Diagnostic Trouble Code (DTC) P0121 TP System Performance

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from about 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is used by the powertrain control module

(PCM) for fuel control and many of the PCM-controlled

outputs. The PCM monitors throttle position and

compares actual throttle position from the TP sensor to a

predicted TP value calculated from engine speed. If the

PCM detects an out-of-range condition, DTC P0121 will

set.

Conditions for Setting the DTC

The engine is running.

No MAP DTCs, or P0121, P0122, P0123 are set.

MAP reading is below 55 kPa.

Throttle is steady, throttle angle is changing less than

1%.

Predicted throttle angle is not close to actual throttle

angle.

Above conditions are present for a total of 12.5

seconds over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0121 can be cleared by using the Tech 2 “Clear

info ” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Skewed MAP signal or faulty Map sensor – An

incorrect MAP signal may cause the PCM to incorrectly

calculate the predicted TP sensor value during high

engine load situations. Check for an unusually low

MAP reading. This condition can cause DTC P0121 to

be set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0121 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1250 of 6000

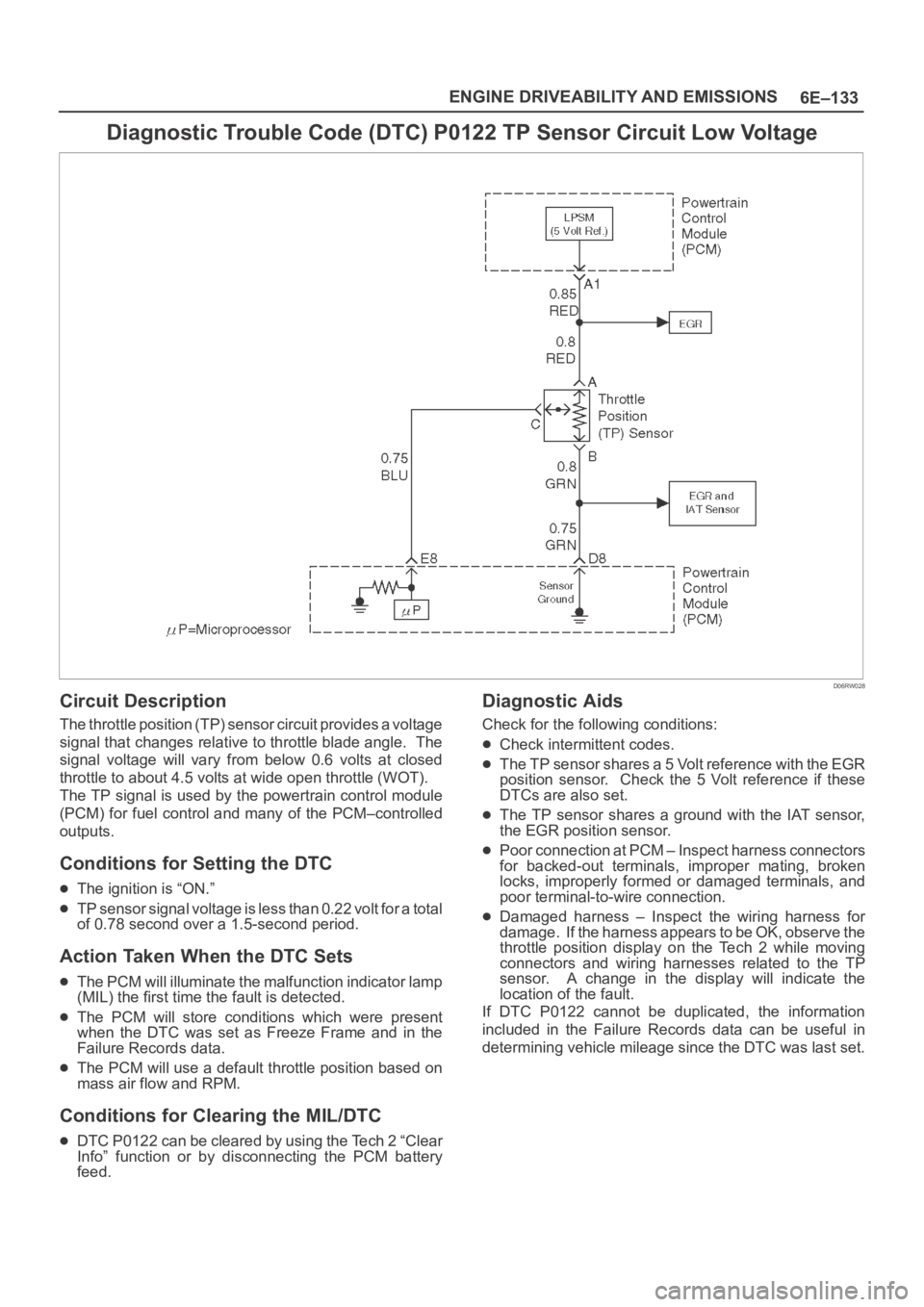

6E–133 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0122 TP Sensor Circuit Low Voltage

D06RW028

Circuit Description

The throttle position (TP) sensor circuit provides a voltage

signal that changes relative to throttle blade angle. The

signal voltage will vary from below 0.6 volts at closed

throttle to about 4.5 volts at wide open throttle (WOT).

The TP signal is used by the powertrain control module

(PCM) for fuel control and many of the PCM–controlled

outputs.

Conditions for Setting the DTC

The ignition is “ON.”

TP sensor signal voltage is less than 0.22 volt for a total

of 0.78 second over a 1.5-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The PCM will use a default throttle position based on

mass air flow and RPM.

Conditions for Clearing the MIL/DTC

DTC P0122 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check intermittent codes.

The TP sensor shares a 5 Volt reference with the EGR

position sensor. Check the 5 Volt reference if these

DTCs are also set.

The TP sensor shares a ground with the IAT sensor,

the EGR position sensor.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

throttle position display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

If DTC P0122 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.