oil dipstick OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 972 of 6000

6A–16

ENGINE MECHANICAL

Lubrication Problems

ConditionPossible causeCorrection

Oil pressure too lowWrong oil in useReplace with correct engine oil

Relief valve stickingReplace

Oil pump not operating properlyCorrect or replace

Oil pump strainer cloggedClean or replace strainer

Oil pump wornReplace

Oil pressure gauge defectiveCorrect or replace

Crankshaft bearing or connecting

rod bearing wornReplace

Oil contaminationWrong oil in useReplace with correct engine oil

Oil filter cloggedReplace oil filter

Cylinder head gasket damageReplace gasket

Burned gases leakingReplace piston and piston rings or

cylinder body assembly

Oil not reaching valve systemOil passage in cylinder head or

cylinder body cloggedClean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the

specified standard.

c. Refer to the “Maintenance and Lubrication” section

of this manual.

2. Check the engine oil level.

The level should fall somewhere between the “ADD”

and the “FULL” marks on the oil level dipstick.

If the oil level does not reach the “ADD” mark on the

oil level dipstick, engine oil must be added.3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal

operating temperature (About 80

C).

6. Measure the oil pressure.

Oil pressure should be:

392–550 kPa (56.9–80.4 psi) at 3000 rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

Page 1486 of 6000

6G–7 ENGINE LUBRICATION

Oil Pan and Crankcase

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Lift vehicle by supporting the frame.

4. Remove front wheels.

5. Remove oil level dipstick from level gauge tube.

6. Remove stone guard.

7. Remove radiator under fan shroud.

8. Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9. Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10. Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11. Remove oil pan fixing bolts.

12. Remove oil pan, using 5–8840–2153–0 sealer cutter,

remove oil pan.

013RS003

13. Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1. Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

The crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

013RW010

Page 1488 of 6000

6G–9 ENGINE LUBRICATION

6. Install suspension cross member and tighten fixing

bolts to the specified torque.

Torque : 78 Nꞏm (8.0 Kgꞏm/58 lb ft)

013RW007

7. Install radiator under fan shroud.

8. Install stone guard.

9. Install engine oil level dipstick.

10. Fill engine oil until full level on engine oil gauge

dipstick.

Page 1490 of 6000

6G–11 ENGINE LUBRICATION

4. Install oil filter assembly and tighten bolts to the

specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Oil Filter

(5) To Oil Filter

5. Install timing pulley on crankshaft.

Install timing belt.

Refer to installation procedure for Timing Belt in this

manual.

6. Install crankshaft pulley.

Refer to install procedure for Crankshaft Pulley in

this manual.

7. Install crankcase assembly.

Refer to installation procedure for Oil Pan and

Crankcase in this manual.

8. Refill engine oil until full level on engine oil dipstick.

Page 1492 of 6000

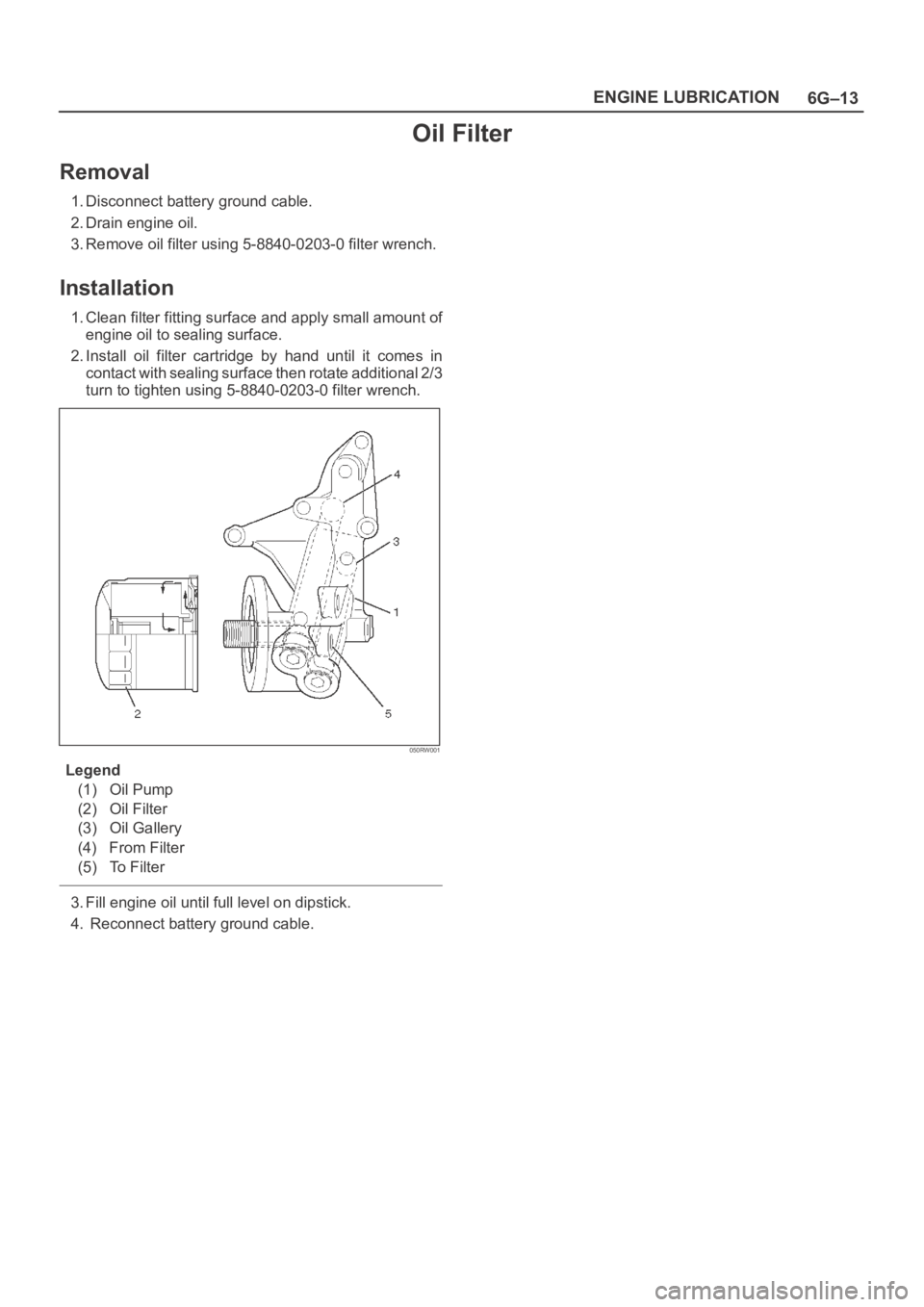

6G–13 ENGINE LUBRICATION

Oil Filter

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Remove oil filter using 5-8840-0203-0 filter wrench.

Installation

1. Clean filter fitting surface and apply small amount of

engine oil to sealing surface.

2. Install oil filter cartridge by hand until it comes in

contact with sealing surface then rotate additional 2/3

turn to tighten using 5-8840-0203-0 filter wrench.

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Filter

(5) To Filter

3. Fill engine oil until full level on dipstick.

4. Reconnect battery ground cable.

Page 4512 of 6000

6A–16

ENGINE MECHANICAL

Lubrication Problems

ConditionPossible causeCorrection

Oil pressure too lowWrong oil in useReplace with correct engine oil

Relief valve stickingReplace

Oil pump not operating properlyCorrect or replace

Oil pump strainer cloggedClean or replace strainer

Oil pump wornReplace

Oil pressure gauge defectiveCorrect or replace

Crankshaft bearing or connecting

rod bearing wornReplace

Oil contaminationWrong oil in useReplace with correct engine oil

Oil filter cloggedReplace oil filter

Cylinder head gasket damageReplace gasket

Burned gases leakingReplace piston and piston rings or

cylinder body assembly

Oil not reaching valve systemOil passage in cylinder head or

cylinder body cloggedClean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the

specified standard.

c. Refer to the “Maintenance and Lubrication” section

of this manual.

2. Check the engine oil level.

The level should fall somewhere between the “ADD”

and the “FULL” marks on the oil level dipstick.

If the oil level does not reach the “ADD” mark on the

oil level dipstick, engine oil must be added.3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal

operating temperature (About 80

C).

6. Measure the oil pressure.

Oil pressure should be:

392–550 kPa (56.9–80.4 psi) at 3000 rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

Page 5026 of 6000

6G–7 ENGINE LUBRICATION

Oil Pan and Crankcase

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Lift vehicle by supporting the frame.

4. Remove front wheels.

5. Remove oil level dipstick from level gauge tube.

6. Remove stone guard.

7. Remove radiator under fan shroud.

8. Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9. Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10. Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11. Remove oil pan fixing bolts.

12. Remove oil pan, using 5–8840–2153–0 sealer cutter,

remove oil pan.

013RS003

13. Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1. Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

The crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

013RW010

Page 5028 of 6000

6G–9 ENGINE LUBRICATION

6. Install suspension cross member and tighten fixing

bolts to the specified torque.

Torque : 78 Nꞏm (8.0 Kgꞏm/58 lb ft)

013RW007

7. Install radiator under fan shroud.

8. Install stone guard.

9. Install engine oil level dipstick.

10. Fill engine oil until full level on engine oil gauge

dipstick.

Page 5030 of 6000

6G–11 ENGINE LUBRICATION

4. Install oil filter assembly and tighten bolts to the

specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Oil Filter

(5) To Oil Filter

5. Install timing pulley on crankshaft.

Install timing belt.

Refer to installation procedure for Timing Belt in this

manual.

6. Install crankshaft pulley.

Refer to install procedure for Crankshaft Pulley in

this manual.

7. Install crankcase assembly.

Refer to installation procedure for Oil Pan and

Crankcase in this manual.

8. Refill engine oil until full level on engine oil dipstick.

Page 5032 of 6000

6G–13 ENGINE LUBRICATION

Oil Filter

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Remove oil filter using 5-8840-0203-0 filter wrench.

Installation

1. Clean filter fitting surface and apply small amount of

engine oil to sealing surface.

2. Install oil filter cartridge by hand until it comes in

contact with sealing surface then rotate additional 2/3

turn to tighten using 5-8840-0203-0 filter wrench.

050RW001

Legend

(1) Oil Pump

(2) Oil Filter

(3) Oil Gallery

(4) From Filter

(5) To Filter

3. Fill engine oil until full level on dipstick.

4. Reconnect battery ground cable.