dimensions OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 496 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–29

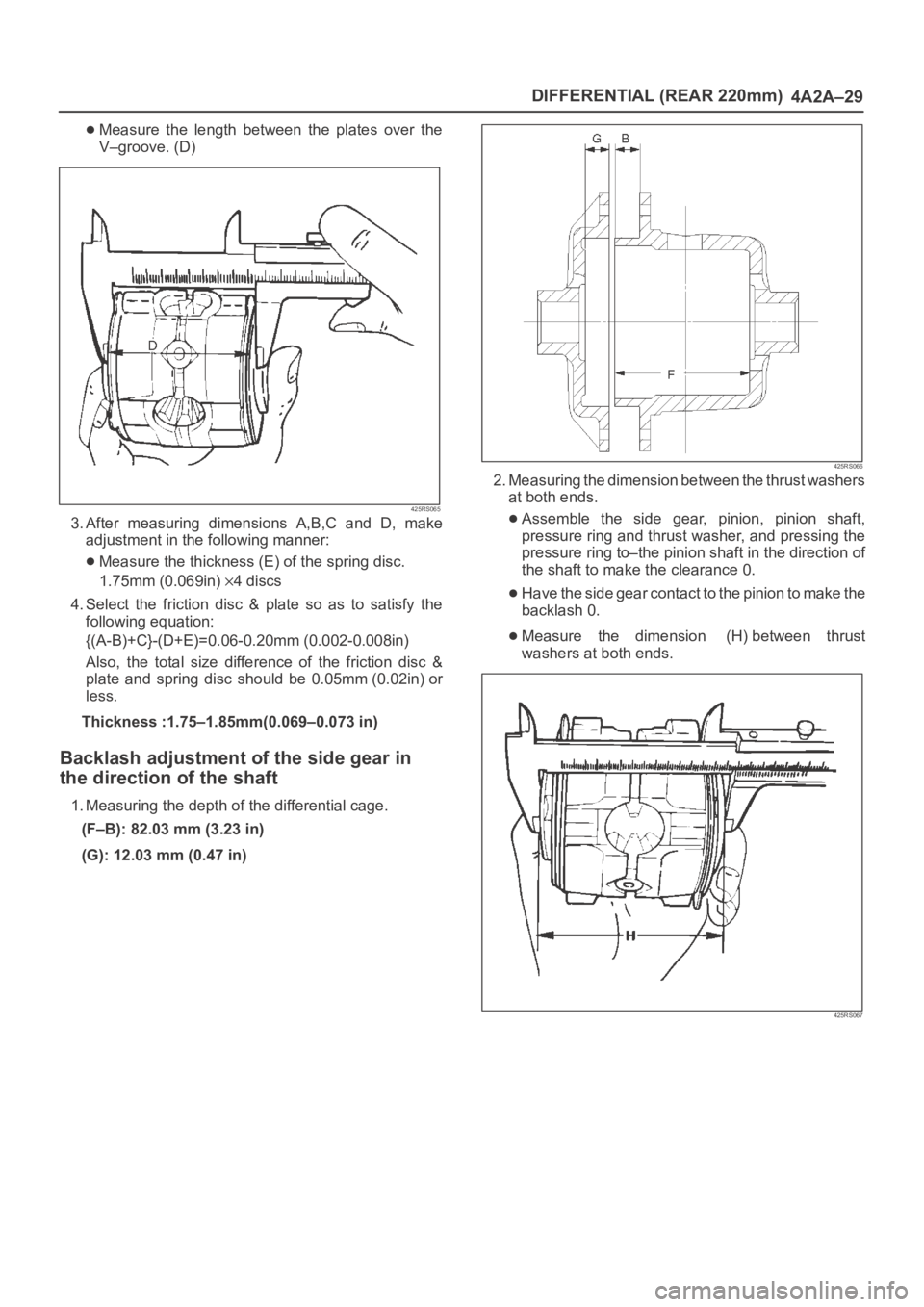

Measure the length between the plates over the

V–groove. (D)

425RS065

3. After measuring dimensions A,B,C and D, make

adjustment in the following manner:

Measure the thickness (E) of the spring disc.

1.75mm (0.069in)

4discs

4. Select the friction disc & plate so as to satisfy the

following equation:

{(A-B)+C}-(D+E)=0.06-0.20mm (0.002-0.008in)

Also, the total size difference of the friction disc &

plate and spring disc should be 0.05mm (0.02in) or

less.

Thickness :1.75–1.85mm(0.069–0.073 in)

Backlash adjustment of the side gear in

the direction of the shaft

1. Measuring the depth of the differential cage.

(F–B): 82.03 mm (3.23 in)

(G): 12.03 mm (0.47 in)

425RS066

2. Measuring the dimension between the thrust washers

at both ends.

Assemble the side gear, pinion, pinion shaft,

pressure ring and thrust washer, and pressing the

pressure ring to–the pinion shaft in the direction of

the shaft to make the clearance 0.

Have the side gear contact to the pinion to make the

backlash 0.

Measure the dimension (H) between thrust

washers at both ends.

425RS067

Page 497 of 6000

4A2A–30

DIFFERENTIAL (REAR 220mm)

3. After measuring dimensions of each of the above

sections, proceed with the adjustment in the following

manner:

Adjust the clearance to satisfy the equation below.

{(F – B) + G – H}=0.05 – 0.20 mm

Also, select the thrust washers so that the

dimensional difference between the back surfaces of

the left and right pressure rings to the thrust washers

is 0.05mm or less.

Thickness : 1.5mm (0.059 in)

1.6 mm(0.063 in)

1.7 mm(0.067 in)

NOTE: When assembling the parts, apply recommended

gear oil sufficiently to each of the parts, especially, to the

contact surfaces and sliding surfaces.

1. Install Differential cage B.

2. Install Thrust washer.

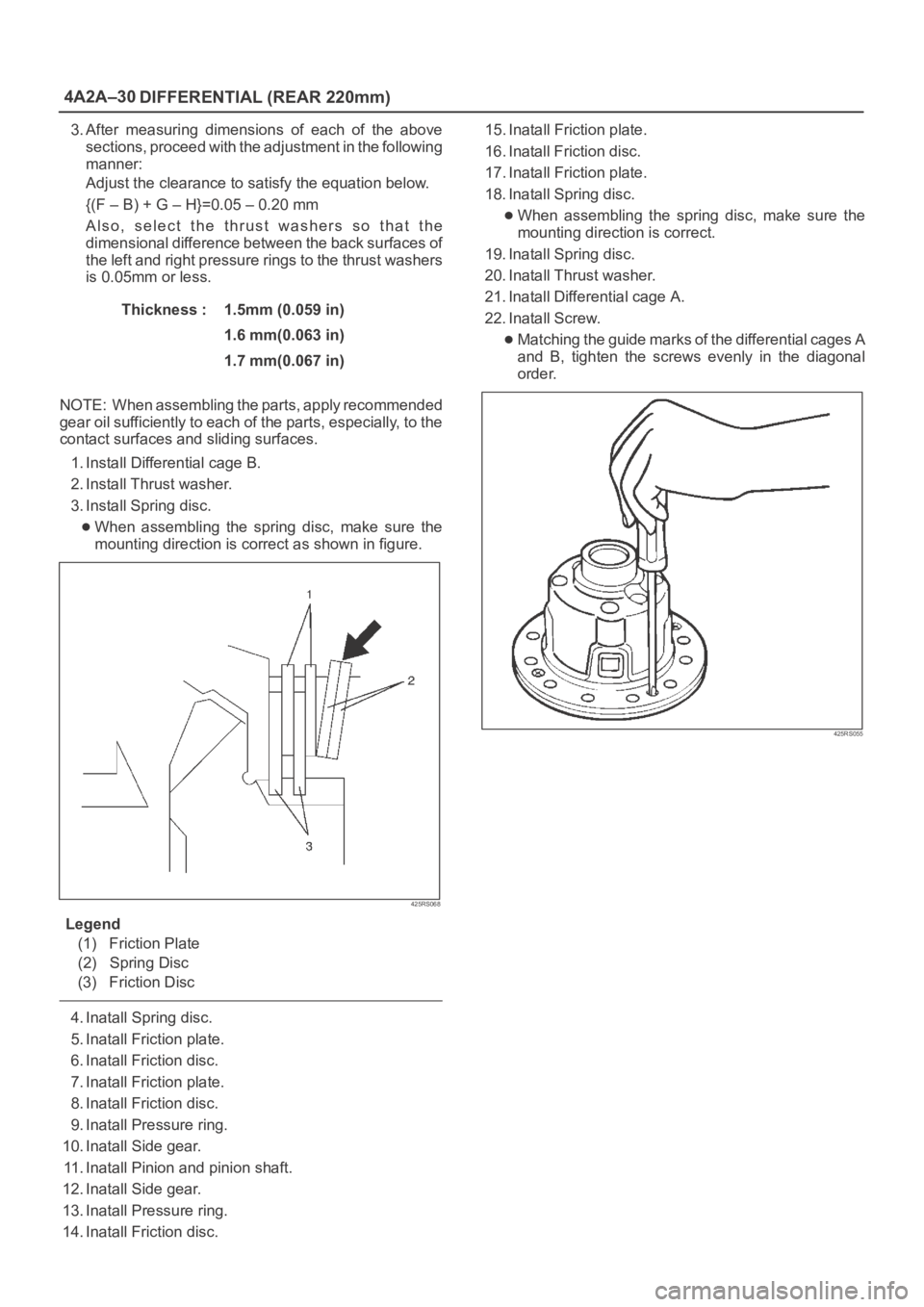

3. Install Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct as shown in figure.

425RS068

Legend

(1) Friction Plate

(2) Spring Disc

(3) Friction Disc

4. Inatall Spring disc.

5. Inatall Friction plate.

6. Inatall Friction disc.

7. Inatall Friction plate.

8. Inatall Friction disc.

9. Inatall Pressure ring.

10. Inatall Side gear.

11. Inatall Pinion and pinion shaft.

12. Inatall Side gear.

13. Inatall Pressure ring.

14. Inatall Friction disc.15. Inatall Friction plate.

16. Inatall Friction disc.

17. Inatall Friction plate.

18. Inatall Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct.

19. Inatall Spring disc.

20. Inatall Thrust washer.

21. Inatall Differential cage A.

22. Inatall Screw.

Matching the guide marks of the differential cages A

and B, tighten the screws evenly in the diagonal

order.

425RS055

Page 3196 of 6000

8F–1 BODY STRUCTURE

BODY AND ACCESSORIES

BODY STRUCTURE

CONTENTS

Service Precaution 8F–3. . . . . . . . . . . . . . . . . . . . . .

Frame 8F–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 8F–3. . . . . . . . . . . . . . . . . . . . . .

Frame Dimensions (L W B) 8F–4. . . . . . . . . . . . . . .

Frame Dimensions (S W B) 8F–5. . . . . . . . . . . . . . .

General Description 8F–6. . . . . . . . . . . . . . . . . . . . .

Front Bumper 8F–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–6. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Bumper Slider Bracket 8F–7. . . . . . . . . . . . . .

Removal 8F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Bumper 8F–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–8. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location (W/Rear Combination Light

and License Light) 8F–10. . . . . . . . . . . . . . . . . . . .

Removal 8F–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location (W/Rear Combination Light) 8F–12

Removal 8F–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Bumper Slider 8F–14. . . . . . . . . . . . . . . . . . . . .

Removal 8F–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 8F–15. . . . . . . . . . . . . . . . . . . . .

Cowl Cover 8F–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–15. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Hood 8F–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Bulge 8F–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–17. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Hood Hinge 8F–18. . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–18. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Hood Lock 8F–19. . . . . . . . . . . . . . . . . . . . . . . Parts Location 8F–19. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator Grille And Front End Lower Panel 8F–20.

Parts Location 8F–20. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Fender Panel 8F–22. . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–22. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Body Mounting 8F–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–24. . . . . . . . . . . . . . . . . . . . . . . .

Removal (No.1 – No. 2) 8F–24. . . . . . . . . . . . . . . .

Removal (No. 3 — No. 6) 8F–25. . . . . . . . . . . . . . .

Installation 8F–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 8F–27. . . . . . . . . . . . . . . . . . . . .

Body Dimension 8F–28. . . . . . . . . . . . . . . . . . . . . . . .

Instrument Panel Assembly 8F–48. . . . . . . . . . . . . . .

Parts Location 8F–48. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cross Beam Assembly 8F–54. . . . . . . . . . . . . . . . . . .

Parts Location 8F–54. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Door Assembly 8F–56. . . . . . . . . . . . . . . . . . . .

Parts Location 8F–56. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Assembly 8F–57. . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–57. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Strikers 8F–58. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 8F–58. . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Check Arm Assembly (Front & Rear) 8F–59. .

Parts Location 8F–59. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8F–60. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Window Regulator, Glass And Glass

Run 8F–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Location 8F–60. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8F–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3199 of 6000

8F–4BODY STRUCTURE

Frame Dimensions (L W B)

This illustration is based on the gasoline engine and A/T

model.

501RW013

Page 3200 of 6000

8F–5 BODY STRUCTURE

Frame Dimensions (S W B)

This illustration is based on the gasoline engine and A/T

model.

501RW014

Page 3251 of 6000

8F–56BODY STRUCTURE

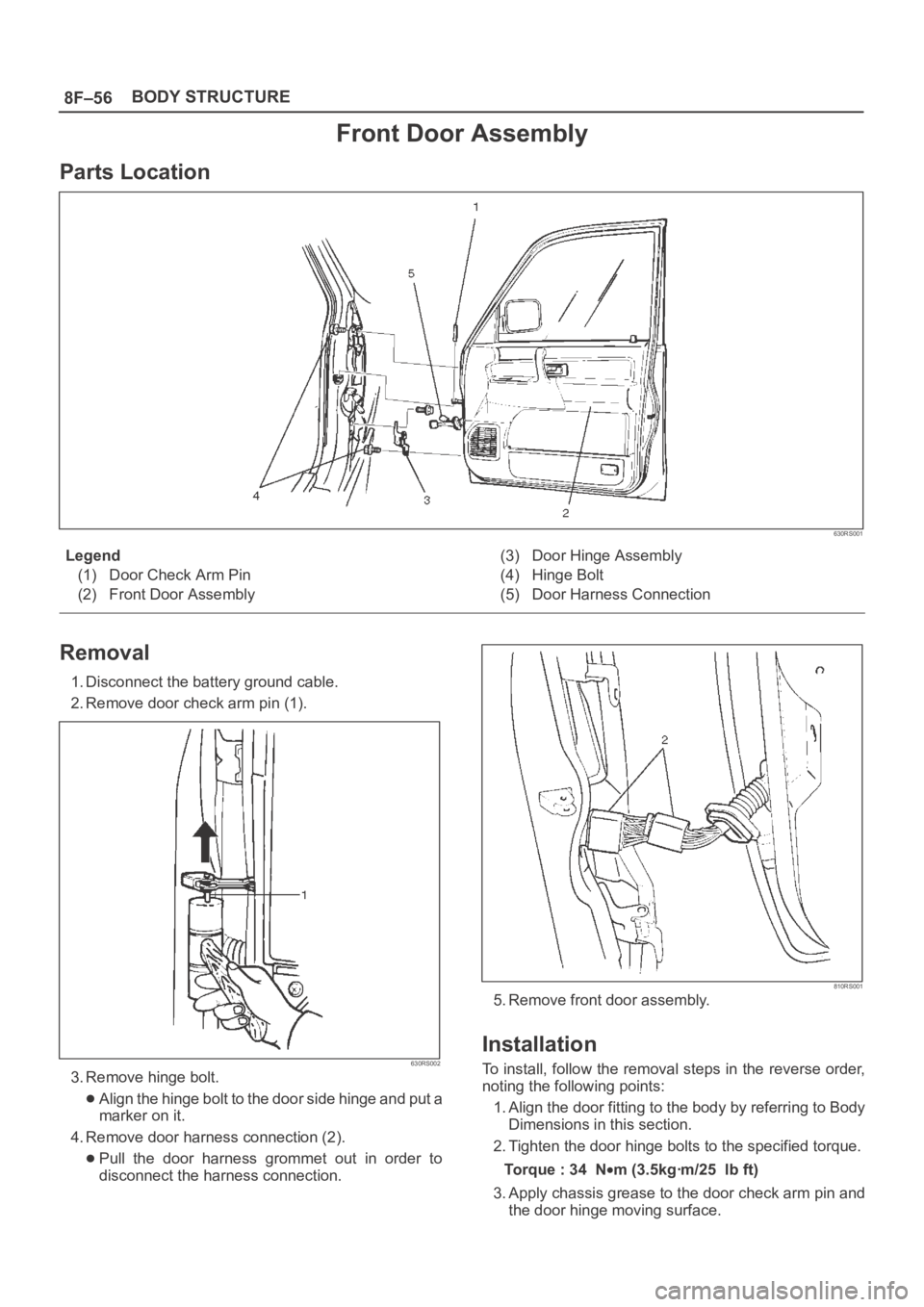

Front Door Assembly

Parts Location

630RS001

Legend

(1) Door Check Arm Pin

(2) Front Door Assembly(3) Door Hinge Assembly

(4) Hinge Bolt

(5) Door Harness Connection

Removal

1. Disconnect the battery ground cable.

2. Remove door check arm pin (1).

630RS002

3. Remove hinge bolt.

Align the hinge bolt to the door side hinge and put a

marker on it.

4. Remove door harness connection (2).

Pull the door harness grommet out in order to

disconnect the harness connection.

810RS001

5. Remove front door assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

1. Align the door fitting to the body by referring to Body

Dimensions in this section.

2. Tighten the door hinge bolts to the specified torque.

Torque : 34 N

m (3.5kgꞏm/25 lb ft)

3. Apply chassis grease to the door check arm pin and

the door hinge moving surface.

Page 3253 of 6000

8F–58BODY STRUCTURE

5. Remove door harness connection (3).

Pull the door harness grommet out in order to

disconnect the door harness connection.

810RS002

6. Remove door assembly

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Align the door fitting to the body by refer to Body

Dimensions in this section.

2. Tighten the door hinge bolts to the specified torque.

Torque : 34 N

m (3.5kgꞏm/25 lb ft)

3. Apply chassis grease to the check arm pin and the

door hinge moving surface.

Door Strikers

Adjustment

632RS001

1. Loosen the striker (1) screws.

2. Tap with a plastic hammer to align.

3. Tighten the striker screws.

Torque : 15 N

m (1.5kgꞏm/11 lb ft)

Page 4001 of 6000

4A2A–32

DIFFERENTIAL (REAR 220mm)

2. Measuring the overall length of the pressurering,

friction disc and friction plate.

Mount the pinion shaft in the pressurering and then

install the friction disc & plate.

Measure the length between the plates over the

V–groove. (D)

425RS065

3. After measuring dimensions A,B,C and D, make

adjustment in the following manner:

Measure the thickness (E) of the spring disc.

1.75mm (0.069in)

2discs

4. Select the friction disc & plate so as to satisfy the

following equation:

{(A-B)+C}-(D+E)=0.06-0.20mm (0.002-0.008in)

Also, the total size difference of the friction disc &

plate and spring disc should be 0.05mm (0.02in) or

less.

Thickness

:1.65–1.75–1.85mm(0.065–0.069–0.073 in)

Backlash adjustment of the side gear in

the direction of the shaft

1. Measuring the depth of the differential cage.

(F–B): 95.63 mm (3.76 in)

(G): 15.63 mm (0.62 in)

425RS066

2. Measuring the dimension between the thrust washers

at both ends.

Assemble the side gear, pinion, pinion shaft,

pressure ring and thrust washer, and pressing the

pressure ring to–the pinion shaft in the direction of

the shaft to make the clearance 0.

Have the side gear contact to the pinion to make the

backlash 0.

Measure the dimension (H) between thrust

washers at both ends.

425RS067

Page 4002 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–33

3. After measuring dimensions of each of the above

sections, proceed with the adjustment in the following

manner:

Adjust the clearance to satisfy the equation below.

{(F – B) + G – H}=0.05 – 0.20 mm

Also, select the thrust washers so that the

dimensional difference between the back surfaces of

the left and right pressure rings to the thrust washers

is 0.05mm or less.

Thickness : 1.5mm (0.059 in)

1.6 mm(0.063 in)

1.7 mm(0.067 in)

NOTE: When assembling the parts, apply recommended

gear oil sufficiently to each of the parts, especially, to the

contact surfaces and sliding surfaces.

1. Install Differential cage B.

2. Install Thrust washer.

3. Install Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct as shown in figure.

425RY004

Legend

(1) Friction Plate

(2) Spring Disc

(3) Friction Disc

4. Install Friction disc.

5. Install Friction plate.6. Install Friction plate.

7. Install Friction disc.

8. Install Friction plate.

9. Install Friction disc.

10. Install Friction plate.

11. Install Pressure ring.

12. Install Side gear.

13. Install Pinion and pinion shaft.

14. Install Side gear.

15. Install Pressure ring.

16. Install Friction plate.

17. Install Friction disc.

18. Install Friction plate.

19. Install Friction disc.

20. Install Friction plate.

21. Install Friction plate.

22. Install Friction plate.

23. Install Spring disc.

When assembling the spring disc, make sure the

mounting direction is correct.

24. Install Spring disc.

25. Install Thrust washer.

26. Install Differential cage A.

27. Install Screw.

Matching the guide marks of the differential cages A

and B, tighten the screws evenly in the diagonal

order.

425RS055

Page 4039 of 6000

4A2B–32DIFFERENTIAL (REAR 244mm)

2. Measuring the overall length of the pressurering,

friction disc and friction plate.

Mount the pinion shaft in the pressurering and then

install the friction disc & plate.

Measure the length between the plates over the

V–groove. (D)

425RS065

3. After measuring dimensions A,B,C and D, make

adjustment in the following manner:

Measure the thickness (E) of the spring disc.

1.75mm (0.069in)

2discs

4. Select the friction disc & plate so as to satisfy the

following equation:

{(A-B)+C}-(D+E)=0.06-0.20mm (0.002-0.008in)

Also, the total size difference of the friction disc &

plate and spring disc should be 0.05mm (0.02in) or

less.

Thickness

:1.65–1.75–1.85mm(0.065–0.069–0.073 in)

Backlash adjustment of the side gear in

the direction of the shaft

1. Measuring the depth of the differential cage.

(F–B): 95.63 mm (3.76 in)

(G): 15.63 mm (0.62 in)

425RS066

2. Measuring the dimension between the thrust washers

at both ends.

Assemble the side gear, pinion, pinion shaft,

pressure ring and thrust washer, and pressing the

pressure ring to–the pinion shaft in the direction of

the shaft to make the clearance 0.

Have the side gear contact to the pinion to make the

backlash 0.

Measure the dimension (H) between thrust

washers at both ends.

425RS067