steering OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 439 of 6000

DIFFERENTIAL (FRONT) 4A1–2

Front Drive Axle

Diagnosis

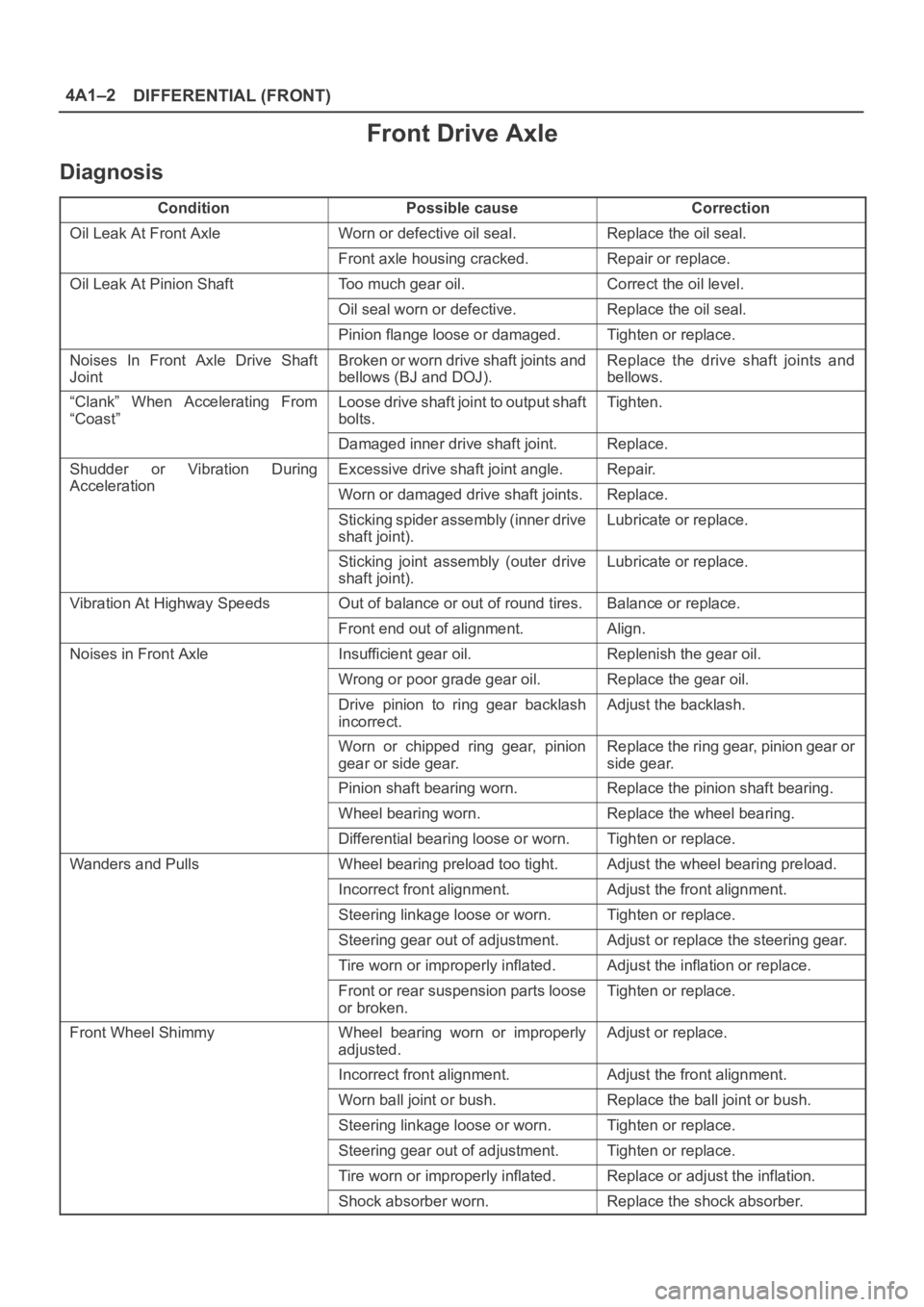

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 443 of 6000

DIFFERENTIAL (FRONT) 4A1–6

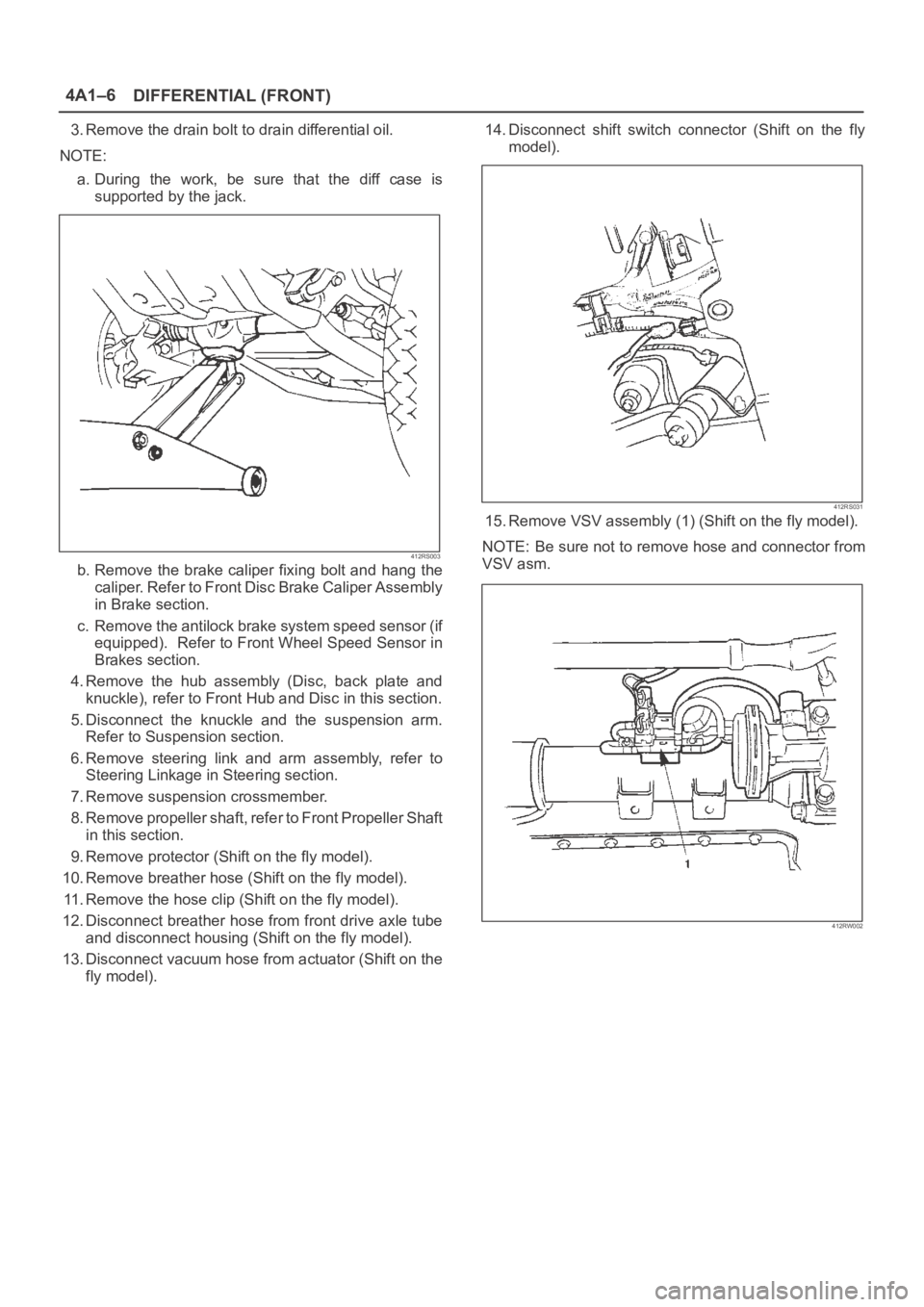

3. Remove the drain bolt to drain differential oil.

NOTE:

a. During the work, be sure that the diff case is

supported by the jack.

412RS003

b. Remove the brake caliper fixing bolt and hang the

caliper. Refer to Front Disc Brake Caliper Assembly

in Brake section.

c. Remove the antilock brake system speed sensor (if

equipped). Refer to Front Wheel Speed Sensor in

Brakes section.

4. Remove the hub assembly (Disc, back plate and

knuckle), refer to Front Hub and Disc in this section.

5. Disconnect the knuckle and the suspension arm.

Refer to Suspension section.

6. Remove steering link and arm assembly, refer to

Steering Linkage in Steering section.

7. Remove suspension crossmember.

8. Remove propeller shaft, refer to Front Propeller Shaft

in this section.

9. Remove protector (Shift on the fly model).

10. Remove breather hose (Shift on the fly model).

11. Remove the hose clip (Shift on the fly model).

12. Disconnect breather hose from front drive axle tube

and disconnect housing (Shift on the fly model).

13. Disconnect vacuum hose from actuator (Shift on the

fly model).14. Disconnect shift switch connector (Shift on the fly

model).

412RS031

15. Remove VSV assembly (1) (Shift on the fly model).

NOTE: Be sure not to remove hose and connector from

VSV asm.

412RW002

Page 445 of 6000

DIFFERENTIAL (FRONT) 4A1–8

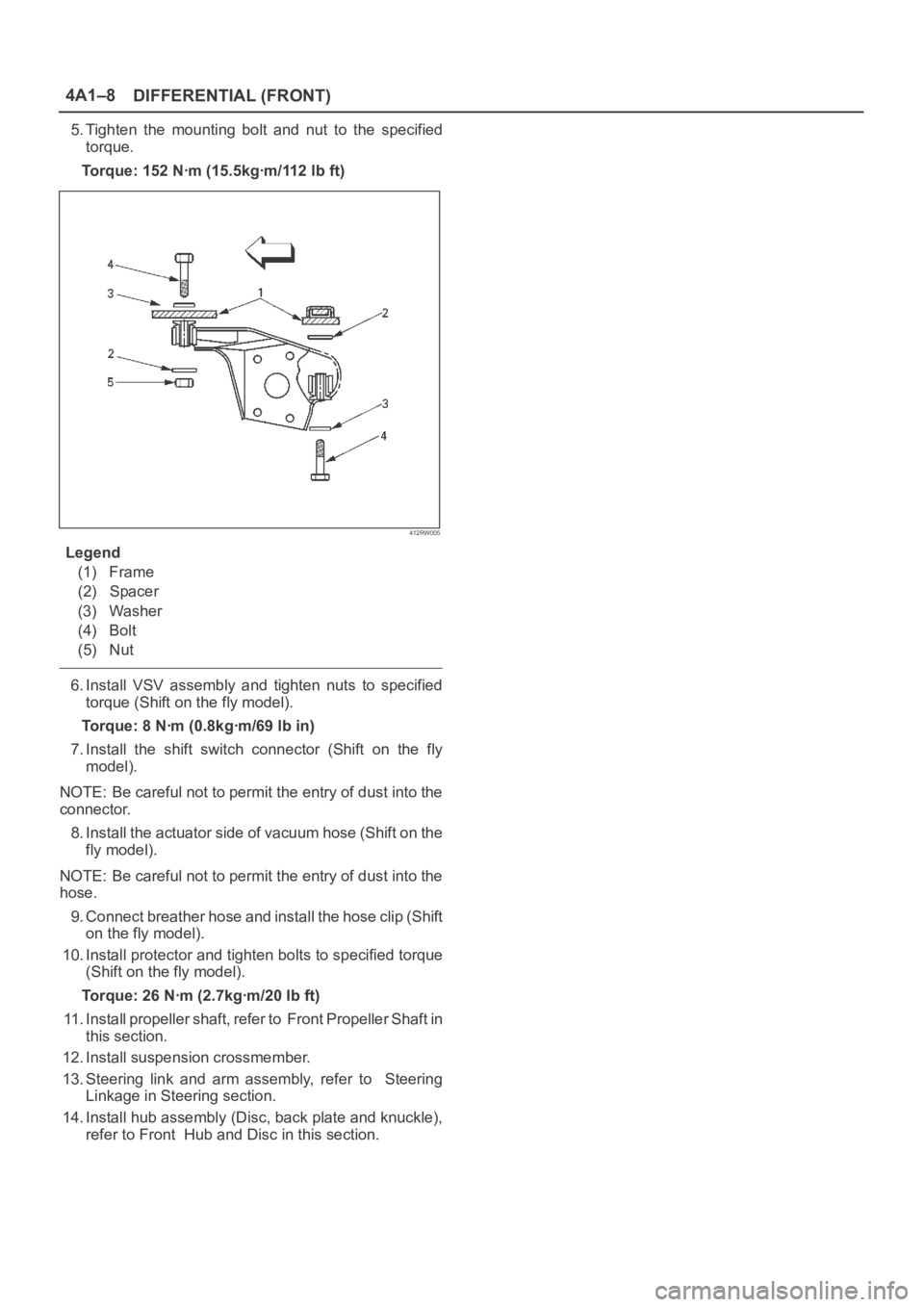

5. Tighten the mounting bolt and nut to the specified

torque.

Torque: 152 Nꞏm (15.5kgꞏm/112 lb ft)

412RW005

Legend

(1) Frame

(2) Spacer

(3) Washer

(4) Bolt

(5) Nut

6. Install VSV assembly and tighten nuts to specified

torque (Shift on the fly model).

Torque: 8 Nꞏm (0.8kgꞏm/69 lb in)

7. Install the shift switch connector (Shift on the fly

model).

NOTE: Be careful not to permit the entry of dust into the

connector.

8. Install the actuator side of vacuum hose (Shift on the

fly model).

NOTE: Be careful not to permit the entry of dust into the

hose.

9. Connect breather hose and install the hose clip (Shift

on the fly model).

10. Install protector and tighten bolts to specified torque

(Shift on the fly model).

Torque: 26 Nꞏm (2.7kgꞏm/20 lb ft)

11. Install propeller shaft, refer to Front Propeller Shaft in

this section.

12. Install suspension crossmember.

13. Steering link and arm assembly, refer to Steering

Linkage in Steering section.

14. Install hub assembly (Disc, back plate and knuckle),

refer to Front Hub and Disc in this section.

Page 475 of 6000

4A2A–8

DIFFERENTIAL (REAR 220mm)

Differential Assembly

Differential Assembly and Associated Parts

425RW055

Legend

(1) Bolt and Nut

(2) Axle Shaft Assembly(3) Parking Brake Cable

(4) Differential Assembly

(5) Nut

Removal

1. Jack up and support the frame with stands.

2. Remove the wheel and tire. Refer to Wheel in

Steering section.

3. Drain the differential oil.

4. Remove the propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Remove the ABS speed sensor(ABS model only).

Refer to 4–Wheel Anti–lock Brake System (ABS) in

Brake section.6. Remove the parking brake cable fastening clip and

disconnect the equalizer section. Refer to Parking

Brakes in Brake section.

7. Remove the bearing holder fixing nuts.

8. Remove axle shaft assembly, be sure not to damage

the oil seal by axle shaft.

9. Remove differential carrier mounting bolts and nuts.

10. Remove differential assembly.

Page 511 of 6000

4A2B–8DIFFERENTIAL (REAR 244mm)

Differential Assembly

Differential Assembly and Associated Parts

425RW044

Legend

(1) Bolt and Nut

(2) Axle Shaft Assembly(3) Parking Brake Cable

(4) Differential Assembly

(5) Nut

Removal

1. Jack up and support the frame with stands.

2. Remove the wheel and tire. Refer to Wheel in

Steering section.

3. Drain the differential oil.

4. Remove the propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Remove the ABS speed sensor. Refer to Anti–lock

Brake System in Brakes section.6. Remove the parking brake cable fastening clip and

disconnect the equalizer section. Refer to Parking

Brakes in Brake section.

7. Remove the bearing holder fixing nuts.

8. Remove axle shaft assembly, be sure not to damage

the oil seal by axle shaft.

9. Remove differential carrier mounting bolts and nuts.

10. Remove differential assembly.

Page 585 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–14

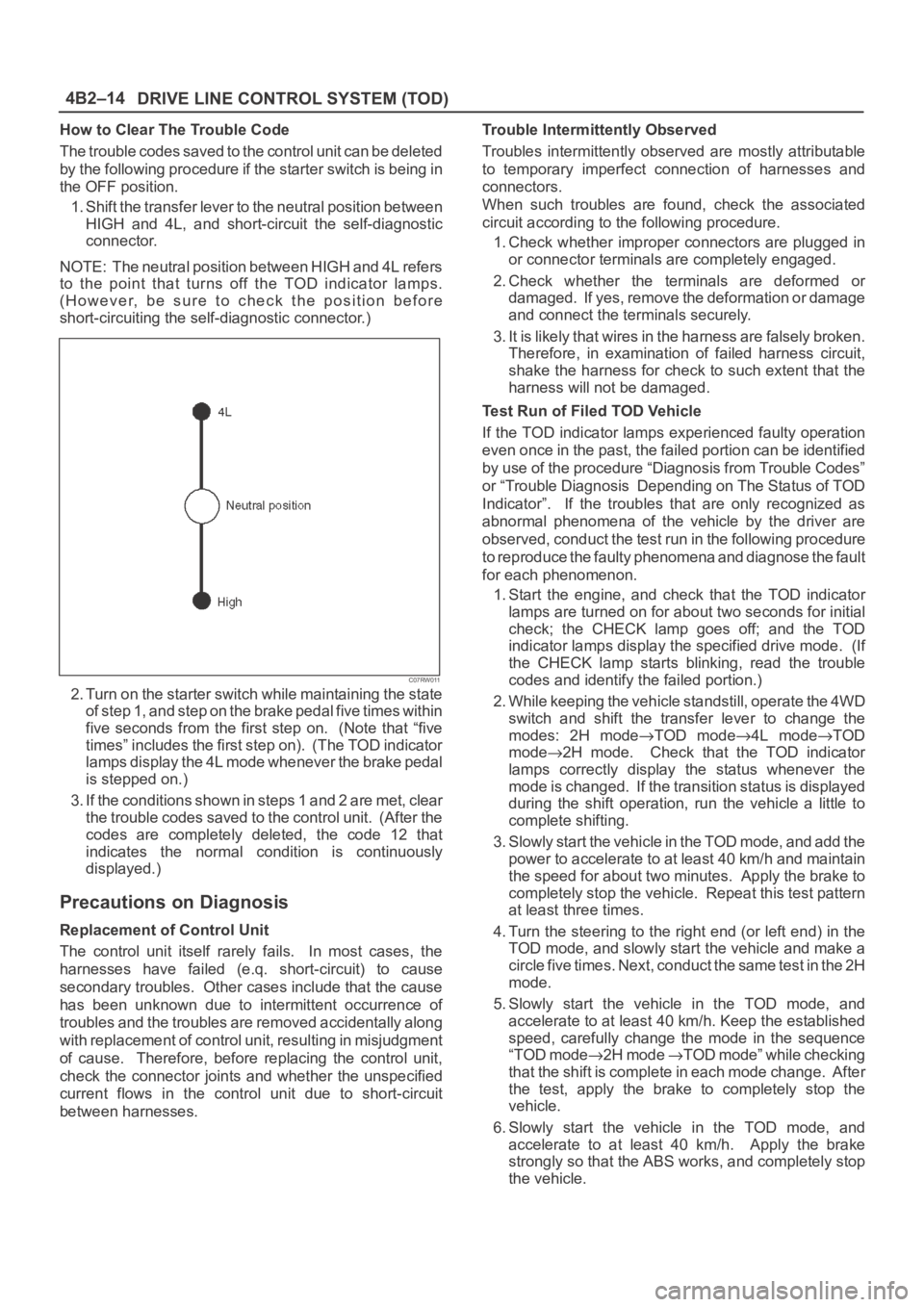

How to Clear The Trouble Code

The trouble codes saved to the control unit can be deleted

by the following procedure if the starter switch is being in

the OFF position.

1. Shift the transfer lever to the neutral position between

HIGH and 4L, and short-circuit the self-diagnostic

connector.

NOTE: The neutral position between HIGH and 4L refers

to the point that turns off the TOD indicator lamps.

(However, be sure to check the position before

short-circuiting the self-diagnostic connector.)

C07RW011

2. Turn on the starter switch while maintaining the state

of step 1, and step on the brake pedal five times within

five seconds from the first step on. (Note that “five

times” includes the first step on). (The TOD indicator

lamps display the 4L mode whenever the brake pedal

is stepped on.)

3. If the conditions shown in steps 1 and 2 are met, clear

the trouble codes saved to the control unit. (After the

codes are completely deleted, the code 12 that

indicates the normal condition is continuously

displayed.)

Precautions on Diagnosis

Replacement of Control Unit

The control unit itself rarely fails. In most cases, the

harnesses have failed (e.q. short-circuit) to cause

secondary troubles. Other cases include that the cause

has been unknown due to intermittent occurrence of

troubles and the troubles are removed accidentally along

with replacement of control unit, resulting in misjudgment

of cause. Therefore, before replacing the control unit,

check the connector joints and whether the unspecified

current flows in the control unit due to short-circuit

between harnesses.Trouble Intermittently Observed

Troubles intermittently observed are mostly attributable

to temporary imperfect connection of harnesses and

connectors.

When such troubles are found, check the associated

circuit according to the following procedure.

1. Check whether improper connectors are plugged in

or connector terminals are completely engaged.

2. Check whether the terminals are deformed or

damaged. If yes, remove the deformation or damage

and connect the terminals securely.

3. It is likely that wires in the harness are falsely broken.

Therefore, in examination of failed harness circuit,

shake the harness for check to such extent that the

harness will not be damaged.

Test Run of Filed TOD Vehicle

If the TOD indicator lamps experienced faulty operation

even once in the past, the failed portion can be identified

by use of the procedure “Diagnosis from Trouble Codes”

or “Trouble Diagnosis Depending on The Status of TOD

Indicator”. If the troubles that are only recognized as

abnormal phenomena of the vehicle by the driver are

observed, conduct the test run in the following procedure

to reproduce the faulty phenomena and diagnose the fault

for each phenomenon.

1. Start the engine, and check that the TOD indicator

lamps are turned on for about two seconds for initial

check; the CHECK lamp goes off; and the TOD

indicator lamps display the specified drive mode. (If

the CHECK lamp starts blinking, read the trouble

codes and identify the failed portion.)

2. While keeping the vehicle standstill, operate the 4WD

switch and shift the transfer lever to change the

modes: 2H mode

TOD mode4L modeTOD

mode

2H mode. Check that the TOD indicator

lamps correctly display the status whenever the

mode is changed. If the transition status is displayed

during the shift operation, run the vehicle a little to

complete shifting.

3. Slowly start the vehicle in the TOD mode, and add the

power to accelerate to at least 40 km/h and maintain

the speed for about two minutes. Apply the brake to

completely stop the vehicle. Repeat this test pattern

at least three times.

4. Turn the steering to the right end (or left end) in the

TOD mode, and slowly start the vehicle and make a

c i r c l e f i v e t i m e s . N e x t , c o n d u c t t h e s a m e t e s t i n t h e 2 H

mode.

5. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Keep the established

speed, carefully change the mode in the sequence

“TOD mode

2H mode TOD mode” while checking

that the shift is complete in each mode change. After

the test, apply the brake to completely stop the

vehicle.

6. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Apply the brake

strongly so that the ABS works, and completely stop

the vehicle.

Page 657 of 6000

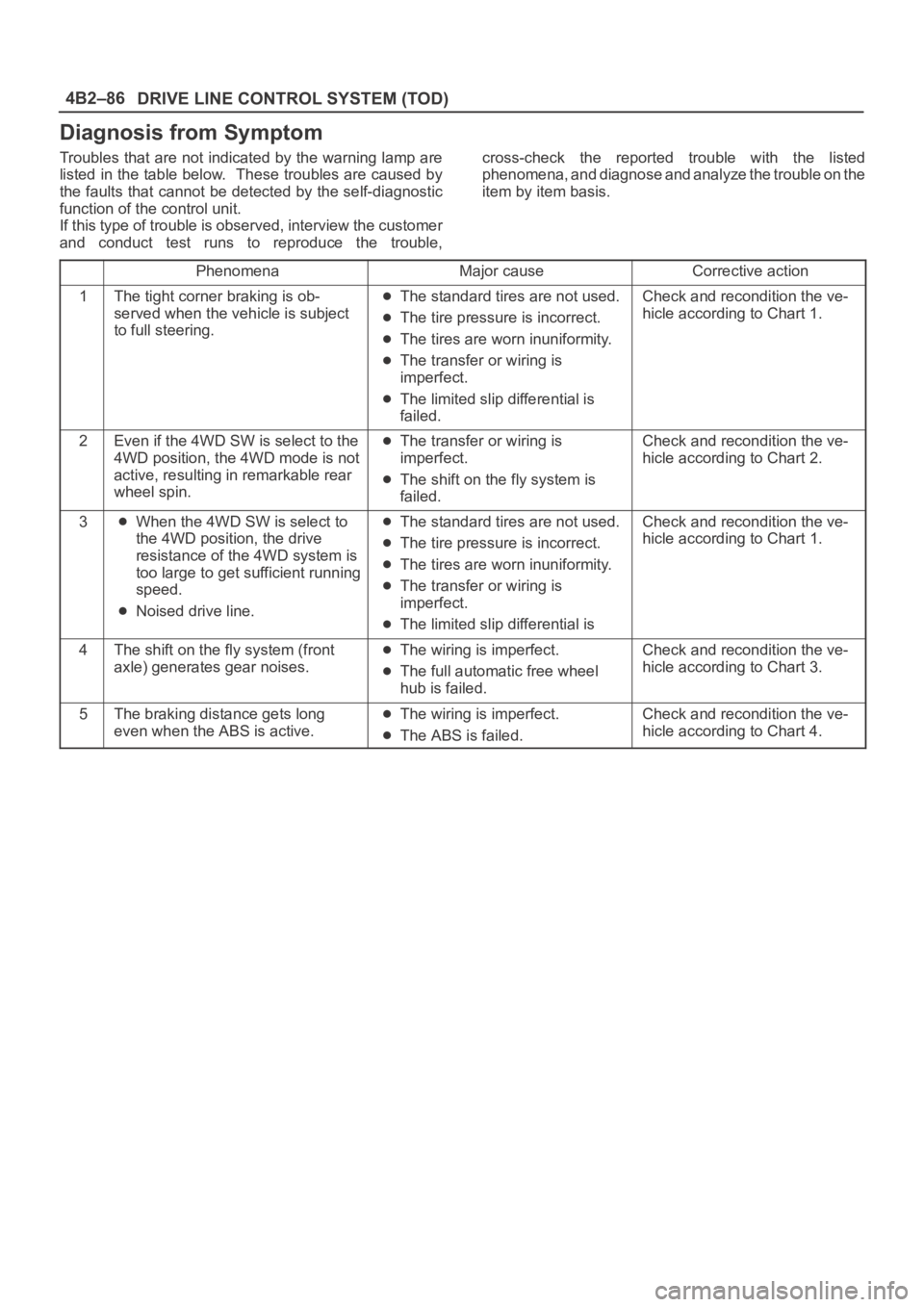

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–86

Diagnosis from Symptom

Troubles that are not indicated by the warning lamp are

listed in the table below. These troubles are caused by

the faults that cannot be detected by the self-diagnostic

function of the control unit.

If this type of trouble is observed, interview the customer

and conduct test runs to reproduce the trouble,cross-check the reported trouble with the listed

phenomena, and diagnose and analyze the trouble on the

item by item basis.

PhenomenaMajor causeCorrective action

1The tight corner braking is ob-

served when the vehicle is subject

to full steering.The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the ve-

hicle according to Chart 1.

2Even if the 4WD SW is select to the

4WD position, the 4WD mode is not

active, resulting in remarkable rear

wheel spin.The transfer or wiring is

imperfect.

The shift on the fly system is

failed.

Check and recondition the ve-

hicle according to Chart 2.

3When the 4WD SW is select to

the 4WD position, the drive

resistance of the 4WD system is

too large to get sufficient running

speed.

Noised drive line.

The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

Check and recondition the ve-

hicle according to Chart 1.

4The shift on the fly system (front

axle) generates gear noises.The wiring is imperfect.

The full automatic free wheel

hub is failed.

Check and recondition the ve-

hicle according to Chart 3.

5The braking distance gets long

even when the ABS is active.The wiring is imperfect.

The ABS is failed.

Check and recondition the ve-

hicle according to Chart 4.

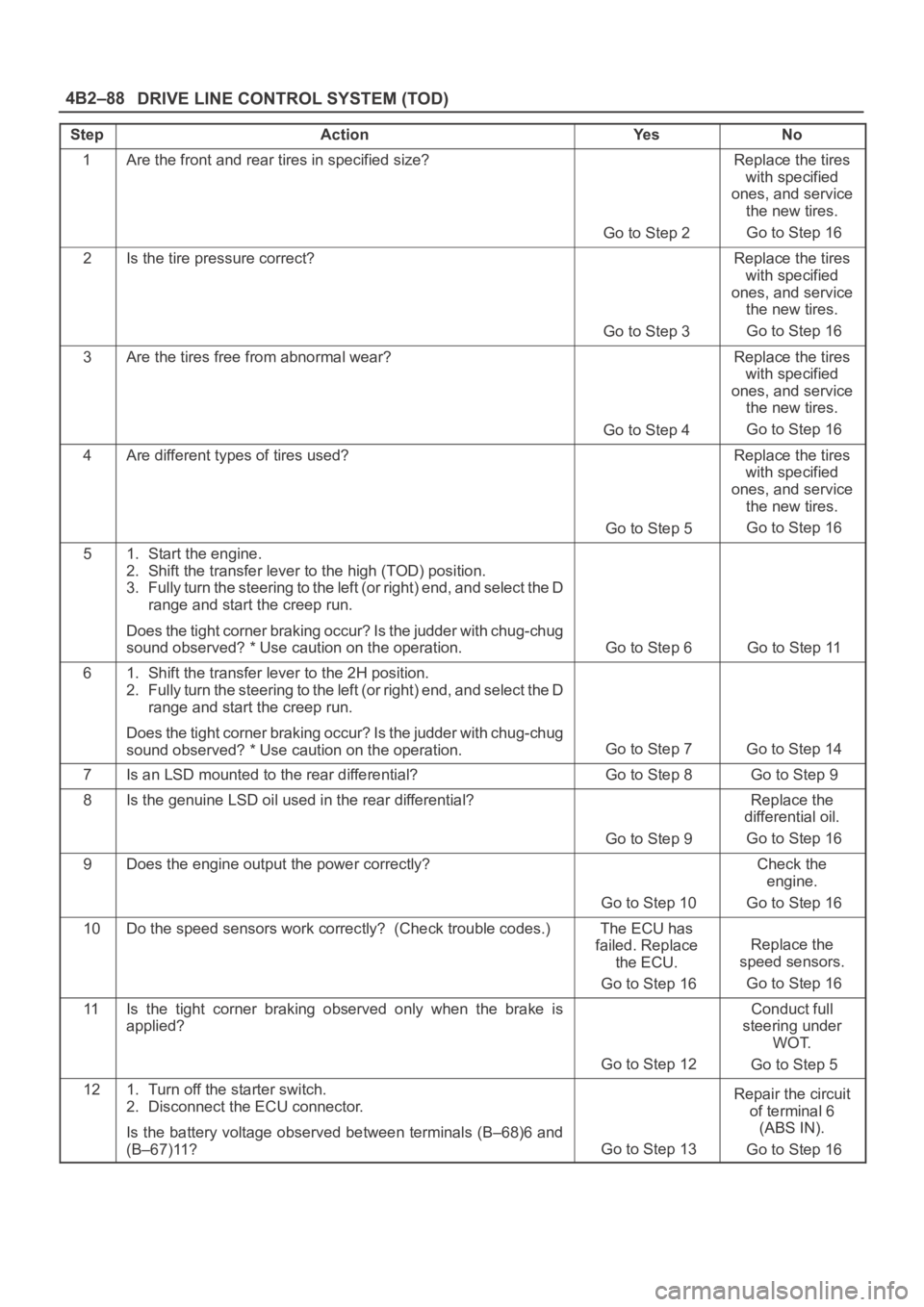

Page 658 of 6000

4B2–87 DRIVE LINE CONTROL SYSTEM (TOD)

Chart 1The tight corner braking is observed.

Function of circuit—

Fail conditionWhen the vehicle is subject to full steering in the TOD mode, the drive resistance gets

large or the judder occurs. Otherwise, the above phenomenon is observed only when the

brake is applied.

D04RW057

Page 659 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 660 of 6000

4B2–89 DRIVE LINE CONTROL SYSTEM (TOD)

StepNo Ye s Action

131. Apply the brake and fully turn the steering to the left (or right)

end, and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?Repair the

transfer

assembly.

Go to Step 16The ECU has

failed. Replace

the ECU.

Go to Step 16

141. Shift the transfer lever to the high (TOD) position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?

Go to Step 15 Go to Step 13

151. Select the 4WD SW to the 2WD position.

2. Jack up the right front wheel.

Does the front tire rotate smoothly?

Repair the

transfer

assembly.

Go to Step 16

The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 16

16Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 16

*NOTE: Before checking this item, run the vehicle more

than 10 meters with the steering wheel in straight position

so that the 4L mechanical lock sleeve can be released

certainly.