radiator cap OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 967 of 6000

6A–11

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine overheatingLevel of Engine Coolant too lowReplenish

Fan clutch defectiveReplace

Incorrect fan installedReplace

Thermostat defectiveReplace

Engine Coolant pump defectiveCorrect or replace

Radiator cloggedClean or replace

Radiator filler cap defectiveReplace

Level of oil in engine crankcase too

low or wrong engine oilChange or replenish

Resistance in exhaust system

increasedClean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrectReplace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shortedCorrect or replace

Cylinder head gasket damagedReplace

Engine overcoolingThermostat defectiveReplace (Use a thermostat set to

open at 82

C (180F))

Engine lacks compression————Refer to Hard Start

OthersTire inflation pressure abnormalAdjust to recommended pressures

Brake dragAdjust

Clutch slippingAdjust or replace

Level of oil in engine crankcase too

highCorrect level of engine oil

Exhaust Gas Recirculation Valve

defectiveReplace

Engine Noisy

Abnormal engine noise often consists of various noises

originating in rotating parts, sliding parts and othermoving parts of the engine. It is, therefore, advisable to

locate the source of noise systematically.

Condition

Possible causeCorrection

Noise from crank journals or from

crank bearings

(Faulty crank journals and crankOil clearance increased due to worn

crank journals or crank bearingsReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

yj

bearings usually make dull noise that

becomes more evident when

accelerating)Crankshaft out of roundReplace crank bearings and

crankshaft or regrind crankshaft and

install the undersize bearing

Crank bearing seizedCrank bearing seized. Replace crank

bearings and crankshaft or regrind

crankshaft and install the undersize

bearing

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with defectivebearing by listening for abnormal noise that stops when

spark plug is shorted out.

Page 1056 of 6000

ENGINE COOLING6B–3

Thermostat

The thermostat is a wax pellet type with a air hole(1) and is

installed in the thermostat housing.

031RW002

Radiator

The radiator is a tube type with corrugated fins. In order to

raise the boiling point of the coolant, the radiator is fitted

with a cap in which the valve is operated at 88.2

117.6

kPa (12.8

1 7 . 0 p s i ) p r e s s u r e . ( N o o i l c o o l e r p r o v i d e d f o r

M/T)

110RS001

Anti Freeze Solution

Relation between the mixing ratio and freezing

temperature of the EC varies with the ratio of

anti–freeze solution in water. Proper mixing ratio can

be determined by referring to the chart. Supplemental

inhibitors or additives claiming to increase cooling

capability that have not been specifically approved by

Isuzu are not recommended for addition to the cooling

system.

Calculating mixing ratio

F06RW005

Page 1058 of 6000

ENGINE COOLING6B–5

Diagnosis

Engine Cooling Trouble

ConditionPossible causeCorrection

Engine overheatingLow Engine Coolant levelReplenish

Incorrect fan installedReplace

Thermo meter unit faultyReplace

Faulty thermostatReplace

Faulty Engine Coolant temperature

sensorRepair or replace

Clogged radiatorClean or replace

Faulty radiator capReplace

Low engine oil level or use of

improper engine oilReplenish or change oil

Clogged exhaust systemClean exhaust system or replace

faulty parts

Faulty Throttle Position sensorReplace throttle valve assembly

Open or shorted Throttle Position

sensor circuitRepair or replace

Damaged cylinder head gasketReplace

Engine overcoolingFaulty thermostatReplace

Engine slow to warm–upFaulty thermostatReplace

Thermo unit faultyReplace

Page 1059 of 6000

6B–6

ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

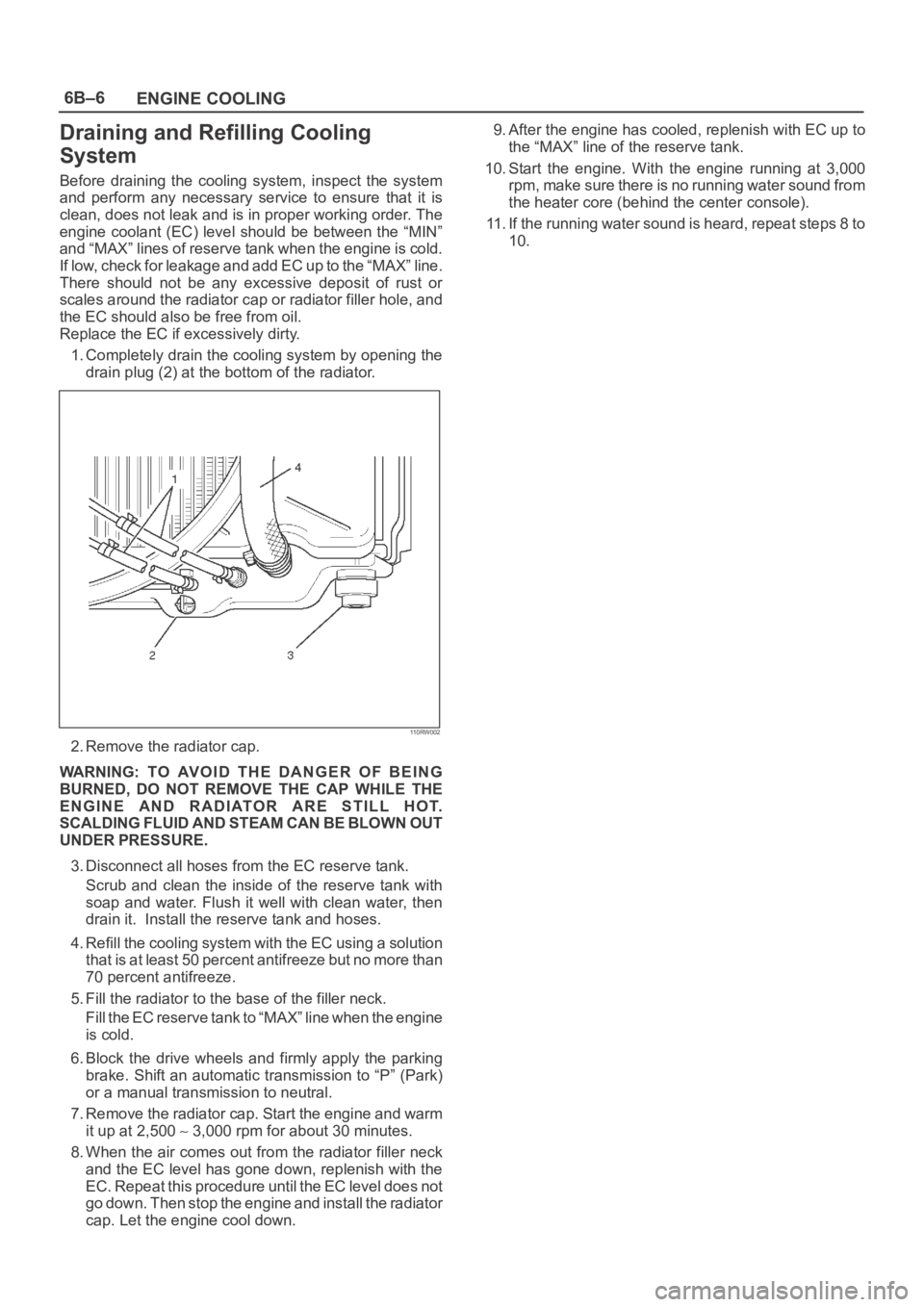

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 1063 of 6000

6B–10

ENGINE COOLING

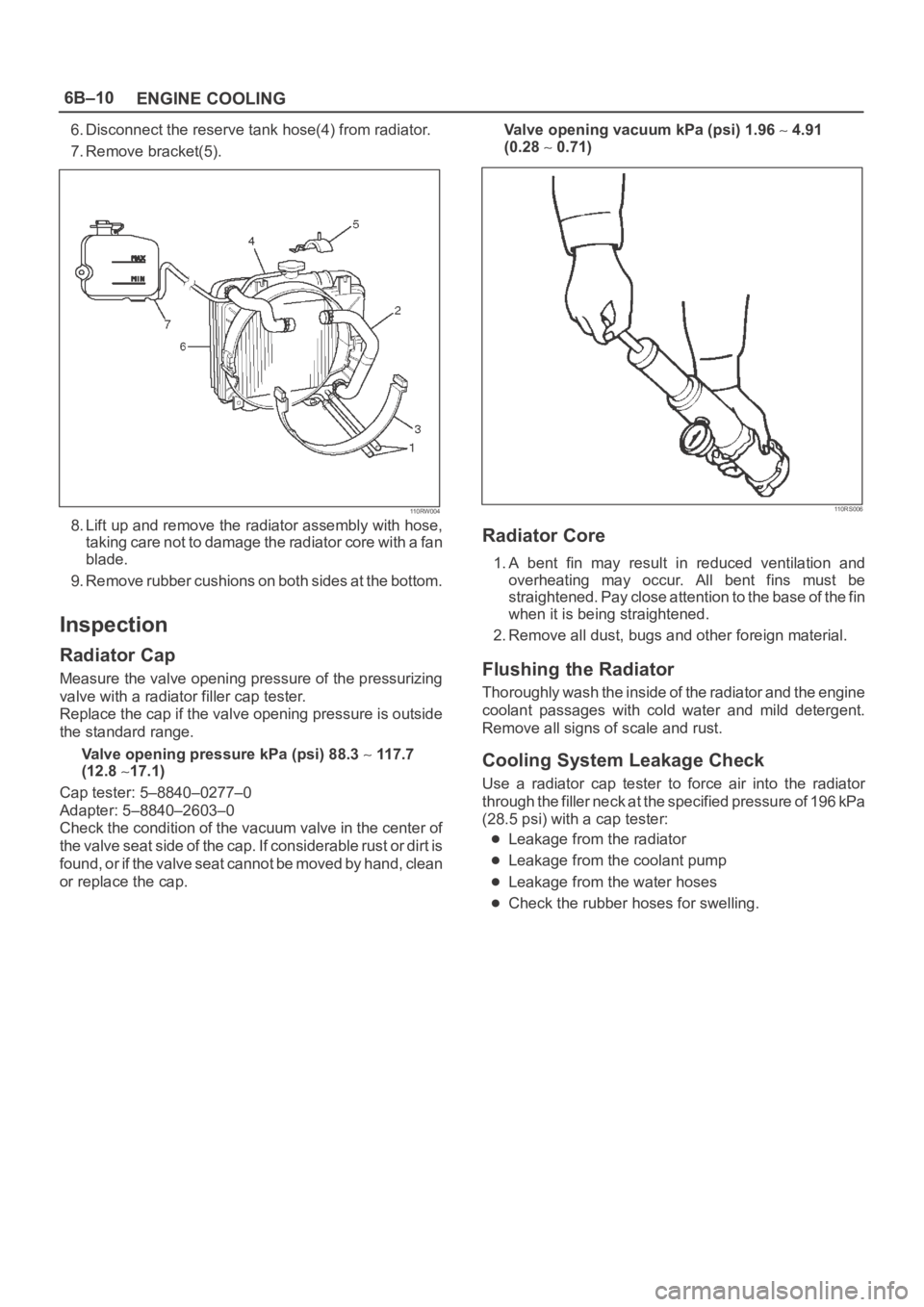

6. Disconnect the reserve tank hose(4) from radiator.

7. Remove bracket(5).

110RW004

8. Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with a fan

blade.

9. Remove rubber cushions on both sides at the bottom.

Inspection

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure kPa (psi) 88.3

117.7

(12.8

17.1)

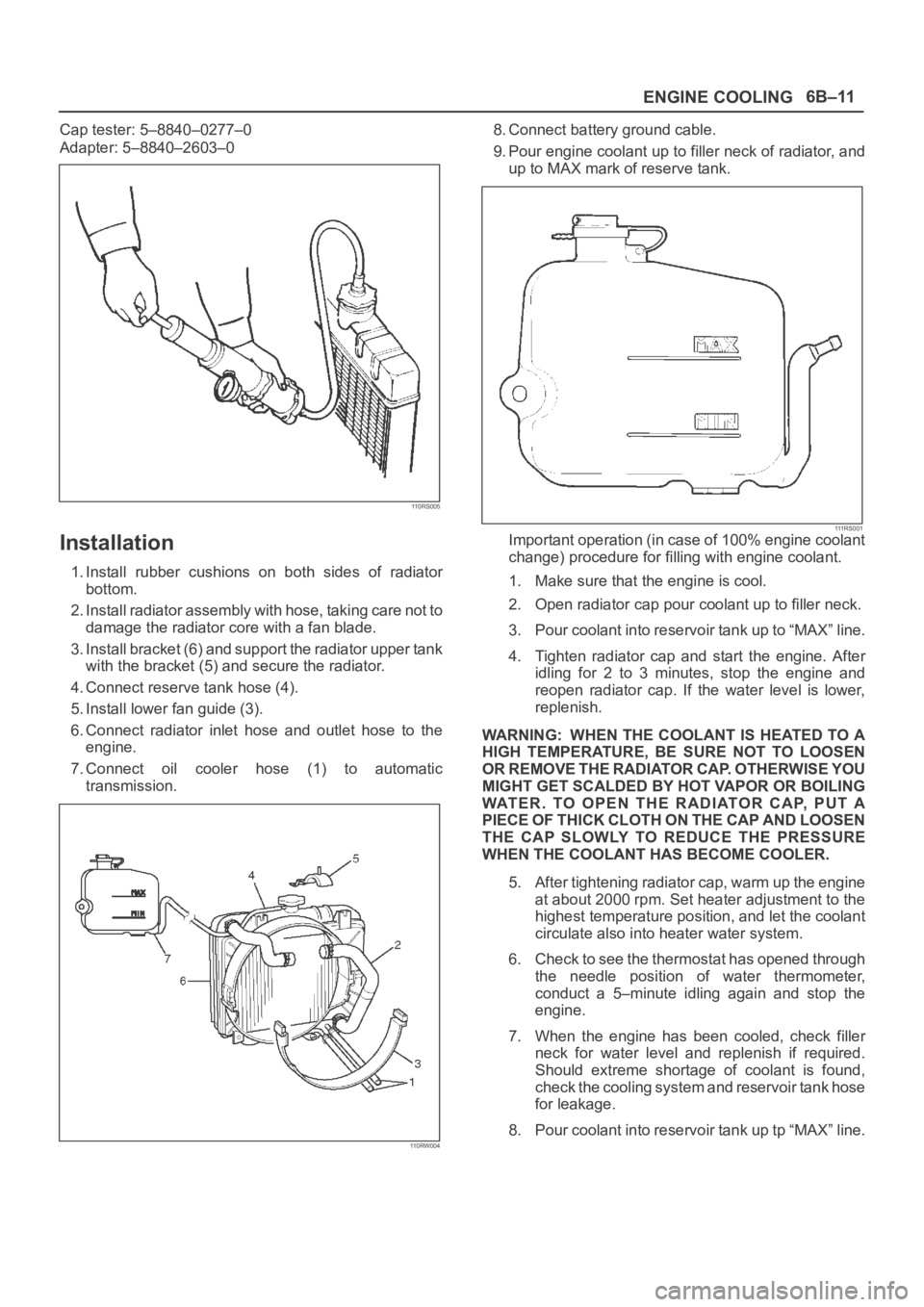

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the center of

the valve seat side of the cap. If considerable rust or dirt is

found, or if the valve seat cannot be moved by hand, clean

or replace the cap.Valve opening vacuum kPa (psi) 1.96

4.91

(0.28

0.71)

110RS006

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the fin

when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent.

Remove all signs of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196 kPa

(28.5 psi) with a cap tester:

Leakage from the radiator

Leakage from the coolant pump

Leakage from the water hoses

Check the rubber hoses for swelling.

Page 1064 of 6000

ENGINE COOLING6B–11

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1. Install rubber cushions on both sides of radiator

bottom.

2. Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3. Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4. Connect reserve tank hose (4).

5. Install lower fan guide (3).

6. Connect radiator inlet hose and outlet hose to the

engine.

7. Connect oil cooler hose (1) to automatic

transmission.

110RW004

8. Connect battery ground cable.

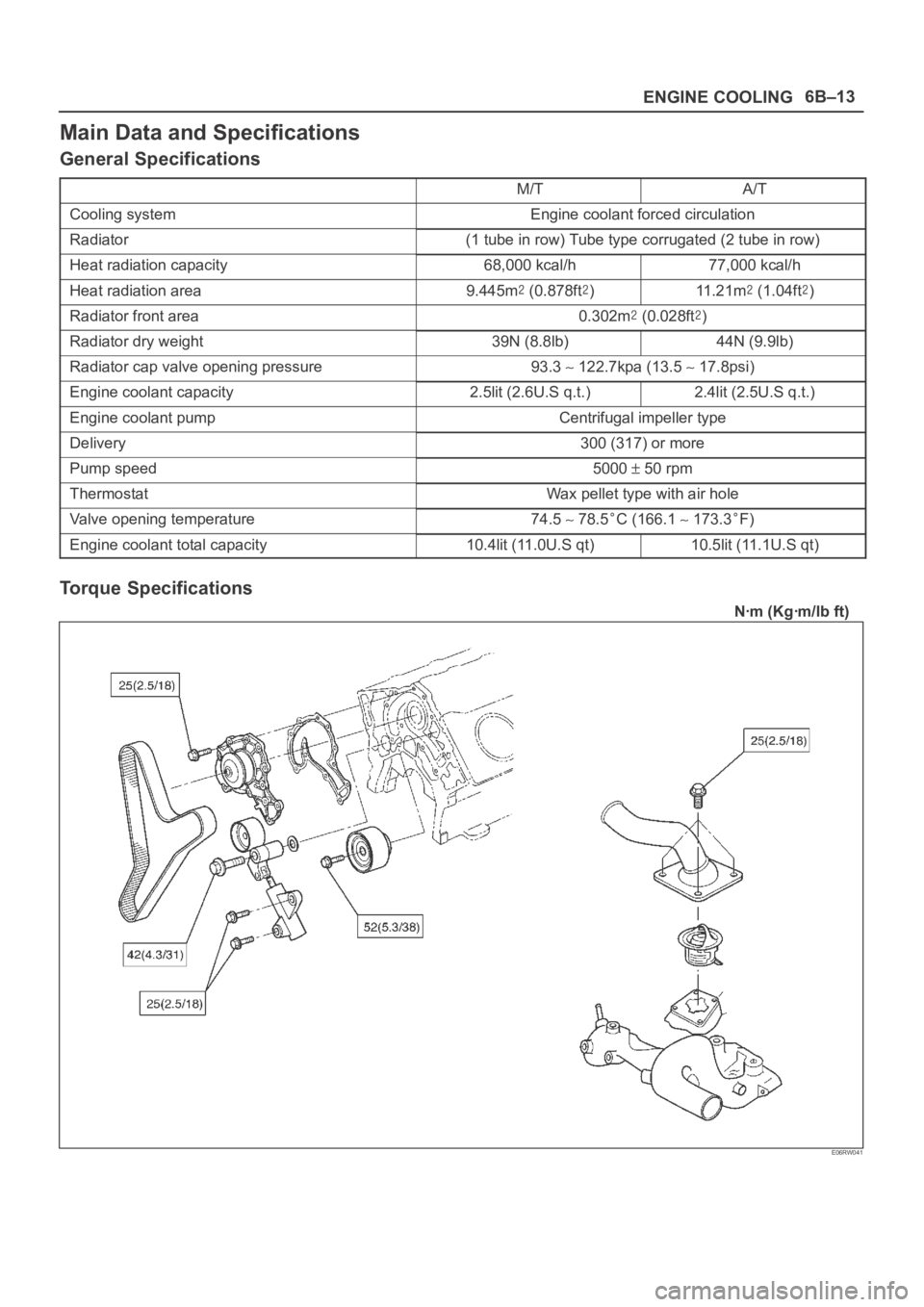

9. Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111 R S 0 0 1Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

1. Make sure that the engine is cool.

2. Open radiator cap pour coolant up to filler neck.

3. Pour coolant into reservoir tank up to “MAX” line.

4. Tighten radiator cap and start the engine. After

idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING: WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

5. After tightening radiator cap, warm up the engine

at about 2000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

6. Check to see the thermostat has opened through

the needle position of water thermometer,

conduct a 5–minute idling again and stop the

engine.

7. When the engine has been cooled, check filler

neck for water level and replenish if required.

Should extreme shortage of coolant is found,

check the cooling system and reservoir tank hose

for leakage.

8. Pour coolant into reservoir tank up tp “MAX” line.

Page 1066 of 6000

ENGINE COOLING6B–13

Main Data and Specifications

General Specifications

M/TA/T

Cooling systemEngine coolant forced circulation

Radiator(1 tube in row) Tube type corrugated (2 tube in row)

Heat radiation capacity68,000 kcal/h77,000 kcal/h

Heat radiation area9.445m (0.878ft)11 . 2 1 m (1.04ft)

Radiator front area0.302m (0.028ft)

Radiator dry weight39N (8.8lb)44N (9.9lb)

Radiator cap valve opening pressure93.3 122.7kpa (13.5 17.8psi)

Engine coolant capacity2.5lit (2.6U.S q.t.)2.4lit (2.5U.S q.t.)

Engine coolant pumpCentrifugal impeller type

Delivery300 (317) or more

Pump speed5000 50 rpm

ThermostatWax pellet type with air hole

Valve opening temperature74.5 78.5C (166.1 173.3F)

Engine coolant total capacity10.4lit (11.0U.S qt)10.5lit (11.1U.S qt)

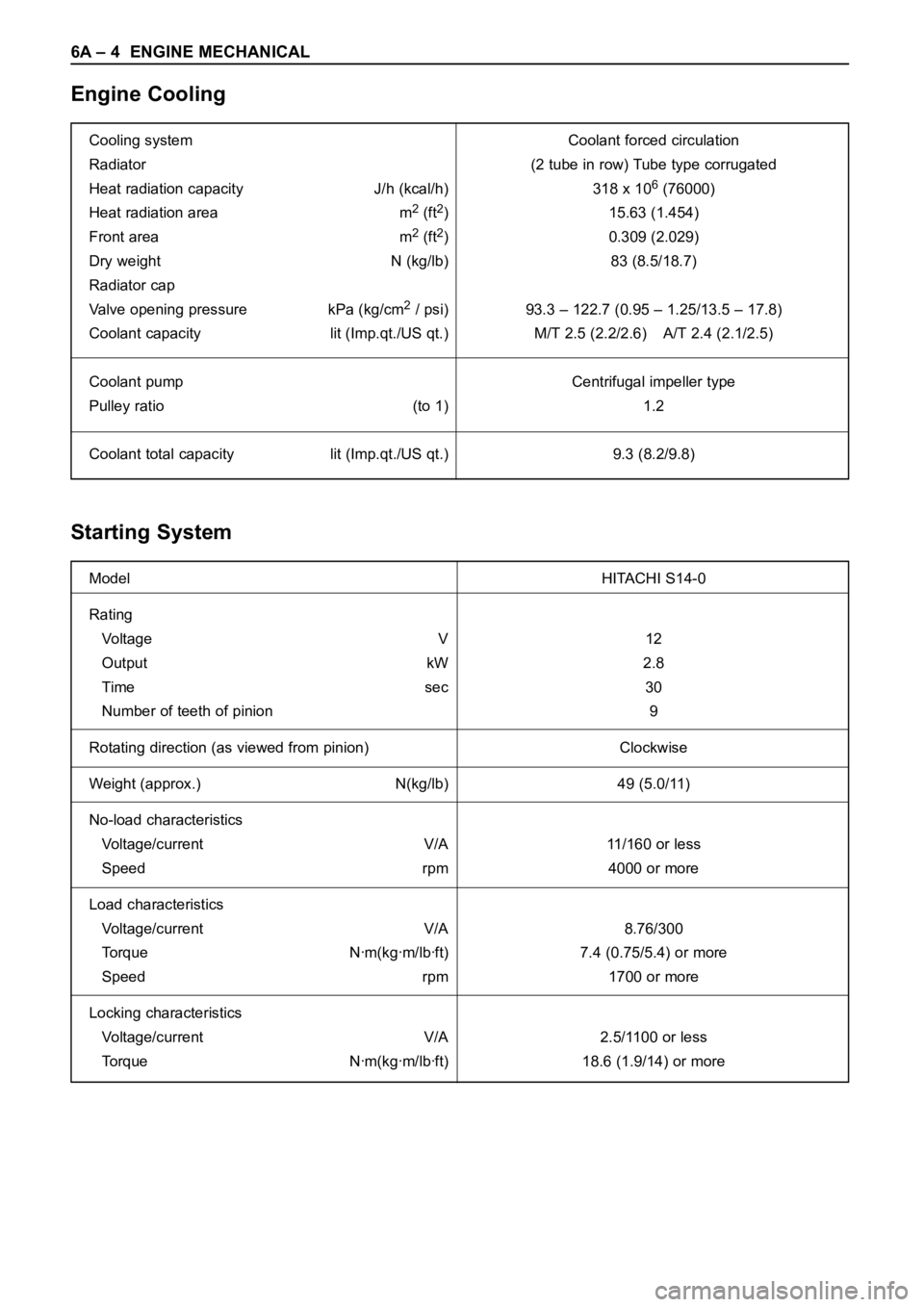

Torque Specifications

Nꞏm (Kgꞏm/lb ft)

E06RW041

Page 1067 of 6000

6B–14

ENGINE COOLING

Special Tool

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–0277–0

(J–24460–01)

Tester; radiator cap

5–8840–2603–0

(J–33984–A)

Adapter; radiator cap

Page 1737 of 6000

6A – 4 ENGINE MECHANICAL

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2/ psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio (to 1) 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Vo l t a ge V 1 2

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 1741 of 6000

6A – 8 ENGINE MECHANICAL

Parts Items Service standard Service limit Remarks

Cylinder

Block—

95.421 – 95.450

(3.7567 – 3.7579)0.20 (0.0079) Warpage

(Upper surface of the cylinder block)

Cylinder bore diameter

Parts Items Service standard Service limit Remarks

Thermostat

Radiator cap83 – 87°C

(181 – 189°F)

More than 9.5 (0.374)

at 100°C (212°F)

88.2 – 117.6 kPa

(12.8 –17.0 psi) Valve opening temperature

Valve full open temperature and lift

Valve opening pressure

Engine Coolingmm (in) mm (in)