towing OPEL GRANDLAND X 2018.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.75, Model line: GRANDLAND X, Model: OPEL GRANDLAND X 2018.75Pages: 273, PDF Size: 7.7 MB

Page 191 of 273

Driving and operating189

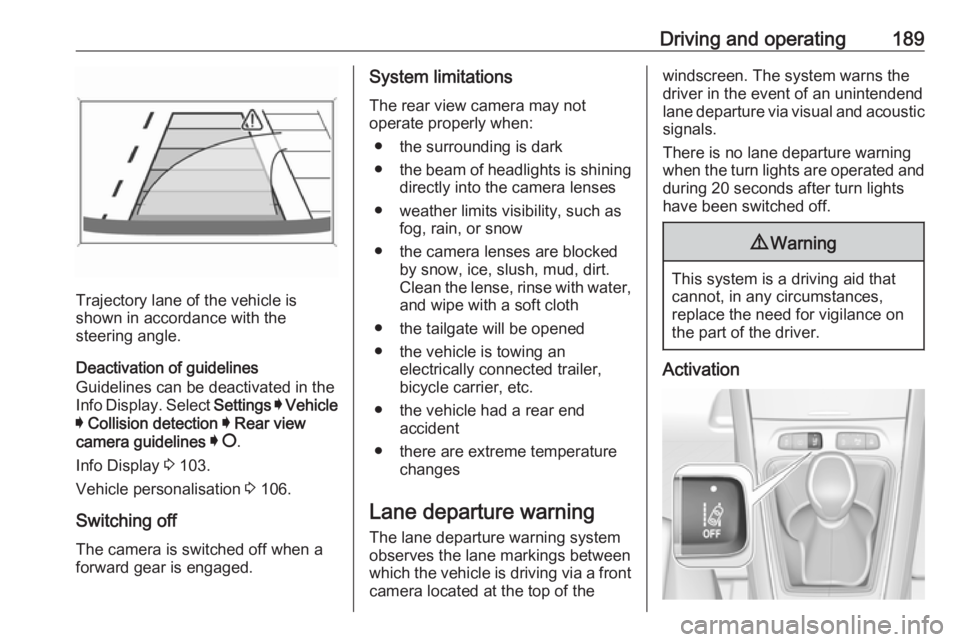

Trajectory lane of the vehicle is

shown in accordance with the

steering angle.

Deactivation of guidelines

Guidelines can be deactivated in the

Info Display. Select Settings I Vehicle

I Collision detection I Rear view

camera guidelines I § .

Info Display 3 103.

Vehicle personalisation 3 106.

Switching off

The camera is switched off when a

forward gear is engaged.

System limitations

The rear view camera may not

operate properly when:

● the surrounding is dark

● the beam of headlights is shining

directly into the camera lenses

● weather limits visibility, such as fog, rain, or snow

● the camera lenses are blocked by snow, ice, slush, mud, dirt.

Clean the lense, rinse with water, and wipe with a soft cloth

● the tailgate will be opened

● the vehicle is towing an electrically connected trailer,

bicycle carrier, etc.

● the vehicle had a rear end accident

● there are extreme temperature changes

Lane departure warning The lane departure warning system

observes the lane markings between which the vehicle is driving via a front camera located at the top of thewindscreen. The system warns the

driver in the event of an unintendend

lane departure via visual and acoustic signals.

There is no lane departure warning when the turn lights are operated and during 20 seconds after turn lights

have been switched off.9 Warning

This system is a driving aid that

cannot, in any circumstances,

replace the need for vigilance on

the part of the driver.

Activation

Page 194 of 273

192Driving and operatingthe correction. A warning message inthe Driver Information Centre

accompanied by a warning chime

alerts the driver when immediate

driver´s action is required.

Deactivation To deactivate the system, press andhold Ó. Deactivation of the system is

confirmed by the illuminated LED in

the button. In the Driver Information

Centre solid grey lines are displayed.

Fault

In the event of a fault, a and H

appear in the instrument panel, accompanied by a display message

and a warning chime. Contact a

dealer or a qualified workshop to have the system checked.

System limitations The system performance may be

affected by:

● windscreen not clean or affected by foreign objects, e.g. stickers

● close vehicles ahead

● banked roads● winding or hilly roads

● road edges

● sudden lighting changes

● adverse environmental conditions, e.g. heavy rain or

snow

● vehicle modifications, e.g. tyres

Switch off the system if the system is

disturbed by tar marks, shadows,

road cracks, temporary or

construction lane markings, or other

road imperfections.9 Warning

Always keep your attention on the

road and maintain proper vehicle

position within the lane, otherwise

vehicle damage, injury or death

could occur.

Lane keep assist does not

continuously steer the vehicle.

The system may not keep the

vehicle in the lane or give an alert,

even if a lane marking is detected.

The steering of the lane keep

assist may not be sufficient to

avoid a lane departure.

The system may not detect hands-

off driving due to external

influences like road condition and

surface and weather. The driver has full responsibility to control the vehicle and is always required to

keep the hands on the steering

wheel while driving.

Using the system while towing a

trailer or on slippery roads could

cause loss of control of the vehicle

and a crash. Switch the system off.

Driver alert

The driver alert system monitores the driving time and the vigilance of the

driver. Monitoring the vigilance of the

driver is based on the trajectory

variations of the vehicle compared to

the lane markings.

The system includes a driving time

alert combined with driver drowsiness detection.

Page 199 of 273

Driving and operating197Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle. If

using non-factory fitted towing

equipment, deactivation of the hands- free tailgate operation may be

required 3 30.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for trailer brake light cannot detect a

partial bulb outage. E.g. in case of

four bulbs with a power of 5 W each,

the function only detects lamp outage

when only a single 5 W lamp remains

or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle to have

it on hand if needed.Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s curb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 255.Trailer towing

Trailer loadsThe permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of altitude. The

gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).

Page 200 of 273

198Driving and operatingThe permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 244.

Vertical coupling load The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (70 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum vertical

coupling load, especially in the case

of heavy trailers. The vertical coupling

load should never fall below 25 kg.Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

60 kg , the gross vehicle weight rating

must not be exceeded. If the

permissible rear axle load is

exceeded, a maximum speed of

100 km/h applies.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

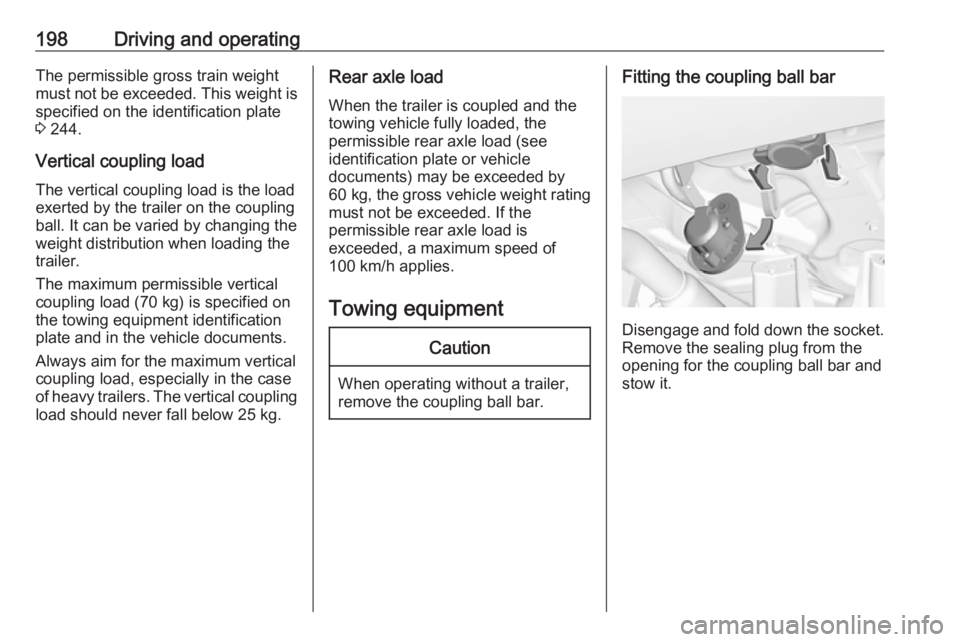

Fitting the coupling ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Page 202 of 273

200Driving and operatingInsert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

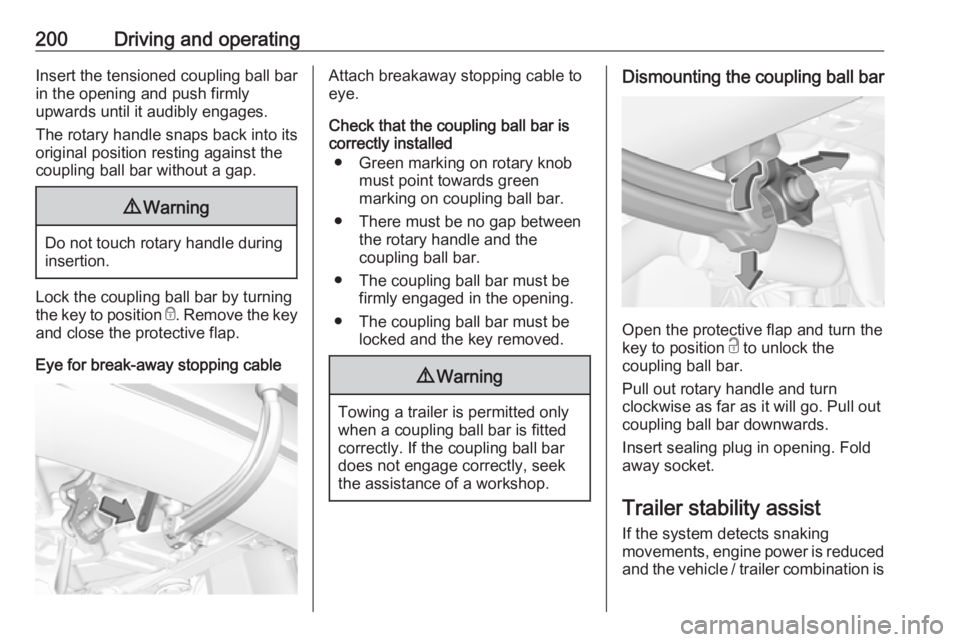

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

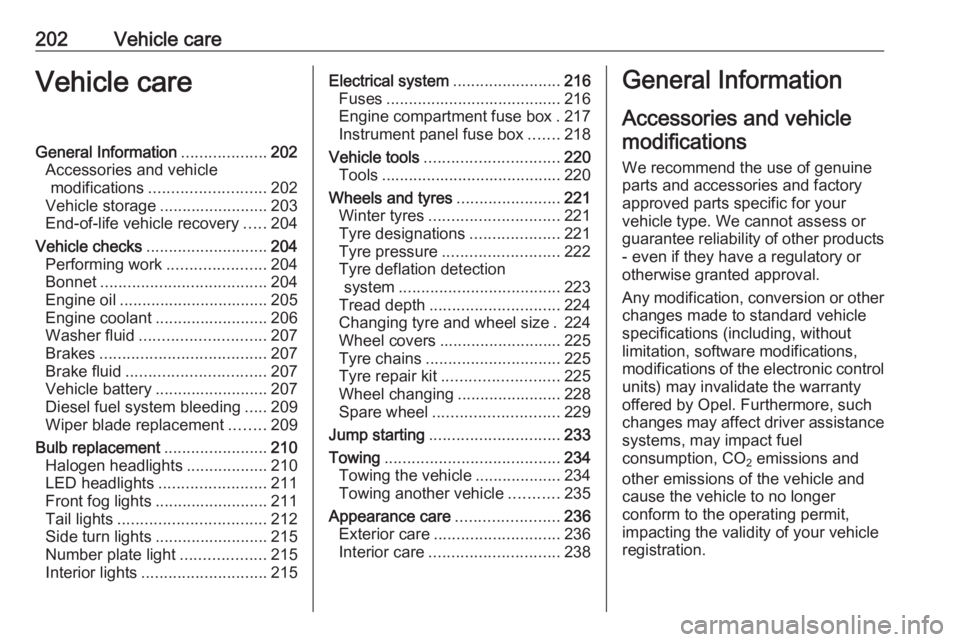

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle / trailer combination is

Page 204 of 273

202Vehicle careVehicle careGeneral Information...................202

Accessories and vehicle modifications .......................... 202

Vehicle storage ........................203

End-of-life vehicle recovery .....204

Vehicle checks ........................... 204

Performing work ......................204

Bonnet ..................................... 204

Engine oil ................................. 205

Engine coolant ......................... 206

Washer fluid ............................ 207

Brakes ..................................... 207

Brake fluid ............................... 207

Vehicle battery ......................... 207

Diesel fuel system bleeding .....209

Wiper blade replacement ........209

Bulb replacement .......................210

Halogen headlights ..................210

LED headlights ........................ 211

Front fog lights ......................... 211

Tail lights ................................. 212

Side turn lights ......................... 215

Number plate light ...................215

Interior lights ............................ 215Electrical system........................216

Fuses ....................................... 216

Engine compartment fuse box . 217

Instrument panel fuse box .......218

Vehicle tools .............................. 220

Tools ........................................ 220

Wheels and tyres .......................221

Winter tyres ............................. 221

Tyre designations ....................221

Tyre pressure .......................... 222

Tyre deflation detection system .................................... 223

Tread depth ............................. 224

Changing tyre and wheel size . 224

Wheel covers ........................... 225

Tyre chains .............................. 225

Tyre repair kit .......................... 225

Wheel changing .......................228

Spare wheel ............................ 229

Jump starting ............................. 233

Towing ....................................... 234

Towing the vehicle ...................234

Towing another vehicle ...........235

Appearance care .......................236

Exterior care ............................ 236

Interior care ............................. 238General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 222 of 273

220Vehicle careNo.Circuit25Airbag26Electronic Stability Control27Alarm28OnStar29Infotainment32Cigarette lighter / Power outlet

front34Heated rear window / Heated

windscreen / Inductive charging35Light switch / Diagnostic

connector module36LightingVehicle tools

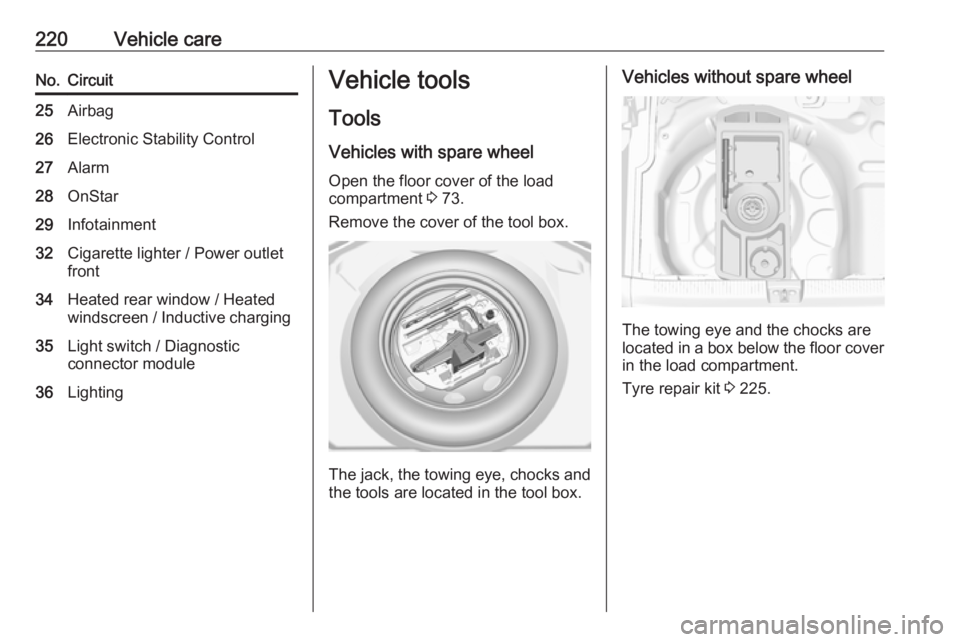

Tools

Vehicles with spare wheel Open the floor cover of the load

compartment 3 73.

Remove the cover of the tool box.

The jack, the towing eye, chocks and

the tools are located in the tool box.

Vehicles without spare wheel

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 225.

Page 223 of 273

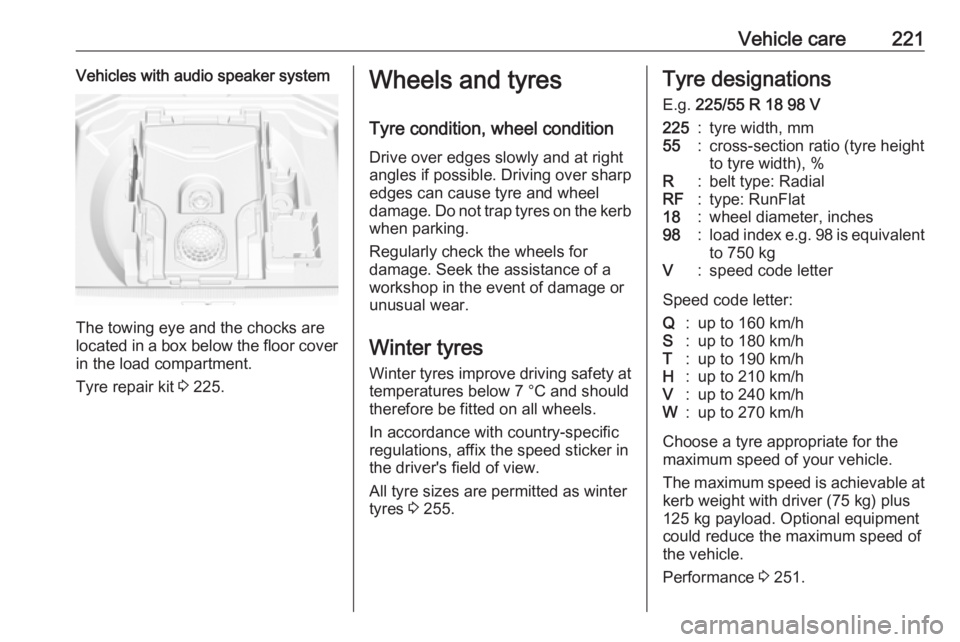

Vehicle care221Vehicles with audio speaker system

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 225.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 255.Tyre designations

E.g. 225/55 R 18 98 V225:tyre width, mm55:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat18:wheel diameter, inches98:load index e.g. 98 is equivalent

to 750 kgV:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 251.

Page 232 of 273

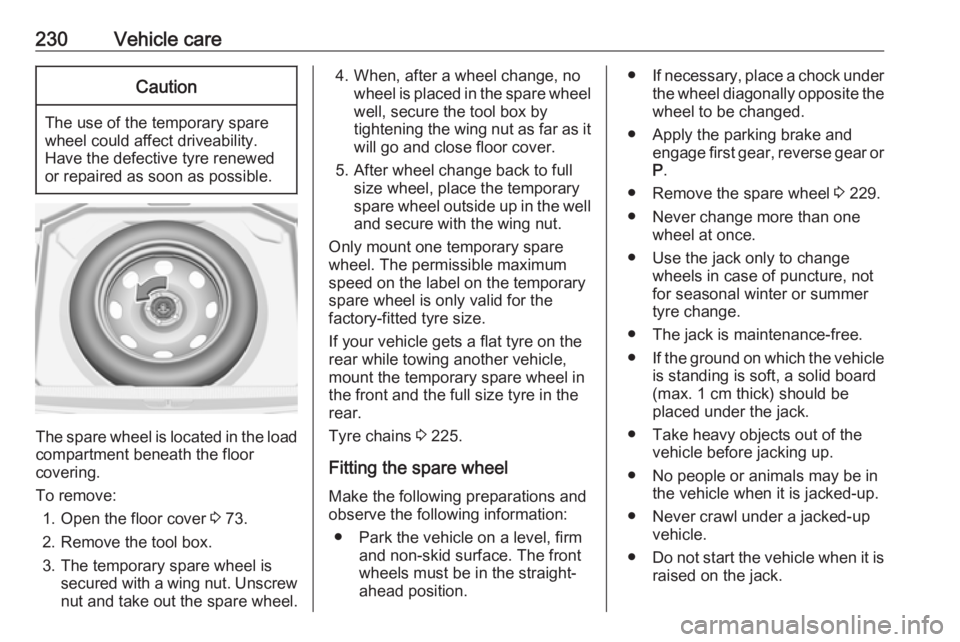

230Vehicle careCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

The spare wheel is located in the load

compartment beneath the floor

covering.

To remove: 1. Open the floor cover 3 73.

2. Remove the tool box.

3. The temporary spare wheel is secured with a wing nut. Unscrew

nut and take out the spare wheel.

4. When, after a wheel change, no wheel is placed in the spare wheelwell, secure the tool box by

tightening the wing nut as far as it will go and close floor cover.

5. After wheel change back to full size wheel, place the temporary

spare wheel outside up in the well

and secure with the wing nut.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

If your vehicle gets a flat tyre on the rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full size tyre in the

rear.

Tyre chains 3 225.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 229.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

Page 234 of 273

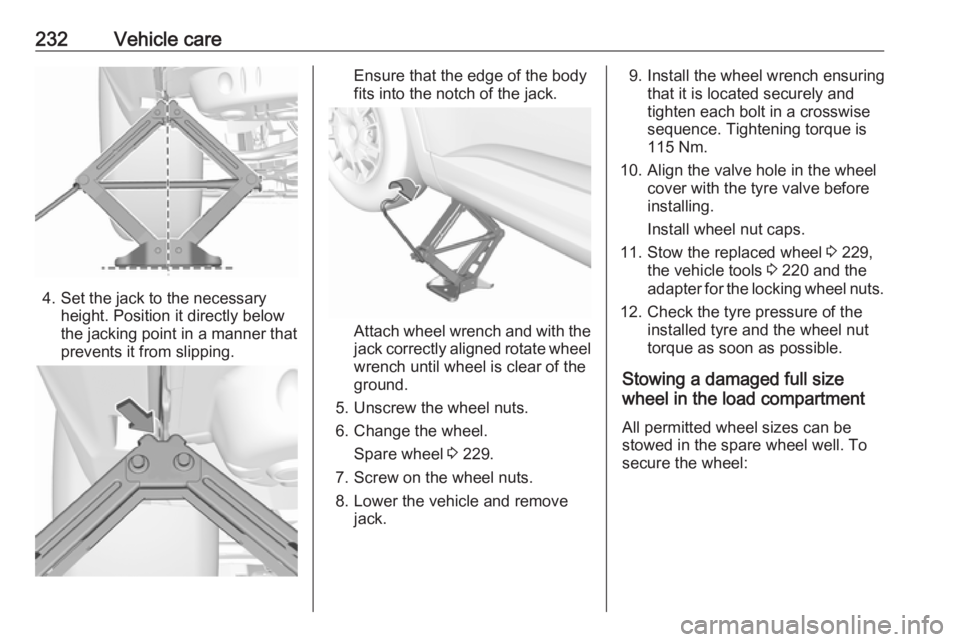

232Vehicle care

4. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Ensure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 229.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

115 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 229,

the vehicle tools 3 220 and the

adapter for the locking wheel nuts.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Stowing a damaged full size

wheel in the load compartment

All permitted wheel sizes can be

stowed in the spare wheel well. To

secure the wheel: