spare wheel OPEL GRANDLAND X 2018 Infotainment system

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: GRANDLAND X, Model: OPEL GRANDLAND X 2018Pages: 265, PDF Size: 7.5 MB

Page 76 of 265

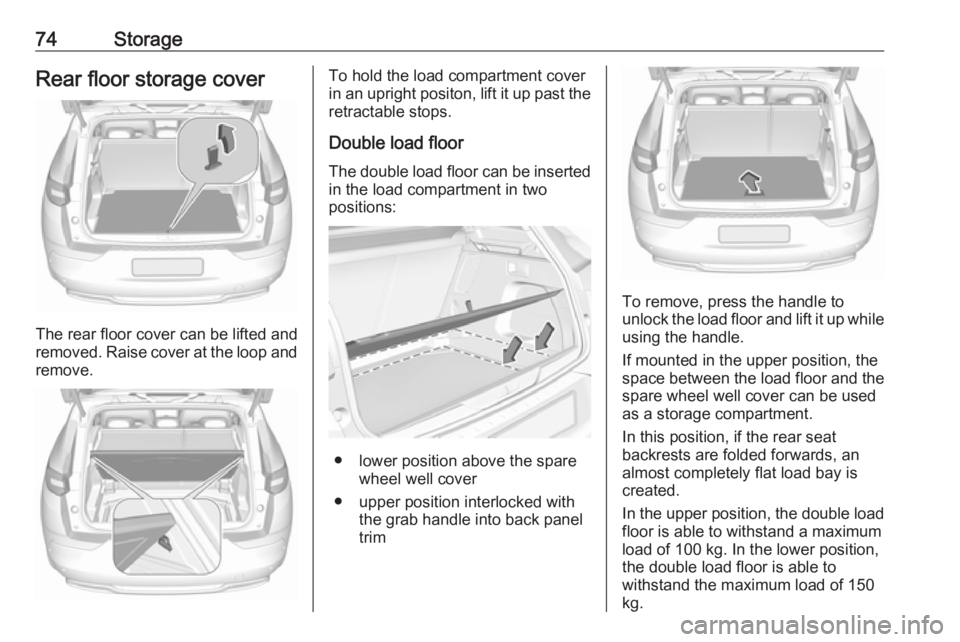

74StorageRear floor storage cover

The rear floor cover can be lifted and

removed. Raise cover at the loop and remove.

To hold the load compartment cover

in an upright positon, lift it up past the

retractable stops.

Double load floor

The double load floor can be inserted

in the load compartment in two

positions:

● lower position above the spare wheel well cover

● upper position interlocked with the grab handle into back panel

trim

To remove, press the handle to

unlock the load floor and lift it up while

using the handle.

If mounted in the upper position, the

space between the load floor and the spare wheel well cover can be used

as a storage compartment.

In this position, if the rear seat

backrests are folded forwards, an

almost completely flat load bay is

created.

In the upper position, the double load

floor is able to withstand a maximum

load of 100 kg. In the lower position,

the double load floor is able to

withstand the maximum load of 150

kg.

Page 170 of 265

168Driving and operatingPressing ß to activate the speed

limiter deactivates cruise control.

Switching off the ignition cancels any

programmed speed value.

Driver's attention ● Use adaptive cruise control carefully on bends or mountain

roads, as it can lose the vehicle

ahead and needs time to detect it again.

● Do not use the system on slippery roads as it can create

rapid changes in tyre traction

(wheel spinning), so that you

could lose control of the vehicle.

● Do not use adaptive cruise control during rain, snow or

heavy dirt, as the radar sensor

can be covered by a water film,

dust, ice or snow. This reduces or suppresses completely the

visibility. In case of sensor

blockage, clean the sensor

cover.

● Do not use the system when the spare wheel is in use.System limits9Warning

The system's automatic brake

force does not permit hard braking and the braking level may not be

sufficient to avoid a collision.

● After a sudden lane change, the system needs a certain time to

detect the next preceding

vehicle. So if a new vehicle is

detected, the system may

accelerate instead of braking.

● Adaptive cruise control does ignore the oncoming traffic.

● Adaptive cruise control does not consider pedestrians and

animals for braking and driving

off.

● Adaptive cruise control considers

stopped vehicles only at low

speed.

● Do not use adaptive cruise control when towing a trailer.

● Do not use adaptive cruise control on roads with an incline ofmore than 10%.

As the radar's field of detection is

quite narrow, it is possible that the

system may not detect:

● Vehicles of reduced width (motorcycles, scooters...).

● Vehicles not running in the middle of the lane,

● Vehicles entering a corner.

● Vehicles suddenly pulling out.

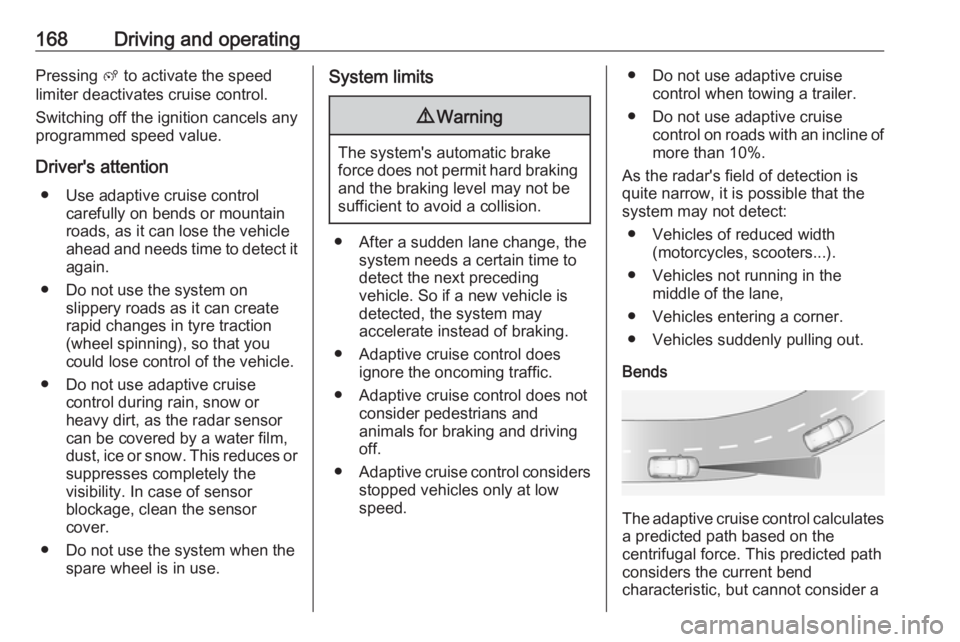

Bends

The adaptive cruise control calculates

a predicted path based on the

centrifugal force. This predicted path

considers the current bend

characteristic, but cannot consider a

Page 205 of 265

Vehicle care203Vehicle careGeneral Information...................203

Accessories and vehicle modifications .......................... 203

Vehicle storage ........................204

End-of-life vehicle recovery .....205

Vehicle checks ........................... 205

Performing work ......................205

Bonnet ..................................... 205

Engine oil ................................. 206

Engine coolant ......................... 207

Washer fluid ............................ 208

Brakes ..................................... 208

Brake fluid ............................... 208

Vehicle battery ......................... 208

Diesel fuel system bleeding .....210

Wiper blade replacement ........210

Bulb replacement .......................211

Halogen headlights ..................211

LED headlights ........................ 212

Fog lights ................................. 212

Tail lights ................................. 213

Side turn signal lights ..............216

Number plate light ...................216

Interior lights ............................ 216

Instrument panel illumination ...216Vehicle tools .............................. 217

Tools ........................................ 217

Wheels and tyres .......................218

Winter tyres ............................. 218

Tyre designations ....................218

Tyre pressure .......................... 218

Tyre deflation detection system .................................... 219

Tread depth ............................. 220

Changing tyre and wheel size . 221

Wheel covers ........................... 221

Tyre chains .............................. 222

Tyre repair kit .......................... 222

Wheel changing .......................225

Spare wheel ............................ 228

Jump starting ............................. 229

Towing ....................................... 230

Towing the vehicle ...................230

Towing another vehicle ...........231

Appearance care .......................232

Exterior care ............................ 232

Interior care ............................. 234General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may affect driver assistance

systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 219 of 265

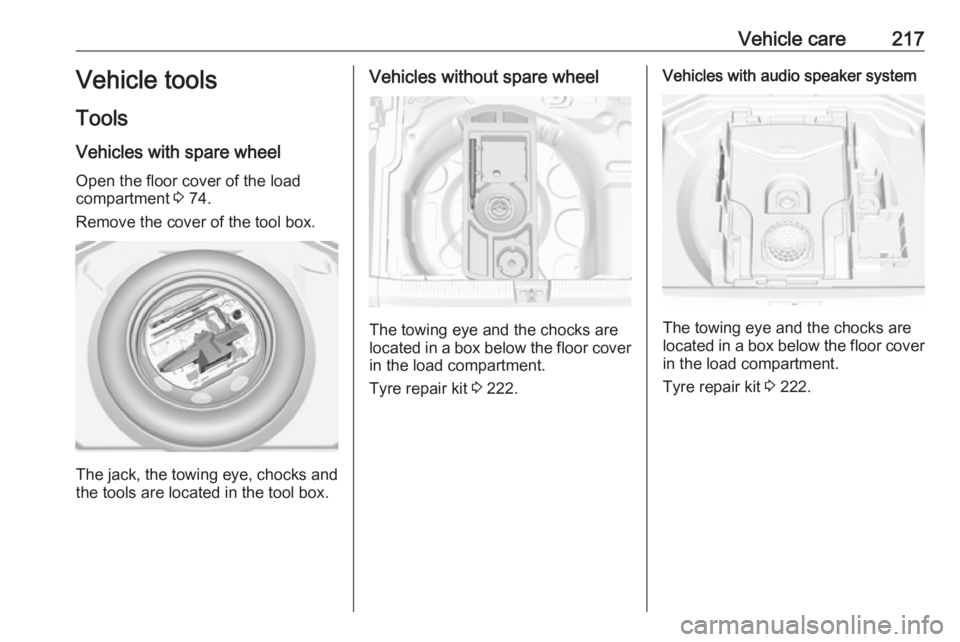

Vehicle care217Vehicle tools

Tools

Vehicles with spare wheel

Open the floor cover of the load

compartment 3 74.

Remove the cover of the tool box.

The jack, the towing eye, chocks and

the tools are located in the tool box.

Vehicles without spare wheel

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 222.

Vehicles with audio speaker system

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 222.

Page 220 of 265

218Vehicle careWheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 250.Tyre designations

E.g. 225/55 R 18 98 V225:tyre width, mm55:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat18:wheel diameter, inches98:load index e.g. 98 is equivalent

to 750 kgV:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 246.

Directional tyres

Directional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

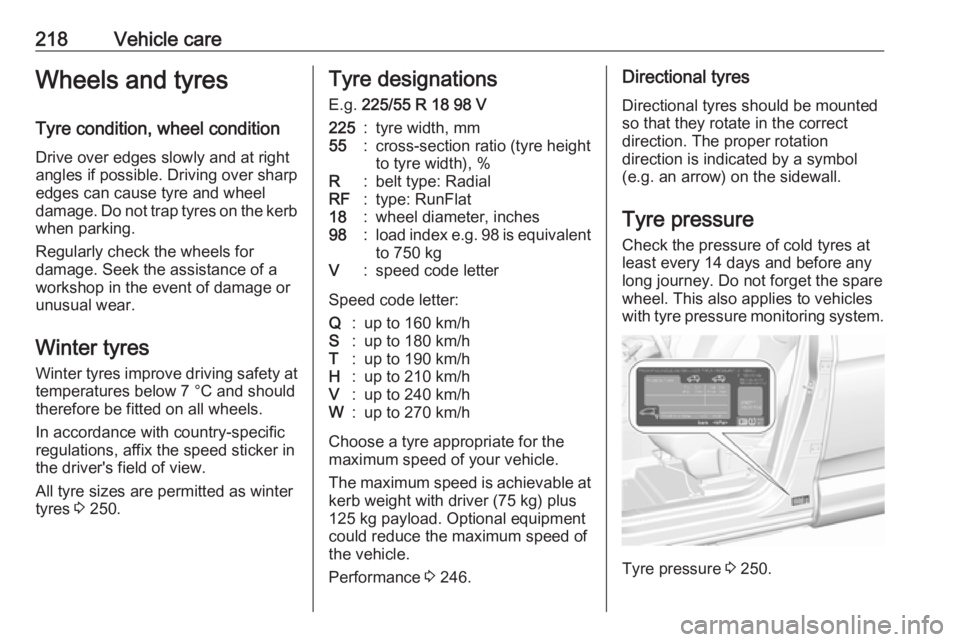

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 250.

Page 221 of 265

Vehicle care219The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter

tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 245.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 250.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.

Tyre deflation detectionsystem

The tyre deflation detection system continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values.

Page 222 of 265

220Vehicle careIf a tyre loses pressure the control

indicator w illuminates and a warning

message is displayed in the Driver

Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 99.

After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.Caution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used. Once the road tyre has

been refitted, check the tyre pressure with cold tyres and initialise the

system.

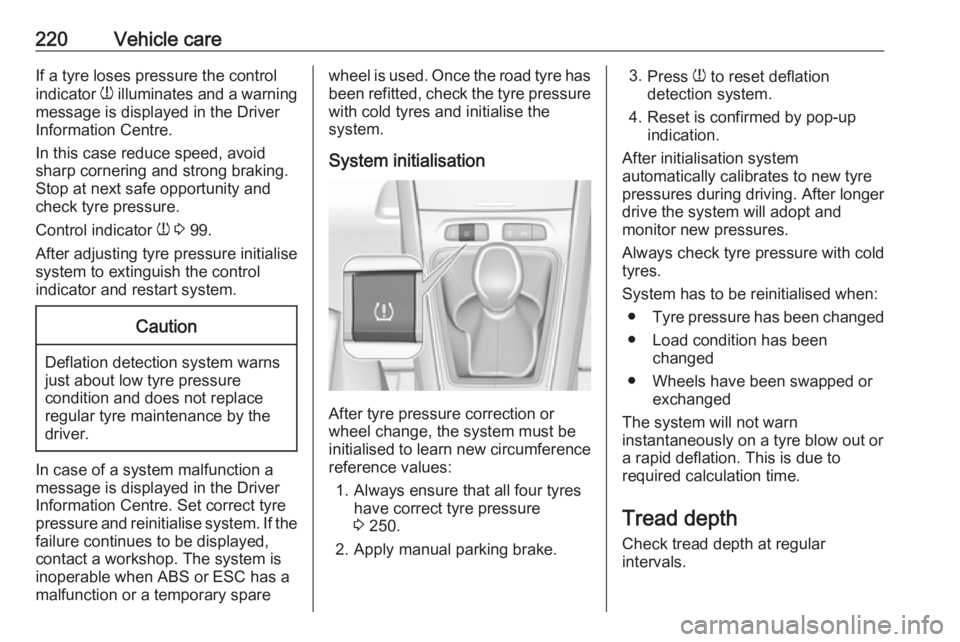

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

1. Always ensure that all four tyres have correct tyre pressure3 250.

2. Apply manual parking brake.

3. Press w to reset deflation

detection system.

4. Reset is confirmed by pop-up indication.

After initialisation system

automatically calibrates to new tyre

pressures during driving. After longer

drive the system will adopt and

monitor new pressures.

Always check tyre pressure with cold

tyres.

System has to be reinitialised when: ● Tyre pressure has been changed

● Load condition has been changed

● Wheels have been swapped or exchanged

The system will not warn instantaneously on a tyre blow out or

a rapid deflation. This is due to

required calculation time.

Tread depthCheck tread depth at regular

intervals.

Page 224 of 265

222Vehicle care9Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 215/70R16, 215/65 R17,

225/55 R18 and 205/55 R19.

Temporary spare wheel

The use of tyre chains is not permitted

on the temporary spare wheel.

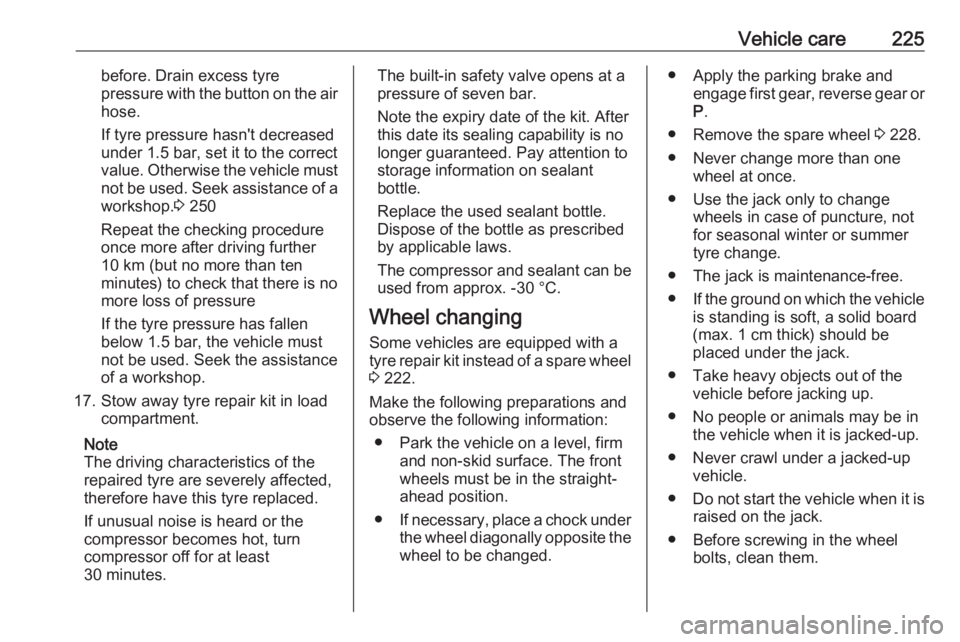

Tyre repair kit

Minor damage to the tyre tread can be repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.

9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in the load

compartment below the floor cover.

1. Remove the sealant bottle and the

compressor.

Page 227 of 265

Vehicle care225before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 1.5 bar, set it to the correct

value. Otherwise the vehicle must

not be used. Seek assistance of a workshop. 3 250

Repeat the checking procedure

once more after driving further

10 km (but no more than ten

minutes) to check that there is no

more loss of pressure

If the tyre pressure has fallen

below 1.5 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in load compartment.

Note

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

Wheel changing

Some vehicles are equipped with a tyre repair kit instead of a spare wheel 3 222.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 228.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.

Page 229 of 265

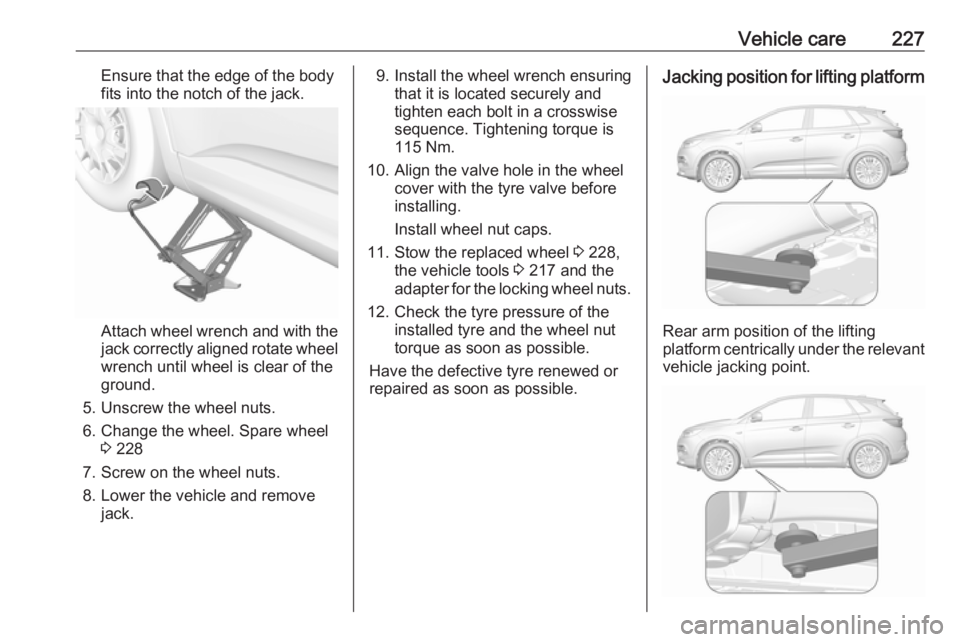

Vehicle care227Ensure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 228

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuringthat it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

115 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 228,

the vehicle tools 3 217 and the

adapter for the locking wheel nuts.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.Jacking position for lifting platform

Rear arm position of the lifting

platform centrically under the relevant vehicle jacking point.