clutch OPEL GT-R 1973 Owners Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 501 of 625

I4I

.7C.140 .1973 OPEL SERVICE MANUAL

J-7004-1SLIDE HAMMER

J-2291 3MAIN SHAFT ASSEMBLY TOOL

J-22929SPEEDOMETER DRIVEN GEAR

REMOVER AND INSTALLER

J-22922J-22926TRANSMISSION CASE EXTENSIONSPEEDOMETER DRIVEN

HOUSING SEAL INSTALLERGEAR PIN REMOVER

J-21715DETENT PIN PLUG REMOVER

J-22934CLUTCH PLATE ALIGNING ARBORTRWARC PLIERS

J-22923REVERSE IDLER SHAFT REMOVER

J-2291 I

J-21 684NEEDLE BEARING LOADER

BEARING PRESS PLATE7&56

Figure

7C-235 Special Tools. Manual Transmission

Page 526 of 625

REFRIGERANT COMPONENTS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

FundamentalPrinciplesofRefrigeration..................

Description of Air Conditioning Components

..........DIAGNOSIS:

GeneralInformation..........................................................

Leak Testing

System1........................................................

Functional Testing System............................................

DiagnosisGuide..................................................................

MAINTENANCE AND ADJUSTMENTS:

General Service Information and

Safety Precautions;........................................................

Charging

andDischargingSystem..............................

AddingOiltotheSystem................................................

Flushing the System........................................................

MAJOR REPAIR:

Removal and Installation Compressor

Opel1900.Manta........................................................

GT

........................................................................................

Removal and Installation Condenser

Receiver-Dehydrator

Assembly

- GT.................................................................

Receiver-Dehydrator

.Opel 1900.Manta................GT..................................................

Removal and Installation Evaporator and

Expansion Valve

- Opel 1900.Manta....................

GT......................................................

Disassembly and Reassembly of Clutch Drive

Plate

andShaftSeal....................................................

Disassembly and Reassembly of Pulley Assembly

and Coil and Housing Assembly..............................

Disassembly and

Reaissembly of Internal

Parts of Compressor and Leak Testing

Compressor..............................................................................

SPECIFICATIONS:

Specifications........................................................................Page No.

9B-18

98-33

98-38

98-39

98-39

90-40

98-41

98-41

9B-47

98-48

98-48

98-56

98-62

90-4990-58

98-52

98-59

98-63

98-67

98-69

98-82REFRIGERANT COMPONENTS ALL MODELS

96-17

Page 535 of 625

98-26 1973 OPEL SERVICE MANUAL

greater than the opposing pressure in the power ele-

ment. Therefore, the valve remains closed. When the

compressor is started, it will reduce the pressure and

temperature of the refrigerant in the cooling coil to

a point where the vapor pressure in the power ele-

ment becomes the stronger. The seat then moves off

the orifice and liquid starts to flow through the valve

orifice into the cooling coil.

The purpose of the power element is to help deter-

mine the quantity of liquid that is being metered into

the cooling coil. As the temperature of the low pres-

sure line changes at the bulb, the pressure of

the

vapor in the power element changes, resulting in a

change of the position of the seat. For example, if the

cooling coil gets more liquid than is required, the

temperature of the low pressure line is reduced and

the resultant lowering of the bulb temperature

reduces the pressure of the vapor in the power ele-

ment, allowing the seat to move closer to the orifice.

This immediately reduces the amount of liquid leav-

ing the valve. Under normal operation, the power

element provides accurate control of the quantity of

refrigerant to the cooling coil.

To employ our tire pump analogy once more for

clarity, it is the same situation that would exist if you were inflating a tire with a very slow leak. Providing

you pumped the air into the tire as fast as it leaked

out, you would be able to maintain pressure even

though the air would merely be circulating through the tire and leaking out through the puncture.

To Sum Up

So far, we’ve discussed only what each unit in an air

conditioning system does. We’ve learned that the

evaporator is the unit in which liquid refrigerant

soaks up heat from the air, the compressor is a pump

for squeezing this heat out of the vapor, the con-

denser is a radiator for getting rid of the heat, and the

thermostatic expansion valve is a device for regulat-

ing the pressure on the refrigerant. Now, let’s

find

out how the temperature of the cooled air is con-

trolled.

METHOD OF TEMPERATURE CONTROL

To achieve temperature control, the compressor is

run intermittently, automatically turning on and off

as necessary to maintain proper temperature.

Thermostatic Switch

The compressor can be started and stopped au-

tomatically through the use of an electro-magnetic

clutch and a thermostat affected by variations of temperature.

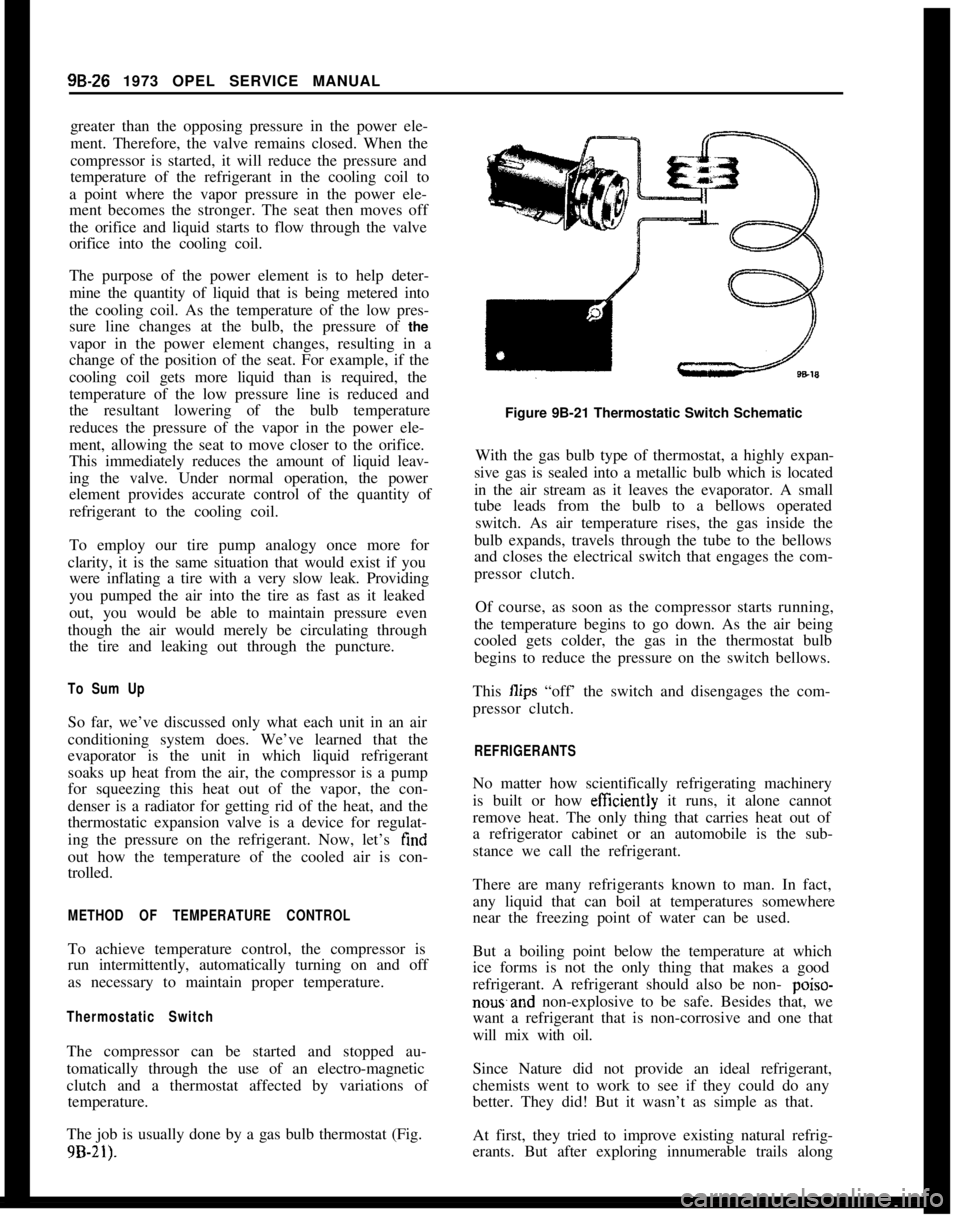

The job is usually done by a gas bulb thermostat (Fig.

9B-21).

Figure 9B-21 Thermostatic Switch Schematic

With the gas bulb type of thermostat, a highly expan-

sive gas is sealed into a metallic bulb which is located

in the air stream as it leaves the evaporator. A small

tube leads from the bulb to a bellows operated switch. As air temperature rises, the gas inside the

bulb expands, travels through the tube to the bellows

and closes the electrical switch that engages the com-

pressor clutch.

Of course, as soon as the compressor starts running,

the temperature begins to go down. As the air being

cooled gets colder, the gas in the thermostat bulb

begins to reduce the pressure on the switch bellows.

This

Ilips “off’ the switch and disengages the com-

pressor clutch.

REFRIGERANTS

No matter how scientifically refrigerating machinery

is built or how

efftciently it runs, it alone cannot

remove heat. The only thing that carries heat out of

a refrigerator cabinet or an automobile is the sub-

stance we call the refrigerant.

There are many refrigerants known to man. In fact,

any liquid that can boil at temperatures somewhere

near the freezing point of water can be used.

But a boiling point below the temperature at which

ice forms is not the only thing that makes a good

refrigerant. A refrigerant should also be non-

poiso-

nowand non-explosive to be safe. Besides that, we

want a refrigerant that is non-corrosive and one that

will mix with oil.

Since Nature did not provide an ideal refrigerant,

chemists went to work to see if they could do any

better. They did! But it wasn’t as simple as that.

At first, they tried to improve existing natural refrig-

erants. But after exploring innumerable trails along

Page 542 of 625

REFRIGERANT COMPONENTS ALL MODELS99- 33

That the attraction of the drying material for mois-

ture is so powerful that if the receiver is left open,

moisture will be drawn in from the outside air.

That just one drop of water added to the refrigerantwill start chemical changes that can result in corro-

sion and eventual breakdown of the chemicals in the

system. Hydrochloric acid is the result of an R-12

mixture with water.

That the smallest amount of air in the refrigeration

system may start reactions that can cause malfunc-

tions.

That the drying agent in the receiver-dehydrator is

Activated Silica Alumina (silica-gel).

That

the inert gas in the expansion valve capillary

line is carbon dioxide.

DESCRIPTION OF AIR CONDITIONING

COMPONENTS

Compressor

The compressor is located in the engine compart-

ment. The purpose of the unit is to draw the low

pressure,gas from the evaporator and compress this

gas into a high temperature, high pressure gas. This

action will result in the refrigerant having a higher

temperature than the surrounding air.

The

cortipressor is of basic double action piston de-

sign. Three horizontal double acting pistons make up

a six cylinder compressor (See Figure

9B-162). The

pistons operate in

l-1/2 inch bore and have a l-1/8

inch stroke. A

wash plate keyed to the shaft drives

the pistons. The shaft is belt driven through a mag-

netic clutch and pulley arrangement. An oil pump

mounted at the rear of the compressor picks up oil

from the

botto’m of the compressor and lubricates the

bearings’and other internal parts of the compressor.

Reed type valves at each end of the compressor open

or close to control the flow of incoming and outgoing refrigerant. Two gas tight passages interconnect

chambers of the front and rear heads so that there is

one common suction port, and one common dis-

charge port. The internal parts of the compressor

function, as follows:

1. Suction Valve Reed Discs and Discharge Valve

Plates

_ The two suction valve reed discs and two

discharge valve plates (see Figure

9B-25) operate in

a similar but opposite manner. The discs are com-

posed of three reeds and function to open when the

pistons are on the intake portion of their stroke

(downstroke), and close on the compression stroke.

The reeds allow low pressure gas to enter the cylin- ders. The discharge valve plates also have three

reeds, however, they function to open when the pis- tons are on the compression portion of their stroke

(upstroke), and close on the intake stroke. High pres-

sure gas exits from discharge ports in the discharge

valve plate. Three retainers riveted directly above the

reeds on the valve plate serve to limit the opening of

the reeds on the compression stroke.

SUCTION VALVE

DISCHARGE-VALVE PLATES

Figure

98-25 - Compressor Suction Valve Reed Discs

and Discharge Valve Plates

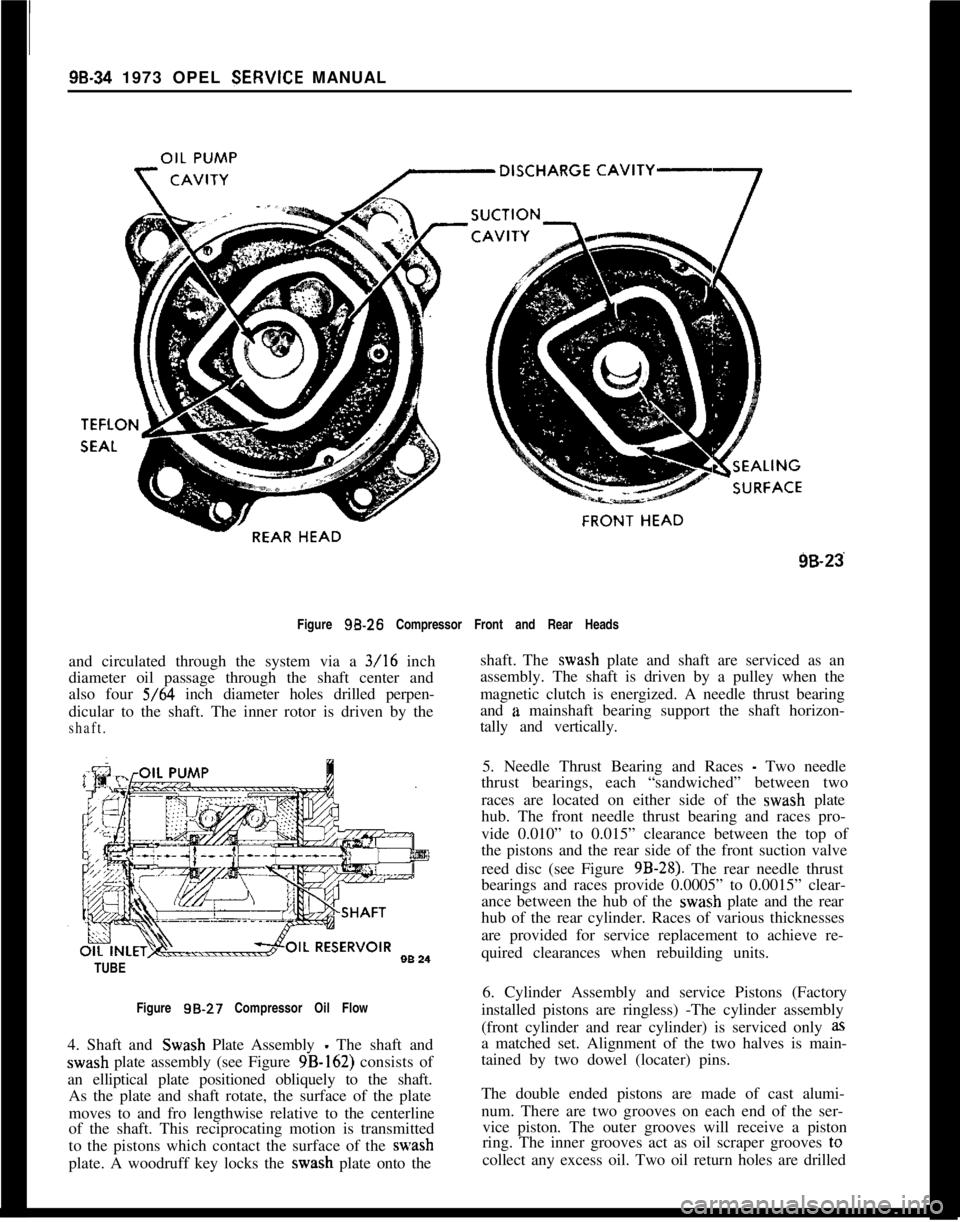

2. Front and Rear Heads - The front and rear heads

(Figure

9B-26) serve to channel the refrigerant into

and out of the cylinders. The front head is divided

into two separate passages and the rear head is di-

vided into three separate passages. The outer passage

on both the front and rear heads channels high pres-

sure gas from the discharge valve reeds. The middle

passage of the rear head also contains the port open-

ing to the superheat switch cavity. This opening in

the rear head permits the superheat switch to be

affected by suction gas pressure and suction gas tem-

perature for the operating protection of the compres-

sor. The inner passage on the rear head houses the

oil pump inner and outer rotors. A Teflon sealing

material is bonded to the sealing surfaces separating

the passages in the rear head.

“0” rings are used to

affect a seal between the mating surfaces of the heads

and the shell. The front head suction and discharge

passages are connected to the suction and discharge

passages of the rear head by a discharge tube and

suction passage in the

body of the cylinder assembly.

A screen located in the suction port of the rear head

prevents foreign material from entering the circuit.

3. Oil Pump

- An internal tooth outer rotor and

external tooth inner rotor comprise the oil pump.

The pump works on the principle of a rotary type pump. Oil is drawn up from oil reservoir in underside

of shell through the oil inlet tube (see Figure

9B-27)

Page 543 of 625

98-34 1973 OPEL 3ERVlCE MANUAL

9B-23Figure

98.26 Compressor Front and Rear Heads

and circulated through the system via a 3/16 inch

diameter oil passage through the shaft center and

also four 5/64 inch diameter holes drilled perpen-

dicular to the shaft. The inner rotor is driven by the

shaft.TUBE

Figure

98-27 Compressor Oil Flow

4. Shaft and

Gash Plate Assembly - The shaft andwash plate assembly (see Figure 9B-162) consists of

an elliptical plate positioned obliquely to the shaft.

As the plate and shaft rotate, the surface of the plate

moves to and fro lengthwise relative to the centerline

of the shaft. This reciprocating motion is transmitted

to the pistons which contact the surface of the wash

plate. A woodruff key locks the wash plate onto theshaft. The wash plate and shaft are serviced as an

assembly. The shaft is driven by a pulley when the

magnetic clutch is energized. A needle thrust bearing

and

L mainshaft bearing support the shaft horizon-

tally and vertically.

5. Needle Thrust Bearing and Races

- Two needle

thrust bearings, each“sandwiched” between two

races are located on either side of the wash plate

hub. The front needle thrust bearing and races pro-

vide 0.010” to 0.015” clearance between the top of

the pistons and the rear side of the front suction valve

reed disc (see Figure

9B-28). The rear needle thrust

bearings and races provide 0.0005” to 0.0015” clear-

ance between the hub of the wash plate and the rear

hub of the rear cylinder. Races of various thicknesses

are provided for service replacement to achieve re-

quired clearances when rebuilding units.

6. Cylinder Assembly and service Pistons (Factory

installed pistons are ringless) -The cylinder assembly

(front cylinder and rear cylinder) is serviced only as

a matched set. Alignment of the two halves is main-

tained by two dowel (locater) pins.

The double ended pistons are made of cast alumi-

num. There are two grooves on each end of the ser-

vice piston. The outer grooves will receive a piston

ring. The inner grooves act as oil scraper grooves to

collect any excess oil. Two oil return holes are drilled

Page 545 of 625

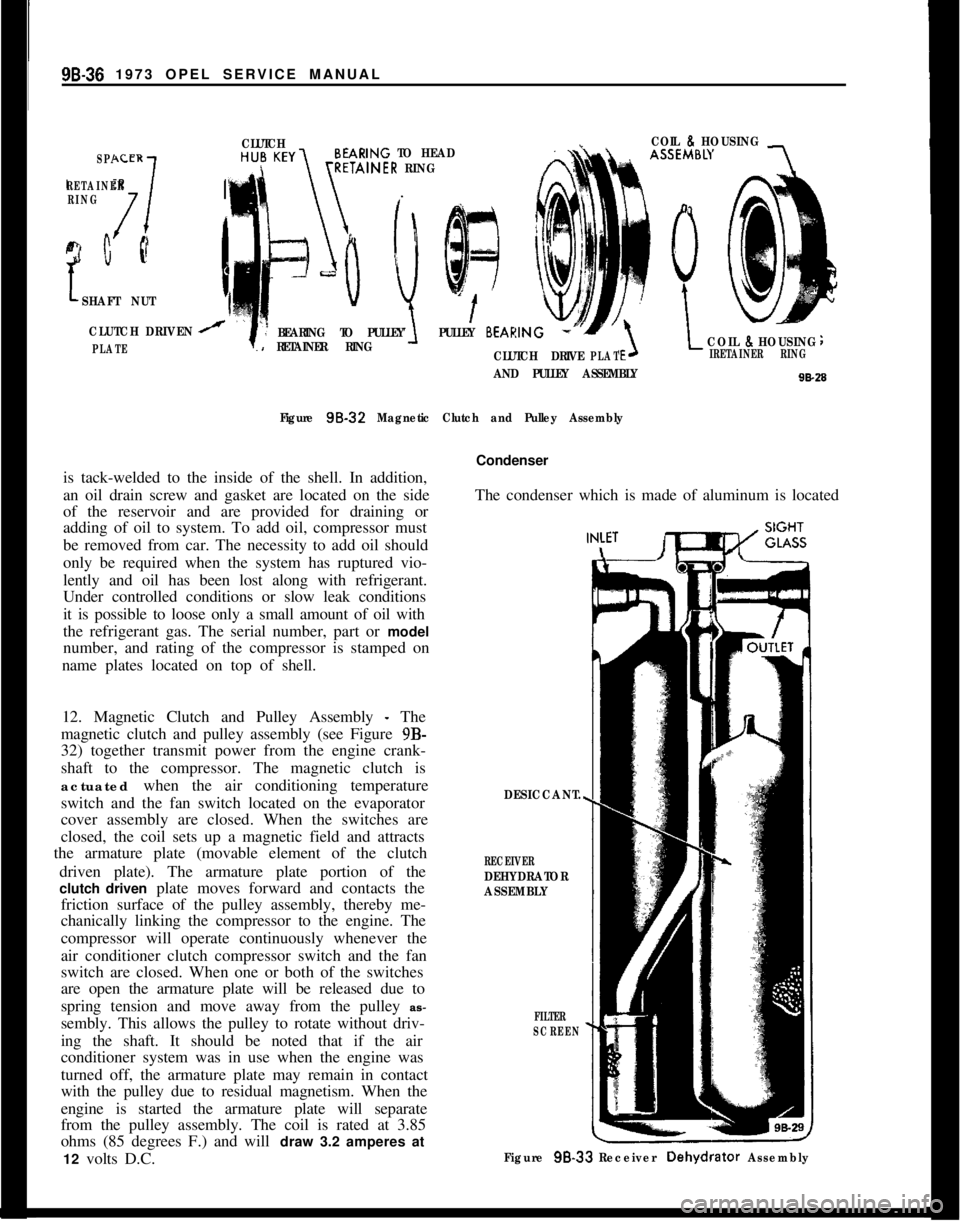

98-36 1973 OPEL SERVICE MANUALSPACER

17

RETAINER

RING

c Q

CLUTCHCOIL 8HOUSINGARING TO HEADTAINER RING

SHAFT NUT

CLUTCH DRIVEN

PLATE

BEARING TO PULLEYPULLEY BEARIN

RETAINER RINGCOIL 8HOUSING

CLUTCH DRIVEPLATIRETAINER RING

AND PULLEY ASSEMBLY

Figure 98-32

Magnetic Clutch and Pulley Assemblyis tack-welded to the inside of the shell. In addition,

an oil drain screw and gasket are located on the side

of the reservoir and are provided for draining or

adding of oil to system. To add oil, compressor must

be removed from car. The necessity to add oil should

only be required when the system has ruptured vio-

lently and oil has been lost along with refrigerant.

Under controlled conditions or slow leak conditions

it is possible to loose only a small amount of oil with

the refrigerant gas. The serial number, part or model

number, and rating of the compressor is stamped on

name plates located on top of shell.

12. Magnetic Clutch and Pulley Assembly

- The

magnetic clutch and pulley assembly (see Figure 9B-

32) together transmit power from the engine crank-

shaft to the compressor. The magnetic clutch is

actuated when the air conditioning temperature

switch and the fan switch located on the evaporator

cover assembly are closed. When the switches are

closed, the coil sets up a magnetic field and attracts

the armature plate (movable element of the clutch

driven plate). The armature plate portion of the

clutch driven plate moves forward and contacts the

friction surface of the pulley assembly, thereby me-

chanically linking the compressor to the engine. The

compressor will operate continuously whenever the

air conditioner clutch compressor switch and the fan

switch are closed. When one or both of the switches

are open the armature plate will be released due to

spring tension and move away from the pulley as-

sembly. This allows the pulley to rotate without driv-

ing the shaft. It should be noted that if the air

conditioner system was in use when the engine was

turned off, the armature plate may remain in contact

with the pulley due to residual magnetism. When the

engine is started the armature plate will separate

from the pulley assembly. The coil is rated at 3.85

ohms (85 degrees F.) and will draw 3.2 amperes at

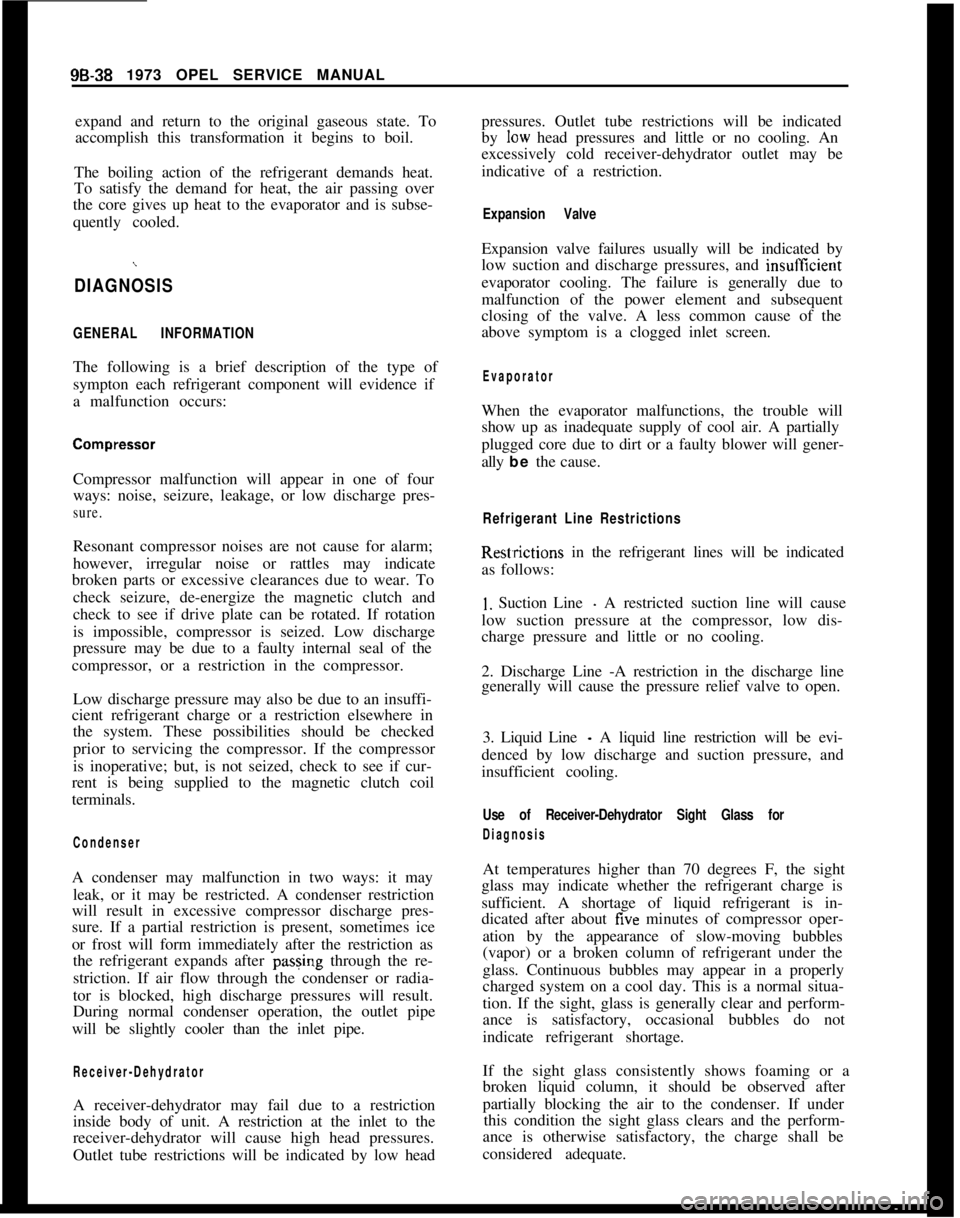

12 volts D.C.Condenser

The condenser which is made of aluminum is locatedIN:ET

DESICCANT.

RECEIVERDEHYDRATOR

ASSEMBLY

FILTER

SCREEN

Figure 98-33 Receiver Dehydrator Assembly

Page 547 of 625

9B-38 1973 OPEL SERVICE MANUAL

expand and return to the original gaseous state. To

accomplish this transformation it begins to boil.

The boiling action of the refrigerant demands heat.

To satisfy the demand for heat, the air passing over

the core gives up heat to the evaporator and is subse-

quently cooled.\

DIAGNOSIS

GENERAL INFORMATIONThe following is a brief description of the type of

sympton each refrigerant component will evidence if

a malfunction occurs:

Compressor malfunction will appear in one of four

ways: noise, seizure, leakage, or low discharge pres-

sure.Resonant compressor noises are not cause for alarm;

however, irregular noise or rattles may indicate

broken parts or excessive clearances due to wear. To

check seizure, de-energize the magnetic clutch and

check to see if drive plate can be rotated. If rotation

is impossible, compressor is seized. Low discharge

pressure may be due to a faulty internal seal of the

compressor, or a restriction in the compressor.

Low discharge pressure may also be due to an insuffi-

cient refrigerant charge or a restriction elsewhere in

the system. These possibilities should be checked

prior to servicing the compressor. If the compressor

is inoperative; but, is not seized, check to see if cur-

rent is being supplied to the magnetic clutch coil

terminals.

CondenserA condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge pres-

sure. If a partial restriction is present, sometimes ice

or frost will form immediately after the restriction as

the refrigerant expands after pas?ing through the re-

striction. If air flow through the condenser or radia-

tor is blocked, high discharge pressures will result.

During normal condenser operation, the outlet pipe

will be slightly cooler than the inlet pipe.

Receiver-DehydratorA receiver-dehydrator may fail due to a restriction

inside body of unit. A restriction at the inlet to the

receiver-dehydrator will cause high head pressures.

Outlet tube restrictions will be indicated by low headpressures. Outlet tube restrictions will be indicated

by

low head pressures and little or no cooling. An

excessively cold receiver-dehydrator outlet may be

indicative of a restriction.

Expansion ValveExpansion valve failures usually will be indicated by

low suction and discharge pressures, and insuff%ient

evaporator cooling. The failure is generally due to

malfunction of the power element and subsequent

closing of the valve. A less common cause of the

above symptom is a clogged inlet screen.

EvaporatorWhen the evaporator malfunctions, the trouble will

show up as inadequate supply of cool air. A partially

plugged core due to dirt or a faulty blower will gener-

ally be the cause.

Refrigerant Line Restrictions

Rest~rictions in the refrigerant lines will be indicated

as follows:

I. Suction Line - A restricted suction line will cause

low suction pressure at the compressor, low dis-

charge pressure and little or no cooling.

2. Discharge Line -A restriction in the discharge line

generally will cause the pressure relief valve to open.

3. Liquid Line

- A liquid line restriction will be evi-

denced by low discharge and suction pressure, and

insufficient cooling.

Use of Receiver-Dehydrator Sight Glass for

DiagnosisAt temperatures higher than 70 degrees F, the sight

glass may indicate whether the refrigerant charge is

sufficient. A shortage of liquid refrigerant is in-

dicated after about

five minutes of compressor oper-

ation by the appearance of slow-moving bubbles

(vapor) or a broken column of refrigerant under the

glass. Continuous bubbles may appear in a properly

charged system on a cool day. This is a normal situa-

tion. If the sight, glass is generally clear and perform-

ance is satisfactory, occasional bubbles do not

indicate refrigerant shortage.

If the sight glass consistently shows foaming or a

broken liquid column, it should be observed after

partially blocking the air to the condenser. If under

this condition the sight glass clears and the perform-

ance is otherwise satisfactory, the charge shall be

considered adequate.

Page 549 of 625

98.40 1973 OPEL SERVICE MANUAL

2. Interconnect manifold and gage set (J-5725-01),

gage charging lines (J-5418) and gage adapters

(J-5420) to air conditioning system as shown in Figure

9B-40.3. Place transmission in “Park” for automatics and

in neutral for manuals. Apply hand brake.

4. Turn blower switch to the “Hi” position.

5. Turn temperature switch to “Max” position.

6. Run engine at 2000 RPM for ten (10) minutes with

car doors and windows closed and the hood up. Place

a high volume industrial type fan in front of radiator

if head pressure should exceed 250 psi and also at

high ambients to bring the pressures to within the

limits specified in the Functional Charts in Division

V.In the case of the Opel 1900 and the Manta, a ther-

mometer should be placed in a position to read the

temperature of the air discharging from the right-

hand A/C outlet. In case of the GT, a thermometer

should be placed in a position to read the tempera-

ture of the air discharging from the left-rear A/C

outlet.

HEATER-AIR CONDITIONER REFRIGERANT

CIRCUIT TROUBLE DIAGNOSIS GUIDE

Insufficient Cooling (Check Air Flow)

Normal Air Flow (Inspect system for visual defects.

Run functional tests.)

Discharge Air

- Normal Temp Check for air leaks

through dash, car body, windows, or from heater or

ventilators.

Discharge Air

- High Temp Check sight glass for

foaming and compressor clutch for engagement.

No Compressor Clutch Engagement Check connec-

tions at clutch switch, harness connectors, and check

clutch switch.

No Foaming Compare evaporator pressure to that

on functional test table.

Foaming System is probably low on refrigerant.

Check for leaks, repair, evacuate, and charge. If

foaming still occurs, check for restriction in refriger-

ant lines between condenser and receiver dehydrator.

Evaporator Pressure Normal Compare head pres-

sure to pressure on functional test table.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-dition

,for approximately 15-30 min.utes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

Plugged inlet screen in the expansion valve; 2)

Broken capillary line; or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.

Evaporator Pressure High Check the expansion

valve to determine if themobulb is making good con-

tact and is properly insulated. Operate engine at 2000

RPM with maximum air conditioning setting. If

evaporator pressure remains high, feel suction line.

If line feels frosty or extremely

(cold with relative

high ambient conditions, then partially cover the

condenser to obtain head pressures from 265 psi to

280 psi maximum. If evaporator pressure rises above

30 psi, change the expansion valve.

Also, check if compressor may be the cause due to

some internal or external mechanical trouble which

prevents reduction of pressure. Check for external

troubles, slipping belt, bad clutch and/or pulley, or

improper clutch engagement, before investigating

the compressor internally.

Head Pressure High Check for the following: Con-

denser air flow low, air in system, excessive refriger-

ant in system, restriction in condenser.Head.PressureLowRestriction in flow of refrigerant

to evaporator, or expansion valve plugged or defec-

tive.

Low Air Flow (Check blower operation and

evaporator. Check operation of controls.)

Ice BIocking Evaporator Run functional test. If

evaporator pressure is low, ice may form on evapora-

tor and reduce air flow.

Evaporator Pressure Low Ice may be forming on

evaporator. Low volume of air discharging at A/C

outlet after system has been running above idle con-

dition for approximately 15-30 minutes. Discharging

air gradually elevating in temperature. Check expan-

sion valve. If valve isn’t permitting flow of liquid,

this will be indicated by a warm pipe out of the

evaporator. This may be caused by: 1) Clogged or

plugged inlet screen in the expansion valve; 2)

Broken capillary line, or 3) Discharged temperature

bulb. If the valve is okay, the pipe out of the evapora-

tor will be cold.BlowerNot OperatingCheck for the following: Fuse

blown, blower switch defective, wire broken or loose

connection, poor ground connection, or blower mo-

tor defective.

Page 558 of 625

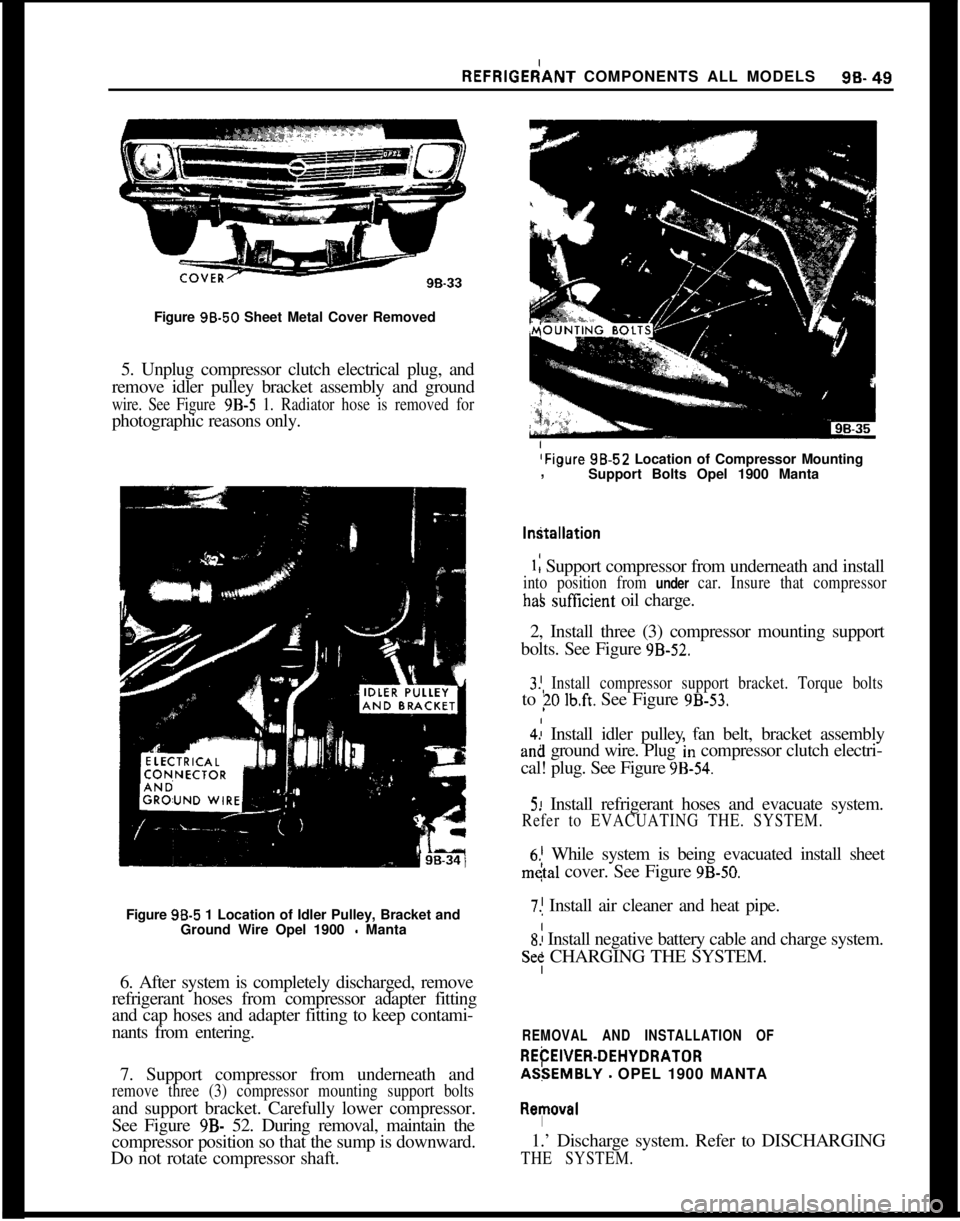

REFRlGEdANT COMPONENTS ALL MODELS96-49Figure 96.50 Sheet Metal Cover Removed

5. Unplug compressor clutch electrical plug, and

remove idler pulley bracket assembly and ground

wire. See Figure 9B-5 1. Radiator hose is removed forphotographic reasons only.

(Figure 98.52 Location of Compressor Mounting

,

Support Bolts Opel 1900 Manta

I

Figure 98-5 1 Location of Idler Pulley, Bracket and

Ground Wire Opel 1900

- Manta

6. After system is completely discharged, remove

refrigerant hoses from compressor adapter fitting

and cap hoses and adapter fitting to keep contami-

nants from entering.

7. Support compressor from underneath and

remove three (3) compressor mounting support boltsand support bracket. Carefully lower compressor.

See Figure

9B- 52. During removal, maintain the

compressor position so that the sump is downward.

Do not rotate compressor shaft.

1: Support compressor from underneath and install

into position from under car. Insure that compressor

haS sutXcient oil charge.

2, Install three (3) compressor mounting support

bolts. See Figure

9B-52.I

3! Install compressor support bracket. Torque boltsto

?O lb.ft. See Figure 9B-53.

4.: Install idler pulley fan belt, bracket assemblyan8 ground wire. Plug

‘In compressor clutch electri-

cal! plug. See Figure

9B-54.

5! Install refrigerant hoses and evacuate system.

Refer to EVACUATING THE. SYSTEM.

6.’ While system is being evacuated install sheet

m&l cover. See Figure 9B-50.

7.1 Install air cleaner and heat pipe.

S! Install negative battery cable and charge system.

Se: CHARGING THE SYSTEM.

REMOVAL AND INSTALLATION OF

REtiEWEFt-DEHYDRATORAS:EMBLY

- OPEL 1900 MANTA

I

R~l!lOV~lI1.’ Discharge system. Refer to DISCHARGING

THE SYSTEM.

Page 567 of 625

98-58 1973 OPEL SERVICE MANUAL

2. Discharge system. Refer to DISCHARGING

SYSTEM.

3. While system is discharging remove air cleaner

and loosen idler pulley and bracket assembly. See

Figure 98-80.

4. Remove bolt holding compressor adapter fitting

into rear head. Disengage from compressor and tape

closed openings in both lines and ports in rear head.

It is important to seal compressor ports to avoid a

loss of refrigeration oil and also to prevent foreign

material and moisture from entering compressor. See

Figure 9B-82.

5. Remove bolt and ground wire, unplug electrical

connector, and remove 2 rear compressor mounting

bolts. See Figure 98-82.

6. Remove 2 front compressor mounting bolts,

clutch drive belt, and lift out compressor. During

removal, maintain the compressor position so that

the sump is downward. Do not’rotate compressor

shaft. See Figure 9B-84.

Installation1. Install compressor into mounting brackets and

secure with 4 mounting bolts. See Figure

9B-84.2. Untape lines and ports, and install compressor

adapter fitting and bolt using new o-rings. See Figure

9B-82.3. Evacuate system. Refer to, EVACUATING

SYSTEM.

4. While system is being evacuated, install drive belt

and tighten idler pulley. See Figure

9B-80.5. Install bolt and ground wire and plug in electrical

connector. See Figure

9B-83.6. Install air cleaner and negative battery cable.

7. Charge system. Refer to, CHARGING SYS-

TEM.

REMOVAL AND INSTALLATION OF

RECEIVER.DEHYDRATOR

ASSEMBLY. GT

Removal1. Discharge system. Refer to DISCHARGING

SYSTEM.

2. Disconnect refrigerant lines to both ends of re-

ceiver-dehydrator and tape closed open ends of

re-

9862Figure 98.85 Refrigeration Hose Clamps Installation

GT

frigerant lines, and also the open

e:nds of the inlet and

outlet pipes of the receiver-dehydrator. See Figure

9B-86.Figure 98.86 Receiver-Dehydrator GT

3. Remove 2 screws securing receiver-dehydrator

and clamps to support bracket and lift out receiver

dehydrator. See Figure

9B-86.

Installation1. Install receiver-dehydrator using new o-rings

during installation. Lubricate o-rings prior to instal-

lation using No. 525 viscosity oil.

.