change wheel OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 17 of 625

IoC-91973 OPEL SERVICE MANUAL

Figure OC-5 Brake Master Cylinder

I

Figure OC-6 Tire Rotation Methods

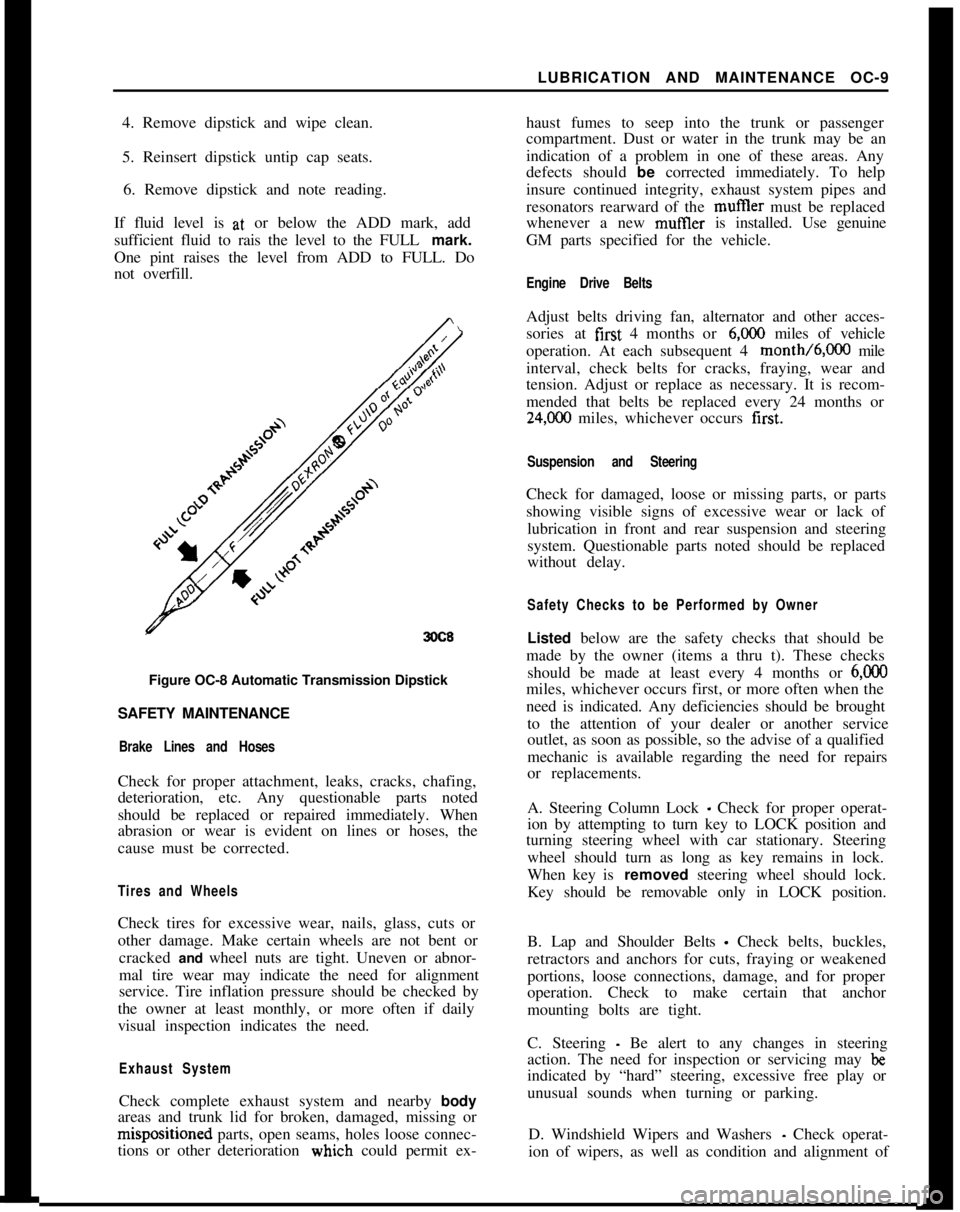

when the clutch pedal has in excess of 1

l/4 inch fr&

travel. See Figure OC-7.

Rear Axle

Change lubricant every

12,ooO miies when vehicle is

used for pulling a trailer.

Cooling SystemCheck at 12-month or

12,000~mile intervals, wash

radiator cap and filler neck with clean water, pres-

sure test system and radiator cap for proper pressure

holding capacity (tighten hose clamps and inspect

condition of all cooling and heater hoses). Replace

hoses every 24 months or 24,000 ,miles or earlier :if

checked, swollen or otherwise deteriorated.

Also each 12 months or

12,ooO miles, clean exteribr

of radiator core. Every 24 months or

24,OCO miles,Floor-Pan

-Clutch Pedal

Figure OC-7 GT Clutch Lash

drain, flush, and refill the cooline svstem with a new

coolant so&ion of permanent

6~; anti-freeze and

water for protection-of -20°F.

D-6 NOT REMOVE

RADIATOR CAP WHEN SOLUTION IS HOT

AND UNDER PRESSURE.

Wheel BearingsClean and repack front wheel bearings with a lubri-

cant as specified on the lubrication chart, Figure

oc-1.

Automatic Transmission FluidUnder normal driving conditions, change the trans-

mission fluid every 24,000 miles. Under unusual con-

ditions such as constant driving in heavy city traffic

during hot weather, trailer pulling, etc., this service

should be performed at

12,COO mile intervals.

General Motors DEXRON Automatic Transmis-

sion Fluid, which has been especially formulated and

tested for use in your automatic transmission, is

recommended. Other automatic transmission fluids

identified with the mark DEXRON are also recom-

mended.

Check the fluid level at each engine oil change

period. To make an accurate fluid level check:

1. Drive car several miles, making frequent starts and

stops, to bring transmission up to normal operating

temperature (approximately

180-190’F.)2. Park car on a level surface.

3. Place selector lever in “Park” and leave engine

running.

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

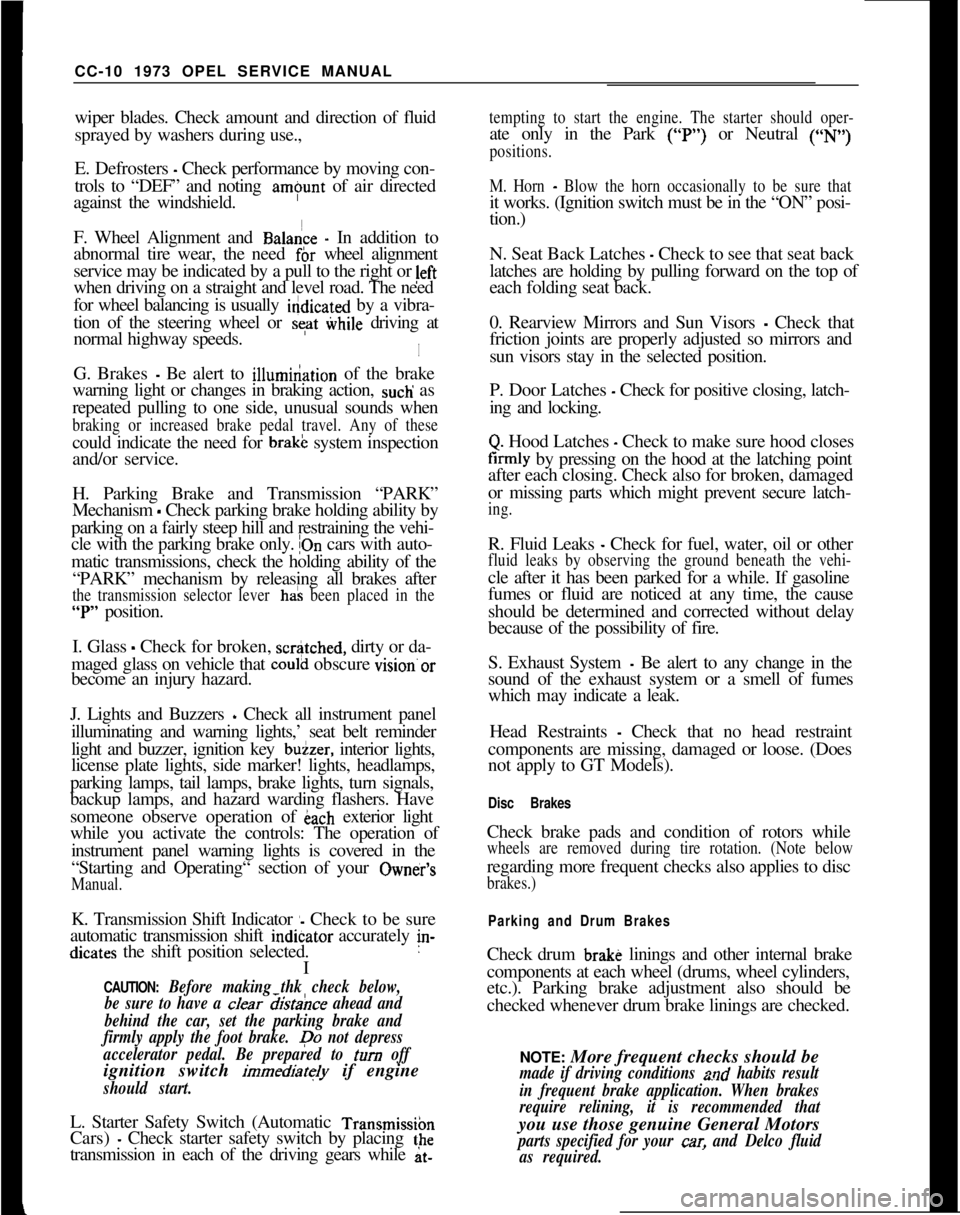

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 19 of 625

CC-10 1973 OPEL SERVICE MANUAL

wiper blades. Check amount and direction of fluid

sprayed by washers during use.,

E. Defrosters - Check performance by moving con-

trols to “DEF” and noting

am$nmt of air directed

against the windshield.

I

F. Wheel Alignment and

Balabce - In addition to

abnormal tire wear, the need fbr wheel alignment

service may be indicated by a pull to the right or

!eftwhen driving on a straight and level road. The need

for wheel balancing is usually

iddicated by a vibra-

tion of the steering wheel or

se;+ tihile driving at

normal highway speeds.I

IG. Brakes

- Be alert to illumiriation of the brake

warning light or changes in braking action,

SUCK as

repeated pulling to one side, unusual sounds when

braking or increased brake pedal travel. Any of thesecould indicate the need for

brakk system inspection

and/or service.

H. Parking Brake and Transmission “PARK”

Mechanism

- Check parking brake holding ability by

parking on a fairly steep hill and restraining the vehi-

cle with the parking brake only.

eon cars with auto-

matic transmissions, check the holding ability of the

“PARK” mechanism by releasing all brakes after

the transmission selector lever hak been placed in the“P” position.

I. Glass

- Check for broken, scrritched, dirty or da-

maged glass on vehicle that

coulld obscure vision’or

become an injury hazard.

J. Lights and Buzzers

- Check all instrument panel

illuminating and warning lights,’ seat belt reminder

light and buzzer, ignition key

b&er, interior lights,

license plate lights, side marker! lights, headlamps,

parking lamps, tail lamps, brake lights, turn signals,

backup lamps, and hazard warding flashers. Have

someone observe operation of

&ach exterior light

while you activate the controls: The operation of

instrument panel warning lights is covered in the

“Starting and Operating“ section of your

Own&%

Manual.K. Transmission Shift Indicator

‘- Check to be sure

automatic transmission shift

indiCator accurately i”-

dicates the shift position selected.

I

CAUTION: Before making thk check below,I

be sure to have a clear dist&e ahead and:

behind the car, set the parking brake and

firmly apply the foot brake.

Do not depress

accelerator pedal. Be prepared to

turn off ’

ignition switch

immediat+y if engine

should start.L. Starter Safety Switch (Automatic Transmissibn

Cars)

- Check starter safety switch by placing the

transmission in each of the driving gears while

at-tempting to start the engine. The starter should oper-ate only in the Park (“P”) or Neutral (“N”)

positions.

M. Horn

- Blow the horn occasionally to be sure thatit works. (Ignition switch must be in the “ON” posi-

tion.)

N. Seat Back Latches

- Check to see that seat back

latches are holding by pulling forward on the top of

each folding seat back.

0. Rearview Mirrors and Sun Visors

- Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

P. Door Latches

- Check for positive closing, latch-

ing and locking.

Q. Hood Latches - Check to make sure hood closesfirmly by pressing on the hood at the latching point

after each closing. Check also for broken, damaged

or missing parts which might prevent secure latch-

ing.R. Fluid Leaks

- Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the vehi-cle after it has been parked for a while. If gasoline

fumes or fluid are noticed at any time, the cause

should be determined and corrected without delay

because of the possibility of fire.

S. Exhaust System

- Be alert to any change in the

sound of the exhaust system or a smell of fumes

which may indicate a leak.

Head Restraints

- Check that no head restraint

components are missing, damaged or loose. (Does

not apply to GT Models).

Disc BrakesCheck brake pads and condition of rotors while

wheels are removed during tire rotation. (Note belowregarding more frequent checks also applies to disc

brakes.)

Parking and Drum BrakesCheck drum

brake linings and other internal brake

components at each wheel (drums, wheel cylinders,

etc.). Parking brake adjustment also should be

checked whenever drum brake linings are checked.

NOTE: More frequent checks should be

made if driving conditions a.nd habits result

in frequent brake application. When brakes

require relining, it is recommended thatyou use those genuine General Motors

parts specified for your car,and Delco fluid

as required.

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.

Page 75 of 625

lG- 54 1973 OPEL SERVICE’ MANtiAL/SIGNAL SYSTEMSCdNTENTS

9Subject

DESCRIPTION AND OPERAT!ON:

Directional Signal Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HazardWarning

Flasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BrakeSystemWarningLight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

SignalSystem,.......................

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUS,TMENTS:

MAJOR REPAIR:

Directional Signal Switch

:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HornRemoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing Horn Contact

. . . . :.............................................

SPECIFICATIONS:

FuseChart. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 G-54

1 G-54

1 G-55

lG-55 _1 G-55

1 G-55

16-551 G-55

1 G-56

DESCRIPTION AND OPERATION

DIRECTIONAL SIGNAL LEVERThe direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal,

and high and low beams. See Figure

lG-1.301Gl

Figure lG-1 Directional Signal Position for Headlamp

OperationThe direction signal lever is provided with a

two-step mechanism for operation of headlight high and

low beams, and passing signal (not in New Jersey).

With headlights off, moving the lever repeatedly to-

wards steering wheel flashes headlights as a passing

signal. With headlights on, moving the lever repeat-

edly towards steering wheel up to first stop also

flashes passing signal regardless whether or not the

direcl:ion signals are switched on. When the lever is

moved up to the second stop, the headlights are

changed from high to low beam

dr vice versa. On all

Rallye cars, when switching from low to high beam

position, with the fog lamp instrument panel switch

“ON” and ignition switch in “RUN” position, the

fog lights are automatically

switChed off. Direction

signals work in the normal manner; pushing the lever

up for right turn signal and pulling the lever down

for left turn signal.

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing

down on the ends of both spokes on Opel 1900 andManta’s or on the center horn button on the Rallye.

The button is provided with a spring-loaded plunger.See Figure

lG-2.

Page 176 of 625

FRONT SUSPENSION3A- 9

8. Press ball stud out of lower control arm.Removal Opel 1900 - MantaBefore raising vehicle, install Hooks J-23697 on re-

spective vehicle side to cross member and upper con-

trol arm. See Figure 3A-7.

1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. At the lower control arm ball joint, remove castle

nut cotter pin and slacken back nut so that the thread

can no longer be damaged.

4. With a suitable drift, detach ball joint from steer-

ing knuckle. With jack, lift up lower control arm,

unscrew castle nut and remove Hooks J-23697.

5. Unscrew upper control arm ball joint and suspend

front wheel hub and brake caliper in wheel house. Do

not turn upper control arm ball joint flange, as this

would result in a change of camber.

6. Remove defective lower control arm ball joint

using Tools J-9519 and Receiver J-23754.

Installation GT

CAUTION:

Fasteners are important attachingparts in

that they could affect the performance of

vitaI com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be replaced with one of

the same part

numer or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.1. When pressing the ball joint in place, make certain

the locating notch in the lower rim of the ball joint

matches the alignment reference mark placed on the

lower control arm prior to removal. The notch in the

ball joint bottom plate, identifying the direction of

the elongated slot, must point towards the brake

drum backing plate. See Figure

3A-17. Alignment

must be within 2 degrees of lower control arm center-

line. If proper positioning of the ball joint is not

accomplished, the result is a limitation of the neces-

sary ball stud movement. If ball stud movement is

limited, an interference between the ball stud and

housing is created, and binding or even fracture may

occur. Replacement ball joints may or may not have

marking notch as shown in Figure

3A-20. If it does

not have a marking notch, the joint is completelysymetrical and may be installed in any position.

When pressing in ball joint do not press on bottom

plate, but on ball joint housing only.2. Install dust cap on lower ball joint and fill with

chassis lubricant. Attach dust cap retainer.

3. Press ball joint into steering knuckle. Use

J-9519-3 as installer and J-21690 as a supporting

sleeve.4. Install castle nut on ball joint stud and torque to

40

Ib.ft. Install new cotter pin.

5. Reconnect shock absorber to lower control arm

and torque to 30 lb.ft.

6. Remove spring compressor.

7. Install front wheel, and lower the car.

8. Always check caster and camber after ball joint

replacement.

Installation Opel 1900 - Manta

CAUTION:

Fasteners are important attachingparts in

that they could

aff’ect the performance of vital com-

ponents and systems, and/or could result in

ma&r

repair expense. They must be

rep/aced with one of

the same part number or with equivalent parts, if

rep/acement becomes necessary. Do not use a re-

p/acement part of lesser quality or substitute design.

Torque valves must be used as

specitied during reas-

sembIy to assure proper retention of these parts.1. Drive new ball joint into lower control arm using

Tools J-9519 as installer and J-23755 as a supporting

sleeve. Do not strike onto ball joint bottom.

The ball joint is maintenance-free. It is supplied as an

assembly only and cannot be disassembled further.

2. On new lower control arm ball joint, make sure

that the marking groove in the housing bottom in

alignment with the axis of the lower control arm.

Permissible deviation: minus 2 degrees to plus 2 de-

grees.This is required, to obtain the maximum freedom of

movement of the ball stud in the housing. See Figure

3A-18.3. Attach steering knuckle together with front wheel

hub and brake caliper to lower control arm ball joint.

Torque castle nut to 54

ft.lbs.4. Attach ball joint to upper control arm and torque

to 29

ft.lbs. Always use new self-locking nuts.

5. Install wheel and tighten nuts to a torque of 65

ft.lbs.6. Lower car and check caster and camber.

Page 177 of 625

3A- 101973 OPEL SERVICE MANUAL

Figure 3A-18 Lower Ball Joint Notch Opel 1900 -

MantaUPPER CONTROL ARM REMOVAL AND

INSTALLATION

Removal GT1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. Install spring compressor and compress spring

until there is 3-l/8” between compressor and lower

spring leaf.

4. Remove cotter pin and castle nut from upper ball

joint stud. Discard cotter pin.

5. Use tie rod remover J-21687 remove ball jointfrom.steering knuckle. 6. Support brake drum to

relieve tension on brake hose.

7. Remove hex nut from upper control arm shaft.

Remove shaft and washers from shock absorber sup

port. Do not damage threads on control arm shaft.

8. Remove control arm from car. Do not lose inner

toothed washers. Note size and location of toothed

washers.Removal

Opel 1900 . Manta

1, Raise car and support at rear of front frame rails.

2. Remove front wheel

3. Unscrew upper control arm to cross member

self-locking attaching nut.4. Unscrew ball joint from upper control arm. Do not

turn upper control arm ball joint flange, as this

would result in a change of camber.

5. Support front wheel hub so that brake hose is not

stressed.6. Pull out upper control shaft to cross member at-

taching bolt and remove control arm. Shims have to

be reinstalled in their original location to maintain

the proper caster setting.

Installation GT

CAUTION:

Fasteners are important attaching parts in

that they could affect the the

perfonmmce of vital

components and systems, and/or could result in ma-

jor repair expense. They must be replaced with one

of the same part number or with an equivalent part

if replacement becomes necessary. Do not use a re-

placement part or lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to

assure proper retention of these parts.If rubber bushings on control arms are worn, arms

must be replaced.

1. Slide rubber rings over bushings. Slide rings over

inner sleeves of bushings. Place control arm in posi-

tion on shock absorber support, installing toothed

washers in their original positions. See Figure 3A-

19.2. From front to rear, install control arm shaft. If

necessary, align washers and control arm bushings

with a small drift prior to installing control arm

shaft. See Figure

3A-19.3. Tighten hex nut on control arm shaft finger tight.

4. Increase tension on spring compressor in order to

relieve tension on control arm shaft. Then torque hex

nut on control arm shaft to 33

Ib.ft.5. Press ball joint stud into steering knuckle and

torque castle nut to 29 lb.ft. Install new cotter pin.

6. Remove spring compressor and lower car.

7. Check front end alignment.

Installation Opel 1900. Manta

CAUTION:

Fasteners are important attaching parts in

that they could at?&

the performance of vital com-

ponents and systems, and/or

coo/d result in major

repair expense. They must be replaced with one of

the same part number or with equivalent parts, if

replacement becomes necessary. Do not use a

re-

Page 190 of 625

FRONT END ALIGNMENT 3C-23

ing geometry, the following checks and inspections

must be made to insure correctness of alignment

equipment readings and alignment adjustments.

1. The front tires should have approximately the

same wear and all tires must be inflated to specified

pressures (see Wheel and Tire Specifications

- Sec-

tion 3G).

2. Check front wheel bearings for looseness and ad-

just if necessary (see Front Suspension Adjustments

- Section 3A).

3. Check for run-out of wheels and tires, (see Section

3G).

4. Check wheels and tires for balance and correct if

out-of-balance (See Section 3G).

5. Check for looseness at ball joints and tie

rdd ends;

if found excessive, it must be

corxcted before align-

ment readings will have any value.

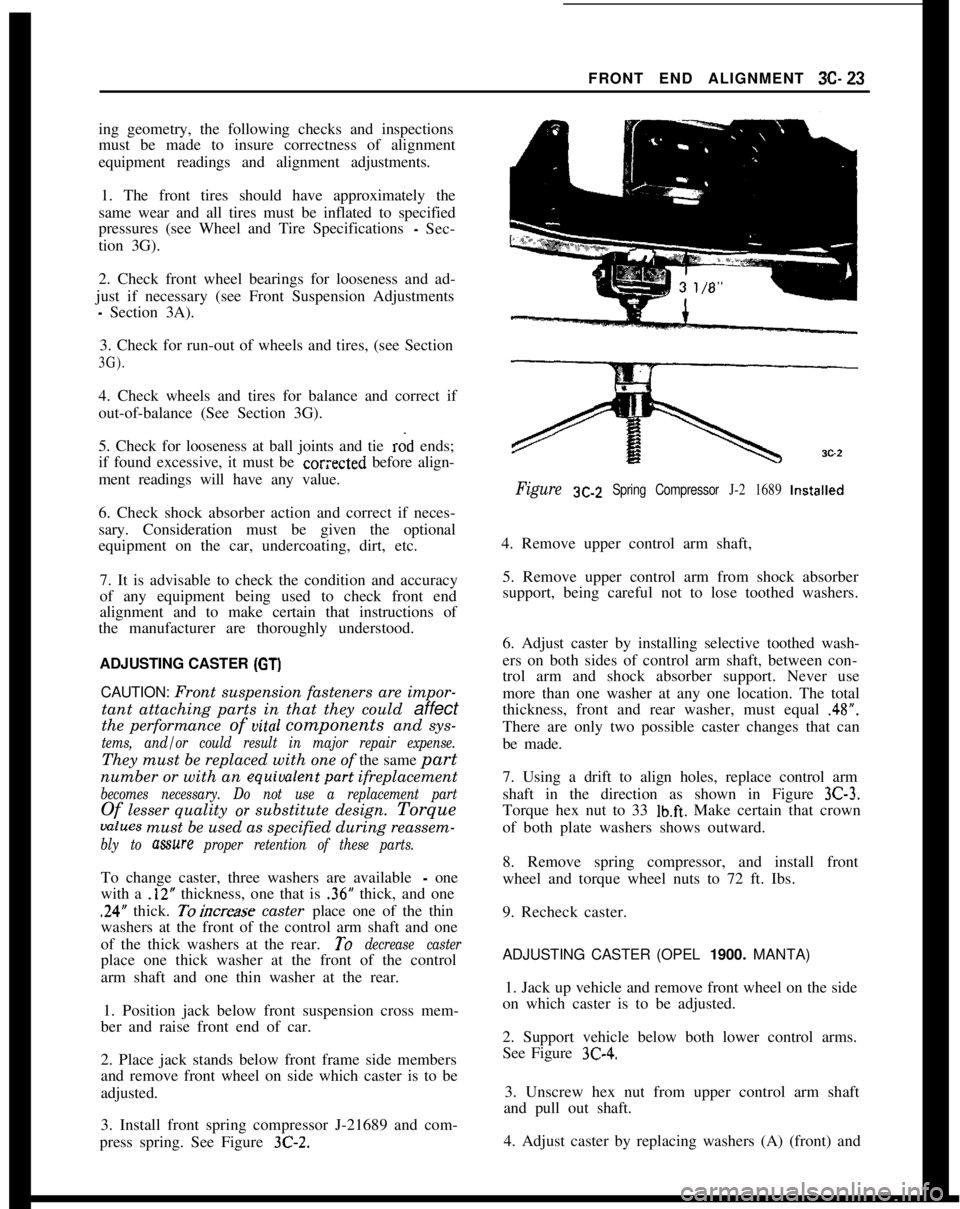

Figure SC-Z Spring Compressor J-2 1689 Installed

6. Check shock absorber action and correct if neces-

sary. Consideration must be given the optional

equipment on the car, undercoating, dirt, etc.

7. It is advisable to check the condition and accuracy

of any equipment being used to check front end

alignment and to make certain that instructions of

the manufacturer are thoroughly understood.

ADJUSTING CASTER (GT)

4. Remove upper control arm shaft,

5. Remove upper control arm from shock absorber

support, being careful not to lose toothed washers.

6. Adjust caster by installing selective toothed wash-

ers on both sides of control arm shaft, between con-

trol arm and shock absorber support. Never use

CAUTION: Front suspension fasteners are impor- more than one washer at any one location. The total

tant attaching parts in that they could

affectthickness, front and rear washer, must equal .48”.

the performance of uital components and sys-

tems, and/or could result in major repair expense.

There are only two possible caster changes that can

be made.

They must be replaced with one of the same

part

number or with an equiualentpart ifreplacement

becomes necessary. Do not use a replacement part

Of lesser quality or substitute design. Torque

values must be used as specified during reassem-

bly to mure proper retention of these parts.

7. Using a drift to align holes, replace control arm

shaft in the direction as shown in Figure

3C-3.

Torque hex nut to 33 lb.ft. Make certain that crown

of both plate washers shows outward.

To change caster, three washers are available

- one

with a

.12” thickness, one that is .36” thick, and one

.24” thick. Toincrease caster place one of the thin

washers at the front of the control arm shaft and one

of the thick washers at the rear.

To decrease caster

place one thick washer at the front of the control

arm shaft and one thin washer at the rear.

1. Position jack below front suspension cross mem-

ber and raise front end of car. 8. Remove spring compressor, and install front

wheel and torque wheel nuts to 72 ft. Ibs.

9. Recheck caster.ADJUSTING CASTER (OPEL

1900. MANTA)

2. Place jack stands below front frame side members

and remove front wheel on side which caster is to be

adjusted. 1. Jack up vehicle and remove front wheel on the side

on which caster is to be adjusted.

3. Install front spring compressor J-21689 and com-

press spring. See Figure

3C-2.

2. Support vehicle below both lower control arms.

See Figure

3C-4.

3. Unscrew hex nut from upper control arm shaft

and pull out shaft.

4. Adjust caster by replacing washers (A) (front) and

Page 202 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY 3E.35

II

OPEL 1900 AND MANTA STEERING COLUMN

ASSEMBLY

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Description and Operation of Directional Signal

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description

andOperationofHorn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description of Steering Column Assembly

. . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

3E-353E-363E-36

Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Disassembly and Reassembly of Direction Signal

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering and

Ignition Lock Cylinder, and Electrical Switch

from Mast Jacket Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering

ColumnSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-363E-383E-393E-403E-41

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

DIRECTIONAL SIGNAL LEVERhigh to low beam or vice versa. On all

19M) Rallye

cars, when switching from low to high beam posi-

tion, with the fog lamp instrument panel switch ON

The direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal and

headlight high and low beams. See Figure

3E-2.The dire&M signal lever is provided with a two-

step mechanism for operation of headlight high and

low beams, and passing signal (not in N.J.). With

headlights off, moving the lever repeatedly towards

steering wheel flashes headlights as a passing signal.

With headlights on, moving the lever repeatedly to-

wards steering wheel up to first stop also flashes

passing signal regardless whether or not the direction

signals are switched on. When the lever is moved up

to the second stop, the headlights are changed from

SE.2Figure

3E-2 Directional Signal Lever Position for

Headlamp Operation

Page 227 of 625

36. 601973 OPEL SERVICE MANUAL

severe or careless driver. Rapid acceleration and de-celeration, severe application of brakes, taking turns

at excessive speed, high-speed driving, and striking

curbs or other obstructions which lead to misalign-

ment are driving habits which will shorten the life of

any tire.hiaintenance of proper inflation pressure and peri-

odic interchanging of tires to equalize wear are

within the control of the driver. Underinflation

raises the internal temperature of a tire greatly due

to the continual friction caused by the flexing of the

side walls. Tire squealing on turns is an indication of

underinflation or excessive speed on the turns. A

combination of underinflation, high road tempera-

tures, and high-speed driving will quickly ruin the

best tire made.

High speed on straight highways or expressways nor-

mally causes more rapid wear on the rear than on thefront tires, although cupping of front tires can result

if the tires are not periodically switched from wheel

to wheel. Driving turns and curves at too high a rate

of speed causes the front tires to wear much faster

than the rear tires.

An inspection of the tires, together with information

as to locality in which the car has been operated willusually indicate whether abnormal wear is due to the

operating conditions described above or to mechani-cal faults which should be corrected.

The various types of

abnormal tire wear and their

causes are described in the following paragraphs.

Shoulder or Underinflation Tread WearWhen a tire is underinflated, the side walls and

shoulders of the tread carry the load, while the centerof tread folds in or compresses due to the low inter-

nal air pressure. This action causes the shoulders to

take all of the driving and braking load, resulting in

much faster wear of shoulders than of the center of

tread. See Figure 3G-7. For maximum results in han-dling, riding and tire life, tire inflation pressures

should never be allowed to go below the specified

minimum pressure.

Continuous high-speed driving on curves, right and

left, may produce tread wear very similar to underin-flation wear and might very easily be mistaken for

such. Side thrust when rounding turns causes wear

on the sides of tire tread. In making a turn to the left,especially at high speeds, the outside shoulder of the

right tire and the inside shoulder of the left tire take

the side thrust and naturally receive the most wear.

The only possible correction is to advise slower

speeds on curves. Do not increase tire inflation pres-

sures beyond specified limits, as this will cause centeror over-inflation wear. See paragraph below.

Canter or Overinflation Tread Wear

Excessive wheel camber, either positive or negative,causes the tire to run at such an angle to the road

surface that one side of the tread wears much more

than the other. See Figure

3G-7.When tire inflation pressures are maintained within

the specified limits, the tire will make a full contact

across the entire width of tread, thereby distributing

the wear evenly over the total surface of the tread

area.

Cross or Toe Tread WearWhen the front wheels have an excessive amount of

either toe-in or toe-out, the tires are actually draggedsideways when they travel straight down the road

and cross wear or scraping action takes place rapidly

wearing away the tread of tires. This cross wear con-dition will usually produce a tapered or feathered

edge on the ribs of the tire tread. See Figure

3G-7.In most cases, this can be detected by rubbing the

hand across the tire tread.

If the tapered or feathered edges are on the inner

sides of the ribs on one of both sides, it indicates thatone or both tires have excessive toe-in, while the

same condition in the outer sides of ribs indicates

excessive toe-out. Usually, excessive toe-in causes

excessive tire wear on the outer edge of the right

front tire and toe-out causes tire wear on the inner

edge of the left front tire. See Section 3C for toe-in

correction.Cornering wear caused by high-speed driving on

curves (see following paragraph) sometimes has the

appearance of toe wear. Care must be used to distin-guish between these two types of wear so that the

proper corrective measures will be used.

Side or Camber WearExcessive wheel camber, either positive or negative,

causes the tire to run at such an angle to the road

surface that one side of the tread wears much more

than the other. See Figure

3G-7.The amount or angle of the camber wear will be

governed by the amount of positive or negative cam-ber. Tire tread wear very similar in appearance to

camber wear may be caused by driving on turns at

excessive speeds. This “cornering” tread wear (see

paragraph below) cannot be corrected by change of

camber angle.

Adjustments for specified camber are covered in Sec-

tion 3C.