maintenance OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 5 of 625

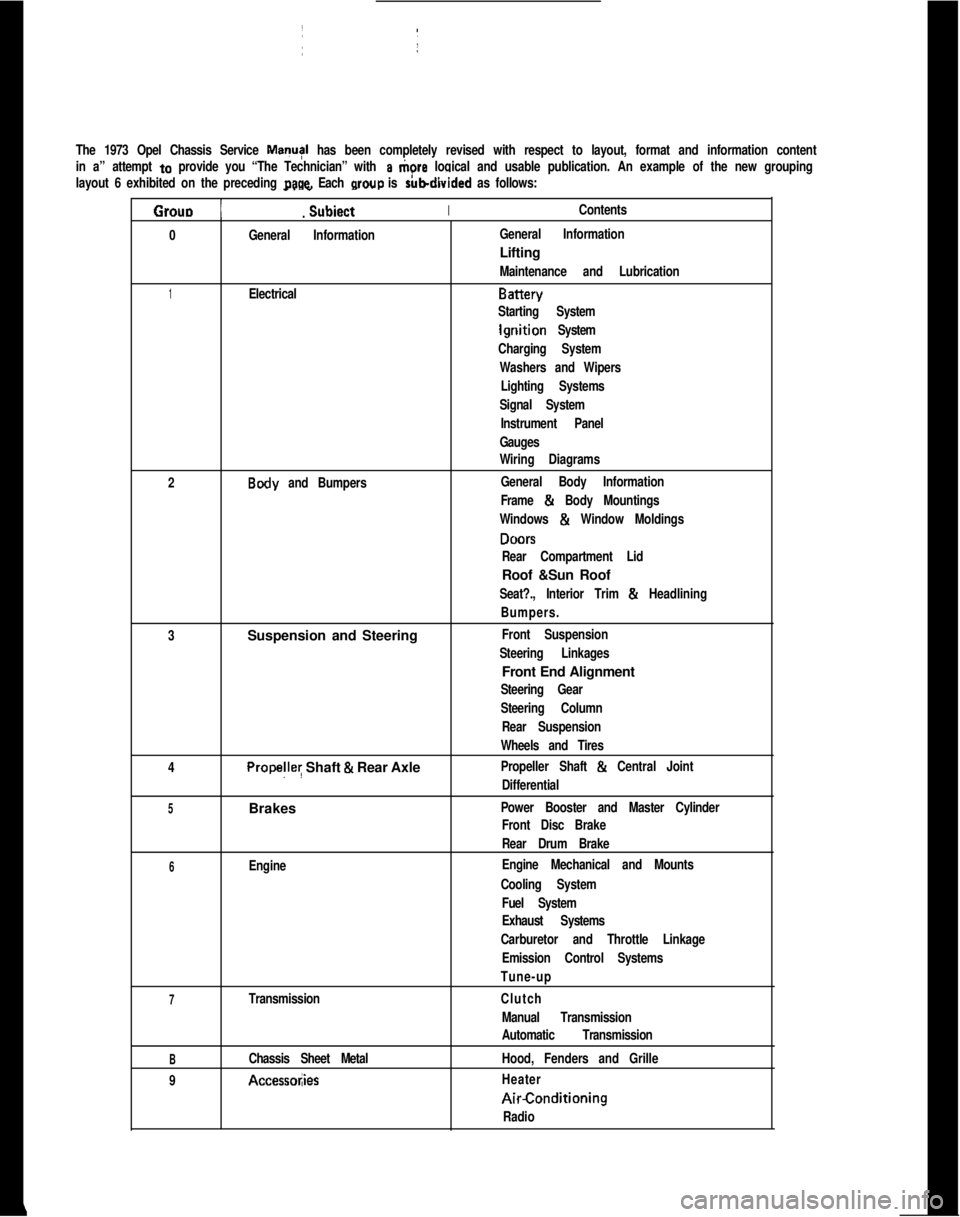

The 1973 Opel Chassis Service MayI has been completely revised with respect to layout, format and information content

in a” attempt

to provide you “The Technician” with a tiore logical and usable publication. An example of the new grouping

layout 6 exhibited on the preceding

page. Each wow is rubdivided as follows:

Grouo 1

_. _

Subiect IIContents.

0

General InformationIGeneral InformationLifting

Maintenance and Lubrication

1ElectricalBattery

Starting System

lgriition System

Charging System

Washers and Wipers

Lighting Systems

Signal SystemI

Instrument Panel

Gauges

Wiring Diagrams

2

Body and Bumpers:General Body InformationI

Frame & Body Mountings

Windows

& Window Moldings

DONS

Rear Compartment LidRoof &Sun Roof

Seat?., Interior Trim & Headlining

Bumpers.

3Suspension and Steering

Front Suspension

Steering Linkages1Front End Alignment

Steering Gear

Steering Column

Rear Suspension

Wheels and Tires

4

Propelley Shaft & Rear AxlePropeller Shaft & Central Joint

Differential

5Brakes ~Power Booster and Master Cylinder

Front Disc BrakeI

Rear Drum Brake

6EngineEngine Mechanical and Mounts

Cooling System

Fuel System

Exhaust Systems

Carburetor and Throttle Linkage

Emission Control Systems

Tune-up

7TransmissionClutch

Manual Transmission

Automatic Transmission

BChassis Sheet MetalHood, Fenders and Grille

9

Accessol;iesHeaterAirConditioning

Radio

Page 6 of 625

INTRODUCTION

The 1973 Opel Service Manual includes information on the Opel 1900,

Manta and GT. It is organized to correspond with current servicing tech-

niques. The various chassis components and systems have been classified

into the nine (9) GROUPS.Every GROUP contains one or more SECTIONS. Each SECTION deals with aspecific version of a component or system.

The service information included in a SECTION is divided into five (5) basic

DIVISIONS. The titles of each DIVISION are:

Description and Operation

Trouble Diagnosis

Maintenance and Adjustments

Major Repair

SpLificaiions

A DIVISION contains one or more PARAGRAPHS which can be identified bytheir specific headings.

SUB-PARAGRAPHS are used when necessary for clarity or to provide distinc-tion between component procedures.

SPECIAL TOOLS

References are made throughout the Manual to special tool numbers, desig-nated by the prefix letter “J”. These tools are manufactured by the

Kent-

Moore Corporation, Inc. If equivalent special tools are not available locally,they may be obtained through:

Kent-Moore Corporation, Inc.

28635 Mound Road

Warren, Michigan 46092LOCATING DESIRED INFORMATION

To locate any desired information, locate the proper GROUP listed on the

second page of the Manual. Bend the Manual until the black tab on the first

page of the GROUP can be seen in line with the GROUP title on the secondpage. The first page of the GROUP lists the SECTIONS contained therein.

Turn to the proper SECTION, locate the desired DIVISION and note the

PARAGRAPH containing the information you are seeking.

Page 8 of 625

GENERAL

INFORMATIONGROUP 0

SectionOA

OB

ocTitle

Page

General

InformationOA-1Vehicle Lifting

Points06-4Maintenance and Lubrication. OC-5

Page 14 of 625

LUBRICATION AND MAINTENANCE OC-5LUBRICATION AND MAINTENANCE

LOEngine Oil ,current “ISCOI-ifVl SE’

-u9 Lubriplate’,9F Hvdraulic Brake Fluid -Delco supreme NO. 11’

CAPAClTlESOPEL 1900Coding SystemMANTA GT

,OW,6 6

UU

3oclFigure OC-1 1973 Lubrication Chart

Page 15 of 625

CC-61973 OPEL SERVICE ‘MANUAL

LUBRICATION AND GENERAL MAINTENANCE

Every 4 months or 3,OW mile3~1*Engine OilEMISSION CONTROL MAINTENANCE

Every 24 months or31 1Engine Conpression

24,ooO~ 32heI cap, Tank and LinesEVsN

24.m milesI 33I Air Cleaner E,eme”tI

‘Alsa an Emision Control Servicel Also a Ssfarv Servicemc21Figure OC-2 1973 Maintenance Schedule

Page 16 of 625

LUBRICATION AND MAINTENANCE OC-7SERVICESLUBE AND GENERAL MAINTENANCE

Vehicle operation under conditions such as heavy

dust, continuous short trips, use of other than un-

leaded or low lead fuels or pulling trailers, is not

considered normal use and therefore more frequent

maintenance will be required. Such additional

maintenance requirements are included where appli-

cable.

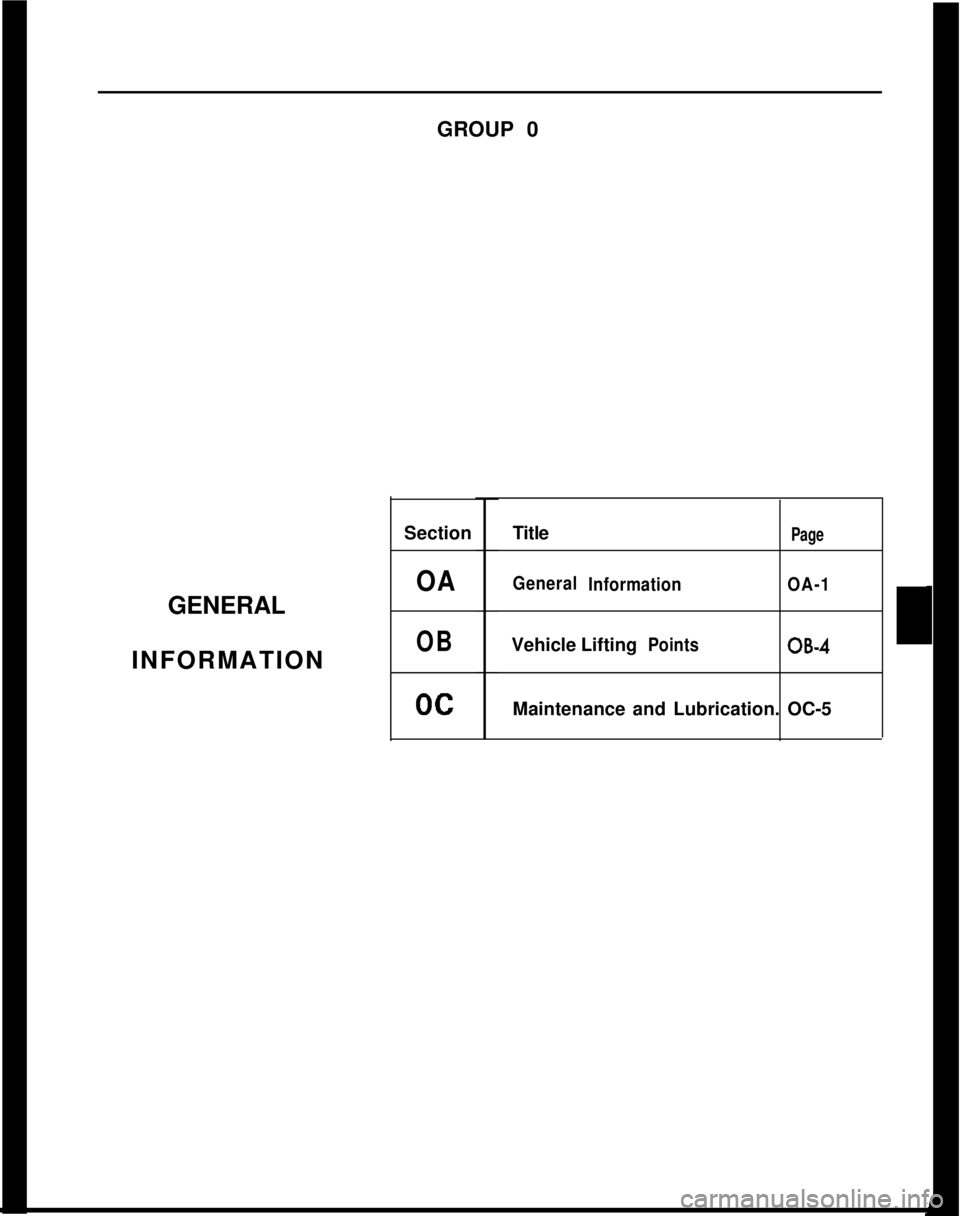

Engine OilChange each 4 months or

3,COO miles, whichever

occurs first, or each 2 months or

3,ooO miles when

the vehicle is operated under the following condi-

tions: (a) driving in dusty conditions, (b) trailer pull-

ing, (c) extensive idling or (d) short-trip operation at

freezing temperatures (with engine not thoroughly

warmed-up).Engine oils have a definite effect on ease of starting,

oil economy, combustion chamber deposits and en-

gine wear. It is recommended that a” oil which,

according to the label on the can is; (1) intended for

service SE and (2) passes car makers’ tests be used.

Oils confotming to these types contain detergent ad-

ditives. -

Select the proper oil viscosity from Figure OC-3.

Engine Oil FilterReplace at the first oil change and every other oil

change thereafter using Part No. 7965051 or equiva-

lent.

ChassisLubricate transmission shift linkage, hood latch and

parking brake cable guides and linkage.

Fluid LevelsCheck level of fluid in brake master cylinder, battery,

engine, axle, transmission and windshield washer.

Engine coolant also should be checked for proper

level and for corrosion and freeze protection to at

least -20°F or to the lowest temperature expected

during the period of vehicle operation. Proper engine

coolant also provides corrosion protection.

Any significant fluid loss in any of these systems or

units could mea” that a malfunction is developing

and corrective action should be taken immediately.

A low fluid level in the brake master cylinder front

reservoir could also be a” indtcator that the disc

brake pads need replacing.

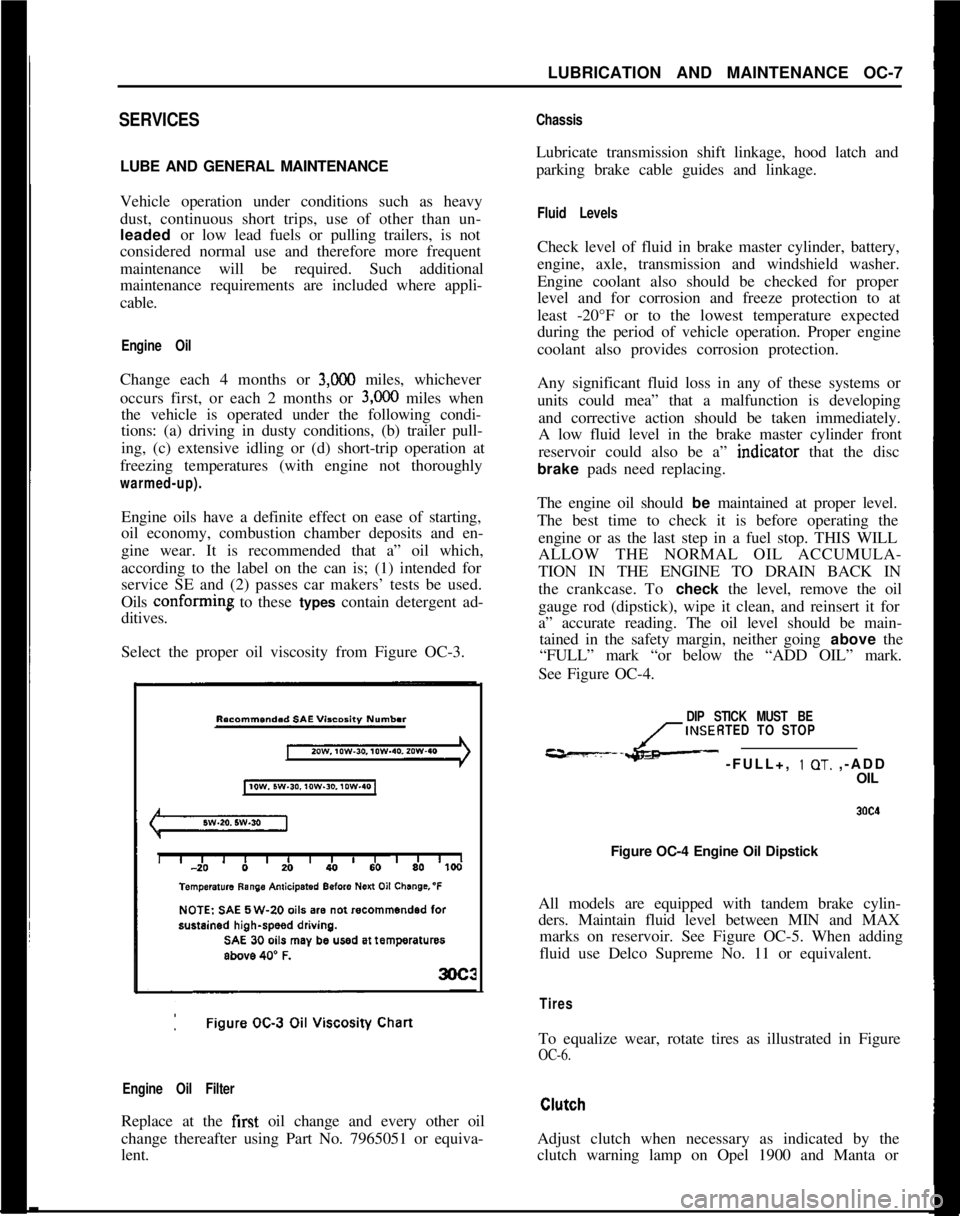

The engine oil should be maintained at proper level.

The best time to check it is before operating the

engine or as the last step in a fuel stop. THIS WILL

ALLOW THE NORMAL OIL ACCUMULA-

TION IN THE ENGINE TO DRAIN BACK IN

the crankcase. To check the level, remove the oil

gauge rod (dipstick), wipe it clean, and reinsert it for

a” accurate reading. The oil level should be main-

tained in the safety margin, neither going above the

“FULL” mark “or below the “ADD OIL” mark.

See Figure OC-4.

DIP STICK MUST BE

INSERTED TO STOP

---L- -FULL+, 1 OT. ,-ADD

OIL

Figure OC-4 Engine Oil Dipstick

All models are equipped with tandem brake cylin-

ders. Maintain fluid level between MIN and MAX

marks on reservoir. See Figure OC-5. When adding

fluid use Delco Supreme No. 11 or equivalent.

TiresTo equalize wear, rotate tires as illustrated in Figure

OC-6.Adjust clutch when necessary as indicated by the

clutch warning lamp on Opel 1900 and Manta or

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

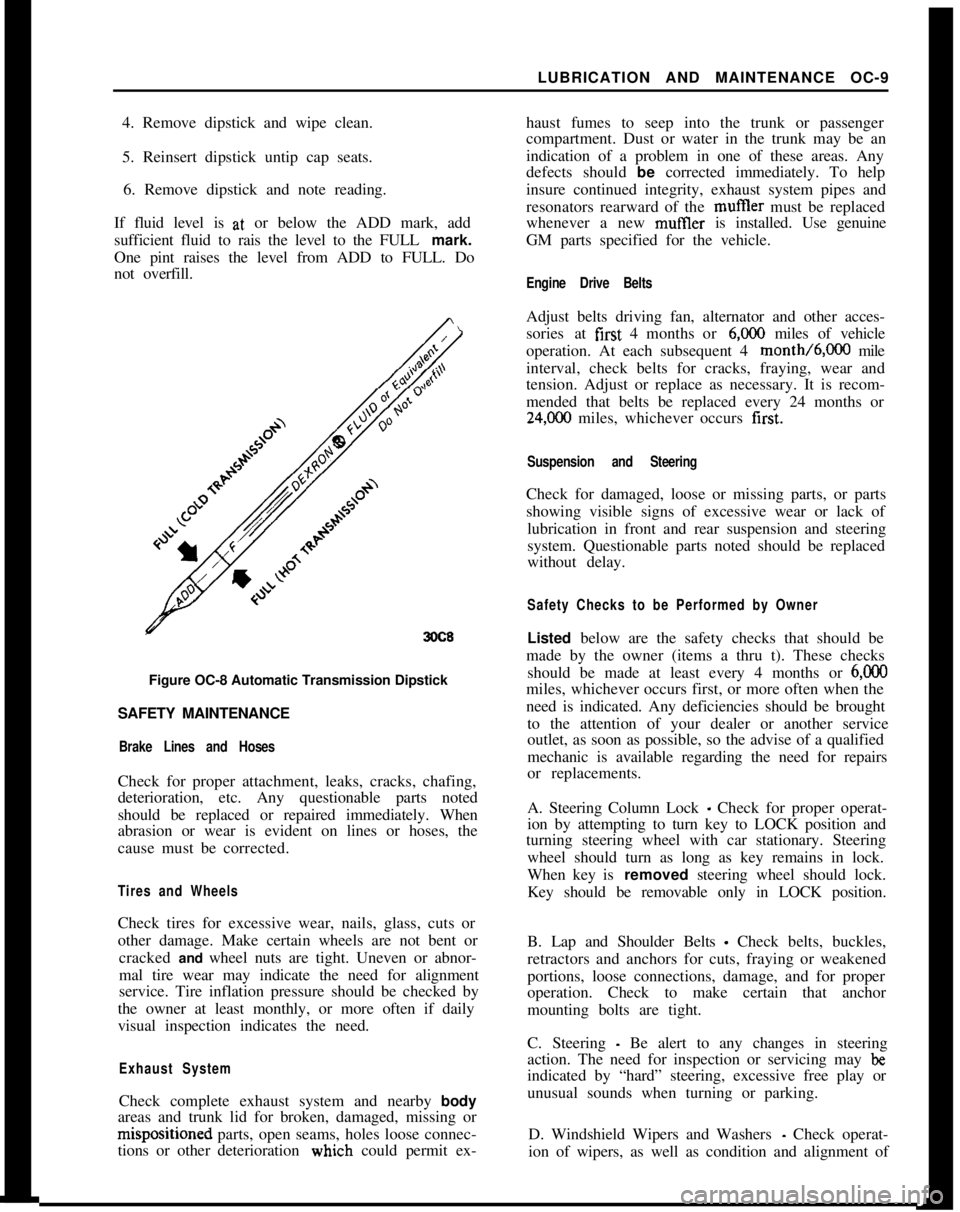

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 20 of 625

LUBRICATION AND MAINTENANCE OC-11

Throttle Linkage

Check for damaged or missing parts, interference or

binding. Any deficiencies should be corrected with-

out delay.

Headlights

Check for proper aim. Correct as necessary. More

frequent checks should be made if oncoming motor-

ists signal when you are already using your low

beams, or if illumination of the area ‘ahead seems

inadequate.

Underbody

In geographic areas using a heavy concentration of

road salt or other corrosive materials for snow re-

moval or road dust control, flush and inspect the

complete under side of the car at least once each

year, preferably after a winter’s exposure. Particular

attention should be given to cleaning out underbody

members where dirt and other foreign materials may

have collected.

EMISSION CONTROL MAINTENANCE

Thermostatically Controlled Air Cleaner

Inspect installation to make certain that all hoses and

ducts are connected and correctly installed. Also,

check valve for proper operation.

Carburetor Choke

Check choke mechanism for free operation. A bind-

ing condition may have developed from petroleum

gum formation on the choke shaft or from overtight-

ening of air cleaner clamp. Also check electric choke

terminal connections and fuse.

Timing, Dwell and Distributor

Adjust timing and dwell accurately as outlined under

Tune-Up in Group 6 at the first 4 months or 6,ooOmiles of operation, then at 12 month or

12,OQO mile

intervals. Adjustments must be made with test equip-

ment known to be accurate.

Replace distributor points every 12 months or 12,000

miles and carefully clean and inspect the complete

distributor cap to prevent misfiring and deteriora-

tion.

Carburetor and Idle

SpeedTorque carburetor attaching bolts and/or nuts to 12

ft.lbs. to compensate for compression of gasket atiirst 4 months or 6,000 miles of vehicle operation.Adjust idle speed to specifications with known accu-

rate equipment.

Proper functioning of the carburetor is particularly

essential to control of emissions. Correct mixtures

for emission compliance and idle quality have been

preset by Opel. Plastic idle mixture limiters have

been installed on the idle mixture screw, idle air

screw, and throttle stop screw to preclude unauthor-

ized adjustment. The plastic caps on the idle mixture

screw and the idle adjustment screw must be

removed to perform an idle speed adjustment. The

plastic cap on the throttle stop screw is not to be

removed unless some major carburetor repair or re-

placement which affects the throttle stop screw ad-

justment has been necessary.

Carburetor Fuel Inlet Filter

Replace filter at 12 month or

12,OCO mile intervals

or more often if clogged.

Spark Plugs

Replace at

6,ooO mile intervals when operating with

leaded fuels or at 12,000 mile intervals when using

unleaded fuels. Use of leaded fuels results in lead

deposits on spark plugs and can cause misfiring at

mileages less than

12,OilO miles. Where misfiring oc-

curs prior to

6,ooO miles, spark plugs in good condi-

tion can often be cleaned, tested and reinstalled in an

engine with acceptable results.

Spark Plug Wires

Inspect spark plug wires for evidence of checking or

cracking of exterior insulation and tight fit in the

distributor cap and at the spark plugs. Exterior of

wires should be cleaned, any evidence of corrosion

on ends removed and wire replace if deteriorated.

Positive Crankcase Ventilation System

The PCV metered orifice should be cleaned at 12,000

mile intervals under normal use, and at 6,000 mile

intervals when the vehicle is used under the follow-

ing conditions: driving in dusty conditions, extensive

idling, trailer pulling and short trip operation at

freezing temperatures (engine not thoroughly

warmed-up).

Evaporation Control System

Check all fuel and vapor lines and hoses for proper

connections and correct routing as well as condition.

Remove canister and check for cracks or damage.

Replace damaged or deteriorated parts as necessary.

Replace filter in open end of canister at 24month/24,000 mile intervals.

Page 21 of 625

!

OC-12 1973 OPEL SERVICE MANUAL iExhaust Gas Recirculation Systep

Check system operation at 12 &onth/12,000 mile

intervals. Clean valve and EGR &usages if required;

A valve with a damaged diaphragm must be re-

placed.I

Engine CompressionTest engine cranking compressi& If a problem

exists, correct it Minimum compression recorded;

many one cylinder should not be less that 70% ‘of

highest cylinder. For example, if fhe highest presstire

in any one cylinder is 150 pounds, the lowest

alloka-ble pressure for any other cylinder would be

l-05pounds (150

x 70% = 105).~

Fuel Cap, Fuel Lines and Fuel TankInspect the fuel tank, cap and lines for damage which

could cause leakage. Inspect fuel cap for correct seal-

ing ability and indications of physical damage. Re-

place any damaged or malfunctionining parts.

Air Cleaner ElementReplace the engine air cleaner element under normal

operating conditions every 24,000 miles. Operation

of vehicle in dusty areas will necessitate more fre-

quent element replacement.

CAUTION: Do not operate the engine with-

out the air cleaner unless temporary re-

moval is necessary during repair or

maintenance of the vehicle. When the aircIeaner is removed, backfiring can cause

fire in the engine compartment.

Page 23 of 625

lA- 21973 OPEL SERVICE MANUAL

BATER~ AND CABLES

ALL/ MODELS

C+NTENTIiSubject

DESCRIPTION AND OPERATION:

GeneralBatteryInformation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Battery and Cables

- Trouble Diagno:sis. . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

PeriodicBatteryInspectionandService. . . . . . . . . . . . . . . . . . . .421BatteryTest

. . . . . . . . . . . . ...! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydrometer Test of Batteiy

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FusibleLinks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BatteryRecharging

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Battery

RemovalandInstallation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FusibleLinksRemovalandInstallation. . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

BatterySpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 A-2

1 A-4

1 A-5

1 A-6

1 A-7lA-8

1 A-9

1 A-9

1 A-9

1 A-9

DESCRIPTION AND OPERATIONGENERAL BATTERY INFORMATION

Registration of BatteryUnited-Delco Battery dealers and distributors

$reprepared to carry out terms of the manufacturer’s

warranty on Delco-General batteries. In order that

Opel owners shall have the protection and benefit of

this warranty, it is necessary for the dealer or car

owner to register his battery with the local United-

Delco Battery dealer or distributor on all new car

deliveries, and on all deliveries of new replacement

Delco batteries. The Battery Owner’s Certificate is

located in the Owner’s Protection Plan Booklet..

Care of Wet Batteries in StorageBatteries in stored new cars, as well as batteries, in

stock, must be given regular attention to prevent

sulphation of plates that may result from inactivity

and self-discharge. All automotive wet batteries will

slowly discharge on standing idle, whether in stored

vehicles or in stock, and will self-discharge muchfaster when warm than when cold.

Batteriesin stock

should be rotated and the oIder ones used tirst.To minimize the extent of self-discharge always store

batteries fully charged and in a cool place where the

temperature does not go below freezing. Every 30

days check the level of electrolyte, add water as re-

quired and charge the batteries at a 5 ampere rate

until fully charged.

Batteries used for display purposes or standing in

cars in storage must be treated in the same manner

as batteries in stock.

When a new car, or a new replacement battery is

delivered, make certain that it is

fuIly charged and

the electrolyte is at

proper level.This is extremely

important because the delivery of a partially dis-

charged battery may not only lead to its return for

charging but may also result in shortened life of

battery.

Importance of Maintaining Electrolyte at PROPER

LevelWater is the only component of the battery which is