four wheel drive OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 225 of 625

3G- 581873 OPEL SERVICE MANUALTire Wear IrregularitiesAn additional cause of vibrations may sometimes be

tire wear irregularities. These can also produce noise

disturbances, and can be generally corrected by

rotating the tires, Figure

3G-6. Before proceeding

further, locate and correct the cause of the irregular

tire wear. See Figure

3G-7.Use the criss-cross method of rotation of tires only

when all four tires are equally worn. In some in-

stances, it may be necessary to put the truest running

assemblies (those with the lowest tolerances) on the

front of the car.

Wheel Nut Torque end Tightening SpecificationsDuring all wheel installations, it is important to use

the correct procedures for installing wheel nuts and

torquing them uniformly and in proper sequence.

This is important in order to avoid possible distor-

tion of the brake drum or disc, and to minimize

damage to lug and nut threads and wheel stud holes.

To assure uniform tightening of wheel lug nuts, the

following procedure is recommended:

1. Install wheel lug nuts in a criss-cross pattern and

tighten just enough to seat wheel against hub. This

assures proper piloting of the wheel on its hub.

2. Tighten lug nuts uniformly to proper torque of 65

Ib.ft. using criss-cross pattern.

An impact wrench should not be used, as uniform

torque control cannot be maintained.

Summary of Diagnosis end Correction of Tire and

Wheel Vibration1. Inflate all tires to recommended pressure and

road-test car with owner to define problem.

2. Spin front tire/wheel assemblies with wheel driv-

ing equipment. Rear wheels may be spun with tires

off the ground and with one wheel held at a time. The

offending tire may cause vibration that may be felt

by touching the bumper or fender. By process of

elimination, determine offending tire/wheel assem-

bly.

3. Check for tire/wheel unbalance. Balance, if neces-

sary.4. Check each tire/wheel assembly on the car for

radial runout on the tire tread. Wheel and tire assem-

blies exceeding

.050 inches may be considered as

offending assemblies. Offending tire/wheel assemblyshould be deflated and the tire repositioned (indexed)

180 degrees from original location.

5. After repositioning, rebalance tire/wheel assembly

(static and dynamic preferred).

6. Test drive and evaluate correction.

The following procedure should be used to determine

cause of roughness or vibration with car in operation

at various speeds:

I. Jack up all wheels having jack support rear end of

car at center of rear axle housing.

2. With transmission in “Drive”, run engine at vari-

ous car speeds to note speeds at which vibration or

roughness occurs.

3. Remove rear wheels and run engine again at the

critical speeds noted in step 2. If roughness is gone,

the condition is caused by unbalanced wheel and tire

assemblies.

4. If roughness still exists with rear wheels removed,

remove rear brake drums and repeat the running

test. Elimination of the roughness indicates out of

balance brake drums.

5. If roughness still exists with brake drums

removed, run engine with transmission in “Neutral”.

Elimination of the roughness indicates that propeller

shaft is out of balance. Continued roughness indi-

cates an out-of- balance engine.

ABNORMAL TIRE WEAR

General Operating ConditionsAssuming that there is no misalignment condition to

cause abnormal wear, the life of tires depends largely

upon car operation conditions and driving habits.

Tires wear at a much faster rate in some localities

than in others because of road and operating condi-

tions. Some types of roads are much more abrasive

than others. Tire wear is also dependent upon the

number of hills and mountains which the car must

go up and down, the severity of grades, the number

of starts and stops, driging speeds, the amount of rain

and snow, and prevailing temperatures. Tire

wear

increases rapidly with speed, temperature, and loadon tire. Tires used at low speeds, in cool climates, or

with light loads will have longer life than tires used

for high-speed driving in hot climates with heavy

loads.

Driving habits have a very important hearing on tire

life. A careful driver may obtain much greater mile-

age from a set of tires than would be obtained by a

Page 242 of 625

REAR AXLE40- 11

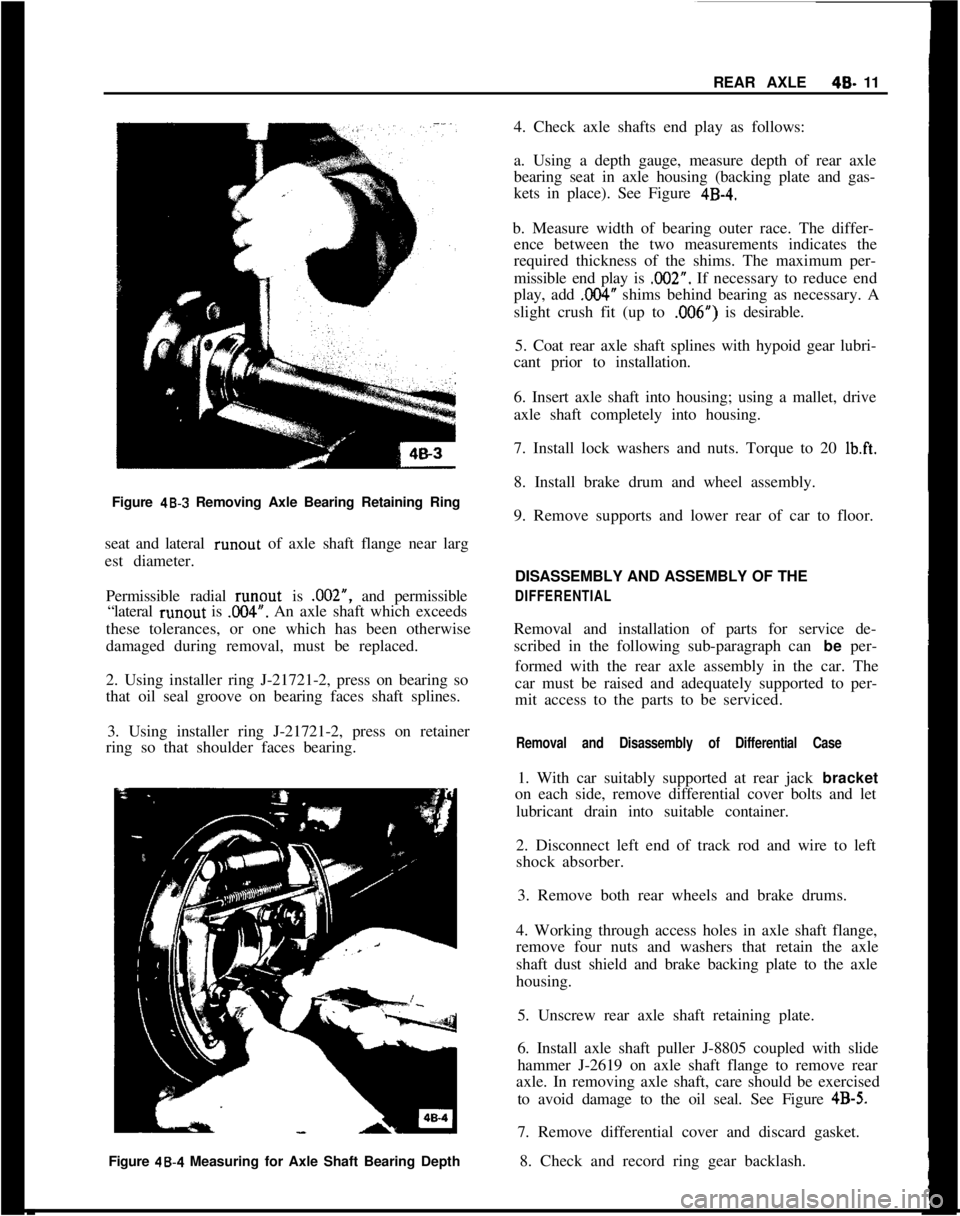

Figure

48-3 Removing Axle Bearing Retaining Ring

seat and lateral runout of axle shaft flange near larg

est diameter.

Permissible radial runout is .002”, and permissible

“lateral runout is

.OO4”. An axle shaft which exceeds

these tolerances, or one which has been otherwise

damaged during removal, must be replaced.

2. Using installer ring J-21721-2, press on bearing so

that oil seal groove on bearing faces shaft splines.

3. Using installer ring J-21721-2, press on retainer

ring so that shoulder faces bearing.

Figure 48.4 Measuring for Axle Shaft Bearing Depth4. Check axle shafts end play as follows:

a. Using a depth gauge, measure depth of rear axle

bearing seat in axle housing (backing plate and gas-

kets in place). See Figure

4B-4.b. Measure width of bearing outer race. The differ-

ence between the two measurements indicates the

required thickness of the shims. The maximum per-

missible end play is .002”. If necessary to reduce end

play, add

,004” shims behind bearing as necessary. A

slight crush fit (up to ,006”) is desirable.

5. Coat rear axle shaft splines with hypoid gear lubri-

cant prior to installation.

6. Insert axle shaft into housing; using a mallet, drive

axle shaft completely into housing.

7. Install lock washers and nuts. Torque to 20

Ib.ft.8. Install brake drum and wheel assembly.

9. Remove supports and lower rear of car to floor.

DISASSEMBLY AND ASSEMBLY OF THE

DIFFERENTIALRemoval and installation of parts for service de-

scribed in the following sub-paragraph can be per-

formed with the rear axle assembly in the car. The

car must be raised and adequately supported to per-

mit access to the parts to be serviced.

Removal and Disassembly of Differential Case1. With car suitably supported at rear jack bracket

on each side, remove differential cover bolts and let

lubricant drain into suitable container.

2. Disconnect left end of track rod and wire to left

shock absorber.

3. Remove both rear wheels and brake drums.

4. Working through access holes in axle shaft flange,

remove four nuts and washers that retain the axle

shaft dust shield and brake backing plate to the axle

housing.

5. Unscrew rear axle shaft retaining plate.

6. Install axle shaft puller J-8805 coupled with slide

hammer J-2619 on axle shaft flange to remove rear

axle. In removing axle shaft, care should be exercised

to avoid damage to the oil seal. See Figure

4B-5.7. Remove differential cover and discard gasket.

8. Check and record ring gear backlash.

Page 274 of 625

DISC BRAKES5B- 15

ConditionPossible Cause

2. Binding brake pedal

mechanism.Correction

2. Check and lubricate, ifnecessary.3. Corroded caliper

assembly.3. Clean and lubricate.

MAINTENANCE AND ADJUSTMENTSDISC BRAKE MAINTENANCE

Checking Brake Fluid Level

The brake fluid level in the brake fluid container

must be checked during predelivery inspection, then

every 3,000 miles during inspection and preventive

maintenance servicing.

The brake fluid level must not be higher than the

inscription “MAX” and must be at least up to

“MIN”. Replenish brake fluid, if necessary.

Because of the relatively large brake caliper bore

cross section and the self-adjustment of the disc

brakes, resulting in a greater piston travel to compen-

sate for friction pad wear, the brake fluid level drops

faster than in fluid containers for drum brakes with

their smaller wheel brake cylinders. For this reason

pay special attention to the fluid level in the brake

fluid container.

Drop of brake fluid level can be due to friction pad

wear and may not be due to leakage in the braking

system.On loss of brake fluid due to leakage, the brake sys-

tem must be checked thoroughly.

Friction Pad Adjustment

Friction pad adjustment is not necessary on the front

wheel disc brakes as this is done automatically by the

pistons in the brake calipers.

Lubricating Front Wheel Bearings

When removing one or both brake discs, check lu-

brication of front wheel bearings and the cavity of

the wheel hub and replenish if necessary (see operat-

ion

“Removing and Reinstalling Brake Disc”).

When carrying out other work on disc brakes which

does not necessitate the removal and installation of

the brake disc, lubricating wheel bearings is not

necessary.Checking Disc Brake Friction Pads for Wear

Whenever a disc brake equipped car is in for periodic

service, while the car is raised, the friction pads in

both brake calipers should be checked for wear by

making a simple measurement. Worn or oily friction

pads must be replaced.

Measure friction pad wear as follows:

1. Remove friction pads.

2. Using a one-inch micrometer, measure the thick-

ness of the pad and friction plate. See Figure

5B-23.Figure 58-23 Checking Brake Friction Pad Thickness

3. If any one of the four measurements is less than

-.280, replace all four friction pads. (Partial replace-

ment of friction pads would cause unequal braking.)

Removal and Installation of Friction Pads

1. Raise car and remove front wheels.

2. Drive dowel pins out of brake calipers toward

center of car. See Figure

5B-24. Dowel pins must be

driven inward because they are secured by enlarge

fluted inner ends.

3. Remove friction pads from brake calipers. See

Figure

5B-25.

Page 277 of 625

58-181973 OPEL SERVICE MANUAL

Figure 58.28 Brake Caliper

to Steering Knuckle

Attaching Bolts

wheel. Disconnect brake caliper with friction pads

from steering knuckle and support the assembly as

shown in Figure

5B-29.Figure 58.29 Supporting Brake Caliper

2. Remove front wheel hub and disc assembly along

with wheel bearings.

3. Mount brake disc and wheel hub between soft

metal jaws in vise.

Do not hold too tightly, to avoidbending whet-1 bolts. Remove four star head bolts

with lockwashers using Star Wrench Adapter

J-

21737.

Piior to removal, markposition ofbrake disc

in relation to wheel hub. See

Figure 5B-30.Figure 58.30 Removing Brake Disc

to Hub Bolts

4. Pull brake disc from wheel hub. Do not drive if off.

Install in reverse sequence, paying attention to the

following:

5. Prior to installation of the brake disc, ensure that

the contacting surface of brake disc to wheel hub is

free of burrs, dirt and high spots. If necessary,

remove high spots and check disc for flatness on a

surface plate. Carefully remove burrs with a scraper

or file.

6. Also check contacting surface of wheel hub to

brake disc to make sure it is in good condition. The

same applies to brake disc aligning shoulder on

wheel hub. See Figure

5B-315831

Figure

5B-31 Brake Disc to Hub Contact Surface

Page 367 of 625

7A- 61973 OPEL SERVICE MANUAL1. FIywheeI and Pressure PlateExamine friction surfaces of flywheel and pressure

plate for scoring or roughness. Slight roughness may

be smoothed with fine emery cloth, but if surface is

deeply scored or grooved the part should be re-

placed.

2.

CJutch Driven Plate

Inspect driven plate for condition of facings, loose

rivets, broken or very loose torsional springs.

If facings are worn down near rivets or are oily, the

plate assembly should be replaced. A very slight

amount of oil on clutch facings will cause clutch grab

and chatter. A large amount of oil on facings will

cause slippage. Removal of oil by solvents or by buff-

ing is not practical since oil will continue to bleed

from facing material when hot.

When oil is found on driven plate facings, examine

transmission drainback hole, pilot bushing, engine

rear main bearing and other points of possible oil

leakage.

Test the fit of driven plate hub on transmission main

drive gear for an easy sliding fit.

Regardless of whether the old plate or a new one is

to be installed, the plate should be checked for run-

out. Lateral run-out measured at disc circumference

should not exceed

.016 inch.

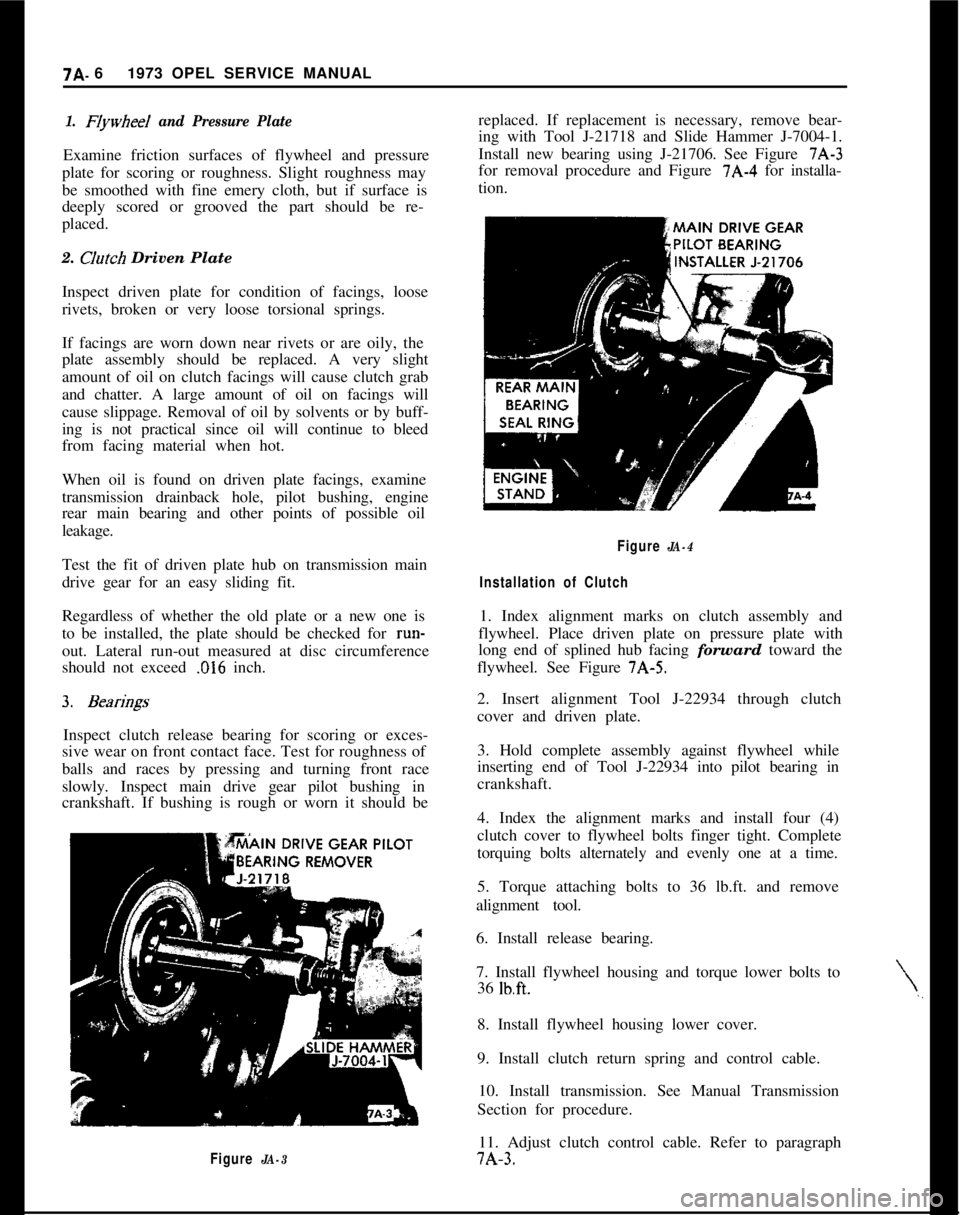

Inspect clutch release bearing for scoring or exces-

sive wear on front contact face. Test for roughness of

balls and races by pressing and turning front race

slowly. Inspect main drive gear pilot bushing in

crankshaft. If bushing is rough or worn it should be

Figure JA-3replaced. If replacement is necessary, remove bear-

ing with Tool J-21718 and Slide Hammer J-7004-1.

Install new bearing using J-21706. See Figure 7A-3

for removal procedure and Figure 7A-4 for installa-

tion.

\,,

Figure JA-4

Installation of Clutch1. Index alignment marks on clutch assembly and

flywheel. Place driven plate on pressure plate with

long end of splined hub facing forward toward the

flywheel. See Figure 7A-5.

2. Insert alignment Tool J-22934 through clutch

cover and driven plate.

3. Hold complete assembly against flywheel while

inserting end of Tool J-22934 into pilot bearing in

crankshaft.

4. Index the alignment marks and install four (4)

clutch cover to flywheel bolts finger tight. Complete

torquing bolts alternately and evenly one at a time.

5. Torque attaching bolts to 36 lb.ft. and remove

alignment tool.

6. Install release bearing.

7. Install flywheel housing and torque lower bolts to

36

lb.ft.8. Install flywheel housing lower cover.

9. Install clutch return spring and control cable.

10. Install transmission. See Manual Transmission

Section for procedure.

11. Adjust clutch control cable. Refer to paragraph7A-3.