radiator cap OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 17 of 625

IoC-91973 OPEL SERVICE MANUAL

Figure OC-5 Brake Master Cylinder

I

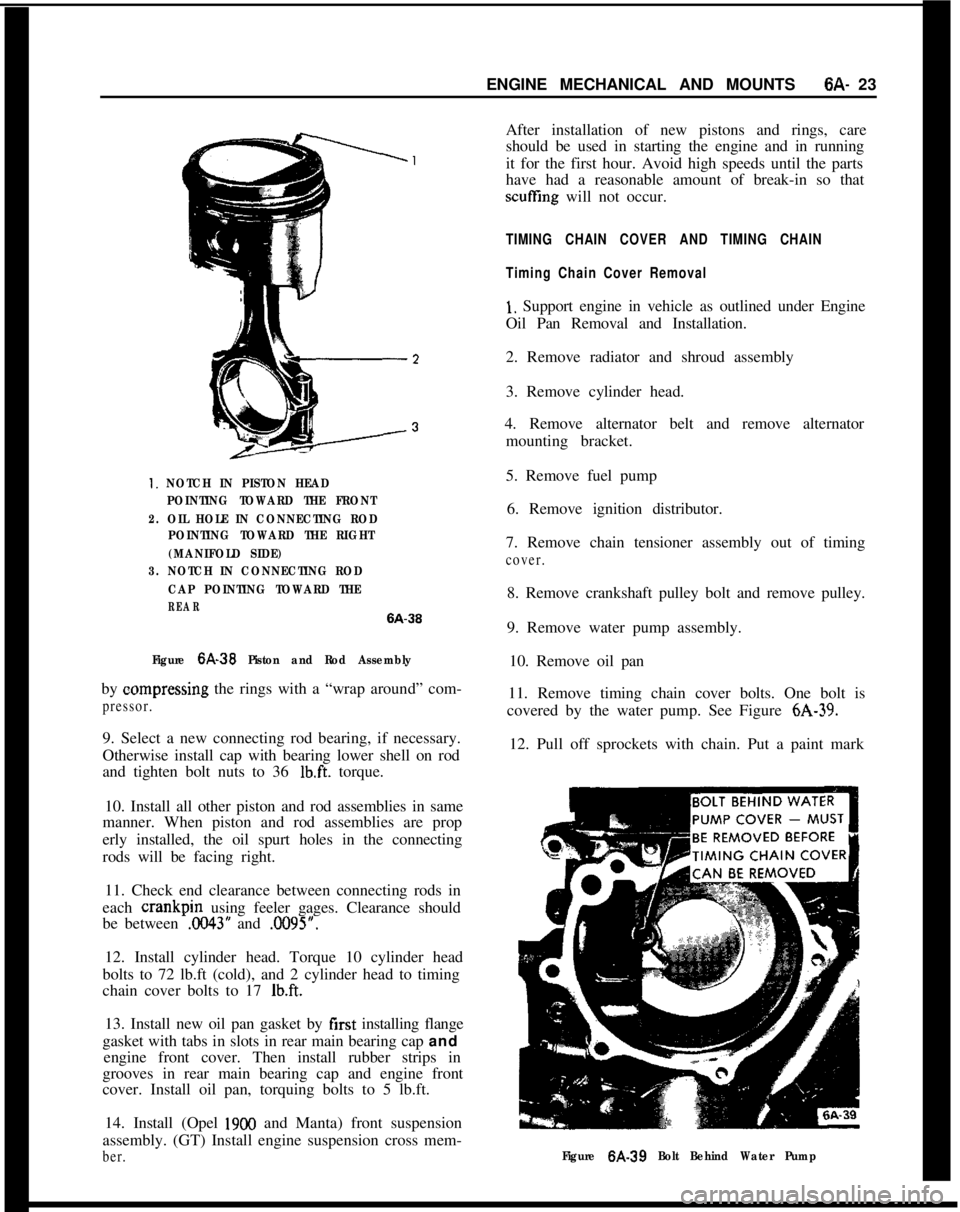

Figure OC-6 Tire Rotation Methods

when the clutch pedal has in excess of 1

l/4 inch fr&

travel. See Figure OC-7.

Rear Axle

Change lubricant every

12,ooO miies when vehicle is

used for pulling a trailer.

Cooling SystemCheck at 12-month or

12,000~mile intervals, wash

radiator cap and filler neck with clean water, pres-

sure test system and radiator cap for proper pressure

holding capacity (tighten hose clamps and inspect

condition of all cooling and heater hoses). Replace

hoses every 24 months or 24,000 ,miles or earlier :if

checked, swollen or otherwise deteriorated.

Also each 12 months or

12,ooO miles, clean exteribr

of radiator core. Every 24 months or

24,OCO miles,Floor-Pan

-Clutch Pedal

Figure OC-7 GT Clutch Lash

drain, flush, and refill the cooline svstem with a new

coolant so&ion of permanent

6~; anti-freeze and

water for protection-of -20°F.

D-6 NOT REMOVE

RADIATOR CAP WHEN SOLUTION IS HOT

AND UNDER PRESSURE.

Wheel BearingsClean and repack front wheel bearings with a lubri-

cant as specified on the lubrication chart, Figure

oc-1.

Automatic Transmission FluidUnder normal driving conditions, change the trans-

mission fluid every 24,000 miles. Under unusual con-

ditions such as constant driving in heavy city traffic

during hot weather, trailer pulling, etc., this service

should be performed at

12,COO mile intervals.

General Motors DEXRON Automatic Transmis-

sion Fluid, which has been especially formulated and

tested for use in your automatic transmission, is

recommended. Other automatic transmission fluids

identified with the mark DEXRON are also recom-

mended.

Check the fluid level at each engine oil change

period. To make an accurate fluid level check:

1. Drive car several miles, making frequent starts and

stops, to bring transmission up to normal operating

temperature (approximately

180-190’F.)2. Park car on a level surface.

3. Place selector lever in “Park” and leave engine

running.

Page 314 of 625

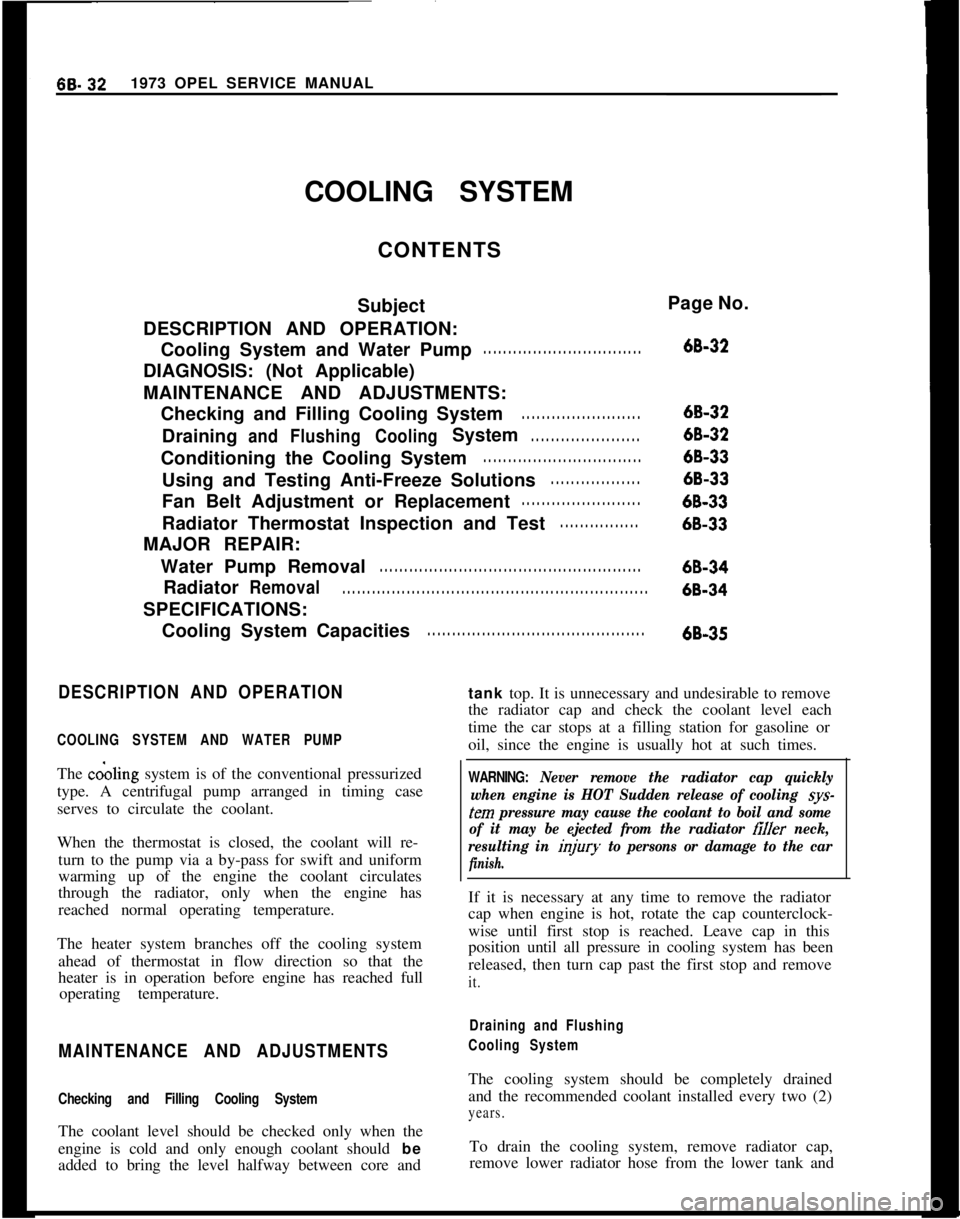

ENGINE MECHANICAL AND MOUNTS6A- 231. NOTCH IN PISTON HEAD

POINTING TOWARD THE FRONT

2. OIL HOLE IN CONNECTING ROD

POINTING TOWARD THE RIGHT

(MANIFOLD SIDE)

3. NOTCH IN CONNECTING ROD

CAP POINTING TOWARD THE

REAR6A-36

Figure

6A-39 Piston and Rod Assemblyby oompressing the rings with a “wrap around” com-

pressor.9. Select a new connecting rod bearing, if necessary.

Otherwise install cap with bearing lower shell on rod

and tighten bolt nuts to 36

lb.ft. torque.

10. Install all other piston and rod assemblies in same

manner. When piston and rod assemblies are prop

erly installed, the oil spurt holes in the connecting

rods will be facing right.

11. Check end clearance between connecting rods in

each crankpin using feeler gages. Clearance should

be between

.0043” and .0095”.

12. Install cylinder head. Torque 10 cylinder head

bolts to 72 lb.ft (cold), and 2 cylinder head to timing

chain cover bolts to 17

lb.ft.13. Install new oil pan gasket by first installing flange

gasket with tabs in slots in rear main bearing cap and

engine front cover. Then install rubber strips in

grooves in rear main bearing cap and engine front

cover. Install oil pan, torquing bolts to 5 lb.ft.

14. Install (Opel

1900 and Manta) front suspension

assembly. (GT) Install engine suspension cross mem-

ber.After installation of new pistons and rings, care

should be used in starting the engine and in running

it for the first hour. Avoid high speeds until the parts

have had a reasonable amount of break-in so that

scuffling will not occur.

TIMING CHAIN COVER AND TIMING CHAIN

Timing Chain Cover Removal

1, Support engine in vehicle as outlined under Engine

Oil Pan Removal and Installation.

2. Remove radiator and shroud assembly

3. Remove cylinder head.

4. Remove alternator belt and remove alternator

mounting bracket.

5. Remove fuel pump

6. Remove ignition distributor.

7. Remove chain tensioner assembly out of timing

cover.8. Remove crankshaft pulley bolt and remove pulley.

9. Remove water pump assembly.

10. Remove oil pan

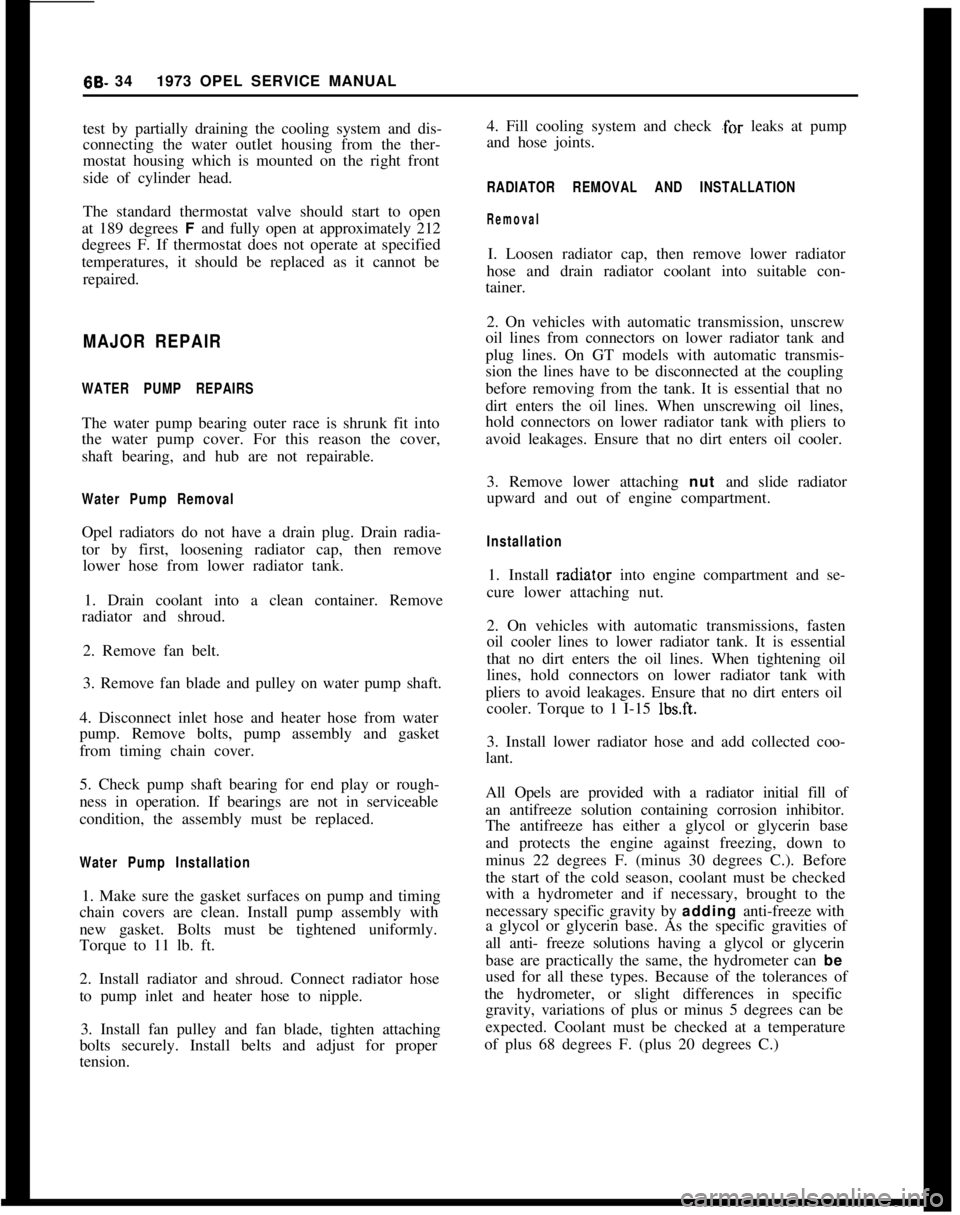

11. Remove timing chain cover bolts. One bolt is

covered by the water pump. See Figure 6A-39.

12. Pull off sprockets with chain. Put a paint mark

Figure 6A-39 Bolt Behind Water Pump

Page 323 of 625

66.321973 OPEL SERVICE MANUAL

COOLING SYSTEM

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Cooling System and Water Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Checking and Filling Cooling System

. . . . . . . . . . . . . . . . . . . . . . . .Draining

andFlushingCoolingSystem. . . . . . . . . . . . . . . . . . . . . .Conditioning the Cooling System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using and Testing Anti-Freeze Solutions

. . . . . . . . . . . . . . . . . .Fan Belt Adjustment or Replacement

. . . . . . . . . . . . . . . . . . . . . . . .Radiator Thermostat Inspection and Test

. . . . . . . . . . . . . . . .MAJOR REPAIR:

Water Pump Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radiator

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Cooling System Capacities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

68-32

6B-32

68-32

68-33

68-33

68-33

68-33

68-34

68-34

6B-35

DESCRIPTION AND OPERATION

COOLING SYSTEM AND WATER PUMPThe coiling system is of the conventional pressurized

type. A centrifugal pump arranged in timing case

serves to circulate the coolant.

When the thermostat is closed, the coolant will re-

turn to the pump via a by-pass for swift and uniform

warming up of the engine the coolant circulates

through the radiator, only when the engine has

reached normal operating temperature.

The heater system branches off the cooling system

ahead of thermostat in flow direction so that the

heater is in operation before engine has reached full

operating temperature.

MAINTENANCE AND ADJUSTMENTS

Checking and Filling Cooling SystemThe coolant level should be checked only when the

engine is cold and only enough coolant should be

added to bring the level halfway between core andtank top. It is unnecessary and undesirable to remove

the radiator cap and check the coolant level each

time the car stops at a filling station for gasoline or

oil, since the engine is usually hot at such times.

WARNING: Never remove the radiator cap quickly

when engine is HOT Sudden release of cooling

sys-

tern pressure may cause the coolant to boil and some

of it may be ejected from the radiator

filler neck,

resulting in

inl’ury to persons or damage to the car

finish.If it is necessary at any time to remove the radiator

cap when engine is hot, rotate the cap counterclock-

wise until first stop is reached. Leave cap in this

position until all pressure in cooling system has been

released, then turn cap past the first stop and remove

it.

Draining and Flushing

Cooling SystemThe cooling system should be completely drained

and the recommended coolant installed every two (2)

years.To drain the cooling system, remove radiator cap,

remove lower radiator hose from the lower tank and

Page 325 of 625

6B- 341973 OPEL SERVICE MANUAL

test by partially draining the cooling system and dis-

connecting the water outlet housing from the ther-

mostat housing which is mounted on the right front

side of cylinder head.

The standard thermostat valve should start to open

at 189 degrees F and fully open at approximately 212

degrees F. If thermostat does not operate at specified

temperatures, it should be replaced as it cannot be

repaired.MAJOR REPAIR

WATER PUMP REPAIRSThe water pump bearing outer race is shrunk fit into

the water pump cover. For this reason the cover,

shaft bearing, and hub are not repairable.

Water Pump RemovalOpel radiators do not have a drain plug. Drain radia-

tor by first, loosening radiator cap, then remove

lower hose from lower radiator tank.

1. Drain coolant into a clean container. Remove

radiator and shroud.

2. Remove fan belt.

3. Remove fan blade and pulley on water pump shaft.

4. Disconnect inlet hose and heater hose from water

pump. Remove bolts, pump assembly and gasket

from timing chain cover.

5. Check pump shaft bearing for end play or rough-

ness in operation. If bearings are not in serviceable

condition, the assembly must be replaced.

Water Pump Installation1. Make sure the gasket surfaces on pump and timing

chain covers are clean. Install pump assembly with

new gasket. Bolts must be tightened uniformly.

Torque to 11 lb. ft.

2. Install radiator and shroud. Connect radiator hose

to pump inlet and heater hose to nipple.

3. Install fan pulley and fan blade, tighten attaching

bolts securely. Install belts and adjust for proper

tension.4. Fill cooling system and check

,for leaks at pump

and hose joints.

RADIATOR REMOVAL AND INSTALLATION

RemovalI. Loosen radiator cap, then remove lower radiator

hose and drain radiator coolant into suitable con-

tainer.

2. On vehicles with automatic transmission, unscrew

oil lines from connectors on lower radiator tank and

plug lines. On GT models with automatic transmis-

sion the lines have to be disconnected at the coupling

before removing from the tank. It is essential that no

dirt enters the oil lines. When unscrewing oil lines,

hold connectors on lower radiator tank with pliers to

avoid leakages. Ensure that no dirt enters oil cooler.

3. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

Installation1. Install radiat,or into engine compartment and se-

cure lower attaching nut.

2. On vehicles with automatic transmissions, fasten

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines, hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 1 I-15

lbs.ft.3. Install lower radiator hose and add collected coo-

lant.

All Opels are provided with a radiator initial fill of

an antifreeze solution containing corrosion inhibitor.

The antifreeze has either a glycol or glycerin base

and protects the engine against freezing, down to

minus 22 degrees F. (minus 30 degrees C.). Before

the start of the cold season, coolant must be checked

with a hydrometer and if necessary, brought to the

necessary specific gravity by adding anti-freeze with

a glycol or glycerin base. As the specific gravities of

all anti- freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.)

Page 505 of 625

8A.41973 OPEL SERVICE MANUAL

Figure SA-5 Location of Fender Attaching Bolts

9. Fit new fender and apply a sealing compound, as

required, to joint. See Figure

SA-6.Figure 8A-6 Sealing Location

10. Coat fender inside with a dampening compound.

REMOVAL AND INSTALLATION OF HEADLAMP

COVERING (OPEL

1900. MANTA)

Removal1. Remove radiator grille.2. In engine compartment unscrew headlamp cover-

ing.

Se:e Figure SA-7.Figure 8A-7 Headlamp Covering Attaching Bolts

Installation1. Install headlamp covering. See Figure

SA-7.2. Install radiator grille.

REMOVAL AND INSTALLATION OF HEADLAMP

ASSEMBLY

(GT)1. Move headlamp to open position and remove

headlamp cover. See Figure

SA-8.Figure EA.8 Removing Headlamp Cap

Page 508 of 625

HOOD, FENDERS, AND GRILLE8A- 72. Remove two plastic caps and phillips screws from

outer end of grille extension.

3. Remove grille extension,

Installation1. Install grille extension and secure with Phillips

screws and two (2) plastic caps.

2. Install hex head screw and washer holding grille

extension to baffle plate.

REMOVAL AND INSTALLATION OF RADIATOR

GRILLE

(OPEL 1900. MANTA)

A. Removal (Model 57)1. Remove the

five (5) radiator grille attaching

screws. See Figure

8A-15.Figure 8A-15 Radiator Grille Attaching Screws

2. Remove radiator grille towards the top so that the

lower guide pins do not break off. See Figure 8A- 16.Figure 8A-16 Removing Radiator Grille

Installation (Model 57)

1. Install radiator grille, aligning guide pins into

lower panel. See Figure

8A-16.2. Secure grille with five (5) attaching screws. See

Figure 8A-2.

Removal (Models 51.53, and 54)

1. Remove the three (3) radiator grille attaching

screws. See Figure

8A-17.Figure 8A.17 Location of Radiator Grille AttachingSCWWS

2. Remove radiator grille towards the top SO that the

lower guide pins do not break off.

Page 513 of 625

9A-4 1973 OPEL SERVICE MANUAL

Figure 9A-4 Heater Control

Blower Switch - This switch actuates blower motor

to low or high blower speed.

HEATER SYSTEM OPERATION

To operate heater proceed as follows:

1. Position air inlet, heater-defroster control as

desired.

White arrow head pointing down--air out of heater

outlets. White arrow head pointing up--air out of

defroster outlets.

Between lower and upper position--air to both heater

and defroster outlets.

2. Position temperature control as desired to increase

or decrease temperature of air flow.

3. Position blower switch as desired to operate

blower at low or high speed.

Dlid3NDSlS

HEATER SYSTEM TROUBLE DIAGNOSIS

TROUBLE

Temperature of heated air at outlets too low.

CAUSE AND CORRECTION

Check radiator cap for proper sealing action-- re-

place if necessary.

Check for adequate coolant supply. If level is down,

correct cause of coolant loss and refill radiator.

Inspect hose for kinks--relieve kink or replace hoses.

Check thermostat operation by measuring tempera-

ture of coolant at radiator. Temperature should be

within 5 degrees F. of thermostat rated value (189

degrees F.).

Check that air doors and water temperature control

valye are operating properly.

Check for plugged heater core--backflush heater core

as necessary.

TROUBLE

Inadequate defrosting action.

CAUSE AND COiiRECTlON

Examine heater-defroster door for proper operat-

ions--adjust bowden cable as required so that door is

fully closed in FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing--seal leaks as necessary with body

sealer. Check for body air leaks and seal as necessary

with body sealer.

TROUBLE

Blower inoperative.

CAUSE AND CORRECTION

Check blower fuse--replace if necessary, fuse position

3 - amperage 8.

Check wiring for open circuit--correct as required. Inspect for defective component (i.e., blower switch

or blower motor)--replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENT

Adjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable

as held by the clamps on the control assembly and

heater case.

To adjust control cables, loosen clamps and move

cable sheath in or out as required to obtain full travel

of lever or of door or both.

Page 518 of 625

HEATER SYSTEM. GT9A- 9

REMOVAL AND INSTALLATION HEATER VALVE

Removal

1. Remove lower radiator hose and drain and collect

coolant.

2. Disconnect control cable.

3. Loosen heater hose clamps and remove valve from

hoses. See Figure 9A-17.SPECIFICATIONS

EngineRecommended Coolant

.__,.__...._...__.,.,...,......Thermostat Opens At (Degrees) F.

..__..___...Installation

1. Install valve into heater hoses and install hose

clamps.

2. Connect control cable.

3. Install lower radiator hose and add collected coo-

lant.

.....................................Ethylene-Glycol Base

...................................................................189Cooling

SystemCapacity(WithHeater)..........................................................................6Qt.BlowerMotorType

......................................................................................................12VDC

BlowerFanType

..................................................................................................SquirrelCage

Page 520 of 625

HEATER SYSTEM. OPEL 1900. MANTA9A- 11air is attained, as the water does not cool down in the

second part of the core.

A Water Outlet

B Water Inlet

The center lever actuates the two-stage blower mo-

tor.Lever positions:

Left to Center

- Motor Switched Off

Right of Center

- Lo Blower

Right

- Hi Blower

The lower lever opens and closes the air door which

channels the air flow to either the lower heater out-

lets or to the defroster outlets.

In the left lever position, the air inlet is closed. Up

to the center position, the air is directed

t,o the lower

heater outlets.

When moving the lever from center position towards

the right, the air flow to the lower

heatezr outlets is

reduced and increased to the defroster

csutlets.With the lever in its right position, the air is directed

to the defroster outlets only. For windshield defrost-

ing, all levers have to be moved to the right.

FUNCTION OF THE HEATER AND VENTILATION

SYSTEMThe engine hood is provided with slots in front of the

windshield. The air is directed through the slots into

the heater housing located in the engine compart-

ment, flows into the air distributor housing, and

from there to the lower heater outlets and,/or defros-

ter outlets, depending on the position of the control.

The two-stage blower motor is arranged in the heater

housing above the heater core and actuated by the

center control. The blower motor draws in the air

entering through the slots, blows the air through the

heater core into the air distributor housin:?, and from

there to the lower heater outlets and/or defroster

outlets, depending on the position of the lower con-

trol. See Figure 9A-32.

The heater valve regulates the flow of coolant

through the heater core, thereby varying

t:he temper-

ature of the air flow past the core.

The ventilation of vehicle interior is completed by a

draft-free air circulation pattern. Vent

slots are ar-

ranged below the back window which

are: connected

through channels to the rear quarter

iside panel.

From here, the inside air escapes into

the! open. TheFigure

9A-32 Air Flow

head wind (caused by the car traveling down the

road) promotes this process so that there is always

fresh air in vehicle interior.

On the Model 54 Station Wagon, there will be no air

outlets in the rear. For adequate flow-through type

ventilation, it will be necessary to open a rear win-

dow.Aside from the fresh air admission through the

heater system, two fresh air inlet nozzles are ar-

ranged in the center of the instrument panel. These

nozzles can be turned to direct the air flow in the

desired direction. In addition, rotary flaps allow the

regulation of the entering air or to shut off the air

completely.

These nozzles admit unheated fresh air only and

operate independent of the heater and defroster sys-

tem.

DIAGNOSIS

HEATER SYSTEM TROUBLE DIAGNOSIS

TROUBLETemperature of heated air at outlets too low.

CAUSE AND CORRECTIONCheck radiator cap for proper sealing action. Re-

place, if necessary.

Check for adequate coolant supply. If level is down,

correct cause of coolant loss and refill radiator.

Inspect hose for kinks. Relieve kink or replace hoses.

Check thermostat operation by measuring tempera-

ture of coolant at radiator. Temperature should be

within 5 degrees F. of thermostat rated value (189

degrees F.).

Page 546 of 625

REFRIGERANT COMPONENTS ALL MODELS

99.37

in front of the radiator so that it receives a high

volume of air flow. Air passing over the condenser

absorbs the heat from the high pressure gas and

causes the refrigerant to condense into a high pres-

sure liquid.Receiver. DehydratorThe receiver-dehydrator is located in the engine

compartment. The purpose of the receiver dehydra-

tor is two fold: the unit insures a solid column of

liquid refrigerant to the expansion valve at all times,

and also absorbs any moisture in the system that

might be present. A bag of desiccant (moisture ab-

sorbing material) is provided to absorb moisture. A

sight glass (see Figure 9B-33) permits visual check-

ing of the refrigerant flow for bubbles or foam. The

continuous appearance of bubbles or foam above an

ambient temperature of 70 degrees F. usually indi-

cates an inadequate refrigerant charge. Bubbles or

foam appearing at ambient temperatures below 70

degrees F. do not necessarily indicate an inadequate

charge and may appear even when the system is

operating properly. A filter screen in the unit pre-

vents foreign material from entering the remainder

of the system.

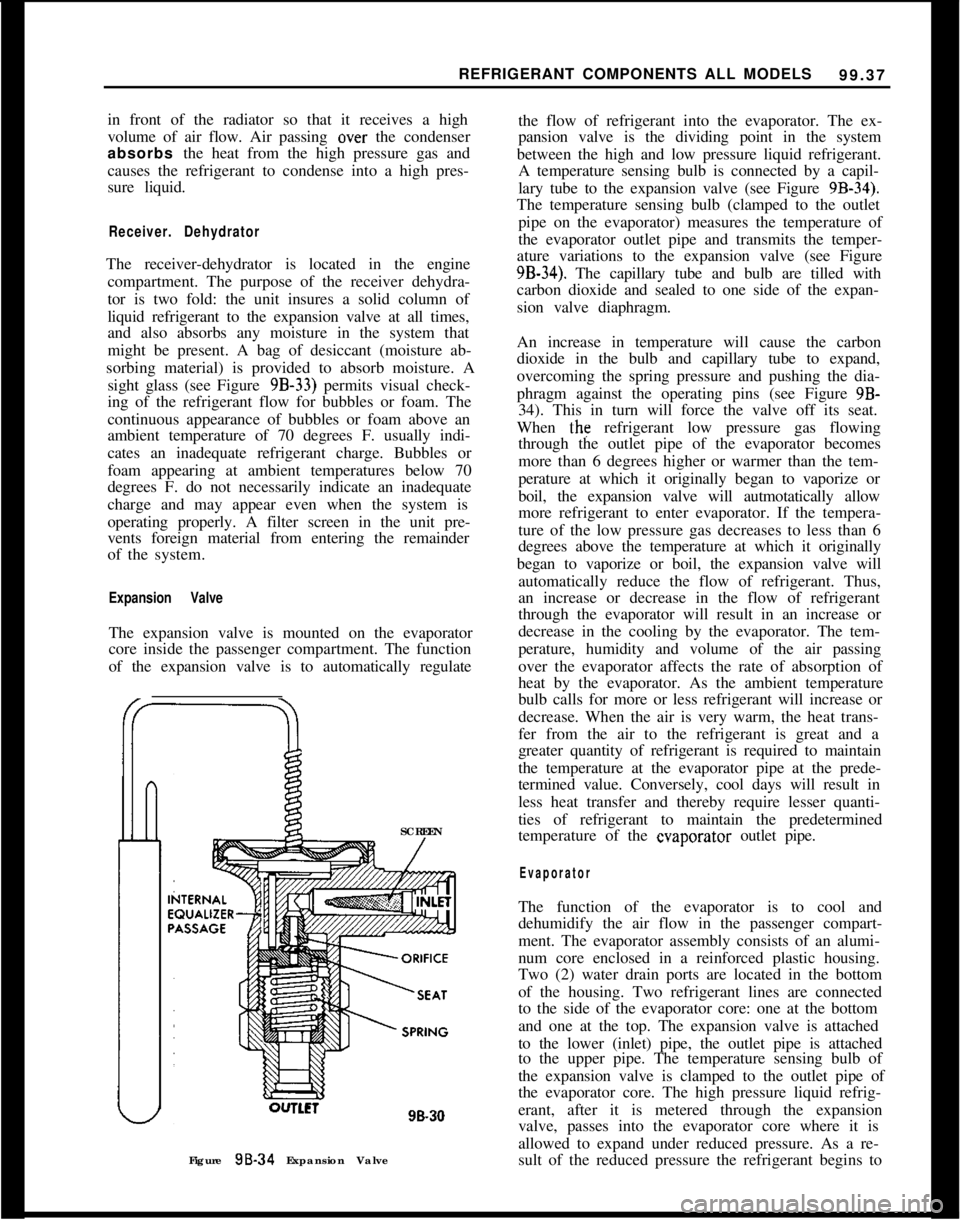

Expansion ValveThe expansion valve is mounted on the evaporator

core inside the passenger compartment. The function

of the expansion valve is to automatically regulate

SCREEN

lLCl98.30

Figure 98-34 Expansion Valvethe flow of refrigerant into the evaporator. The ex-

pansion valve is the dividing point in the system

between the high and low pressure liquid refrigerant.

A temperature sensing bulb is connected by a capil-

lary tube to the expansion valve (see Figure

9B-34).The temperature sensing bulb (clamped to the outlet

pipe on the evaporator) measures the temperature of

the evaporator outlet pipe and transmits the temper-

ature variations to the expansion valve (see Figure

9B-34). The capillary tube and bulb are tilled with

carbon dioxide and sealed to one side of the expan-

sion valve diaphragm.

An increase in temperature will cause the carbon

dioxide in the bulb and capillary tube to expand,

overcoming the spring pressure and pushing the dia-

phragm against the operating pins (see Figure 9B-

34). This in turn will force the valve off its seat.

When the refrigerant low pressure gas flowing

through the outlet pipe of the evaporator becomes

more than 6 degrees higher or warmer than the tem-

perature at which it originally began to vaporize or

boil, the expansion valve will autmotatically allow

more refrigerant to enter evaporator. If the tempera-

ture of the low pressure gas decreases to less than 6

degrees above the temperature at which it originally

began to vaporize or boil, the expansion valve will

automatically reduce the flow of refrigerant. Thus,

an increase or decrease in the flow of refrigerant

through the evaporator will result in an increase or

decrease in the cooling by the evaporator. The tem-

perature, humidity and volume of the air passing

over the evaporator affects the rate of absorption of

heat by the evaporator. As the ambient temperature

bulb calls for more or less refrigerant will increase or

decrease. When the air is very warm, the heat trans-

fer from the air to the refrigerant is great and a

greater quantity of refrigerant is required to maintain

the temperature at the evaporator pipe at the prede-

termined value. Conversely, cool days will result in

less heat transfer and thereby require lesser quanti-

ties of refrigerant to maintain the predetermined

temperature of the evaporator outlet pipe.

EvaporatorThe function of the evaporator is to cool and

dehumidify the air flow in the passenger compart-

ment. The evaporator assembly consists of an alumi-

num core enclosed in a reinforced plastic housing.

Two (2) water drain ports are located in the bottom

of the housing. Two refrigerant lines are connected

to the side of the evaporator core: one at the bottom

and one at the top. The expansion valve is attached

to the lower (inlet) pipe, the outlet pipe is attached

to the upper pipe. The temperature sensing bulb of

the expansion valve is clamped to the outlet pipe of

the evaporator core. The high pressure liquid refrig-

erant, after it is metered through the expansion

valve, passes into the evaporator core where it is

allowed to expand under reduced pressure. As a re-

sult of the reduced pressure the refrigerant begins to