check engine OPEL INSIGNIA BREAK 2017.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.75, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2017.75Pages: 323, PDF Size: 9.18 MB

Page 174 of 323

172Driving and operatingNote

In case of high AdBlue consumption, the Driver Information Centre may

display this warning without the

previous warning stages.

The last warning level is entered

when the AdBlue tank is empty.

Restart of the engine is not possible.

The following warning messages are

alternately displayed and cannot be

dismissed:

● AdBlue Empty Refill Now

● Engine Will Not Restart .

Additionally, control indicator Y

flashes continuously.

With active prevention of an engine

start, the following message will be

displayed:

Refill AdBlue To Start Vehicle .

The tank must be refilled completely with AdBlue, otherwise restarting of

the engine is not possible.High emission warnings

If the exhaust emission rises above a certain value, warnings similar to the

range warnings will be displayed in the Driver Information Centre.

Requests to have the exhaust system checked and finally the

announcement of the prevention of

an engine restart are displayed.

These restrictions are a legal

requirement.

Consult a workshop for assistance.

Refilling AdBlueCaution

Only use AdBlue that complies

with European standards

DIN 70 070 and ISO 22241-1.

Do not use additives.

Do not dilute AdBlue.

Otherwise the selective catalytic

reduction system could be

damaged.

Note

Whenever a filling pump with a

nozzle for passenger cars is not

available at a filling station, use only

AdBlue bottles or canisters with a

sealed refill adapter for refilling, to

prevent splashback and overspill,

and in order to ensure that the fumes

from the tank are captured and do

not emerge. AdBlue in bottles or

canisters is available in many filling

stations and can be purchased e.g. at Opel dealers and other retail

outlets.

Since AdBlue has a limited

durability, check the date of expiry

before refilling.

Note

The refilling of AdBlue is only

detected by the system when the

above mentioned liquid level switch

in the tank is activated.

In case AdBlue refill is not

successfully detected:

Page 183 of 323

Driving and operating181The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often without engine

running as this will discharge the

vehicle battery.

Releasing

Switch on ignition. Keep foot brake

pedal depressed and then push

switch m.

Drive away function

Vehicles with manual transmission:

Depressing the clutch pedal and then slightly releasing the clutch pedal and

slightly depressing the accelerator

pedal releases the electric parking

brake automatically. This is not

possible when switch m is pulled at

the same time.

Vehicles with automatic transmission: Engaging D and then depressing the

accelerator pedal releases the

electric parking brake automatically.

This is not possible when switch m is

pulled at the same time.Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Automatic applying

If the vehicle is equipped with

automatic transmission and adaptive cruise control is active, electric

parking brake is applied automatically when vehicle is stopped by the

system for more than two minutes.

Parking brake releases automatically

after moving off.

Functionality check

When the vehicle is not moving, the

electric parking brake might be

applied automatically. This is done to

check the system.Fault

Failure mode of electric parking brake

is indicated by a control indicator j

and by a vehicle message which is

displayed in the Driver Information

Centre. Vehicle messages 3 124.

Apply electric parking brake: pull and

hold the switch m for more than

five seconds. If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: push

and hold the switch m for more than

two seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or

released. When continuously

flashing, release electric parking

brake and retry applying.

Brake assist If brake pedal is depressed quickly

and forcefully, maximum brake force

is automatically applied.

Page 241 of 323

Vehicle care239Vehicle careGeneral Information...................239

Accessories and vehicle modifications .......................... 239

Vehicle storage ........................240

End-of-life vehicle recovery .....240

Vehicle checks ........................... 241

Performing work ......................241

Bonnet ..................................... 241

Engine oil ................................. 242

Engine coolant ......................... 243

Washer fluid ............................ 244

Brakes ..................................... 244

Brake fluid ............................... 244

Vehicle battery ......................... 245

Diesel fuel system bleeding .....246

Wiper blade replacement ........247

Bulb replacement .......................248

Halogen headlights ..................248

LED headlights ........................ 250

Fog lights ................................. 250

Tail lights ................................. 251

Side turn signal lights ..............256

Number plate light ...................256

Interior lights ............................ 256

Instrument panel illumination ...256Electrical system ........................257

Fuses ....................................... 257

Engine compartment fuse box . 258

Instrument panel fuse box .......260

Vehicle tools .............................. 262

Tools ........................................ 262

Wheels and tyres .......................263

Winter tyres ............................. 263

Tyre designations ....................263

Tyre pressure .......................... 264

Tyre pressure monitoring system .................................... 265

Tread depth ............................. 267

Changing tyre and wheel size . 267

Wheel covers ........................... 268

Tyre chains .............................. 268

Tyre repair kit .......................... 268

Wheel changing .......................273

Spare wheel ............................ 275

Jump starting ............................. 277

Towing ....................................... 278

Towing the vehicle ...................278

Towing another vehicle ...........279

Appearance care .......................280

Exterior care ............................ 280

Interior care ............................. 282General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 242 of 323

240Vehicle careCaution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 243 of 323

Vehicle care241Vehicle checks

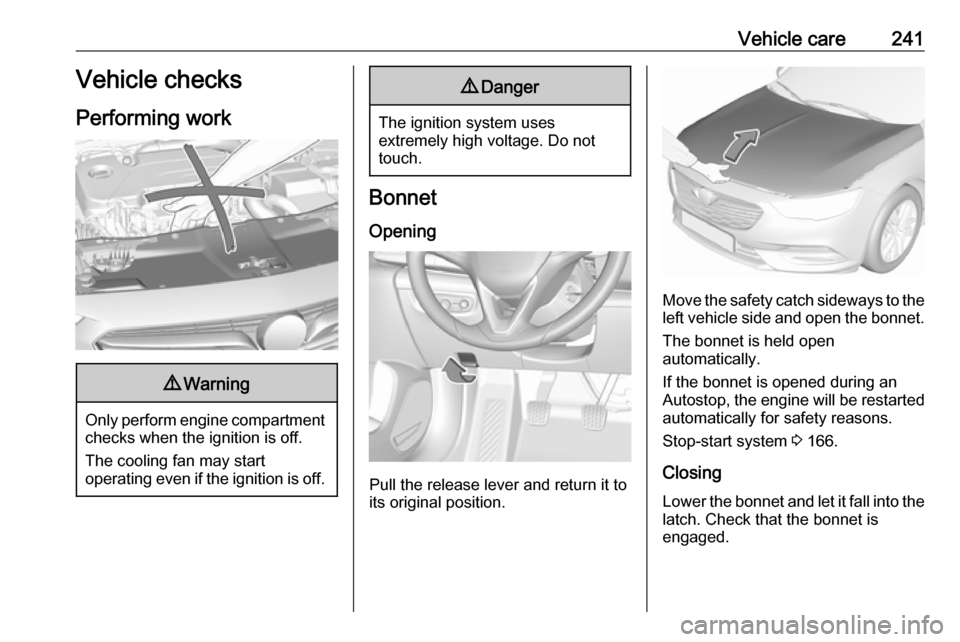

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways to the left vehicle side and open the bonnet.

The bonnet is held open

automatically.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Stop-start system 3 166.

Closing Lower the bonnet and let it fall into the

latch. Check that the bonnet is

engaged.

Page 244 of 323

242Vehicle careCaution

Do not press the bonnet into the

latch to avoid dents.

Active bonnet 3 70.

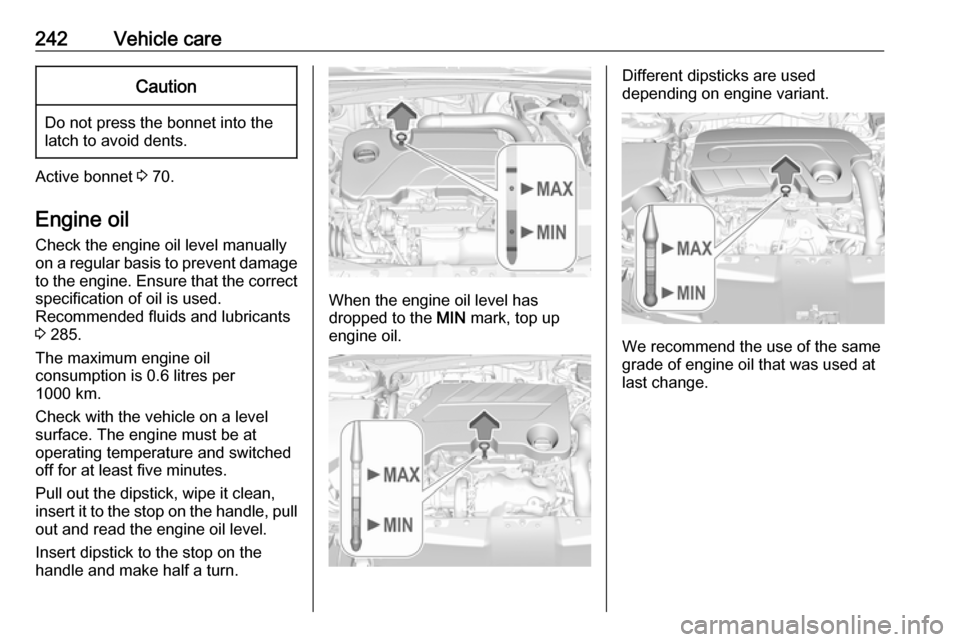

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 285.

The maximum engine oil

consumption is 0.6 litres per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

When the engine oil level has

dropped to the MIN mark, top up

engine oil.

Different dipsticks are used

depending on engine variant.

We recommend the use of the same

grade of engine oil that was used at

last change.

Page 246 of 323

244Vehicle careDepending on the engine, the

position of the coolant container may be different.9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up, use a 1:1 mixture of

released coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Washer fluid

Fill with clean water mixed with a

suitable quantity of approved

windscreen washer fluid which

contains antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Washer fluid 3 285.

Brakes

In the event of minimum thickness of

the brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

Page 250 of 323

248Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.

Halogen headlights

Halogen headlights with separate

bulbs for low beam and high beam.

Low beam ( 1) outer bulb.

High beam ( 2) inner bulb.

Low beam (1)

1. Rotate the cap anticlockwise and remove it.

2. Disengage bulb holder bypressing the retainer to the front.

Withdraw the bulb holder from the

reflector housing.

Page 266 of 323

264Vehicle careDirectional tyres

Directional tyres should be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

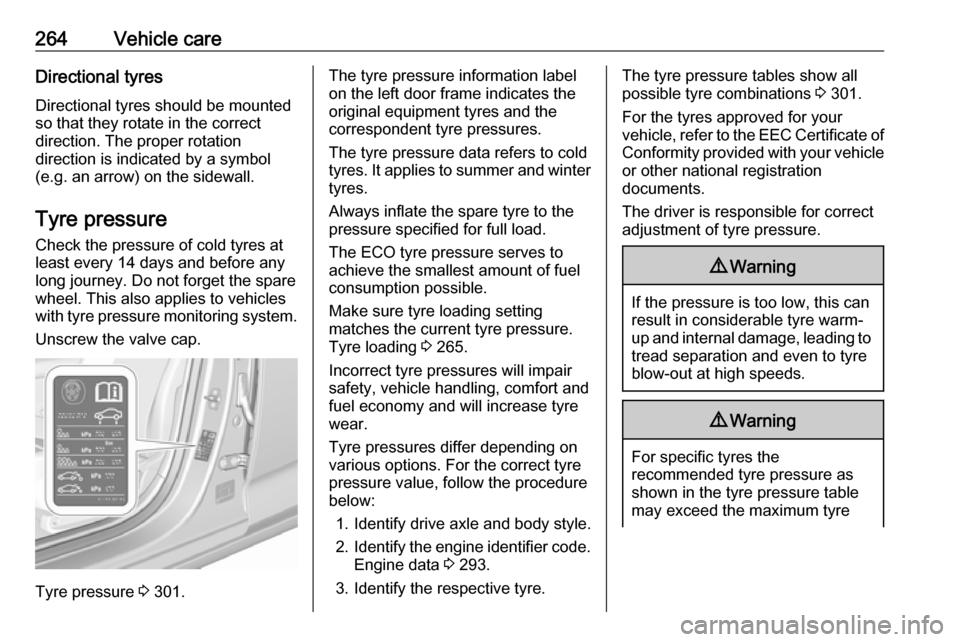

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 301.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 265.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify drive axle and body style.

2. Identify the engine identifier code.

Engine data 3 293.

3. Identify the respective tyre.The tyre pressure tables show all

possible tyre combinations 3 301.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

Page 273 of 323

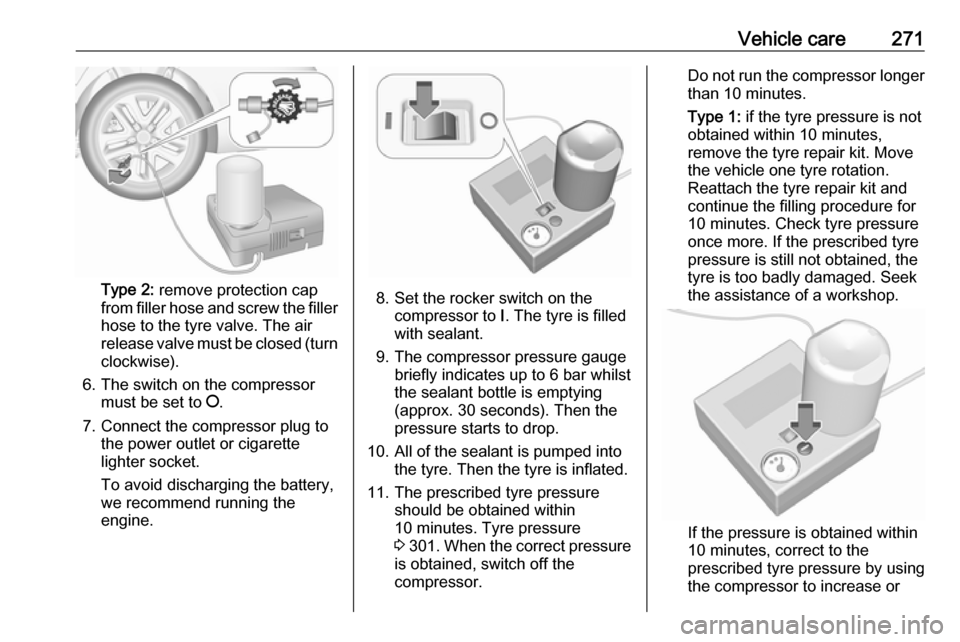

Vehicle care271

Type 2: remove protection cap

from filler hose and screw the filler

hose to the tyre valve. The air

release valve must be closed (turn

clockwise).

6. The switch on the compressor must be set to J.

7. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.8. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

9. The compressor pressure gauge briefly indicates up to 6 bar whilst

the sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

10. All of the sealant is pumped into the tyre. Then the tyre is inflated.

11. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 301 . When the correct pressure

is obtained, switch off the

compressor.

Do not run the compressor longer

than 10 minutes.

Type 1: if the tyre pressure is not

obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. Check tyre pressure

once more. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained within

10 minutes, correct to the

prescribed tyre pressure by using

the compressor to increase or