tow bar OPEL INSIGNIA BREAK 2017.75 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.75, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2017.75Pages: 323, PDF Size: 9.18 MB

Page 220 of 323

218Driving and operatingVehicle personalisation 3 126.

Info-Display 3 120.

The system is deactivated if the

vehicle is towing a trailer.

Deactivation is indicated by a

message in the Driver Information

Centre.

System limitations Occasional missed alerts can occur

under normal circumstances or in

sharp curves. The system can

temporarily alert of objects in the blind spot at specific weather conditions

(rain, hail etc). Driving on a wet road

or in the transitions from a dry area to

a wet area can cause the control

indicator F to light up, as water

splash can be interpreted as an object. Otherwise the control indicator F may illuminate due to guardrails,

signs, trees, shrubs or other immobile objects. This is normal operation and

the system does not need to be

serviced.The system may not operate properly

when:

● Ice, snow, mud, stickers, magnets, metal plates, or

anything else covers the sensors.

● Driving in heavy rainstorms. ● The vehicle had an accident or if the area surrounding the

detection sensor is damaged or

not properly repaired.

● There are extreme temperature changes.

● The vehicle is towing a trailer

In the event of a fault in the system or if the system does not work due to

temporary conditions, a message is

displayed in the Driver Information

Centre. Seek the assistance of a

workshop.

Note

After production, the system

requires a calibration. For optimal

performance, drive as soon as

possible on a straight highway road

with roadside objects, e.g. guardrails

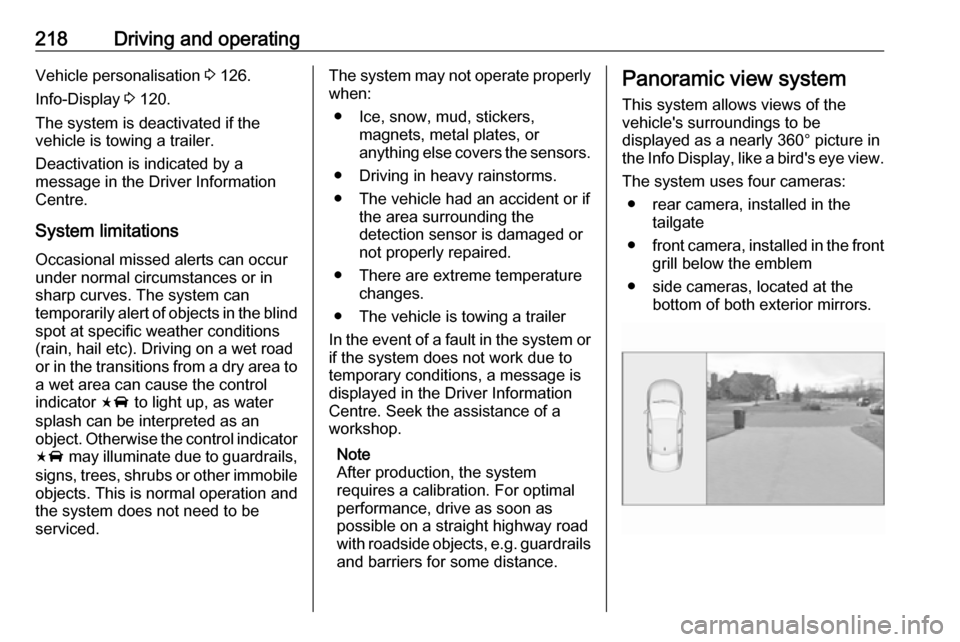

and barriers for some distance.Panoramic view system

This system allows views of the

vehicle's surroundings to be

displayed as a nearly 360° picture in

the Info Display, like a bird's eye view.

The system uses four cameras: ● rear camera, installed in the tailgate

● front camera, installed in the front

grill below the emblem

● side cameras, located at the bottom of both exterior mirrors.

Page 237 of 323

Driving and operating235Trailer hitch

General information

The factory-fitted towing equipment is

folded up under the rear bumper

fascia.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment. Only use

towing equipment that has been

approved for your vehicle.

To avoid vehicle damage, the power

tailgate cannot be operated with the

electronic key when a trailer is

electrically connected.

The bulb outage detection function for trailer brake light cannot detect a

partial bulb outage, e.g. in case of four

times five watt bulbs, the function only detects lamp outage when only a

single five Watt lamp remains or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball

bar for towing.Driving characteristics and

towing tips

Before attaching a trailer, lubricate the coupling ball. However, do not do so if a stabiliser, which acts on thecoupling ball, is being used to reduce

snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s kerb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 301.Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of altitude. The gross train weight does not have to be reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).

Page 238 of 323

236Driving and operatingThe permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 288.

Vertical coupling load The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load of 60 kg

(engines B20DTH: 90 kg) is specified

on the towing equipment identification plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

70 kg (engines B20DTH: 80 kg), the

gross vehicle weight rating must not

be exceeded. If the permissible rear

axle load is exceeded, a maximum

speed of 100 km/h applies.

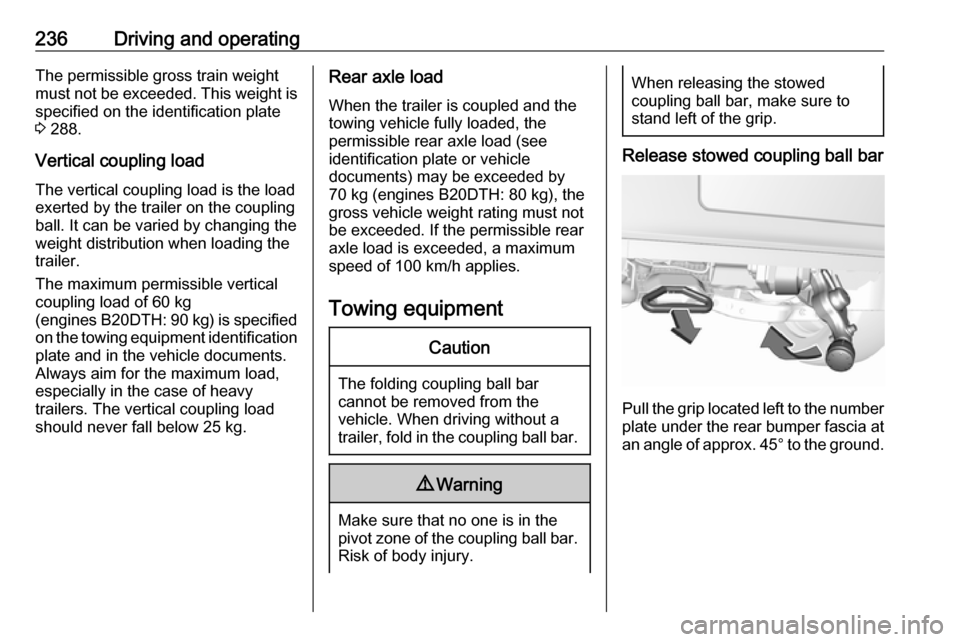

Towing equipmentCaution

The folding coupling ball bar

cannot be removed from the

vehicle. When driving without a

trailer, fold in the coupling ball bar.

9 Warning

Make sure that no one is in the

pivot zone of the coupling ball bar. Risk of body injury.

When releasing the stowed

coupling ball bar, make sure to

stand left of the grip.

Release stowed coupling ball bar

Pull the grip located left to the number

plate under the rear bumper fascia at an angle of approx. 45° to the ground.

Page 239 of 323

Driving and operating237

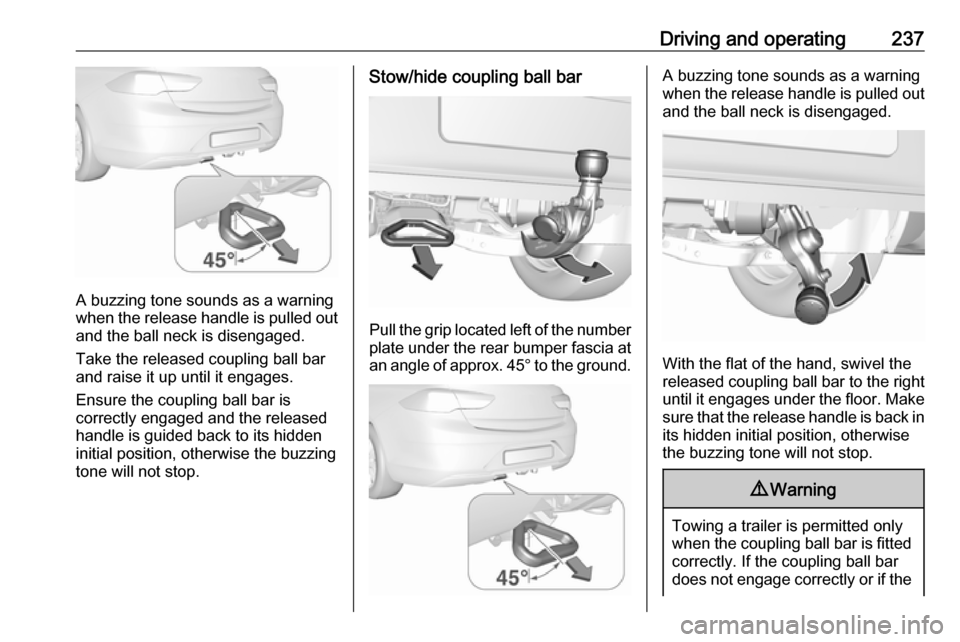

A buzzing tone sounds as a warning

when the release handle is pulled out and the ball neck is disengaged.

Take the released coupling ball bar

and raise it up until it engages.

Ensure the coupling ball bar is

correctly engaged and the released

handle is guided back to its hidden

initial position, otherwise the buzzing

tone will not stop.

Stow/hide coupling ball bar

Pull the grip located left of the number

plate under the rear bumper fascia at an angle of approx. 45° to the ground.

A buzzing tone sounds as a warning

when the release handle is pulled out and the ball neck is disengaged.

With the flat of the hand, swivel the

released coupling ball bar to the right

until it engages under the floor. Make sure that the release handle is back inits hidden initial position, otherwise

the buzzing tone will not stop.

9 Warning

Towing a trailer is permitted only

when the coupling ball bar is fitted correctly. If the coupling ball bar

does not engage correctly or if the

Page 274 of 323

272Vehicle caredecrease with the button over the

pressure indicator.

Type 2: remove tyre repair kit and

drive immediately up to 10 km, but not longer than 10 minutes. Check

tyre pressure once more. If the

tyre pressure is not obtained,

reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained, correct to the prescribed tyre pressure byusing the compressor to increase

or decrease by opening the air

release valve (turn anticlockwise)

at the air filler hose.

12. Detach the tyre repair kit. Type 1: push catch on bracket to

remove sealant bottle from

bracket. Screw tyre inflation hose

to the free connection of sealant

bottle. This prevents sealant from

escaping.

Type 2: Sealant bottle can not be

removed from the compressor.Have the sealant bottle replaced

by your workshop.

13. Stow tyre repair kit in the load compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve.If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in the box.

18. Fix the box with the screw.

Note

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30

minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Page 284 of 323

282Vehicle careIce residues, pollution and continuouswiping on dry windows will damage or

even destroy the wiper blades.

Sunroof Never clean with solvents or abrasive

agents, fuels, aggressive media

(e.g. paint cleaner, acetone-

containing solutions etc.), acidic or

highly alkaline media or abrasive

pads. Do not apply wax or polishing

agents to the sunroof.

Wheels and tyres Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage

Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.Underbody

Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen/rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Liquid gas system9 Danger

Liquid gas is heavier than air and

can collect in sink points.

Take care when performing work

at the underbody in a pit.

For painting work and when using a

drying booth at a temperature above

60 °C, the liquid gas tank must be

removed.

Do not make any modifications to the

liquid gas system.

Towing equipment

Do not clean the coupling ball bar with a steam-jet or high-pressure jet

cleaner.

Interior care

Interior and upholstery

Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Page 321 of 323

319Performance .............................. 295

Performing work ........................241

Power button .............................. 163

Power outlets ............................... 94

Power seat adjustment ................49

Power windows ............................ 39

Preheating ................................. 110

Puncture ..................................... 273

Q Quickheat ................................... 158

R

Radio Frequency Identification (RFID) ..................................... 314

Reading lights ............................ 145

Rear cross traffic alert ................223

Rear floor storage cover ..............79

Rear fog light .....................112, 143

Rear seats .................................... 54

Rear storage ................................. 79

Rear view camera ...................... 221

Rear window wiper/washer .......... 91

Recommended fluids and lubricants ........................ 285, 290

Refuelling ................................... 232

Registered trademarks ...............312

Retained power off .....................164

Reversing lights .........................144

Ride control systems ..................182

Roof .............................................. 42Roof load...................................... 85

Roof rack ..................................... 84

S Safety belts ................................... 55

Safety net .................................... 80

Seat adjustment ............................. 6 Seat belt ........................................ 8

Seat belt reminder .....................106

Seat belts ..................................... 55 Seat heating Seat heating, front .....................52

Seat heating, rear .....................54

Seat position ................................ 46

Selective catalytic reduction .......171

Service ............................... 160, 284

Service display .......................... 105

Service information ....................284

Side airbag system ......................61

Side blind zone assistant ............215

Sidelights .................................... 135

Side turn signal lights ................256

Software acknowledgement .......310

Software update ......................... 312

Spare wheel ............................... 275

Speed limiter....................... 112, 189

Speedometer ............................. 102

Starting and operating ................162

Starting off ................................... 18

Starting the engine ....................164Steering...................................... 162

Steering wheel adjustment ......9, 88

Steering wheel controls ...............88

Stop-start system........................ 166

Storage ......................................... 72

Storage compartments .................72

Sunglasses storage .....................73

Sunroof ........................................ 42

Sunvisor lights ........................... 146

Sun visors .................................... 41

Symbols ......................................... 4

T Tachometer ............................... 104

Tail lights ................................... 251

Three-point seat belt .................... 56

Tools .......................................... 262

Tow bar....................................... 235

Towing ................................ 235, 278

Towing another vehicle .............279

Towing equipment .....................236

Towing hitch installation dimensions ............................. 306

Towing the vehicle .....................278

Traction Control system ............. 182

Traction Control system off......... 110

Traffic sign assistant ...........112, 224

Trailer coupling ........................... 235

Trailer stability assist .................238

Trailer towing ............................. 235