tyre pressure OPEL INSIGNIA BREAK 2018 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2018Pages: 323, PDF Size: 9.37 MB

Page 184 of 323

182Driving and operatingOperation of brake assist might

become apparent by a pulse in the brake pedal and a greater resistancewhen depressing the brake pedal.

Maintain steady pressure on the

brake pedal as long as full braking is

required. Maximum brake force is

automatically reduced when brake

pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the brake pedal after

stopping on an incline, brakes remain

on for further two seconds. The

brakes release automatically as soon as the vehicle begins to accelerate.Ride control systems

Traction Control system The Traction Control system (TC) is a

component of the Electronic Stability

Control (ESC).

TC improves driving stability when

necessary, regardless of the type of

road surface or tyre grip, by

preventing the drive wheels from

spinning.

As soon as the drive wheels starts to spin, engine output is reduced and

the wheel spinning the most is braked individually. This considerably

improves the driving stability of the

vehicle on slippery road surfaces.

TC is operational after each engine

start as soon as the control indicator

b extinguishes.

When TC operates b flashes.

9 Warning

Do not let this special safety

feature tempt you into taking risks

when driving.

Adapt speed to the road

conditions.

Control indicator b 3 109.

Deactivation

TC can be switched off when spinning of drive wheels is required: press t

briefly.

Page 237 of 323

Driving and operating235Driving characteristics and

towing tips

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

During trailer towing do not exceed a

speed of 80 km/h. A maximum speed

of 100 km/h is only appropriate if an

oscillation damper is used and the

permissible gross trailer weight does

not exceed the vehicle’s kerb weight.

For trailers with low driving stability

and caravan trailers, the use of an

oscillation damper is strongly

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 301.Trailer towing

Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to 12%.

The permissible trailer load applies

up to the specified incline and at sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of altitude. The gross train weight does not have to be

reduced when driving on roads with

slight inclines (less than 8%, e.g.

motorways).The permissible gross train weight must not be exceeded. This weight is specified on the identification plate

3 288.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load of 60 kg

(engines B20DTH / B20NFT: 90 kg) is

specified on the towing equipment

identification plate and in the vehicle

documents. Always aim for the

maximum load, especially in the case

of heavy trailers. The vertical coupling load should never fall below 25 kg.

Page 240 of 323

238Vehicle careVehicle careGeneral Information...................238

Accessories and vehicle modifications .......................... 238

Vehicle storage ........................239

End-of-life vehicle recovery .....239

Vehicle checks ........................... 240

Performing work ......................240

Bonnet ..................................... 240

Engine oil ................................. 241

Engine coolant ......................... 242

Washer fluid ............................ 243

Brakes ..................................... 243

Brake fluid ............................... 243

Vehicle battery ......................... 244

Diesel fuel system bleeding .....245

Wiper blade replacement ........245

Bulb replacement .......................246

Halogen headlights ..................246

LED headlights ........................ 248

Fog lights ................................. 248

Tail lights ................................. 250

Side turn signal lights ..............255

Number plate light ...................256

Interior lights ............................ 256

Instrument panel illumination ...256Electrical system ........................256

Fuses ....................................... 256

Engine compartment fuse box . 257

Instrument panel fuse box .......260

Vehicle tools .............................. 261

Tools ........................................ 261

Wheels and tyres .......................262

Winter tyres ............................. 262

Tyre designations ....................263

Tyre pressure .......................... 263

Tyre pressure monitoring system .................................... 264

Tread depth ............................. 266

Changing tyre and wheel size . 267

Wheel covers ........................... 267

Tyre chains .............................. 267

Tyre repair kit .......................... 268

Wheel changing .......................272

Spare wheel ............................ 275

Jump starting ............................. 277

Towing ....................................... 278

Towing the vehicle ...................278

Towing another vehicle ...........279

Appearance care .......................280

Exterior care ............................ 280

Interior care ............................. 282General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Opel. Furthermore, such

changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 241 of 323

Vehicle care239Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 265 of 323

Vehicle care263Tyre designations

E.g. 215/60 R 16 95 V215:tyre width, mm60:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgV:speed code letter

Speed code letter:

Q:up to 160 km/hS:up to 180 km/hT:up to 190 km/hH:up to 210 km/hV:up to 240 km/hW:up to 270 km/h

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 294.

Directional tyres

Directional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

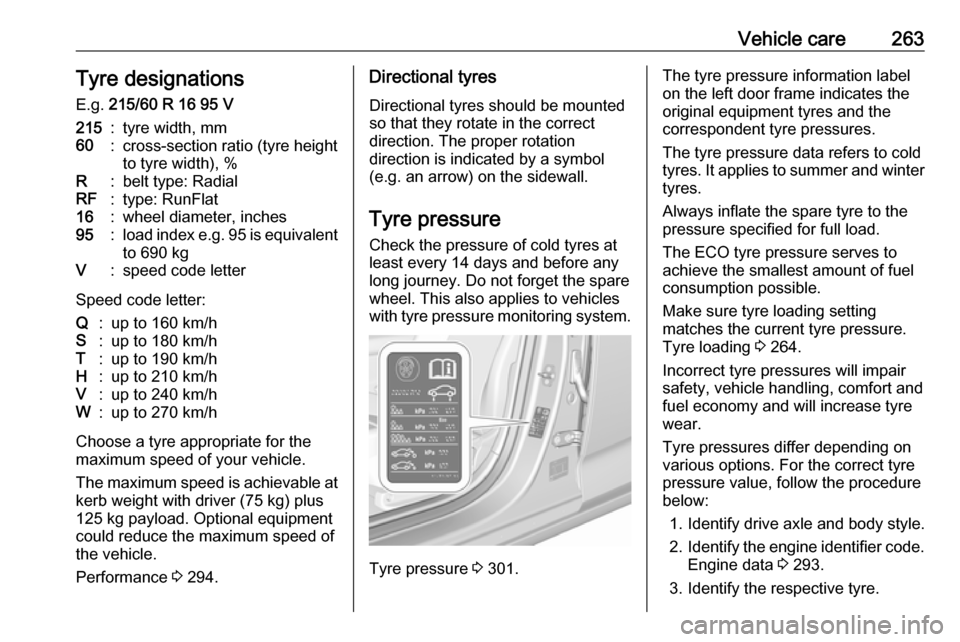

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 301.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 264.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify drive axle and body style.

2. Identify the engine identifier code.

Engine data 3 293.

3. Identify the respective tyre.

Page 266 of 323

264Vehicle careThe tyre pressure tables show allpossible tyre combinations 3 301.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

After adjusting tyre pressure, select

the according tyre loading setting on

the page Tyre load in the Driver

Information Centre, 3 113.

Temperature dependency The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

10 kPa for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.Tyre pressure monitoring

system

The tyre pressure monitoring system

checks the pressure of all four wheels once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns just about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

Select the Tyre pressure monitoring

page under the Info Menu in the

Driver Information Centre 3 113.

Page 267 of 323

Vehicle care265

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in the Driver Information Centre.

The system considers the tyre

temperature and the tyre loading

setting for the warnings.

Tyre loading setting, see below in this chapter.

Temperature dependency 3 263.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 110.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 301.

Ensure that vehicle loading status

matches selected tyre pressure.

Vehicle loading status, see below in

this chapter.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

continue to illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 124.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressuremonitoring system is not operational

for these wheels. Control indicator w

illuminates. For the further three

wheels the system remains

operational.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced tyre

pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor replace valve

core and sealing ring, for clipped

sensor replace complete valve stem.

Use only original plastic valve caps to protect valve on any damage.Caution

Do not use metal valve caps as

they lead to valve oxidation and

damage.

Page 268 of 323

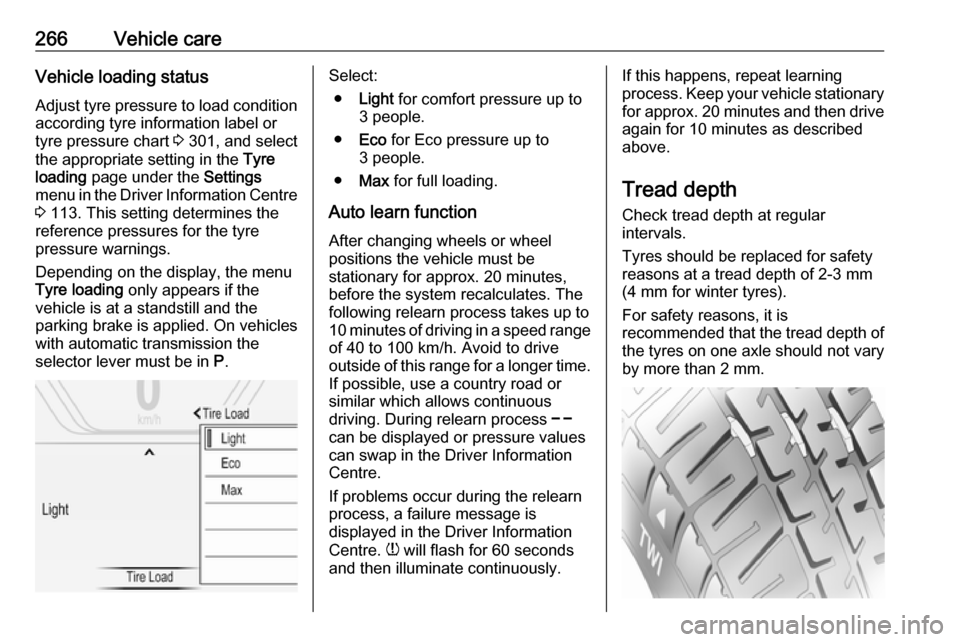

266Vehicle careVehicle loading status

Adjust tyre pressure to load condition according tyre information label or

tyre pressure chart 3 301, and select

the appropriate setting in the Tyre

loading page under the Settings

menu in the Driver Information Centre

3 113. This setting determines the

reference pressures for the tyre

pressure warnings.

Depending on the display, the menu

Tyre loading only appears if the

vehicle is at a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever must be in P.Select:

● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full loading.

Auto learn function After changing wheels or wheel

positions the vehicle must be

stationary for approx. 20 minutes,

before the system recalculates. The

following relearn process takes up to

10 minutes of driving in a speed range

of 40 to 100 km/h. Avoid to drive

outside of this range for a longer time.

If possible, use a country road or

similar which allows continuous

driving. During relearn process $

can be displayed or pressure values can swap in the Driver Information

Centre.

If problems occur during the relearn

process, a failure message is

displayed in the Driver Information

Centre. w will flash for 60 seconds

and then illuminate continuously.If this happens, repeat learning

process. Keep your vehicle stationary for approx. 20 minutes and then drive

again for 10 minutes as described

above.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

Page 269 of 323

Vehicle care267The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel size

If tyres of a different size than thosefitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.After converting to a different tyre

size, have the label with tyre

pressures replaced and the tyre

deflation detection system

reinitialised. 3 2649 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Page 273 of 323

Vehicle care2719. The compressor pressure gaugebriefly indicates up to 6 bar whilst

the sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

10. All of the sealant is pumped into the tyre. Then the tyre is inflated.

11. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 301 . When the correct pressure

is obtained, switch off the

compressor.

Do not run the compressor longer

than 10 minutes.

Type 1: if the tyre pressure is not

obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. Check tyre pressure

once more. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained within

10 minutes, correct to the

prescribed tyre pressure by using

the compressor to increase or

decrease with the button over the

pressure indicator.

Type 2: remove tyre repair kit and

drive immediately up to 10 km, but not longer than 10 minutes. Check

tyre pressure once more. If the

tyre pressure is not obtained,

reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained, correct to the prescribed tyre pressure byusing the compressor to increase

or decrease by opening the air

release valve (turn anticlockwise)

at the air filler hose.

12. Detach the tyre repair kit. Type 1: push catch on bracket to

remove sealant bottle from

bracket. Screw tyre inflation hose

to the free connection of sealant

bottle. This prevents sealant from

escaping.

Type 2: Sealant bottle can not be

removed from the compressor.

Have the sealant bottle replaced

by your workshop.

13. Stow tyre repair kit in the load compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.