wheel torque OPEL INSIGNIA BREAK 2020 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2020Pages: 315, PDF Size: 9.45 MB

Page 172 of 315

170Driving and operatingDrive systems

All-wheel drive

The All-wheel drive system enhances

driving characteristics and stability,

and helps to achieve the best

possible driveability regardless of

ground surface. The system is always

active and cannot be deactivated.

The torque is distributed steplessly

between the wheels of the front and

rear axle up to a torque split of 50%

to 50%. Depending on the driving

conditions, i.e. steady state driving,

All wheel drive system transfers a

minimum amount of torque for fuel

efficiency. Additionally the torque

vectoring between the rear wheels is

distributed depending on the vehicle

dynamic and surface.

This is possible because the All wheel drive system operates with two

clutches, one on each side.

For optimum system performance,

the vehicle's tyres should not have

varying degrees of wear.If a service message is displayed in

the Driver Information Centre, the

system may have limited functionality

(or be completely disabled in some

cases, i.e. the vehicle switches to

Front-wheel drive). Seek the

assistance of a workshop.

Towing the vehicle 3 271.Brakes

The brake system comprises two independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The braking distance is extended. Seek

the assistance of a workshop before

continuing the journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 107.

Active emergency braking 3 194.

Antilock brake system Antilock brake system (ABS)

prevents the wheels from locking.

Page 177 of 315

Driving and operating175Have the cause of the fault remedied

by a workshop.

Electronic Stability Control

Electronic Stability Control (ESC)

improves driving stability when

necessary, regardless of the type of

road surface or tyre grip.

As soon as the vehicle starts to

swerve (understeer / oversteer),

engine output is reduced and the

wheels are braked individually.

ESC operates in combination with the Traction Control system (TC). It

prevents the drive wheels from

spinning.

Torque distribution is a special

feature that allocates the torque to the drive wheels before the ESC

intervenes. When cornering, the

wheels on the inner curve are braked

individually. Additionally, engine

torque will be delivered to the drive

wheel on the outer curve. This

reduces the tendency of

understeering and improves traction

when cornering fast.

ESC is operational after each engine

start as soon as the control indicator

b extinguishes.

When ESC operates b flashes.

9 Warning

Do not let this special safety

feature tempt you into taking risks

when driving.

Adapt speed to the road

conditions.

Control indicator b 3 108.

Deactivation

ESC and TC can be deactivated:

● hold t pressed for a minimum of

five seconds: ESC and TC are

both deactivated. k and t

illuminate and status messages appear in the Driver Information Centre.

Page 270 of 315

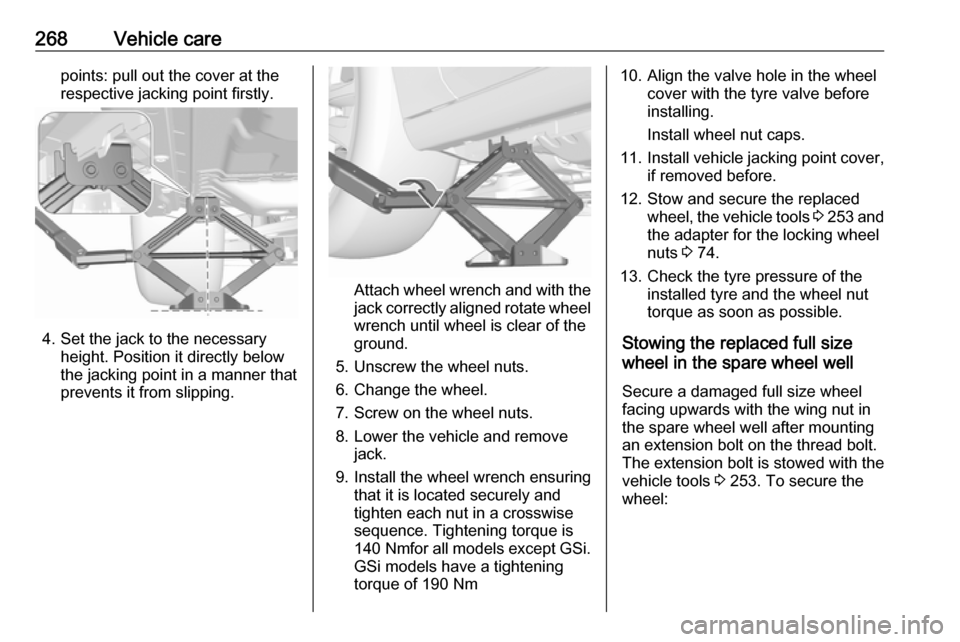

268Vehicle carepoints: pull out the cover at the

respective jacking point firstly.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm for all models except GSi.

GSi models have a tightening

torque of 190 Nm

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Install vehicle jacking point cover,

if removed before.

12. Stow and secure the replaced wheel, the vehicle tools 3 253 and

the adapter for the locking wheel

nuts 3 74.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Stowing the replaced full size

wheel in the spare wheel well

Secure a damaged full size wheel facing upwards with the wing nut in

the spare wheel well after mounting

an extension bolt on the thread bolt.

The extension bolt is stowed with the

vehicle tools 3 253. To secure the

wheel: