box OPEL INSIGNIA BREAK 2020 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2020, Model line: INSIGNIA BREAK, Model: OPEL INSIGNIA BREAK 2020Pages: 315, PDF Size: 9.45 MB

Page 251 of 315

Vehicle care249

Grab the fuse with the fuse extractor

and withdraw the fuse.

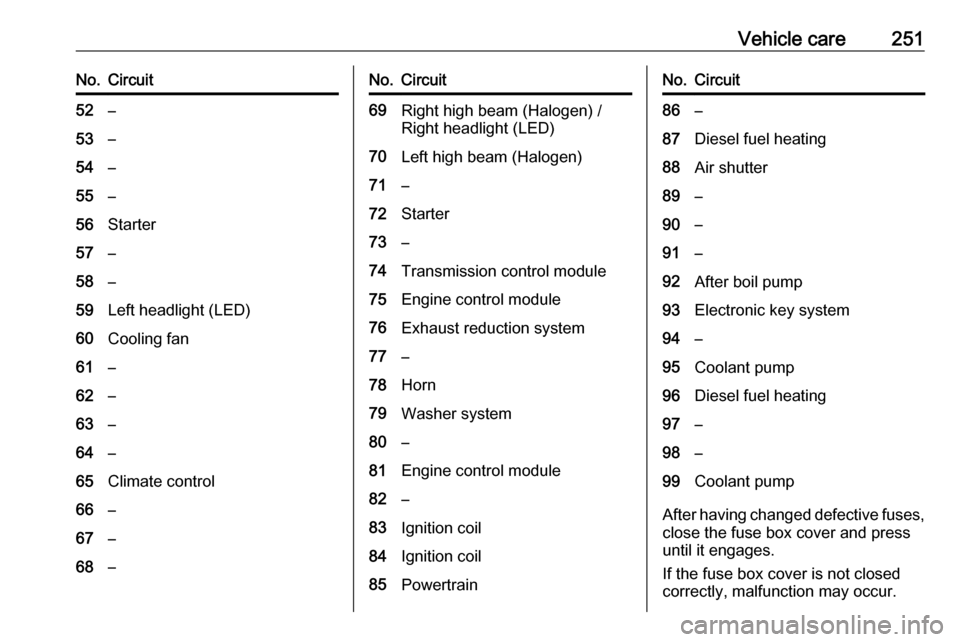

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and remove it.

Page 253 of 315

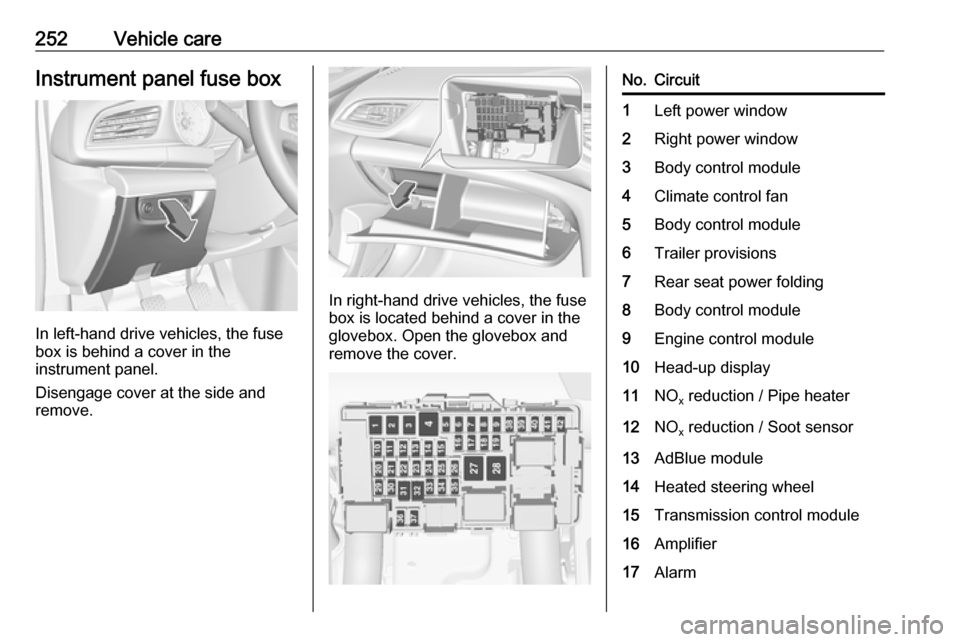

Vehicle care251No.Circuit52–53–54–55–56Starter57–58–59Left headlight (LED)60Cooling fan61–62–63–64–65Climate control66–67–68–No.Circuit69Right high beam (Halogen) /

Right headlight (LED)70Left high beam (Halogen)71–72Starter73–74Transmission control module75Engine control module76Exhaust reduction system77–78Horn79Washer system80–81Engine control module82–83Ignition coil84Ignition coil85PowertrainNo.Circuit86–87Diesel fuel heating88Air shutter89–90–91–92After boil pump93Electronic key system94–95Coolant pump96Diesel fuel heating97–98–99Coolant pump

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 254 of 315

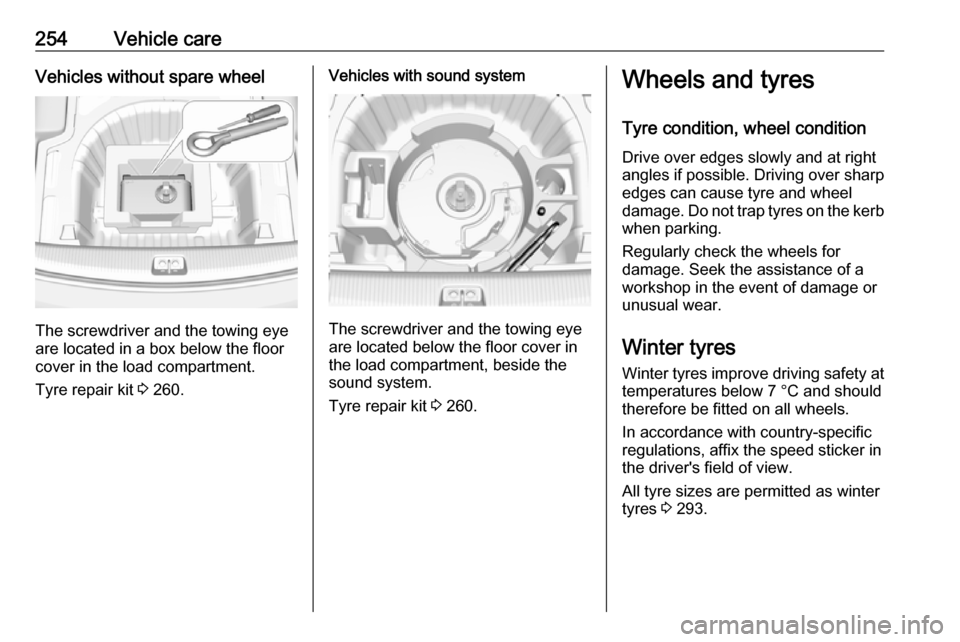

252Vehicle careInstrument panel fuse box

In left-hand drive vehicles, the fuse

box is behind a cover in the

instrument panel.

Disengage cover at the side and

remove.

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

No.Circuit1Left power window2Right power window3Body control module4Climate control fan5Body control module6Trailer provisions7Rear seat power folding8Body control module9Engine control module10Head-up display11NO x reduction / Pipe heater12NO

x reduction / Soot sensor13AdBlue module14Heated steering wheel15Transmission control module16Amplifier17Alarm

Page 255 of 315

Vehicle care253No.Circuit18Body control module19AdBlue module20Body control module21Body control module22Body control module23Electric steering wheel lock24Airbag25Diagnostic connector26Power outlet load compartment27EBCM valve28Police provision29–30–31Steering wheel controls32Ignition switch33Climate control34Central gateway moduleNo.Circuit35AUX / USB connector36Wireless charger37Rear wiper38Emergency call39Display40Parking assist41Overhead console42Infotainment SystemVehicle tools

Tools

Vehicles with spare wheel

The jack with wheel wrench, the tools,

an extension bolt for securing a

damaged wheel and the towing eye

are placed in the tool box below the

spare wheel in the load compartment.

Spare wheel 3 265.

Page 256 of 315

254Vehicle careVehicles without spare wheel

The screwdriver and the towing eye

are located in a box below the floor

cover in the load compartment.

Tyre repair kit 3 260.

Vehicles with sound system

The screwdriver and the towing eye

are located below the floor cover in

the load compartment, beside the

sound system.

Tyre repair kit 3 260.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 293.

Page 263 of 315

Vehicle care261●Type 2 indicated by the on/off

switch at the side of the

compressor.

If vehicle has a flat tyre:

Apply the parking brake and engage first gear, reverse gear or P.

On vehicles with audio speaker

system, the tyre repair kit is stowed together with the tools.

On other versions, the tyre repair kit

is stored in a bag.

Loosen the screw and remove the

bag.

Take the sealant bottle and the

compressor out of the box.

1. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 266 of 315

264Vehicle carerelease valve (turn anticlockwise)

at the air filler hose.

12. Detach the tyre repair kit. Type 1: push catch on bracket to

remove sealant bottle from

bracket. Screw tyre inflation hose

to the free connection of sealant

bottle. This prevents sealant from

escaping.

Type 2: Sealant bottle can not be

removed from the compressor.

Have the sealant bottle replaced

by your workshop.

13. Stow tyre repair kit in the load compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in the box.

18. Fix the box with the screw.

Note

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters possibly supplied can

be used to pump up other items e.g. footballs, air mattresses, inflatable

dinghies etc. They can be located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Page 268 of 315

266Vehicle careOnly mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.Caution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Caution

If driving with a temporary spare

wheel, active emergency braking

has to deactivated.

The spare wheel is located in the load

compartment beneath the floor

covering.

To remove: 1. Open the floor cover.

2. The spare wheel is secured with a

wing nut. Unscrew the wing nut

and take out the spare wheel.

Under the spare wheel there is the

box with vehicle tools.

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut as far as it will go and close floor cover.

4. After wheel change back to full size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel.

● Never change more than one wheel at once.

Page 269 of 315

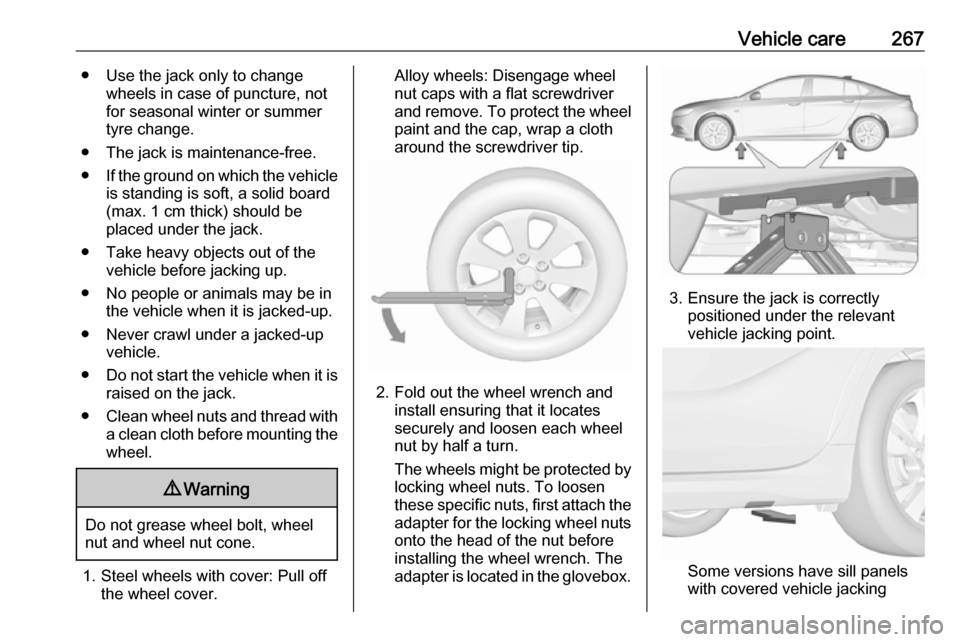

Vehicle care267● Use the jack only to changewheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels with cover: Pull off the wheel cover.

Alloy wheels: Disengage wheel

nut caps with a flat screwdriver

and remove. To protect the wheel paint and the cap, wrap a cloth

around the screwdriver tip.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts, first attach the adapter for the locking wheel nuts

onto the head of the nut before

installing the wheel wrench. The

adapter is located in the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Some versions have sill panels

with covered vehicle jacking

Page 311 of 315

309Child restraint systems ................65

Climate control ............................. 16

Clock............................................. 93

Collision damage repair ..............301

Control indicators........................ 105

Control of the vehicle .................152

Controls ........................................ 89

Convex shape .............................. 38

Coolant and antifreeze ...............279

Cruise control ....................110, 178

Cupholders .................................. 74

Curtain airbag system .................. 63

Curve lighting.............................. 133

D Danger, Warnings and Cautions ...4

Daytime running lights ...............133

Declaration of conformity ............297

DEF ............................................ 162

Diesel exhaust fluid ....................162

Diesel fuel system bleeding .......237

Door open .................................. 111

Doors ............................................ 30

Driver assistance systems ..........178

Driver Information Centre ...........111

Driving characteristics and towing tips .............................. 225

Driving hints ................................ 152E

Electric adjustment ......................38

Electrical system......................... 248

Electric parking brake .........107, 171

Electric parking brake fault .........107

Electronic climate control system 143

Electronic driving programmes ..167

Electronic key system ...................23

Electronic Stability Control.......... 175

Electronic Stability Control and Traction Control system ..........108

Electronic Stability Control off..... 108

Emergency call ........................... 127

End-of-life vehicle recovery .......230

Engine compartment fuse box ...249

Engine coolant ........................... 233

Engine coolant temperature ......108

Engine coolant temperature gauge ..................................... 103

Engine data ............................... 286

Engine exhaust .......................... 160

Engine identification ...................282

Engine oil ................... 232, 279, 283

Engine oil pressure ....................109

Entry lighting .............................. 138

Event data recorders ..................304

Exhaust filter ............................... 160

Exit lighting ................................ 138

Exterior care .............................. 273

Exterior light ............................... 110Exterior lighting ....................13, 129

Exterior mirrors ............................. 38

F

Fault ........................................... 168

First aid kit ................................... 85

Fixed air vents ........................... 150

Floor mats................................... 276

Folding mirrors ............................. 39

Following distance ......................108

Following distance indication ......193

Forward collision alert................. 190

Front airbag system .....................62

Front fog lights ...........110, 135, 240

Front pedestrian protection ........197

Front seats.................................... 48

Front storage ................................ 75

Fuel............................................. 221

Fuel for diesel engines ..............222

Fuel for petrol engines ...............221

Fuel gauge ................................. 103

Funnel......................................... 223

Fuses ......................................... 248

G Gauges ....................................... 101

Gear selection ........................... 165

Gear shifting ............................... 108

General information ...................225

Glovebox ..................................... 74