ignition OPEL KADETT 1991 Electronic Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1991, Model line: KADETT, Model: OPEL KADETT 1991Pages: 1070, PDF Size: 41.39 MB

Page 1026 of 1070

Downloaded from www.Manualslib.com manuals search engine Gas Analysis

Diagnostics using a 4 Gas Analyser

Before attempting to perform any diagnostics using a 4 gas analyser, it is important to

understand the equipment and the results obtained.

We shall begin with explaining the different gases tested :

Hydrocarbons (HC)Hydrocarbons are unburned or partially burnt fuel particles. High levels of HC,

measured in PPM (parts per million) in the exhaust gases, is usually due to

malfunctions in the ignition or fuel systems.

Carbon Monoxide (CO)Carbon monoxide is formed when there is insufficient oxygen present during

combustion and is measured as a percentage of exhaust gases. (CO - one part carbon

to one part oxygen) The most common cause of high CO is incorrect adjustment of

fuel mixtures. Refer to the relevant manufacturers manuals for correct setting

procedures.

Carbon Dioxide CO2CO2 - one part carbon to two parts oxygen. The greater the percentage of CO2 in the

exhaust gases, the more efficient the running of the engine, ideal specification for a 4

cylinder engine is between 13 and 16 %. If the CO2 level dropped too low, this would

indicate an incorrect air fuel mixture either caused by malfunctions in the

management system or incorrect adjustments.

Oxygen (O2)Oxygen is measured as a percentage of the exhaust gases and should be between 1 -

1.5% indicating an efficient combustion and air fuel mixture. Whilst adjustments are

being performed, it is important to note the changes in O2, as a sharp change of

between 0.5 - 1.0 % and 1.0 - 0.5 % will indicate the cross-over point from a rich or

lean mixture respectively. O2 measurement is also useful in detecting leaks and

misfiring as well as the efficiency of combustion.

Oxides of Nitrogen (Nox)Engines use O2 in the combustion process and exhaust Nitrogen (N2). This exhausted

N2 is exposed to high temperatures during the combustion process and is converted to

Oxides of Nitrogen (NOx) when that temperature exceeds approx. 1370 degrees

Celsius. Although NOx compounds do not directly affect the efficiency of an engine,

they are responsible for smog when combined with HC. Part of the solution to

minimise NOx is the catalytic converter and the exhaust gas recirculation process.

Page 1027 of 1070

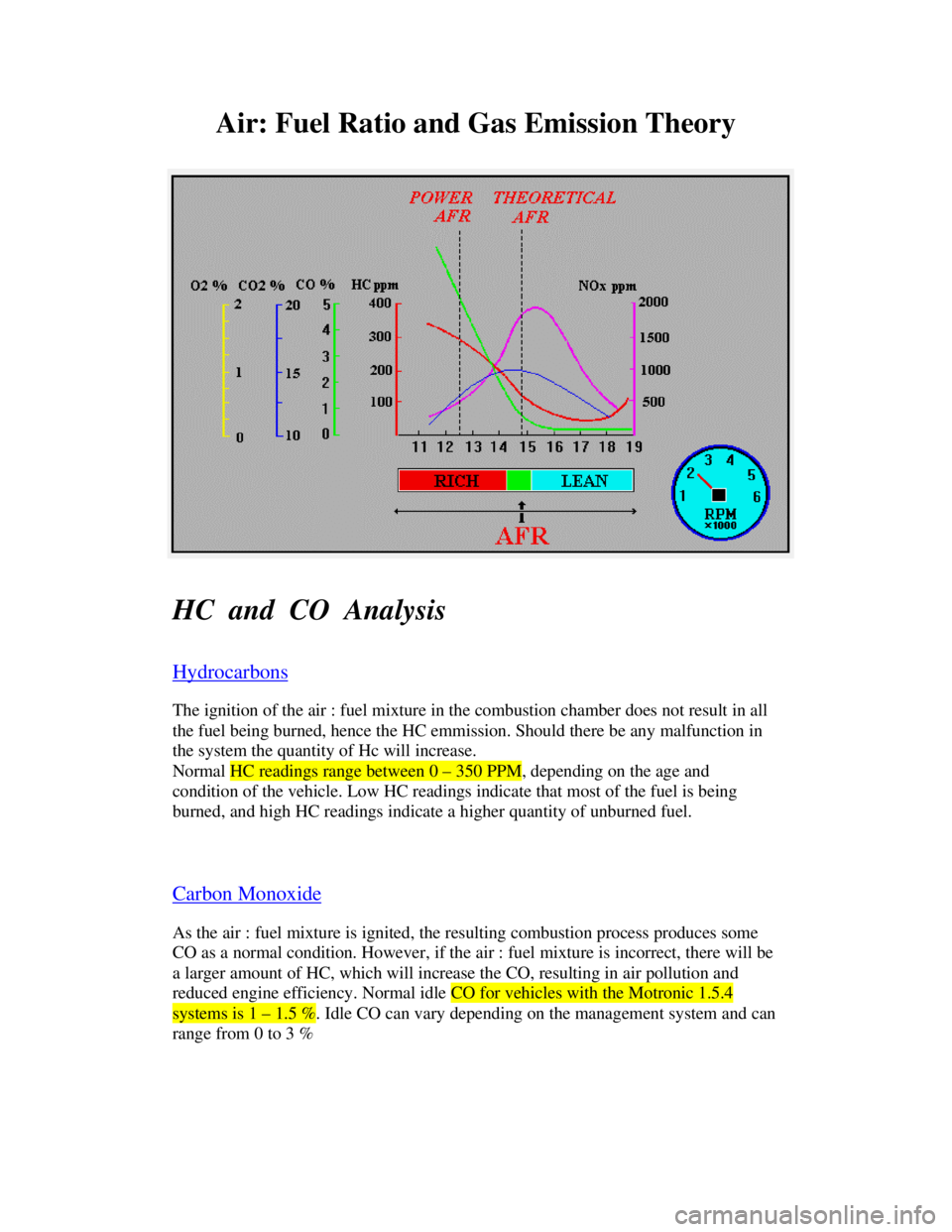

Downloaded from www.Manualslib.com manuals search engine Air: Fuel Ratio and Gas Emission Theory

HC and CO Analysis

HydrocarbonsThe ignition of the air : fuel mixture in the combustion chamber does not result in all

the fuel being burned, hence the HC emmission. Should there be any malfunction in

the system the quantity of Hc will increase.

Normal HC readings range between 0 – 350 PPM, depending on the age and

condition of the vehicle. Low HC readings indicate that most of the fuel is being

burned, and high HC readings indicate a higher quantity of unburned fuel.

Carbon MonoxideAs the air : fuel mixture is ignited, the resulting combustion process produces some

CO as a normal condition. However, if the air : fuel mixture is incorrect, there will be

a larger amount of HC, which will increase the CO, resulting in air pollution and

reduced engine efficiency. Normal idle CO for vehicles with the Motronic 1.5.4systems is 1 – 1.5 %. Idle CO can vary depending on the management system and can

range from 0 to 3 %

Page 1034 of 1070

Downloaded from www.Manualslib.com manuals search engine CONTENTS

1.0 PRODUCT DESCRIPTION

2.0 FEATURES

3.0 PRODUCT IDENTIFICATION AND APPLICATION

4.0 SPECIFICATION

4.1 Electrical

4.2 Environmental

4.3 Fuel delivery

5.0 CONNECTIONS

6.0 SPARK TIMING

6.1 Distributor bypass operation

6.2 Engine speed and crankshaft

position measurement

6.3 Engine load measurement

6.4 Advance angle look-up

6.5 Ignition firing delay calculation

6.6 Dwell time calculation

6.7 Engine water temperature measurement

7.0 FUEL INJECTION

7.1 Air mass to fuel mass ratio

7.2 Air mass measurement

7.3 Speed density concept

7.4 Fuel metering

7.5 Continuous fuel flow rate

7.6 Injector opening and closing times

7.7 Injection timing

7.8 Injection duration

7.9 Correction factors

7.9.1 Injection hardware deficiencies

7.9.2 Engine operating conditions

7.9.3 Intake air temperature

7.9.4 Engine temperature

7.9.5 Cold starting conditions

7.9.6 Post-start and warm-up conditions

7.9.7 Acceleration conditions

7.9.8 Deceleration lean-out conditions

Page 1035 of 1070

Downloaded from www.Manualslib.com manuals search engine 7.9.9 Coasting conditions

7.9.10 Flooded engine conditions

7.9.11 Full load operation

8.0 IDLE SPEED

9.0 IMMOBILISER OPERATION

10.0 DEFAULT MODE SELECTION

11.0 DIAGNOSTICS

11.1 Diagnostic codes

11.2 Volt- and ohmmeter

11.2.1 Battery voltage

11.2.2 Ignition voltage

11.2.3 TPS supply voltage

11.2.4 TPS input signal voltage

11.2.5 CO potentiometer supply voltage

11.2.6 MAP sensor supply voltage

11.2.7 MAP sensor signal voltage

11.2.8 Timing map selector

11.2.9 Fuel mixture selector

11.2.10 EWT sensor

11.2.11 MAT sensor

11.3 Fault finding

11.4 D-TEQ200 PC based tester

11.4.1 Description

11.4.2 Installation

11.4.3 Operation

11.5 C-TEQ200 component tester

11.5.1 Description

11.5.2 Operation

Page 1039 of 1070

Downloaded from www.Manualslib.com manuals search engine 4 SPECIFICATION

The following specification is applicable to DEFITA200 P/N:

A020-C ECU's unless otherwise stated:

4.1 Electrical

Operating voltage : 9 to 15 VDC continuous : 6 to 16 VDC limited functions : 24 VDC for 60 seconds maximum

Operating current : Less than 500 mA

Standby current : Less than 12 mA (>1 minute after

ignition off)

Timing accuracy : +/- 0.5 degrees

R.p.m. limit : 6,297

Reference signal : Negative edge from Distributor Y24

at 10ø BTDC

Base timing : 10ø BTDC r.p.m. < 450 or diagnostics initia- lised after starting

Mapped timing : r.p.m. > 450 and diagnostics dis-

abled

Selectable octane maps : 97 RON Factory fitted

: 93 RON

: 87 RON

: 87D RON (For fuel with octane

below 87 RON)

Selectable by interchanging octane plug on harness

Page 1043 of 1070

Downloaded from www.Manualslib.com manuals search engine 01B - Phase 1D drive signal to stepper motor

terminal D

02B - Phase 1C drive signal to stepper motor

terminal C

03B - Phase 2B drive signal to stepper motor

terminal B

04B - Phase 2A drive signal to stepper motor

terminal A

05B - TPS input signal from terminal C

06B - Bypass signal to distributor terminal C

07B - Coil driver output signal to distributor

terminal A

08B - Reference signal input from distributor

terminal B

09B - 5V output to TPS terminal A

10B - A/C relay output signal

11B - Fuel pump relay output

12B - Power ground connection

13B - Injector drive output signal

14B - Sensor/signal ground connection

15B - MAP sensor signal input from terminal B

16B - EWT signal input

17B - MAT signal input

18B - Fuel map selection input

19B - Timing map selection input

20B - CO mixture adjust input signal

21B - Sensor/signal ground connection

22B - Ignition voltage input

23B - 5V output to CO adjustment potentiometer

24B - 5V output to MAP sensor terminal C

25B - Power ground connection

26B - Battery voltage input

Page 1044 of 1070

Downloaded from www.Manualslib.com manuals search engine 6 SPARK TIMING

Spark timing and fuel injection for DEFITA200 ECU's is

calculated by a central processing unit and are based on:

I - MAP

II - EWT

III - Battery voltage

IV - Crankshaft position

V - Engine speed

VI - Throttle position

The optimum timing advance curves for a given engine are

determined by running the engine on an engine dynamometer

under any combination of the above-mentioned conditions.

This process is known as mapping the engine. The mapping is

further refined by extensive driving tests.

The mapped data regarding the engine is stored in a ROM

(Read Only Memory) within the ECU.

The following processes take place when calculating the

advance angle:

I - engine speed and crankshaft position measurement

II - engine load measurement

III - advance angle look-up

IV - ignition firing delay calculation

Page 1045 of 1070

Downloaded from www.Manualslib.com manuals search engine 6.1 Distributor bypass operation

At engine speeds below 450 r.p.m. the ECU does not control

the firing angle. The ECU keeps the bypass line to terminal

C of the distributor low for engine speeds below 450 r.p.m.

The spark advance for the vehicle is set to 10ø BTDC by the

distributor, while the engine speed is below 450 r.p.m..

Above 450 r.p.m. the ECU takes the bypass line high (+5

volt) and takes over control of the spark advance as de-

scribed below.

6.2 Engine speed and crankshaft position measurement

Engine speed is calculated by measuring the period from one

negative edge to the next negative edge of the distributor

reference signal. The reference signals are separated by

180 degrees.

The distributor generates a signal as shown in the reference

and ignition waveform diagram. The time taken for the crank-

shaft to rotate from 10ø BTDC to the next 10ø BTDC marker

is measured. Knowing the time it takes the crankshaft to

rotate through 180ø it is possible to calculate the current

engine speed in degrees per second (ø/s). Crankshaft posi-

tion is obtained by sensing the falling edges of the refer-

ence signal.

Page 1047 of 1070

Downloaded from www.Manualslib.com manuals search engine 6.5 Ignition firing delay calculation

The advance angle obtained from the look-up matrix is sub-

tracted from the 10ø BTDC marker on the distributor shaft to

obtain the firing angle delay.

Example: Advance angle = -20ø on next cycle

Marker position = -10ø

Firing angle delay = 180ø-(-10ø)-20ø

= 170ødelay

Having determined the engine speed previously in degrees per

second it is now possible to calculate the delay time after

the BTDC marker that corresponds with the required advance

angle.

Example: Crankshaft speed = 5,400 r.p.m.

Distributor speed = 2,700 r.p.m.

= 2,700 / 60 r.p.s.

= 45 r.p.s.

= 45x360 ø/s

Crankshaft speed = 2x45x360 ø/s

= 30,400 ø/s

170ø rotation delay = 170 / 30,400 s

= 5.59 milli-second delay

Page 1048 of 1070

Downloaded from www.Manualslib.com manuals search engine 6.6 Dwell time calculation

Dwell time is the time during which the battery voltage must

be applied to the ignition coil's primary winding prior to

an ignition pulse. The correct dwell time is important to

ensure constant spark energy.

The correct dwell time depends on the battery voltage. A

look-up matrix contains dwell time versus battery voltage.

The prevailing battery voltage is measured and compared with

the voltages stored in the dwell look-up matrix. The corre-

sponding dwell time is used to energise the ignition coil.

6.7 Engine water temperature measurement

EWT measurement is accomplished by a NTC (Negative

Temperature Coefficient) sensor mounted on the engine block.

The base advance angles are increased with decreasing

engine temperatures. This is necessary because it takes

longer to reach maximum cylinder pressure after ignition

when an engine is cold. Typical additional advance required

for an engine at -20ø Celsius ranges from 3ø to 8ø with

respect to an engine operating at 100ø Celsius.