wheel OPEL KARL 2019 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2019, Model line: KARL, Model: OPEL KARL 2019Pages: 191, PDF Size: 5.51 MB

Page 157 of 191

Vehicle care155●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

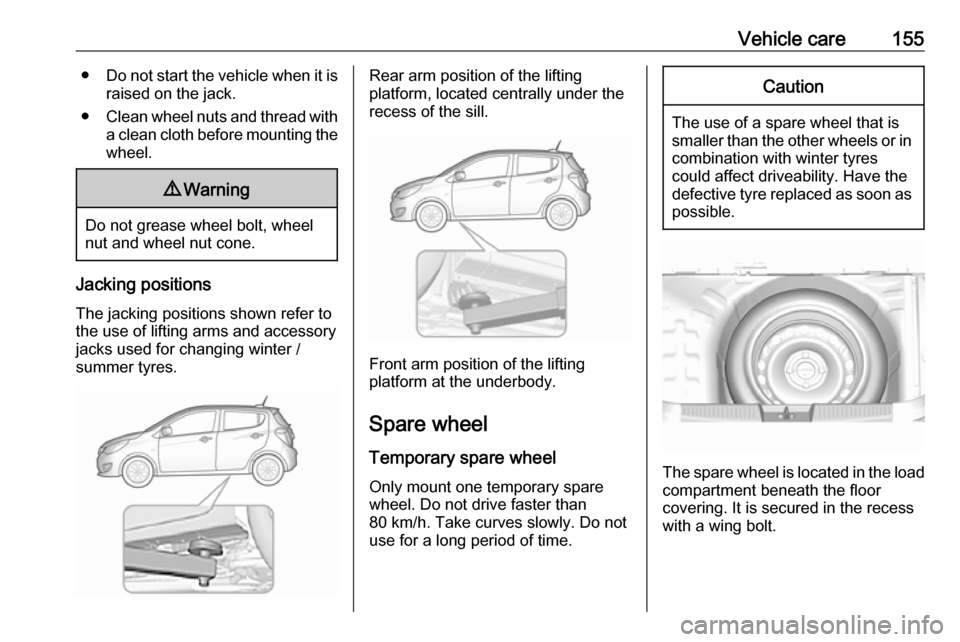

Jacking positions

The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform, located centrally under the

recess of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel Temporary spare wheel

Only mount one temporary spare

wheel. Do not drive faster than

80 km/h. Take curves slowly. Do not

use for a long period of time.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured in the recess

with a wing bolt.

Page 158 of 191

156Vehicle careOnly mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear or reverse gear.

● Remove the spare wheel 3 155.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels:

Pull off the wheel cover.

Alloy wheels with bolt caps

Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

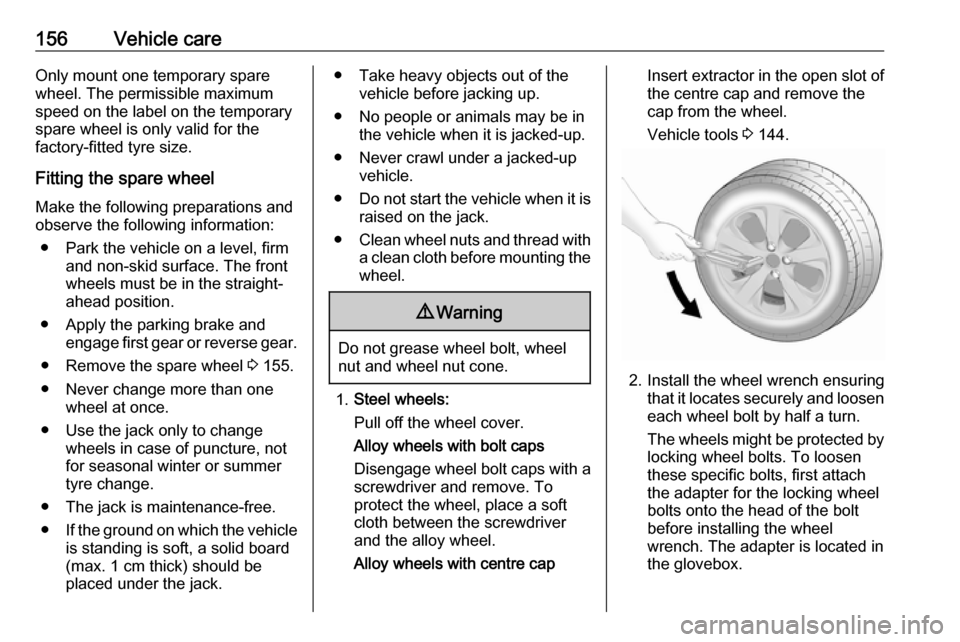

Alloy wheels with centre cap

Insert extractor in the open slot of

the centre cap and remove the

cap from the wheel.

Vehicle tools 3 144.

2. Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

Page 159 of 191

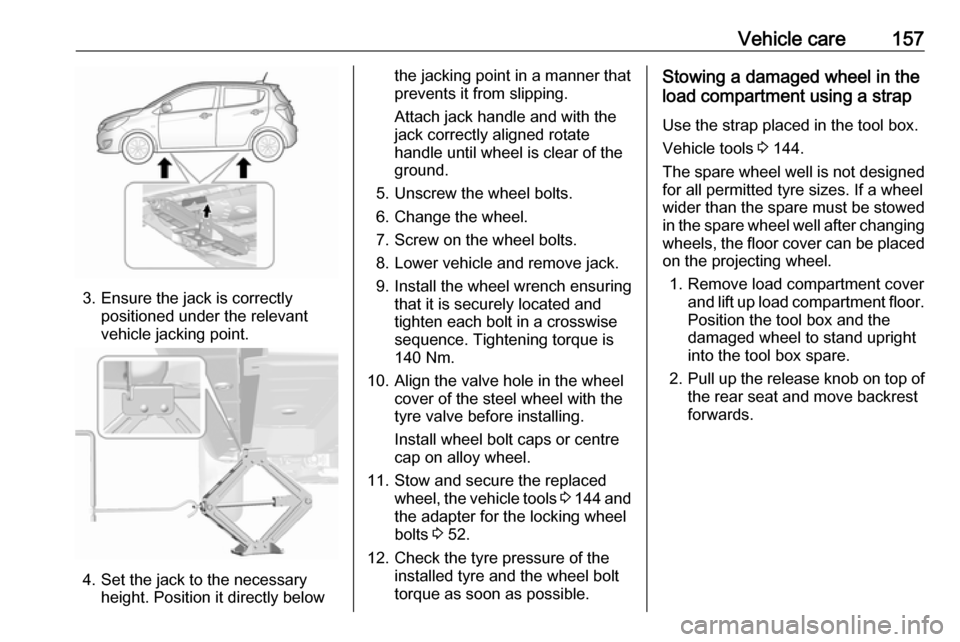

Vehicle care157

3. Ensure the jack is correctlypositioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle and remove jack.

9. Install the wheel wrench ensuring that it is securely located and

tighten each bolt in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 144 and

the adapter for the locking wheel

bolts 3 52.

12. Check the tyre pressure of the installed tyre and the wheel bolt

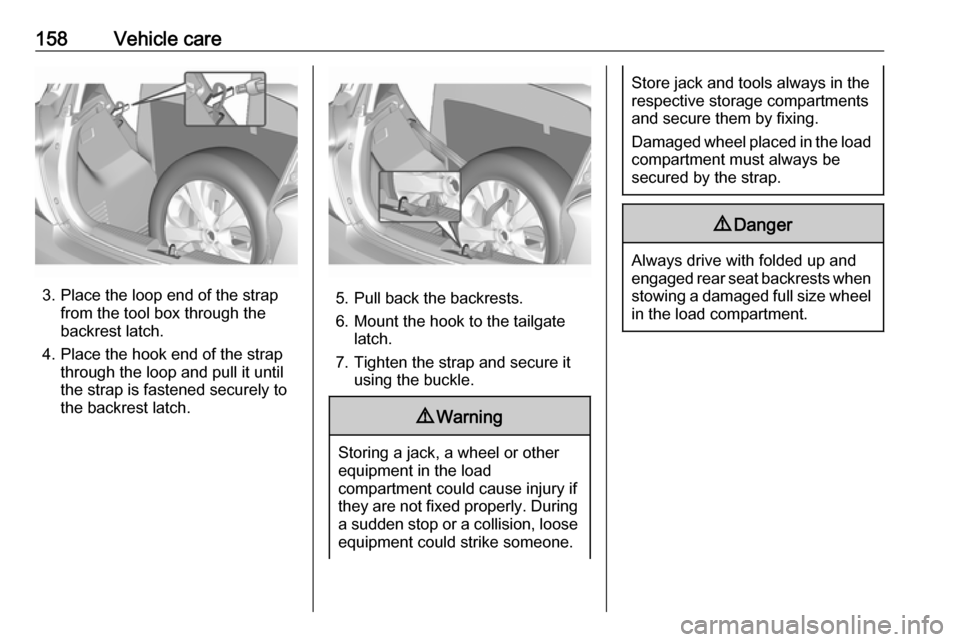

torque as soon as possible.Stowing a damaged wheel in the

load compartment using a strap

Use the strap placed in the tool box.

Vehicle tools 3 144.

The spare wheel well is not designed for all permitted tyre sizes. If a wheel

wider than the spare must be stowed

in the spare wheel well after changing

wheels, the floor cover can be placed on the projecting wheel.

1. Remove load compartment cover and lift up load compartment floor.

Position the tool box and the

damaged wheel to stand upright

into the tool box spare.

2. Pull up the release knob on top of

the rear seat and move backrest

forwards.

Page 160 of 191

158Vehicle care

3. Place the loop end of the strapfrom the tool box through the

backrest latch.

4. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the backrest latch.5. Pull back the backrests.

6. Mount the hook to the tailgate latch.

7. Tighten the strap and secure it using the buckle.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, loose

equipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured by the strap.9 Danger

Always drive with folded up and

engaged rear seat backrests when

stowing a damaged full size wheel

in the load compartment.

Page 163 of 191

Vehicle care161

2. Screw in the towing eye as far asit will go until it stops in a

horizontal position.

3. Attach a tow rope – or better still a

tow rod – to the towing eye.

General

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

The vehicle must be towed facing

forward, not faster than 88 km/h. In all

other cases and when the

transmission is defective, the front

axle must be raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap and engage in the front

bumper.

Appearance care

Exterior care

Locks The locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use a de-icing agent only

when absolutely necessary, as this

has a degreasing effect and impairs

lock function. After using a de-icing

agent, have the locks regreased by a workshop.

Washing The paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly. When using automatic vehicle

washes, select a programme that

includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

Page 164 of 191

162Vehicle careIf using a car wash, comply with the

car wash manufacturer's instructions. The windscreen wiper and rear

window wiper must be switched off.

Remove antenna and external

accessories such as roof racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Do not use hard objects to remove

spots of tar. Use tar removal spray on

painted surfaces.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax painted parts of the vehicle

regularly (at the latest when water no longer beads). Otherwise, the

paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Unpainted plastic body parts must not

be treated with wax or polishing

agents.

Windows and windscreen wiper

blades

Switch off wipers before handling in

their areas.

Use a soft lint-free cloth or chamois leather together with window cleaner

and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Page 165 of 191

Vehicle care163SunroofNever clean with solvents or abrasive

agents, fuels, aggressive media (e.g.

paint cleaner, acetone-containing

solutions etc.), acidic or highly

alkaline media or abrasive pads. Do

not apply wax or polishing agents to

the sunroof.

Wheels and tyres Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage

Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen / rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Interior care

Interior and upholstery Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light-

coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.Caution

Close Velcro fasteners as open

Velcro fasteners on clothing could damage seat upholstery.

The same applies to clothing with

sharp-edged objects, like zips or

belts or studded jeans.

Plastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol

in particular. Do not use high-

pressure jet cleaners.

Page 175 of 191

![OPEL KARL 2019 Manual user Technical data173Vehicle dimensionsLength [mm]3675Width without exterior mirrors [mm]1595 - 16324)Width with two exterior mirrors [mm]1876Height (without antenna) [mm] without roof rack1476 - 1495 4)L OPEL KARL 2019 Manual user Technical data173Vehicle dimensionsLength [mm]3675Width without exterior mirrors [mm]1595 - 16324)Width with two exterior mirrors [mm]1876Height (without antenna) [mm] without roof rack1476 - 1495 4)L](/img/37/18884/w960_18884-174.png)

Technical data173Vehicle dimensionsLength [mm]3675Width without exterior mirrors [mm]1595 - 16324)Width with two exterior mirrors [mm]1876Height (without antenna) [mm] without roof rack1476 - 1495 4)Length of load compartment floor [mm]486Length of load compartment with folded rear seats [mm]1109Load compartment width [mm]968Load compartment height with cover [mm]499Height of load compartment opening [mm]608Wheelbase [mm]2385Turning circle diameter [m] 4)9.8 - 10.74)

Depending on equipment variants.

Page 176 of 191

![OPEL KARL 2019 Manual user 174Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/ OPEL KARL 2019 Manual user 174Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/](/img/37/18884/w960_18884-175.png)

174Technical dataTyre pressuresComfort with up to 3 peopleECO with up to 3 peopleWith full loadTyresfrontrearfrontrearfrontrear[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])[kPa/bar]

([psi])165/65 R14,

185/55 R15,

195/45 R16220/2.2 (32)210/2.1 (30)270/2.7 (39)250/2.5 (36)260/2.6 (38)300/3.0 (44)Temporary spare wheel

T105/70D14420/4.2 (60)

Page 182 of 191

180Customer informationEnGIS Technologies, Inc.

BringGo ®

is a registered trademark of

EnGIS Technologies, Inc.Google Inc.

Android™ and Google Play™ Store

are trademarks of Google Inc.Stitcher Inc.

Stitcher™ is a trademark of Stitcher,

Inc.Verband der Automobilindustrie e.V.

AdBlue ®

is a registered trademark of

the VDA.Vehicle data recording

and privacy

Event data recorders

Electronic control units are installed in

your vehicle. Control units process

data which is received by vehicle

sensors, for example, or which they

generate themselves or exchange

amongst themselves. Some control

units are necessary for the safe

functioning of your vehicle, others

assist you while you drive (driver

assistance systems), while others

provide comfort or infotainment

functions.

The following contains general

information about data processing in

the vehicle. You will find additional

information as to which specific data

is uploaded, stored and passed on to third parties and for what purpose in

your vehicle under the key word Data Protection closely linked to the

references for the affected functional

characteristics in the relevant owner's

manual or in the general terms of

sale. These are also available online.Operating data in the vehicle

Control units process data for

operation of the vehicle.

This data includes, e.g.: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate, "seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient, not

stored for longer than an operational

cycle, and only processed on board

the vehicle itself. Control units often

include data storage (including the vehicle key). This is used to allowinformation to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.