instrument panel OPEL MANTA 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: MANTA, Model: OPEL MANTA 1973Pages: 625, PDF Size: 17.22 MB

Page 115 of 625

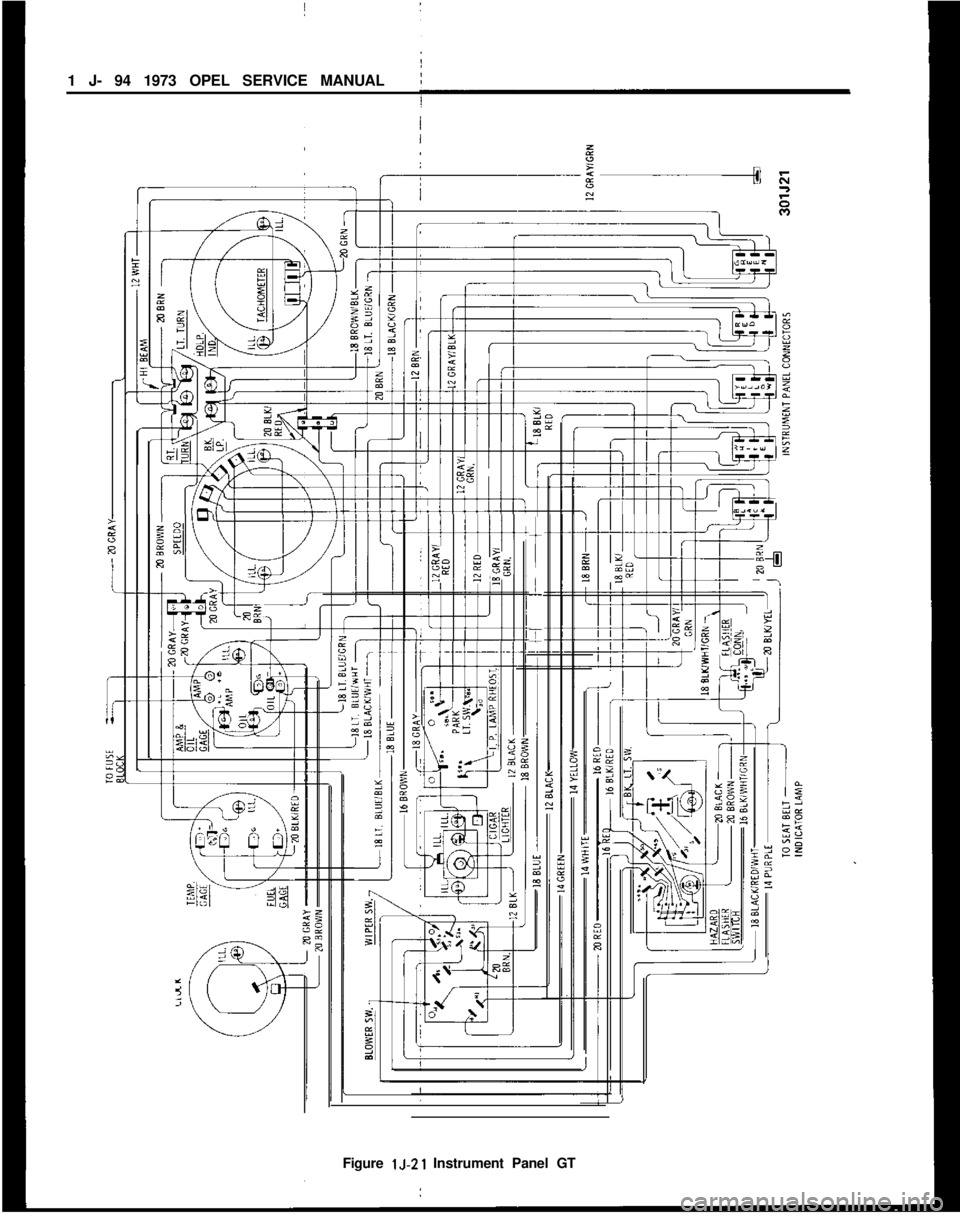

1 J- 94 1973 OPEL SERVICE MANUALi

I

IFigure lJ-21 Instrument Panel GT

Page 157 of 625

26-341973 OPEL SERVICE MANUAL

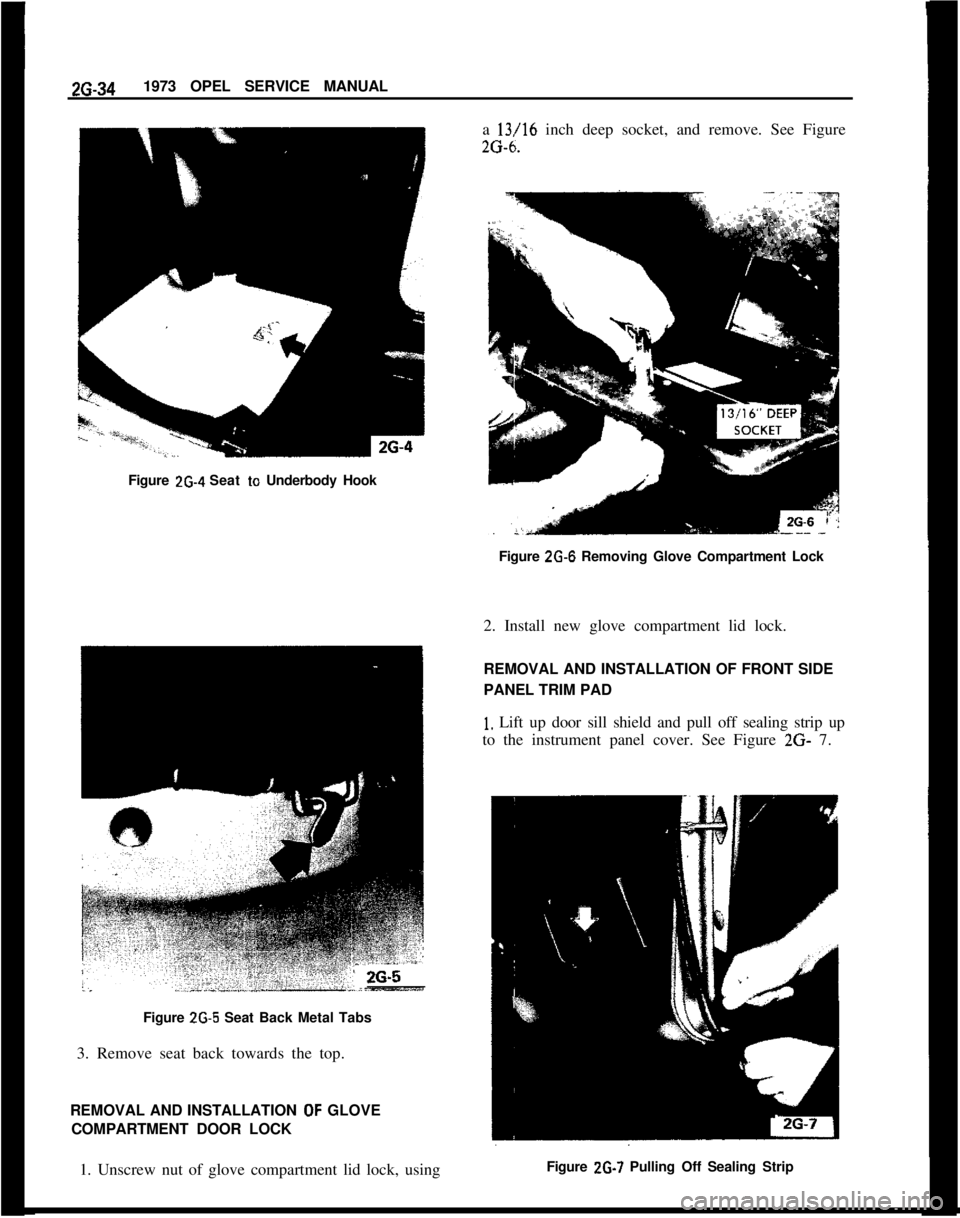

a 13/16 inch deep socket, and remove. See Figure2G-6.Figure

ZG-4 Seat to Underbody Hook

Figure

ZG-5 Seat Back Metal Tabs

3. Remove seat back towards the top.

REMOVAL AND INSTALLATION

OF GLOVE

COMPARTMENT DOOR LOCK

1. Unscrew nut of glove compartment lid lock, usingFigure ZG-6 Removing Glove Compartment Lock

2. Install new glove compartment lid lock.

REMOVAL AND INSTALLATION OF FRONT SIDE

PANEL TRIM PAD

1, Lift up door sill shield and pull off sealing strip up

to the instrument panel cover. See Figure 2G- 7.

Figure

ZG-7 Pulling Off Sealing Strip

Page 202 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY 3E.35

II

OPEL 1900 AND MANTA STEERING COLUMN

ASSEMBLY

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Description and Operation of Directional Signal

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description

andOperationofHorn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description of Steering Column Assembly

. . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

3E-353E-363E-36

Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Disassembly and Reassembly of Direction Signal

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering and

Ignition Lock Cylinder, and Electrical Switch

from Mast Jacket Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering

ColumnSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-363E-383E-393E-403E-41

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

DIRECTIONAL SIGNAL LEVERhigh to low beam or vice versa. On all

19M) Rallye

cars, when switching from low to high beam posi-

tion, with the fog lamp instrument panel switch ON

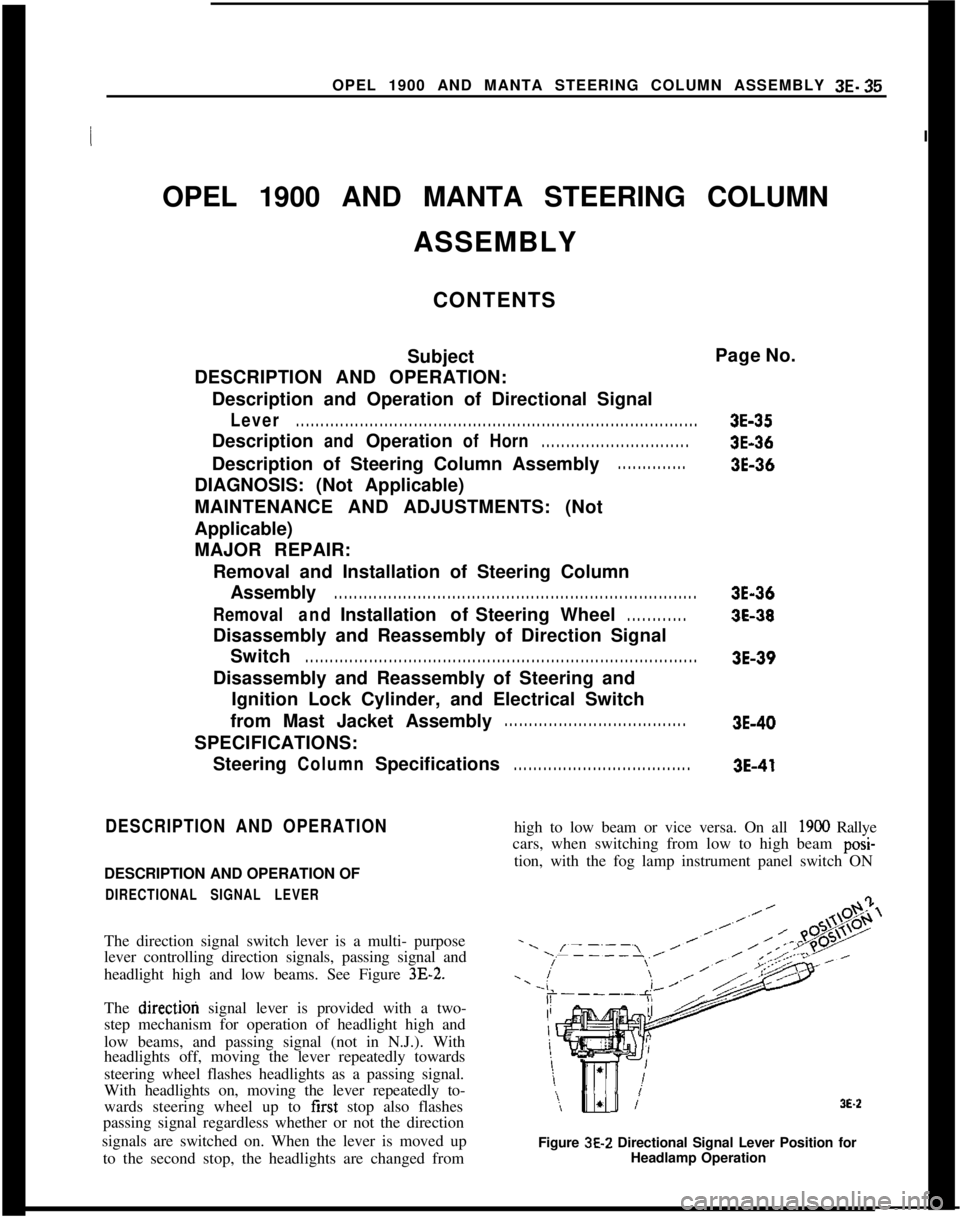

The direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal and

headlight high and low beams. See Figure

3E-2.The dire&M signal lever is provided with a two-

step mechanism for operation of headlight high and

low beams, and passing signal (not in N.J.). With

headlights off, moving the lever repeatedly towards

steering wheel flashes headlights as a passing signal.

With headlights on, moving the lever repeatedly to-

wards steering wheel up to first stop also flashes

passing signal regardless whether or not the direction

signals are switched on. When the lever is moved up

to the second stop, the headlights are changed from

SE.2Figure

3E-2 Directional Signal Lever Position for

Headlamp Operation

Page 205 of 625

3E- 38 ,1973 OPEL SERVICE MANUAL

ponents and systems, and/or could result in major

repair expense. They must be replaced with one or

the same part number or with

an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque

values must be used as specified during reas-

sembly to assure proper retention of these parts.On installation, make sure steering wheel spokes

point downwards and steering gear is in high point.

1. Carefully insert steering mast into universal joint

flange.

2. Loosely attach slide-off base attaching nuts at un-

derside of instrument panel.

3. Attach steering mast jacket at front of dash, using

a notched hex nut.

4. Torque nuts at slide-off base to II

lb.ft.5. Tighten screw at steering mast clamp to 22

lb.ft.6. Reconnect wires to directional signal switch and

ignition switch.

7. Reconnect battery.

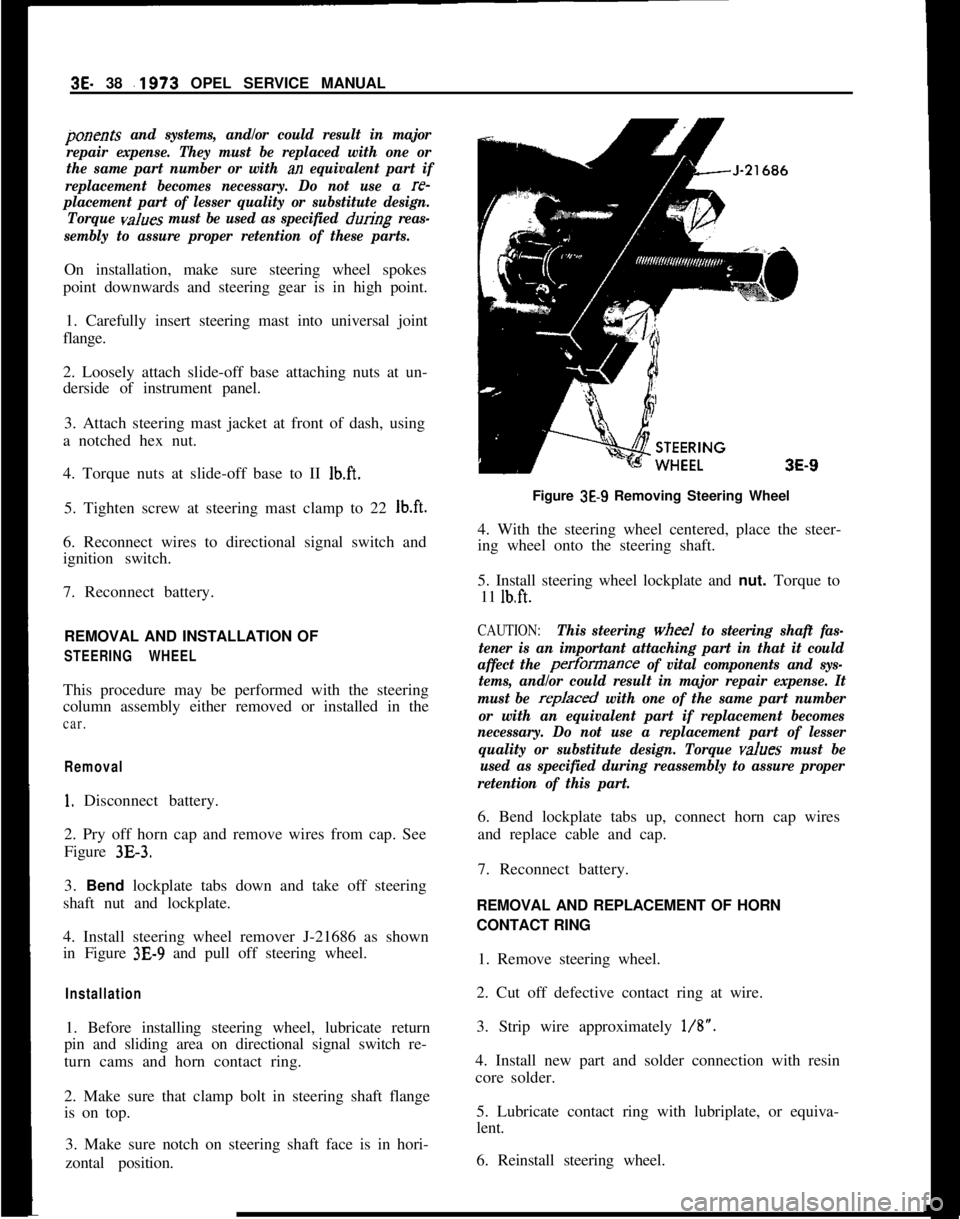

REMOVAL AND INSTALLATION OF

STEERING WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.

Removal

1. Disconnect battery.

2. Pry off horn cap and remove wires from cap. See

Figure

3E-3.3. Bend lockplate tabs down and take off steering

shaft nut and lockplate.

4. Install steering wheel remover J-21686 as shown

in Figure

3E-9 and pull off steering wheel.

Installation1. Before installing steering wheel, lubricate return

pin and sliding area on directional signal switch re-

turn cams and horn contact ring.

2. Make sure that clamp bolt in steering shaft flange

is on top.

3. Make sure notch on steering shaft face is in hori-

zontal position.Figure

3E-9 Removing Steering Wheel

4. With the steering wheel centered, place the steer-

ing wheel onto the steering shaft.

5. Install steering wheel lockplate and nut. Torque to

11

lb.ft.

CAUTION:

This steering wheeI to steering shaft fas-

tener is an important attaching part in that it could

affect the

performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be repked

with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque

values must be

used as specified during reassembly to assure proper

retention of this part.6. Bend lockplate tabs up, connect horn cap wires

and replace cable and cap.

7. Reconnect battery.

REMOVAL AND REPLACEMENT OF HORN

CONTACT RING

1. Remove steering wheel.

2. Cut off defective contact ring at wire.

3. Strip wire approximately

l/8”.4. Install new part and solder connection with resin

core solder.

5. Lubricate contact ring with lubriplate, or equiva-

lent.

6. Reinstall steering wheel.

Page 206 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY3E- 39~~~A~SEMBLY AND ~EASBEMBL~ 0~

DIRECTIONAL SIGNAL SWITCHThis procedure may be performed with the steering

column assembly removed or installed in the car.

Disassembly (Opel 1900. Manta)

1. Remove steering wheel (see paragraph above).

2. Pull off signal switch and steering and ignition

lock wire set.

3. Pull directional signal lever out of seat. Lever is

held in place by a lock ball.

4. Unscrew lower half of signal switch housing cover.

See Figure

3E-10.Figure

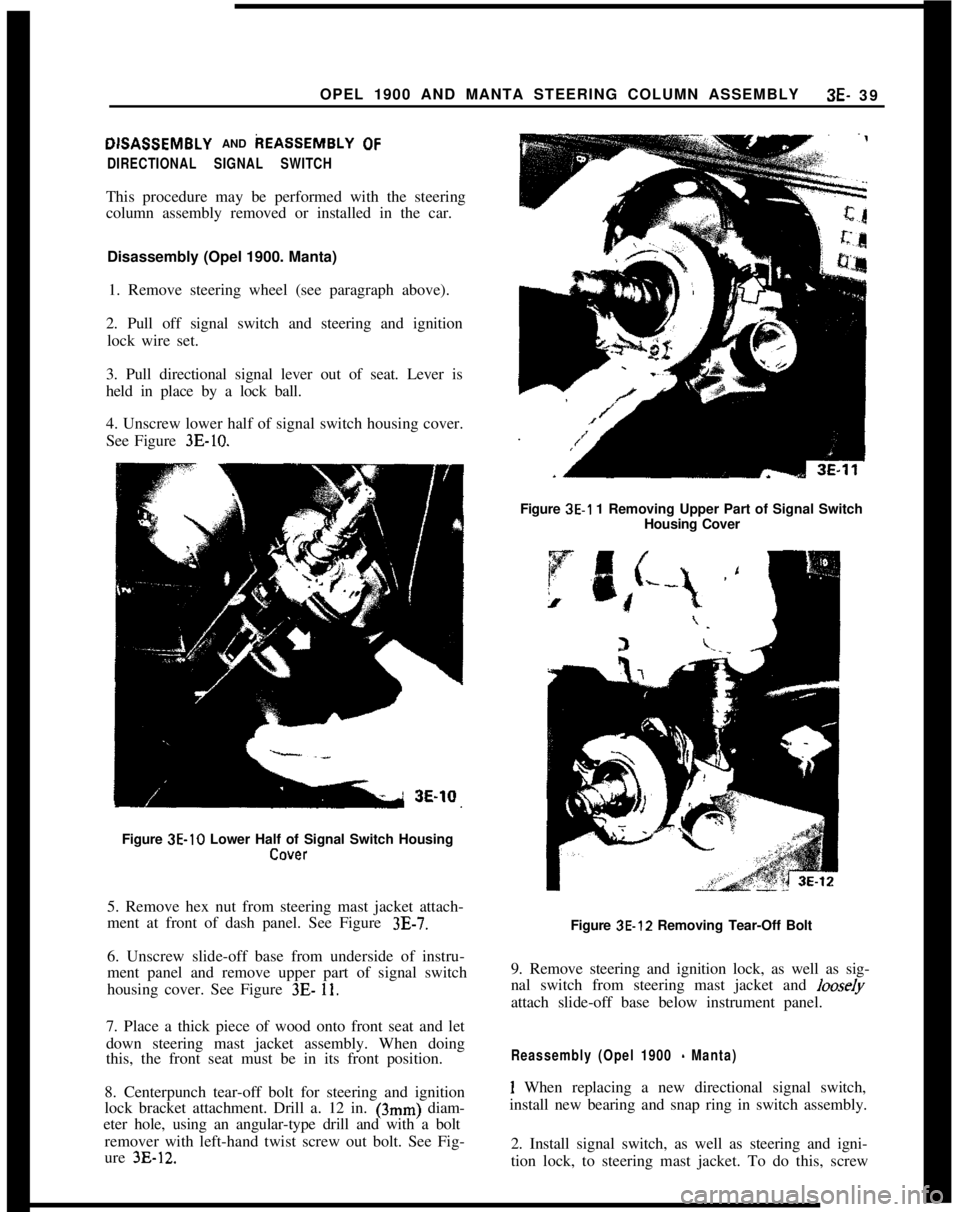

3E-1 1 Removing Upper Part of Signal Switch

Housing Cover

Figure 3E-10 Lower Half of Signal Switch Housing

COVSr5. Remove hex nut from steering mast jacket attach-

ment at front of dash panel. See Figure

3E-7.6. Unscrew slide-off base from underside of instru-

ment panel and remove upper part of signal switch

housing cover. See Figure 3E-

11,7. Place a thick piece of wood onto front seat and let

down steering mast jacket assembly. When doing

this, the front seat must be in its front position.

8. Centerpunch tear-off bolt for steering and ignition

lock bracket attachment. Drill a. 12 in. (3mm) diam-

eter hole, using an angular-type drill and with a bolt

remover with left-hand twist screw out bolt. See Fig-

ure

3E-12.Figure

3E-12 Removing Tear-Off Bolt

9. Remove steering and ignition lock, as well as sig-

nal switch from steering mast jacket and

foosefyattach slide-off base below instrument panel.

Reassembly (Opel 1900 - Manta)

1 When replacing a new directional signal switch,

install new bearing and snap ring in switch assembly.

2. Install signal switch, as well as steering and igni-

tion lock, to steering mast jacket. To do this, screw

Page 211 of 625

3E. 441973 OPEL SERVICE’MANUAL

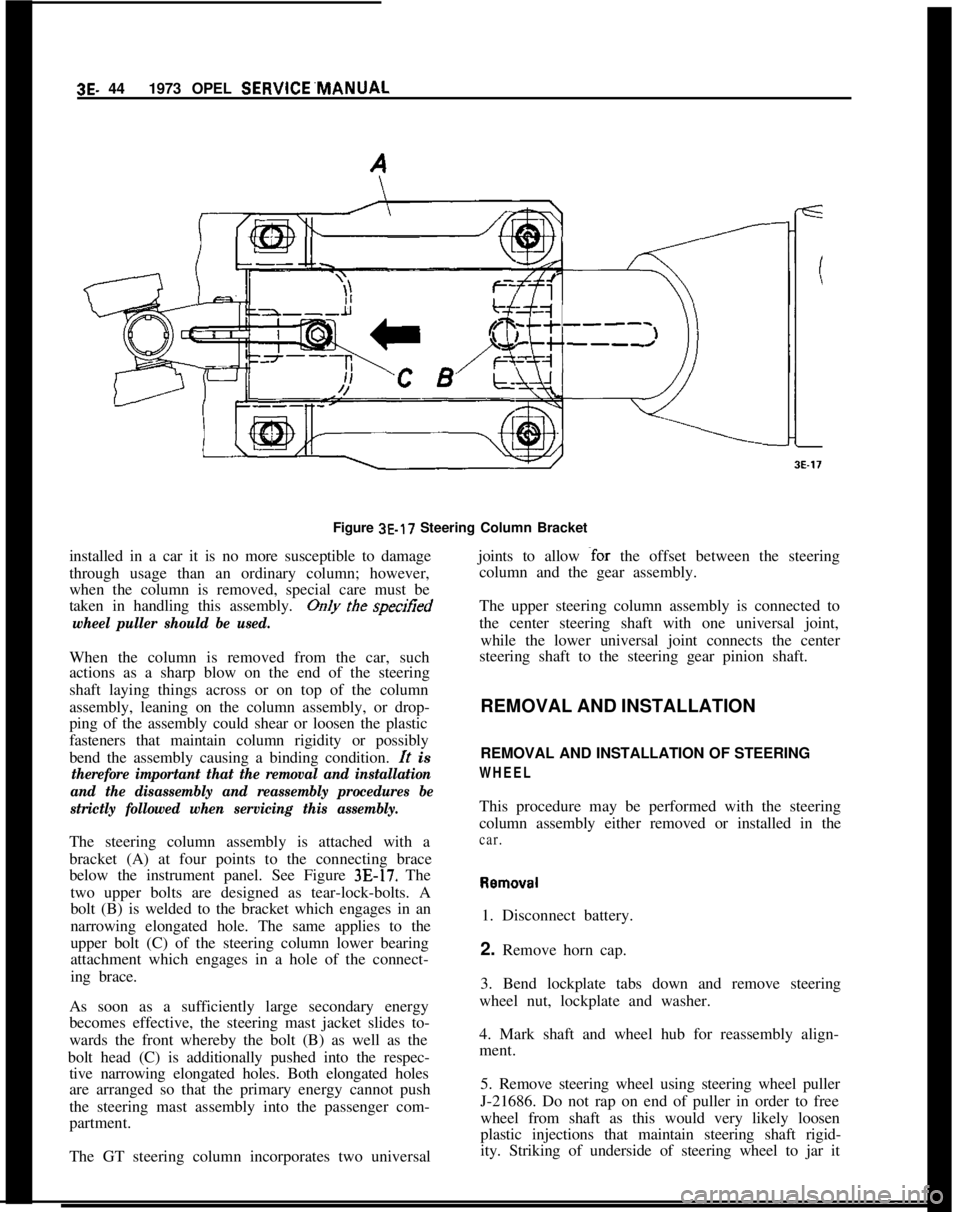

Figure 3E-17 Steering Column Bracket

installed in a car it is no more susceptible to damage

through usage than an ordinary column; however,

when the column is removed, special care must be

taken in handling this assembly.Only the speufied

wheel puller should be used.When the column is removed from the car, such

actions as a sharp blow on the end of the steering

shaft laying things across or on top of the column

assembly, leaning on the column assembly, or drop-

ping of the assembly could shear or loosen the plastic

fasteners that maintain column rigidity or possibly

bend the assembly causing a binding condition.

It is

therefore important that the removal and installation

and the disassembly and reassembly procedures be

strictly followed when servicing this assembly.The steering column assembly is attached with a

bracket (A) at four points to the connecting brace

below the instrument panel. See Figure

3E-17. The

two upper bolts are designed as tear-lock-bolts. A

bolt (B) is welded to the bracket which engages in an

narrowing elongated hole. The same applies to the

upper bolt (C) of the steering column lower bearing

attachment which engages in a hole of the connect-

ing brace.

As soon as a sufficiently large secondary energy

becomes effective, the steering mast jacket slides to-

wards the front whereby the bolt (B) as well as the

bolt head (C) is additionally pushed into the respec-

tive narrowing elongated holes. Both elongated holes

are arranged so that the primary energy cannot push

the steering mast assembly into the passenger com-

partment.

The GT steering column incorporates two universaljoints to allow

~for the offset between the steering

column and the gear assembly.

The upper steering column assembly is connected to

the center steering shaft with one universal joint,

while the lower universal joint connects the center

steering shaft to the steering gear pinion shaft.

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION OF STEERING

WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.Removal

1. Disconnect battery.

2. Remove horn cap.

3. Bend lockplate tabs down and remove steering

wheel nut, lockplate and washer.

4. Mark shaft and wheel hub for reassembly align-

ment.

5. Remove steering wheel using steering wheel puller

J-21686. Do not rap on end of puller in order to free

wheel from shaft as this would very likely loosen

plastic injections that maintain steering shaft rigid-

ity. Striking of underside of steering wheel to jar it

Page 362 of 625

CLUTCH7A. 1

CLUTCH

CONTENTS

Subject

DESCRIPTION AND OPERATION: Clutch andClutch

PedalMechanisms

. . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS:

Clutch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .

MAINTENANCE AND ADJUSTMENTS: Clutch LashAdjustment (GTOnly)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Adjustment (All 1.9 Engines Except GT). . . .

Control CableAdjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .

MAJOR REPAIR:

Clutch Removal and Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Control Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS:

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No.

7A-

1

7A-2

7A-4

7A-4

7A-4

IA-5

7A- 7

7A-7

DESCRIPTION AND OPERATION

CLUTCH PEDAL MECHANISM GT Only

The pedal lever pivots on a tubular steel shaft and

operates the clutch release yoke thru a sheathed ca-

ble attached directly to the upper end of the pedallever. Pedal return is accomplished thru the cable by

the clutch yoke return spring at the transmission.

The pedal return stop

is a nonadjustable rubber

bumper inserted through the upper end of the pedal leverjust below the cable attaching point. The clutch

cable is sheathed in woven steel and weather pro-

tected by a plastic and fabric covering. An eyelet is

wedged on the upper end and fits over a formed

hook on the upper end of the pedal. The lower end

is provided with a

wedged ball stud arrangement

that slips into a slot in the clutch release lever. See

Figure

7A-6.

Opel 1900 and Manta

The pedal lever pivots on a tubular steel shaft and

operates the clutch release yoke through a sheathed

cable attached directly to the upper end of the pedal

lever. Pedal return is accomplished through a spring

attached to the pedal below the pivot shaft and to the

pedal assembly mounting bracket at the bulkhead. Clutch actuation works without pedal-free travel and

a warning device is provided which actuates an in-

dicator lamp in the instrument panel indicating

necessity of clutch adjustment. The clutch cable is

sheathed in

woven steel and weather protected by a

plastic fabric covering. An eyelet is wedged on the

upper end and fits over a formed hook on the upper

end of the pedal. The lower end is provided with a

wedged ball stud arrangement that slips into a slot in the clutch release lever. See Figure

7A-7.

Clutch Mechanism

The clutch assembly is enclosed in the bell housing.

The clutch release bearing and release fork are of

conventional design, with the fork pivoting on a ball

stud located opposite the control cable attaching

point. The bearing flange tits over two vertical pins

which are riveted to and extend into the eye of the

yoke.

The clutch pressure plate is similar in design to the

Buick Century pressure plate. A radially slotted dia-

phragm pivoting on two steel wire rings is retained

to the clutch cover by eight rivets. The clutch driven

member is a

6-3/4 inches diameter single plate dry

disc with torsional damper springs and spring leaves

between facings to cushion application. Dampener

springs in clutch disc assembly are

preloaded.

Page 365 of 625

7A- 41973 dPEL SERVICE MANUALConditionPossible CauseCorrectionHeat-blued driven plate

and pressure plate

assembly.

1. Improper pedal1. Replace only driven plate, and

adjustment.adjust clutch pedal and cable.

Grab and chatter with

oil present on clutch

assembly.1. Oil leak.1. Correct oil leakage, clean

pressure plate in solvent, replace

driven plate and adjust pedal lash.

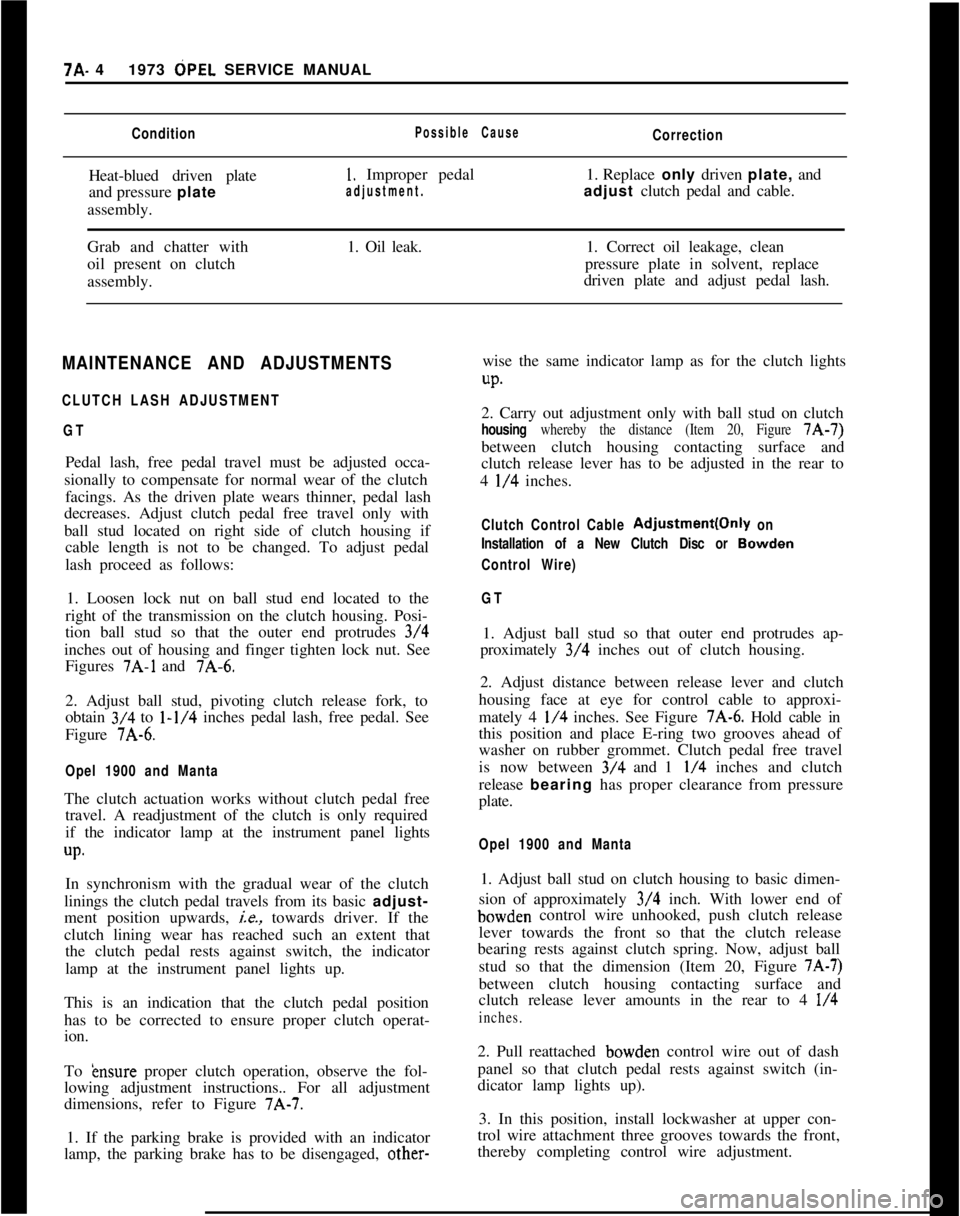

MAINTENANCE AND ADJUSTMENTS

CLUTCH LASH ADJUSTMENT

GTPedal lash, free pedal travel must be adjusted occa-

sionally to compensate for normal wear of the clutch

facings. As the driven plate wears thinner, pedal lash

decreases. Adjust clutch pedal free travel only with

ball stud located on right side of clutch housing if

cable length is not to be changed. To adjust pedal

lash proceed as follows:

1. Loosen lock nut on ball stud end located to the

right of the transmission on the clutch housing. Posi-

tion ball stud so that the outer end protrudes 3/4

inches out of housing and finger tighten lock nut. See

Figures

7A-1 and 7A-6.

2. Adjust ball stud, pivoting clutch release fork, to

obtain 3/4 to

l-1/4 inches pedal lash, free pedal. See

Figure 7A-6.

Opel 1900 and MantaThe clutch actuation works without clutch pedal free

travel. A readjustment of the clutch is only required

if the indicator lamp at the instrument panel lights

up.In synchronism with the gradual wear of the clutch

linings the clutch pedal travels from its basic adjust-

ment position upwards,

ie., towards driver. If the

clutch lining wear has reached such an extent that

the clutch pedal rests against switch, the indicator

lamp at the instrument panel lights up.

This is an indication that the clutch pedal position

has to be corrected to ensure proper clutch operat-

ion.

To

&~sure proper clutch operation, observe the fol-

lowing adjustment instructions.. For all adjustment

dimensions, refer to Figure 7A-7.

1. If the parking brake is provided with an indicator

lamp, the parking brake has to be disengaged, other-wise the same indicator lamp as for the clutch lights

UP.2. Carry out adjustment only with ball stud on clutch

housing whereby the distance (Item 20, Figure 7A-7)

between clutch housing contacting surface and

clutch release lever has to be adjusted in the rear to

4

l/4 inches.

Clutch Control Cable Adjustment(Only on

Installation of a New Clutch Disc or

Bowden

Control Wire)

GT1. Adjust ball stud so that outer end protrudes ap-

proximately 3/4 inches out of clutch housing.

2. Adjust distance between release lever and clutch

housing face at eye for control cable to approxi-

mately 4

l/4 inches. See Figure 7A-6. Hold cable in

this position and place E-ring two grooves ahead of

washer on rubber grommet. Clutch pedal free travel

is now between 3/4 and 1

l/4 inches and clutch

release bearing has proper clearance from pressure

plate.

Opel 1900 and Manta1. Adjust ball stud on clutch housing to basic dimen-

sion of approximately 3/4 inch. With lower end ofbowden control wire unhooked, push clutch release

lever towards the front so that the clutch release

bearing rests against clutch spring. Now, adjust ball

stud so that the dimension (Item 20, Figure

7A-7)between clutch housing contacting surface and

clutch release lever amounts in the rear to 4

l/4

inches.2. Pull reattached bowden control wire out of dash

panel so that clutch pedal rests against switch (in-

dicator lamp lights up).

3. In this position, install lockwasher at upper con-

trol wire attachment three grooves towards the front,

thereby completing control wire adjustment.

Page 503 of 625

8A-2 1973 OPEL SERVICE MANUAL

HOOD, FENDERS, AND GRILLE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

GTHeadlampOperation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS

GTHeadlampMechanism

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Removal and Installation

Hood (1900

- Manta). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fender(1900-Manta). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlamp Covering (1900

- Manta). . . . . . . . . . . . . . . . . . . . . . . .Headlamp Assembly

(GT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlamp

CableAssembly(GT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Grille

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

DESCRIPTION AND OPERATION

DESCRIPTION AND OPERATION OF GT

HEADLAMP MECHANISMThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps, pulling lever closes headlamps. Two

meshing gear segments convert the movement of the

lever to a rotation of 180 degrees. The pivots of the

headlamps lie below the centerline so that with head-

lamps in closed position the headlamp housing is

flush with front sheet metal.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened and

locked. The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating

mechanism.

MAINTENANCE AND ADJUSTMENTS

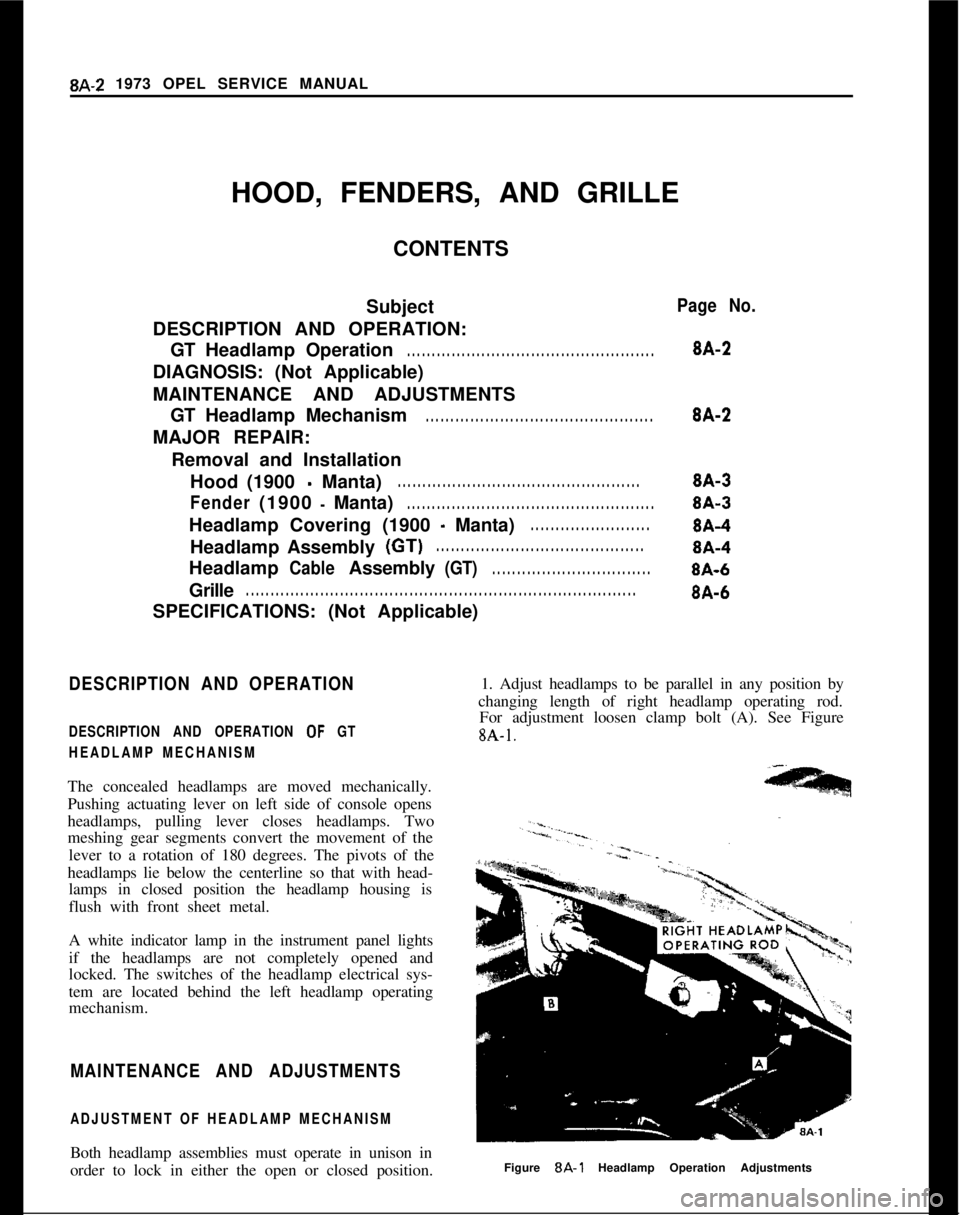

ADJUSTMENT OF HEADLAMP MECHANISMBoth headlamp assemblies must operate in unison in

order to lock in either the open or closed position.

Page No.

8A-2

8A-2

8A-3

8A-3

8A-4

8A-4

8A-6

8A-61. Adjust headlamps to be parallel in any position by

changing length of right headlamp operating rod.

For adjustment loosen clamp bolt (A). See Figure

8A-1.Figure

8A-l Headlamp Operation Adjustments

Page 511 of 625

9A-2 1973 OPEL SERVICE MANUALHEATER SYSTEM

- GT

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Flow-ThroughVentilationSystem................................

Heater System Description............................................

HeaterSystemOperation................................................

DIAGNOSIS:

Heater and Defroster........................................................

MAINTENANCE AND ADJUSTMENTS:

Control

CableAdjustment..............................................

MAJOR REPAIR:

Removal

81 Installation Instrument Panel

FreshAirOutlet..............................................................

Removal

& Installation Kick Panel Fresh

AirOutlet..........................................................................

Removal&InstallationBlowerSwitch......................

Removal&InstallationHeater......................................

Removal&InstallationDefrosterOutlet..................

Removal

81InstallationHeaterValve........................

SPECIFICATIONS:

Specifications......................................................................Page No.9A-29A-29A-49A-49A-49A-59A-59A-59A-59A-09A-99A-9

DESCRIPTION AND OPERATION

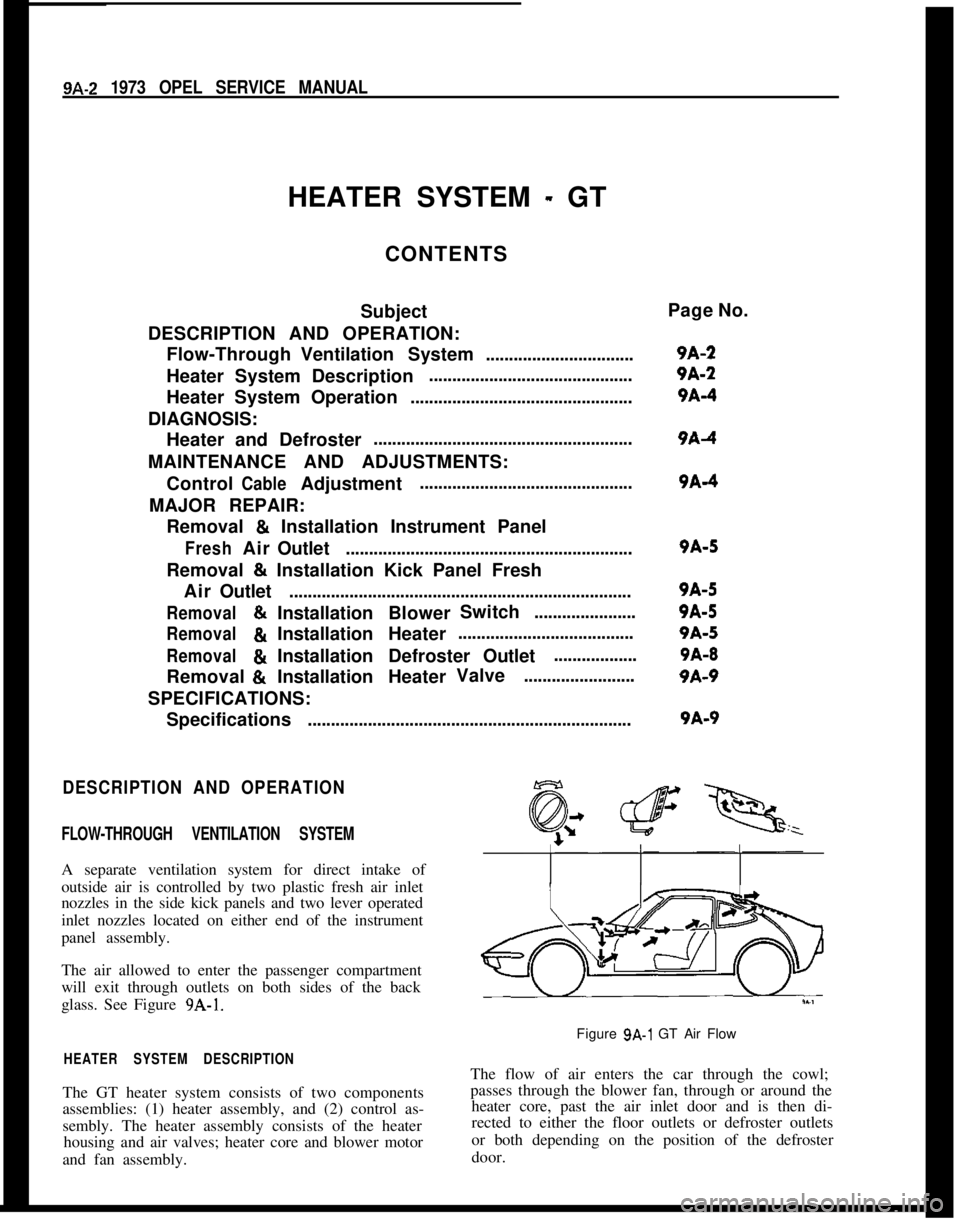

FLOW-THROUGH VENTILATION SYSTEMA separate ventilation system for direct intake of

outside air is controlled by two plastic fresh air inlet

nozzles in the side kick panels and two lever operated

inlet nozzles located on either end of the instrument

panel assembly.

The air allowed to enter the passenger compartment

will exit through outlets on both sides of the back

glass. See Figure 9A-1.

HEATER SYSTEM DESCRIPTIONThe GT heater system consists of two components

assemblies: (1) heater assembly, and (2) control as-

sembly. The heater assembly consists of the heater

housing and air valves; heater core and blower motor

and fan assembly.Figure

9A-1 GT Air Flow

The flow of air enters the car through the cowl;

passes through the blower fan, through or around the

heater core, past the air inlet door and is then di-

rected to either the floor outlets or defroster outlets

or both depending on the position of the defroster

door.