carburetor OPEL MANTA 1973 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: MANTA, Model: OPEL MANTA 1973Pages: 625, PDF Size: 17.22 MB

Page 453 of 625

7C- 92

1973 OPEL SERVICE MANUAL

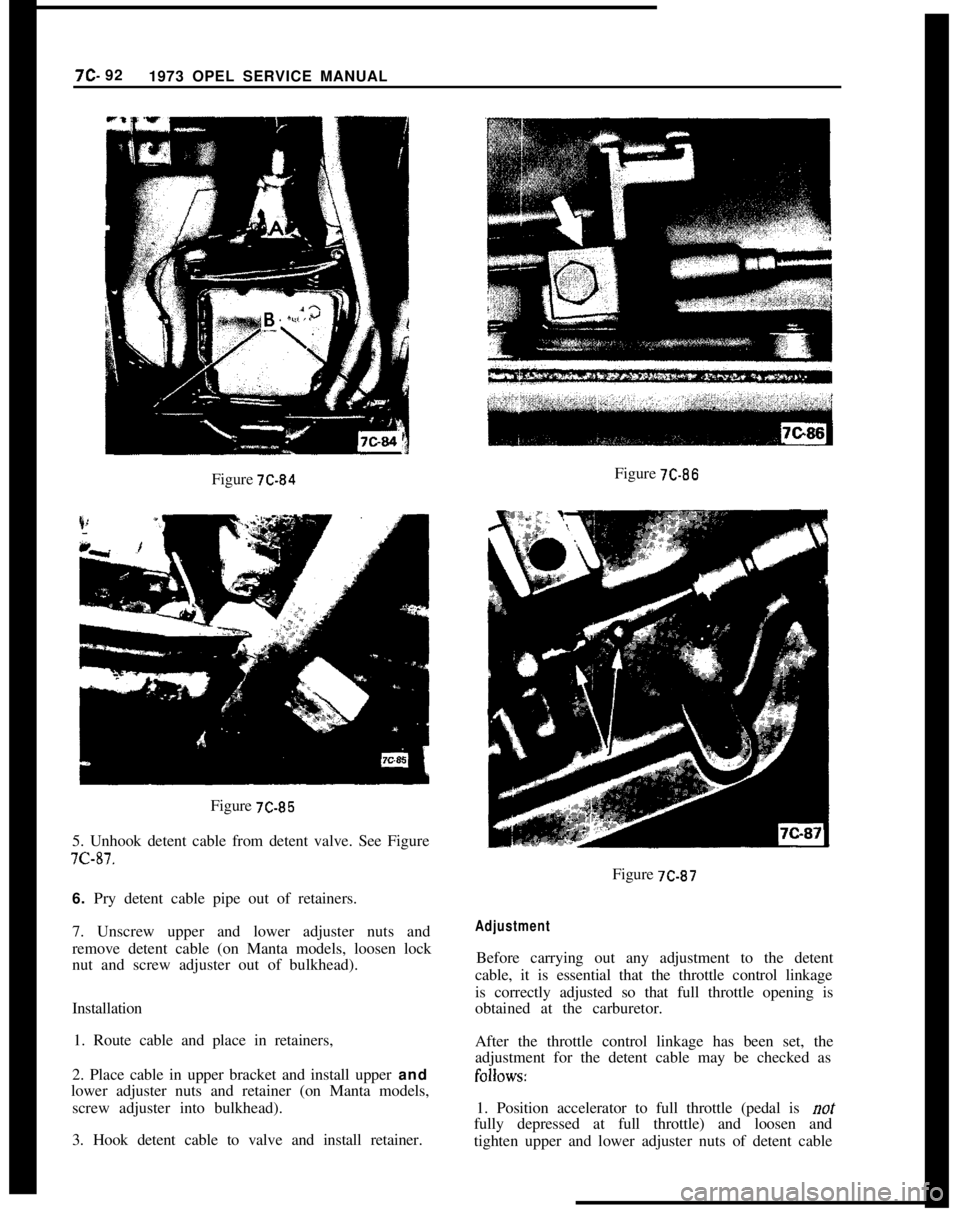

Figure 7C-84Figure

7C-855. Unhook detent cable from detent valve. See Figure7c-87.

6. Pry detent cable pipe out of retainers.

7. Unscrew upper and lower adjuster nuts and

remove detent cable (on Manta models, loosen lock

nut and screw adjuster out of bulkhead).

Installation

1. Route cable and place in retainers,

2. Place cable in upper bracket and install upper and

lower adjuster nuts and retainer (on Manta models,

screw adjuster into bulkhead).

3. Hook detent cable to valve and install retainer.Figure

7C-86Figure

7C.87

AdjustmentBefore carrying out any adjustment to the detent

cable, it is essential that the throttle control linkage

is correctly adjusted so that full throttle opening is

obtained at the carburetor.

After the throttle control linkage has been set, the

adjustment for the detent cable may be checked as

FOllOWS:1. Position accelerator to full throttle (pedal is nol

fully depressed at full throttle) and loosen and

tighten upper and lower adjuster nuts of detent cable

Page 557 of 625

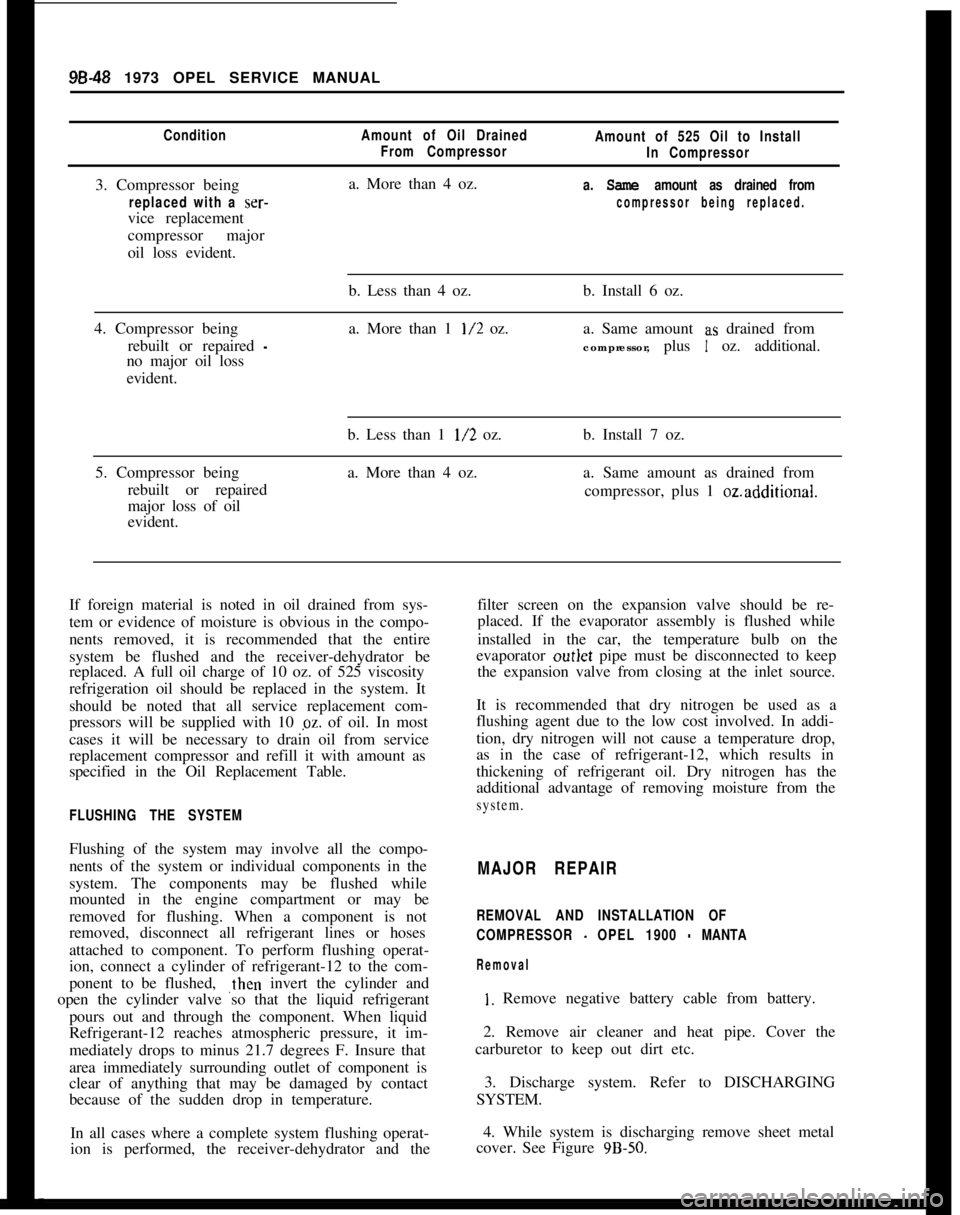

98-48 1973 OPEL SERVICE MANUALCondition3. Compressor being

replaced with a ser-vice replacement

compressor major

oil loss evident.

Amount of Oil Drained

From Compressora. More than 4 oz.Amount of 525 Oil to Install

In Compressor

a.

Same amount as drained from

compressor being replaced.4. Compressor being

rebuilt or repaired

-no major oil loss

evident.b. Less than 4 oz.

a. More than 1

l/2 oz.b. Install 6 oz.

a. Same amount a.s drained from

compressor, plus

1 oz. additional.

5. Compressor being

rebuilt or repaired

major loss of oil

evident.b. Less than 1

l/2 oz.

a. More than 4 oz.b. Install 7 oz.

a. Same amount as drained from

compressor, plus 1

ozadditional.If foreign material is noted in oil drained from sys-

tem or evidence of moisture is obvious in the compo-

nents removed, it is recommended that the entire

system be flushed and the receiver-dehydrator be

replaced. A full oil charge of 10 oz. of 525 viscosity

refrigeration oil should be replaced in the system. It

should be noted that all service replacement com-

pressors will be supplied with 10 pz. of oil. In most

cases it will be necessary to drain oil from service

replacement compressor and refill it with amount as

specified in the Oil Replacement Table.filter screen on the expansion valve should be re-

placed. If the evaporator assembly is flushed while

installed in the car, the temperature bulb on the

evaporator outlet pipe must be disconnected to keep

the expansion valve from closing at the inlet source.

FLUSHING THE SYSTEMIt is recommended that dry nitrogen be used as a

flushing agent due to the low cost involved. In addi-

tion, dry nitrogen will not cause a temperature drop,

as in the case of refrigerant-12, which results in

thickening of refrigerant oil. Dry nitrogen has the

additional advantage of removing moisture from thesystem.Flushing of the system may involve all the compo-

nents of the system or individual components in the

system. The components may be flushed while

mounted in the engine compartment or may be

removed for flushing. When a component is not

removed, disconnect all refrigerant lines or hoses

attached to component. To perform flushing operat-

ion, connect a cylinder of refrigerant-12 to the com-

ponent to be flushed, ,then invert the cylinder and

open the cylinder valve so that the liquid refrigerant

pours out and through the component. When liquid

Refrigerant-12 reaches atmospheric pressure, it im-

mediately drops to minus 21.7 degrees F. Insure that

area immediately surrounding outlet of component is

clear of anything that may be damaged by contact

because of the sudden drop in temperature.MAJOR REPAIR

REMOVAL AND INSTALLATION OF

COMPRESSOR

- OPEL 1900 - MANTA

Removal

I. Remove negative battery cable from battery.

2. Remove air cleaner and heat pipe. Cover the

carburetor to keep out dirt etc.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

In all cases where a complete system flushing operat-4. While system is discharging remove sheet metal

ion is performed, the receiver-dehydrator and thecover. See Figure

9B-50.

Page 621 of 625

SubjectPage Number

Subject Page Number

A

Air Conditioning Refrigerant Components .................

98.17

Opel 1900

& Manta-In Car Components .....9B-90

GT.ln Car Components..................98-97

Alignment Opel 1900

& Manta .....................3C-22

GT-Opel ..............................

3C-22

Alternator Description ...........................

lD-28

Specifications. .........................1 D-35

Overhaul K-l..........................lD-30

Removal & Installation ..................lD-30

Testing...............................lD-29

Wiring Diagrams

Manta .............................

1 J-105

Opel 1900

..........................lJ-103

GT ................................

lJ-107

AM

Radio-GT............................9C-105

AM Radio-Opel 1900 &Manta ...............

9C-109

Antenna, Installation .......................

9C-111

Antenna Trimmer .........................

9C-110

Assembly of Transmission from Major Units Manual ...............................

78-23

3 Speed Automatic .....................

7C-103

Axle,

R&r, Disassembly ....................48~11

Bolt Torque Specifications

Engine ...............................

6A-27

Transmission. Manual ....................

78-33

3 Speed Automatic .....................

7C-136

Clutch ...............................

7A-7

Body ................................

2A-4

Brakes

Brake Drum, Shoes & Linings .............5C-28

Hydraulic Wheel Cylinder ................

5C-30

Hydraulic Master Cylinder ................

5A-2

Parking Brake Cables .....................

5C-33

Standard Brakes ........................

X-22

Disc Brakes...........................5B-10

Brake Booster and Vacuum

Coritrol Valve ....5A-5

Bumpers, Front and Rear ...................

ZH-33

C

B

Balance,,Wheel and Tire....................3G-62

Ball

J&tUpper .........................3A-7

Lower ...............................

3A-7

Battery

Specifications ..........................

lA-9

Testing...............................lA-6

Charging ..............................lA-9

Trouble Diagnosis ......................lA-4

Battery Test 421.........................l A-6

Belt Tensions ............................

68.33

Blower and Air Inlet Assembly, Removal and Installation

Owl 1900&Manta.....................9A-15

GT

.: ................................9A-5

Body Name Plate ............................

OA-1

Style’Numbers ......................... OA-2

Windows and Weatherstrips ...............

ZC-9

Doors ................................

ZD-13

Interior Trim and Headlining ..............

26-33

Seatsi................................26-33

Roof&d Sunroof-Opel 1900

& Manta ......2F.24 Camshaft,

1.9L

Engine .....................6A-25

Car Model Identification .......

.,............OA-1

Carburetor..............................6E-44

Trouble Diagnosis ......................

6E-49

Description ...........................

6E-44

Overhaul .............................

6E-53

Adjust ...............................

6E-50

Removal

& Installation ......,............6E-52

Specifications ..........................

6E-58

Charging

System

Description ..............

:............ 1 D-28

Specifications. ............

.,............lD-35

Testing..................:............lD-29

Wiring Diagrams

Manta .............................

lJ-105

Opel 1900 ..........................

lJ.103

GT ................................

lJ-107

Chart Lubrication ........................ OC-5

Chassis Springs, Front. ........

!............3A-15

Clutch, Second-Automatic Transmission .......

7C-103

Clutch Adjustment .........................

7A-4

Control Arm Front Upper ...................

:............3A-10

Lower ...............................

3A-11

Converter Checking Procedure ................

7C-125

Coolant Flow ............................

68-32

4 Speed Manual Transmission ...

!,...........7B-12

Cranking System. See Starting

SyStem

Crankshaft..............................6A-16

Cylinder Head ...............

:............6A-12

D

Description

3.Speed Automatic.....................7C-37