water OPEL MANTA 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: MANTA, Model: OPEL MANTA 1973Pages: 625, PDF Size: 17.22 MB

Page 17 of 625

IoC-91973 OPEL SERVICE MANUAL

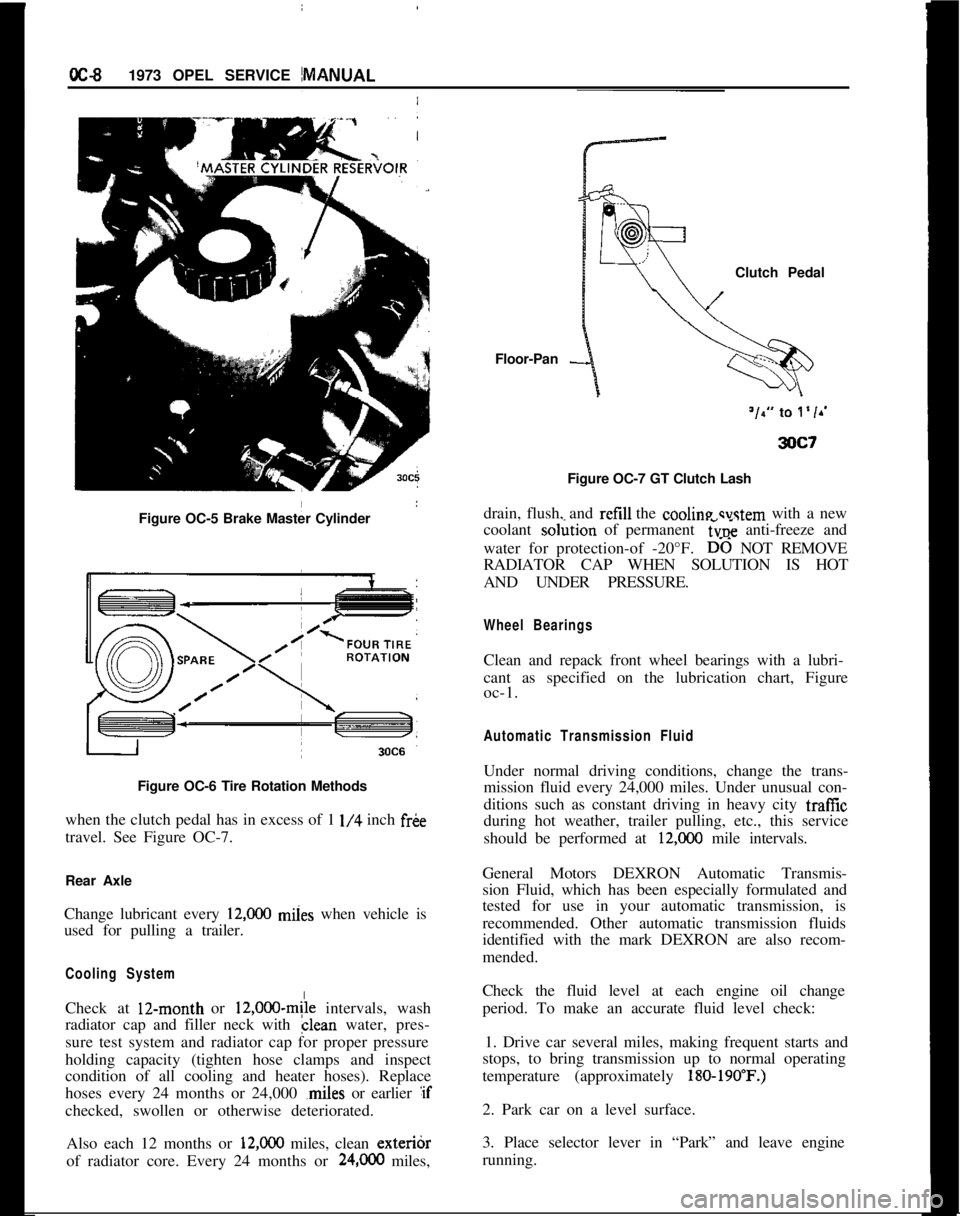

Figure OC-5 Brake Master Cylinder

I

Figure OC-6 Tire Rotation Methods

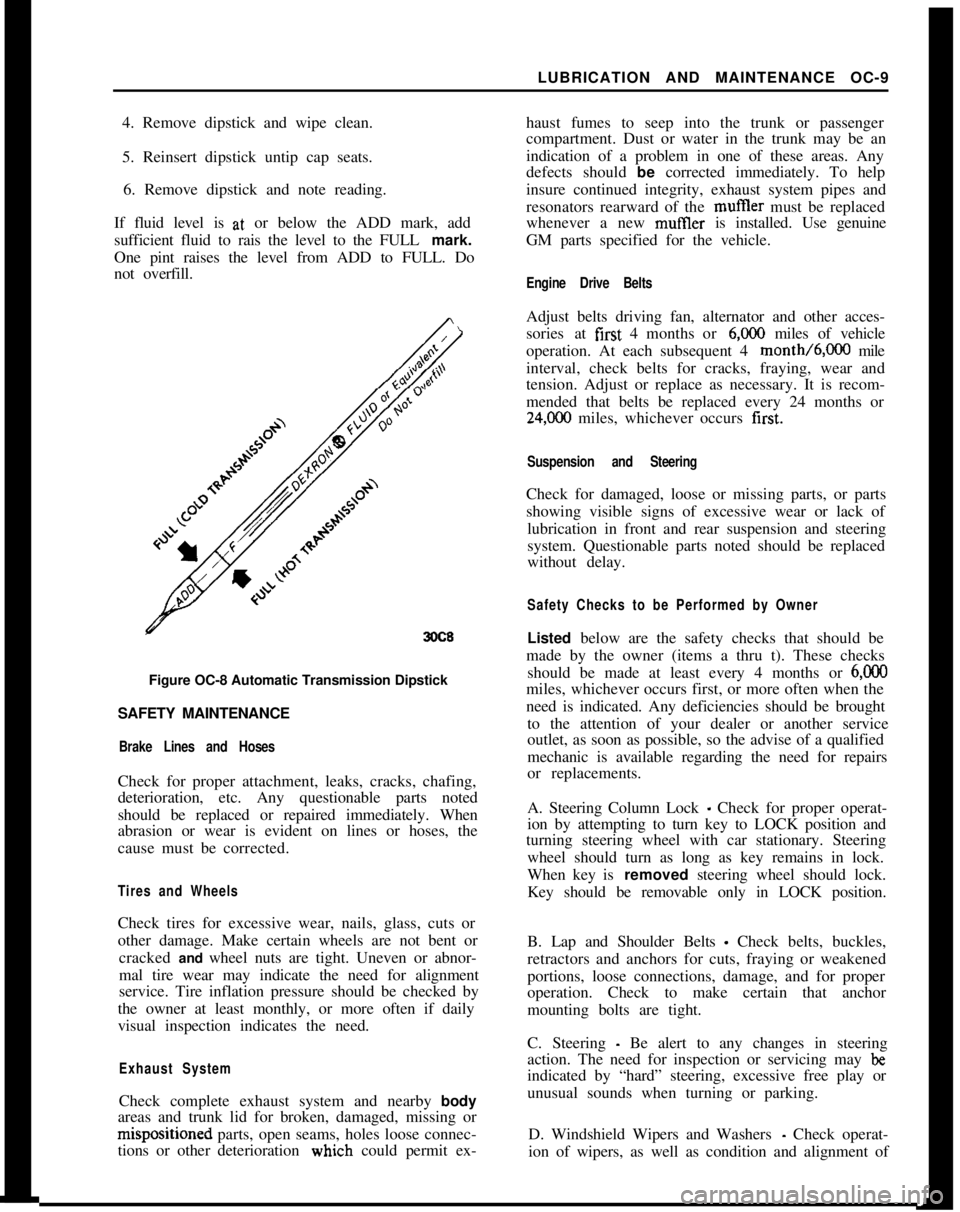

when the clutch pedal has in excess of 1

l/4 inch fr&

travel. See Figure OC-7.

Rear Axle

Change lubricant every

12,ooO miies when vehicle is

used for pulling a trailer.

Cooling SystemCheck at 12-month or

12,000~mile intervals, wash

radiator cap and filler neck with clean water, pres-

sure test system and radiator cap for proper pressure

holding capacity (tighten hose clamps and inspect

condition of all cooling and heater hoses). Replace

hoses every 24 months or 24,000 ,miles or earlier :if

checked, swollen or otherwise deteriorated.

Also each 12 months or

12,ooO miles, clean exteribr

of radiator core. Every 24 months or

24,OCO miles,Floor-Pan

-Clutch Pedal

Figure OC-7 GT Clutch Lash

drain, flush, and refill the cooline svstem with a new

coolant so&ion of permanent

6~; anti-freeze and

water for protection-of -20°F.

D-6 NOT REMOVE

RADIATOR CAP WHEN SOLUTION IS HOT

AND UNDER PRESSURE.

Wheel BearingsClean and repack front wheel bearings with a lubri-

cant as specified on the lubrication chart, Figure

oc-1.

Automatic Transmission FluidUnder normal driving conditions, change the trans-

mission fluid every 24,000 miles. Under unusual con-

ditions such as constant driving in heavy city traffic

during hot weather, trailer pulling, etc., this service

should be performed at

12,COO mile intervals.

General Motors DEXRON Automatic Transmis-

sion Fluid, which has been especially formulated and

tested for use in your automatic transmission, is

recommended. Other automatic transmission fluids

identified with the mark DEXRON are also recom-

mended.

Check the fluid level at each engine oil change

period. To make an accurate fluid level check:

1. Drive car several miles, making frequent starts and

stops, to bring transmission up to normal operating

temperature (approximately

180-190’F.)2. Park car on a level surface.

3. Place selector lever in “Park” and leave engine

running.

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

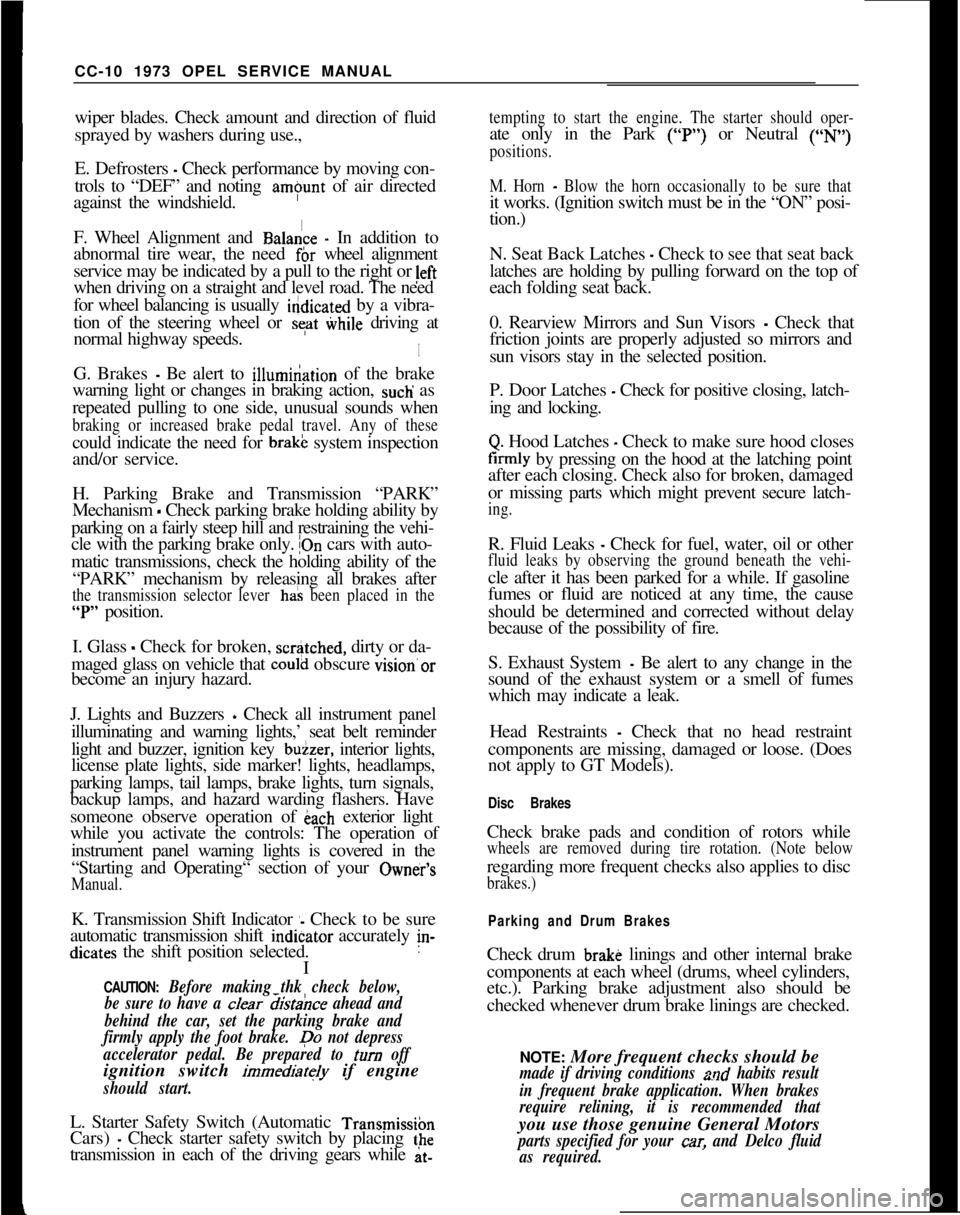

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 19 of 625

CC-10 1973 OPEL SERVICE MANUAL

wiper blades. Check amount and direction of fluid

sprayed by washers during use.,

E. Defrosters - Check performance by moving con-

trols to “DEF” and noting

am$nmt of air directed

against the windshield.

I

F. Wheel Alignment and

Balabce - In addition to

abnormal tire wear, the need fbr wheel alignment

service may be indicated by a pull to the right or

!eftwhen driving on a straight and level road. The need

for wheel balancing is usually

iddicated by a vibra-

tion of the steering wheel or

se;+ tihile driving at

normal highway speeds.I

IG. Brakes

- Be alert to illumiriation of the brake

warning light or changes in braking action,

SUCK as

repeated pulling to one side, unusual sounds when

braking or increased brake pedal travel. Any of thesecould indicate the need for

brakk system inspection

and/or service.

H. Parking Brake and Transmission “PARK”

Mechanism

- Check parking brake holding ability by

parking on a fairly steep hill and restraining the vehi-

cle with the parking brake only.

eon cars with auto-

matic transmissions, check the holding ability of the

“PARK” mechanism by releasing all brakes after

the transmission selector lever hak been placed in the“P” position.

I. Glass

- Check for broken, scrritched, dirty or da-

maged glass on vehicle that

coulld obscure vision’or

become an injury hazard.

J. Lights and Buzzers

- Check all instrument panel

illuminating and warning lights,’ seat belt reminder

light and buzzer, ignition key

b&er, interior lights,

license plate lights, side marker! lights, headlamps,

parking lamps, tail lamps, brake lights, turn signals,

backup lamps, and hazard warding flashers. Have

someone observe operation of

&ach exterior light

while you activate the controls: The operation of

instrument panel warning lights is covered in the

“Starting and Operating“ section of your

Own&%

Manual.K. Transmission Shift Indicator

‘- Check to be sure

automatic transmission shift

indiCator accurately i”-

dicates the shift position selected.

I

CAUTION: Before making thk check below,I

be sure to have a clear dist&e ahead and:

behind the car, set the parking brake and

firmly apply the foot brake.

Do not depress

accelerator pedal. Be prepared to

turn off ’

ignition switch

immediat+y if engine

should start.L. Starter Safety Switch (Automatic Transmissibn

Cars)

- Check starter safety switch by placing the

transmission in each of the driving gears while

at-tempting to start the engine. The starter should oper-ate only in the Park (“P”) or Neutral (“N”)

positions.

M. Horn

- Blow the horn occasionally to be sure thatit works. (Ignition switch must be in the “ON” posi-

tion.)

N. Seat Back Latches

- Check to see that seat back

latches are holding by pulling forward on the top of

each folding seat back.

0. Rearview Mirrors and Sun Visors

- Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

P. Door Latches

- Check for positive closing, latch-

ing and locking.

Q. Hood Latches - Check to make sure hood closesfirmly by pressing on the hood at the latching point

after each closing. Check also for broken, damaged

or missing parts which might prevent secure latch-

ing.R. Fluid Leaks

- Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the vehi-cle after it has been parked for a while. If gasoline

fumes or fluid are noticed at any time, the cause

should be determined and corrected without delay

because of the possibility of fire.

S. Exhaust System

- Be alert to any change in the

sound of the exhaust system or a smell of fumes

which may indicate a leak.

Head Restraints

- Check that no head restraint

components are missing, damaged or loose. (Does

not apply to GT Models).

Disc BrakesCheck brake pads and condition of rotors while

wheels are removed during tire rotation. (Note belowregarding more frequent checks also applies to disc

brakes.)

Parking and Drum BrakesCheck drum

brake linings and other internal brake

components at each wheel (drums, wheel cylinders,

etc.). Parking brake adjustment also should be

checked whenever drum brake linings are checked.

NOTE: More frequent checks should be

made if driving conditions a.nd habits result

in frequent brake application. When brakes

require relining, it is recommended thatyou use those genuine General Motors

parts specified for your car,and Delco fluid

as required.

Page 23 of 625

lA- 21973 OPEL SERVICE MANUAL

BATER~ AND CABLES

ALL/ MODELS

C+NTENTIiSubject

DESCRIPTION AND OPERATION:

GeneralBatteryInformation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Battery and Cables

- Trouble Diagno:sis. . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

PeriodicBatteryInspectionandService. . . . . . . . . . . . . . . . . . . .421BatteryTest

. . . . . . . . . . . . ...! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydrometer Test of Batteiy

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FusibleLinks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BatteryRecharging

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Battery

RemovalandInstallation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FusibleLinksRemovalandInstallation. . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

BatterySpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 A-2

1 A-4

1 A-5

1 A-6

1 A-7lA-8

1 A-9

1 A-9

1 A-9

1 A-9

DESCRIPTION AND OPERATIONGENERAL BATTERY INFORMATION

Registration of BatteryUnited-Delco Battery dealers and distributors

$reprepared to carry out terms of the manufacturer’s

warranty on Delco-General batteries. In order that

Opel owners shall have the protection and benefit of

this warranty, it is necessary for the dealer or car

owner to register his battery with the local United-

Delco Battery dealer or distributor on all new car

deliveries, and on all deliveries of new replacement

Delco batteries. The Battery Owner’s Certificate is

located in the Owner’s Protection Plan Booklet..

Care of Wet Batteries in StorageBatteries in stored new cars, as well as batteries, in

stock, must be given regular attention to prevent

sulphation of plates that may result from inactivity

and self-discharge. All automotive wet batteries will

slowly discharge on standing idle, whether in stored

vehicles or in stock, and will self-discharge muchfaster when warm than when cold.

Batteriesin stock

should be rotated and the oIder ones used tirst.To minimize the extent of self-discharge always store

batteries fully charged and in a cool place where the

temperature does not go below freezing. Every 30

days check the level of electrolyte, add water as re-

quired and charge the batteries at a 5 ampere rate

until fully charged.

Batteries used for display purposes or standing in

cars in storage must be treated in the same manner

as batteries in stock.

When a new car, or a new replacement battery is

delivered, make certain that it is

fuIly charged and

the electrolyte is at

proper level.This is extremely

important because the delivery of a partially dis-

charged battery may not only lead to its return for

charging but may also result in shortened life of

battery.

Importance of Maintaining Electrolyte at PROPER

LevelWater is the only component of the battery which is

Page 24 of 625

BATTERY AND CABLES - ALL MODELSlA- 3

lost as the result of charging and discharging, and it

must be replaced before the electrolyte level falls to

the tops:of the separators. If the water is not replacedand the plates become exposed, they may become

permanently sulphated, which would impair the

per-forma”& of the plates. Also, the plates cannot take

full

par! in the battery action unless they are com-

pletely covered by the electrolyte.

Importance of Keeping Battery Properly Charged

The battery has three major functions: (1) It provides

a source of energy for cranking the engine. (2) It actsas a stabilizer to the voltage in the electrical system.

(3) It

c+n for a limited time furnish energy when the

demand: of the electrical units in operation exceed

the output of the generator.

In

ordei for the battery to continue to function, it is

necessaiy that current withdrawal from the battery

be balanced by current input from the generator so

that the battery is maintained in a properly chargedconditidn. If the outgo exceeds the input, the battery

will be&me discharged so that it cannot.supply suffi-cient energy.

The state of charge of the battery as well as the

temperature of the electrolyte has an important bear-ing on its capacity for supplying energy. Battery effi-

ciency is greatly reduced by decreased electrolyte

temper&e as it has a decided numbing effect on its

electrodhemical action. Under high discharge such

as cranking, battery voltage drops to lower values incold temperatures than in warm temperatures.

In

extrkmely cold climates it is important to keepbatter& in a nearly full charged condition to avoid

the possibility of freezing, which will damage any

battery!

The following table shows the temperatures at whichfreezing will occur in electrolytes of

differennt densi-

ties, wifh specific gravity corrected to 80 degrees l?

Specific Gravity Freezing Point

1.220 -35 degrees F.

1.200

-35 degrees F.

1.160

d degrees F.

Care of Dry Batteries in StorageA “dry charge” battery contains fully charged posi-

tive

a$ negative plates but no electrolyte.

Dry charged batteries should be stored in a dry placeaway from excessive heat. A dry charged battery

should

p kept in its original carton until ready to beput into service. This type of battery will retain its

“charged” condition indefinitely if protected from

moisture. Dry batteries may be stacked in vertical

columns provided they are not stacked more than

four high.

Preparing Dry Charged Batteries For ServiceTo prepare “dry charge” batteries for service use

approved battery-grade acid electrolyte (1.265 sp. gr.

at 80 degrees F). Care should be exercised in its useto prevent bodily injury or damage to clothing or

other material resulting from actual contact with the

electrolyte.

Electrolyte should be added to dry charged batteriesin an area where water is readily available for flush-

ing in case the electrolyte comes into contact with the

body. Refer to instructions on side of electrolyte con-tainer for antidotes to use if electrolyte comes into

contact with the body.

It is strongly recommended that a person filling bat-

teries with electrolyte wear glasses (preferably safetyglasses) to prevent possible damage to the eyes

should any spattering of the electrolyte occur.

1, Remove dry charged battery from its original car-

ton.2. Remove the vent plugs.

3. Using a glass or acid-proof plastic funnel, till eachbattery cell with electrolyte. Do not use a metal

funnel for filling the battery. The cell is properlytilled when the electrolyte level rises to the split ring

at the bottom of the vent well. Do not overfill orundertill. Overfilling will cause acid corrosion in the

,battery area; undertilling will cause early battery fail-

UR.4. After tilling cells, wait five to ten minutes and add

additional electrolyte, if necessary, to bring the elec-

trolyte to the proper level.

5. Never finish tilling a dry charge battery with wa-

ter. If electrolyte is spilled, more electrolyte must be

obtained.

Test After Batteries

ere Prepared For ServiceThe Delco Dry Charge Battery may be put into ser-

vice immediately after activation. However, to insuregood battery performance, the following activation

tests are recommended:1. After adding electrolyte,, check the open circuit

voltage. Less than 10 volts mdicates a reverse cell oran open circuit and the battery should be replaced.

2. Check the specific gravity of all cells. If the specific

Page 26 of 625

BATTERY AND CABLES - ALL MODELSlA- 5

and terminal connections should not exceed 2/10

volt.

5. Connedt voltmeter positive lead to ground on en-

gine.

At&h prod to voltmeter negative lead and

apply prod to center of battery negative post. Volt-

age drop across the battery ground cable and termi-

nal conne$tions should not exceed 2/10 volt at

200amps.

6. A reading in excess of 2/10 volt when testing

either battery cable indicates excessive resistance in

cable or cpnnections. Clean and tighten cable or con-

nections. Clean and tighten cable terminals

(sub-para. c, below) and recheck for voltage drop. If volt-

age drop Still exceeds 2/10 volt, replace cable with a

genuine Buick-Opel cable to insure ample capacity.

Undercharge Failure of BatteryThe most frequent trouble experienced with storage

batteries is failure to maintain a state of charge suffi-

cient to crank the engine and also furnish current to

the ignitibn system, lights and accessories. Failure to

maintain a proper state of charge may be due to one

or more of the following conditions:

1.

Opertiting Conditions. When determining cause

of premature failure of a battery, consideration must

be given /to the conditions under which the car is

operated.,

In very low temperatures the capacity of a storage

battery

ii considerably reduced and the energy re-

quired f& cranking the. engine is considerably in-

creased. :

Frequent starting, particularly in cold weather,

ac-compani

place in the limited running time. This condition is

aggravated by night driving when lights are turned

on, or by operation of an air conditioner in heavy

traffic.

When thk car is operated under these conditions,adjusting,the voltage regulator to the high limit may

allow enough increase to keep the battery at a safe

state of charge. If the high limit setting does not

maintain a safe state of charge, an occasional booster

charge should be given to the battery.

2. Low charging Rate. In case of premature battery

failure, tbe charging rate of alternator should always

be checked and adjusted if below specifications.

3.

Zntemd Condition The internal condition of the

battery niay be such that it cannot hold a chargesatisfactoiily. Check electrolyte level and test the

battery using the 421 Battery Test.

Overcharge Failure of BatteryA common cause of battery failure is overcharging,

that is, continued input of excessive charging current

after the battery has reached a fully charged condi-

tion.

One evidence that battery is being overcharged is the

need for frequent addition of water to the battery in

order to maintain the electrolyte level above the tops

of the battery separators, since overcharging causes

rapid water loss. When this becomes evident, the

charging rate of alternator should be immediately

checked, as well as the voltage regulator, and ad-

justed to avoid internal damage to battery.

ADJUSTMENTS AND MINOR SERVICEPERIODIC BATTERY INSPECTION AND SERVICE

The battery requires very little attention, but peri-

odic inspection is essential to secure the maximum

efficiency and life. The following services are essen-

tial to maintain the battery at maximum efficiency.

WARNING: Never expose battery to open flame or

electric spark

- battery action generates hydrogen gas

which is flammable and explosive. Do not allow bat-

tery fluid to contact skin, eyes, fabrics or painted

surfaces

- fluidis a sulfuric acid solution which could

cause serious personal injury or property damage.

Wear eye protection when working with battery.

Maintain Electrolyte LevelAdd distilled water as required to maintain the elec-

trolyte level at the split ring at bottom of tiller well.

See Figure IA-2.

Figure lA-2

Battery Filler Well

Page 27 of 625

j

/lA- 61973 OPEL SERVICE MANUAL

Do not overfill, as electrolyte may

be sprayed out by

gassing or may overtlow due to heat expansion dur:

ing charging.

If distilled water is not available, it is better to add

clean, mineral-free tap water than to allow the

elec2trolyte level to remain below the top of the plates:

In freezing weather the water should be added just

before using the car or otherwise charging the bat-

tery so that the water will be mixed with the acid

before it is allowed to stand in freezing temperatures.

If it is found necessary to add water to the

batterimore frequently than about every

1,ooO miles and the

quantity of water added per cell is’ excessive, check

setting of voltage regulator and adjust, if necessary:

Abnormal water loss is an indication that the battery

is being overcharged.

Inspect Battery, Mounting and Cables

Check outside of battery for damage or signs of se&ous abuse such as broken case or broken covers:

Check inside of battery by removing the vent caps

and inspecting for signs of abuse

stich as electrolyte

level too low to see, or bad or unusual odors. If

battery shows signs of serious damage or abuse, it

should be replaced.

Check the battery hold down bolts to make certain

that battery is securely held in place. The nut should

be drawn up to 20 lbs. in.;excessjve tightening may

distort or crack the battery case.If the top of battery is dirty or the hold down str?e

is corroded, clean thoroughly with a brush dipped

IFammonia or soda solution. Care must be used td

prevent any solution from getting into battery

cellslAfter the foaming of solution stops, flush off witli

clean water and dry thoroughly. If hold down strap

is corroded it should be painted with acid-resisting

paint after cleaning.

Check battery cables to make certain they are tight

at bracket and junction block. If a connection is

found loose it should be cleaned before being tight;ened as arcing and corrosion may have taken place

in the loose connection. Check condition of cables

and replace if badly corroded or frayed.

Special attention must be given to,the battery posi-

tive cable position to eliminate the possibility of con-

tact with the exhaust manifold on the 1.1 liter engine.

The cable clamp must be rotated clockwise as neces-

sary for the cable to run at a 45 degree angle toward

the right wheelhouse panel.

Cleaning Cable Terminals

If loose connections are found by inspection, or highresistance is found by voltage test, disconnect the

cable for thorough cleaning of terminals. When

removing a corroded cable terminal from battery

post, do not pry against battery case or hammer on

terminal to break it loose, since either practice will

result in broken cell covers. Use a screw-type termi-

nal puller if terminal cannot be loosened by hand.

Thoroughly clean all corrosion from disconnected

battery cable terminals and terminal posts, using

suitable wire brushes. If wire brushes are not availa-

ble, corroded terminals may be cleaned by brushing

with a strong soda solution, using care not to get

solution into battery cells.

If

cabbz strands are broken, corroded, or loose in

terminals, the cable should be replaced with the cor-

rect cable to insure ample capacity.

To prevent corrosion of battery terminals and con-

nections, apply a coating of petroleum jelly over the

battery post and cable terminals after cables have

been installed on terminals.

421 BATTERY TEST421 Battery Testers, manufactured and sold by a

number of companies, are the only battery testers

approved by Delco-Remy Division for testing one-

piece cover batteries. They are also used by United

Motors Service to determine whether or not a battery

is defective.

Figure lA-3 421 Battery Tester-Charger

The

42,l Battery Tester shows, in a few minutes, the

state-of-charge of the battery and whether it is good

or bad. The tester can be used with any 12 volt

battery, in or out of the car. The test can be made

regardless of the state of charge of the battery; it can

also be made when the electrolyte level is low

- even

below the top of the plates.

Page 28 of 625

BATTERY AND CABLES - ALL MODELSlA- 7

421 Test

F$ocedure1. Visual Inspection

- The first step in testing the

Energizer br 12-V& Battery should be a visual in-

spection

which very often will save time, labor and

expense in determining the condition.

(a) Check for broken or cracked case or cover.

(b) Check ,for loose terminal posts.

fiozeck Ifor defective or mutilated sealing com-(d) Check for other visible signs of physical damage.

Obvious d?mage as a result of conditions described

above indicates the need for Energizer or batteryreplaceme$t.

2. The “421” Test is a programmed test procedure

consisting bf a series of timed discharge and charge

events, reqtdring approximately 2 to 3 minutes, that

will determine the condition of the Energizer or bat-

tery with a high degree of accuracy when used inconjunctioti with this entire test procedure. “421”

Testers

a$ produced by a number of different manu-

facturers

r+nd their directions for tester operation

should be carefully followed. General comments on

overall “42 1” Tester operation follow:

(a) Energi@rs or batteries should

nor be charged

prior to

making this test. Defects within the unit can

be hidden by the charging and erroneous test results

will be obtpined.

(b) Erratic, or extremely low, initial meter readings

may indicate poor connections at the tester termi-

nals.Obt{in clean and tight connections beforeper-

forming the 421

Test.(c) All meter readings should be made immediately

after the meter indicator light comes on even if the

meter needle is still moving.

(d) If additional discharges are required after the

initial discbarge, set meter indicator following thefast discharge cycle.

(e) Batteries designated as “bad” by the tester should

be replaced.

(f) Batteries designated as “good” with no owner’s

complaint or indication of poor performance, should

be left in s+vice. Posts, cable clamps, and top should

be cleaned, water should be added and recharging

should be

,performed, if required. For dependable

and reliable battery service, the battery should be in

at least a

75 per cent state-of-charge.

(g) Batteries designated as “good” that are suspected

of being questionable because of owner complaint, orage of the battery, should be further tested by the

Hydrometer Test.

HYDROMETER TEST OF BATTERY

The 421 Battery Test as described in the previous

paragraph is the fastest and most accurate means of

determining the serviceability of a one-piece cover

battery. However, ifa 421 Battery Tester is not avail-

able, a hydrometer test may be used on a battery that

has failed to give proper service.

Hydrometer Test1. Fully charge battery.

2. Measure specific gravity of each cell as described

in sub-paragraph below.

Decide battery serviceability as follows:

(a) If all cells read between 1.230 and 1.310, the

battery is okay. All it needed was a full charge.

(b) After fully charging battery, if any cell reads less

than 1.230, the battery is defective and should be

replaced.

Use of HydrometerThe Hydrometer measures the percentage of sulphu-

ric acid in the battery electrolyte in terms of specific

gravity. As a battery drops from a charged to a dis-

charged condition, the acid leaves the solution and

enters the plates, causing a decrease in specific

gravity of electrolyte. With a hydrometer, an indica-

tion of the concentration of the electrolyte is ob-

tained.

The specific gravity of the electrolyte varies not only

with the percentage of acid in the liquid, it also varies

with temperature. As temperature increases, the

electrolyte expands so that the specific gravity is re-

duced. As temperature drops, the electrolyte con-

tracts so that the specific gravity increases. Unless

these variations in specific gravity are taken into

account, the specific gravity obtained by the hy-

drometer may not give a true indication of the con-

centration of acid in the electrolyte.

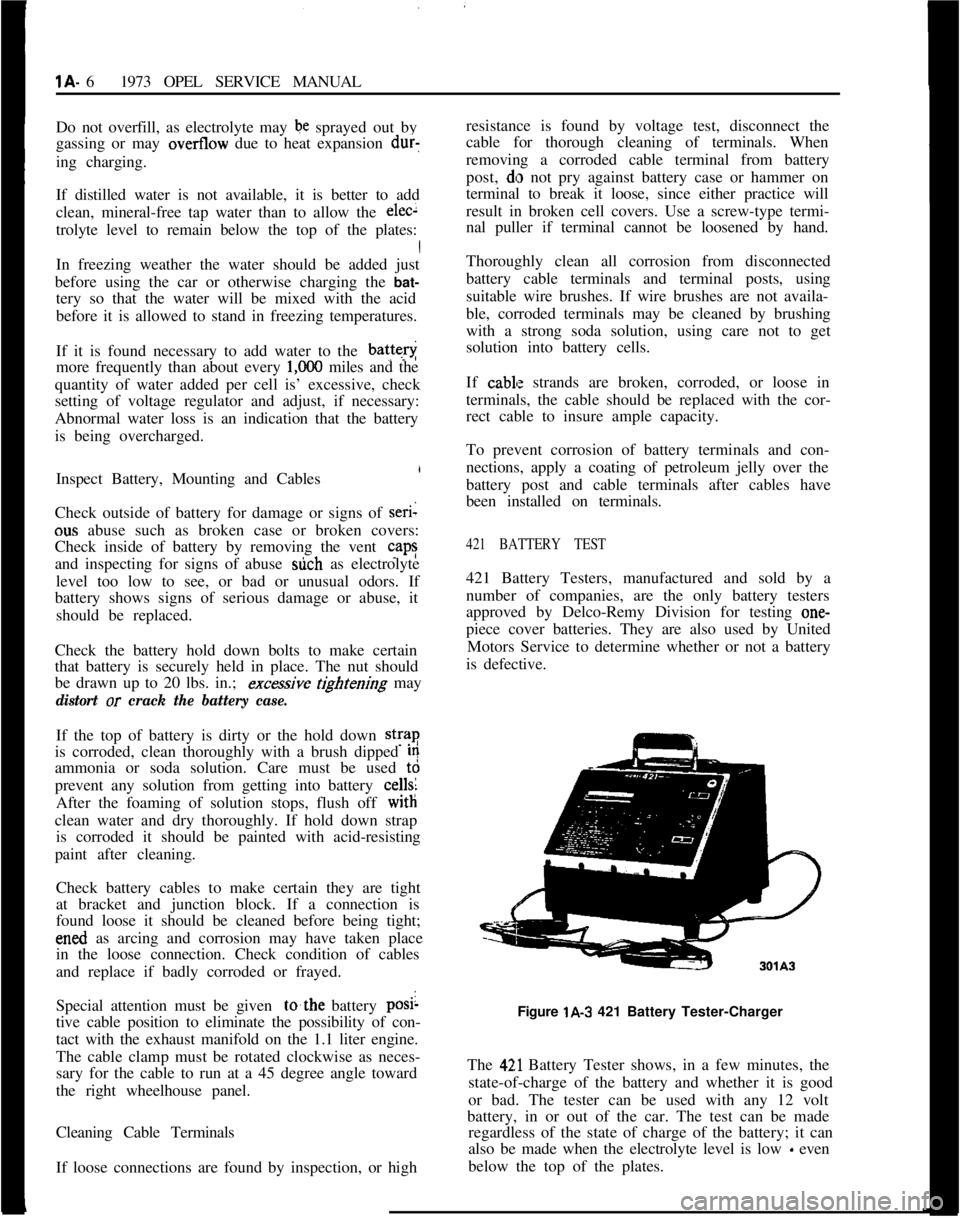

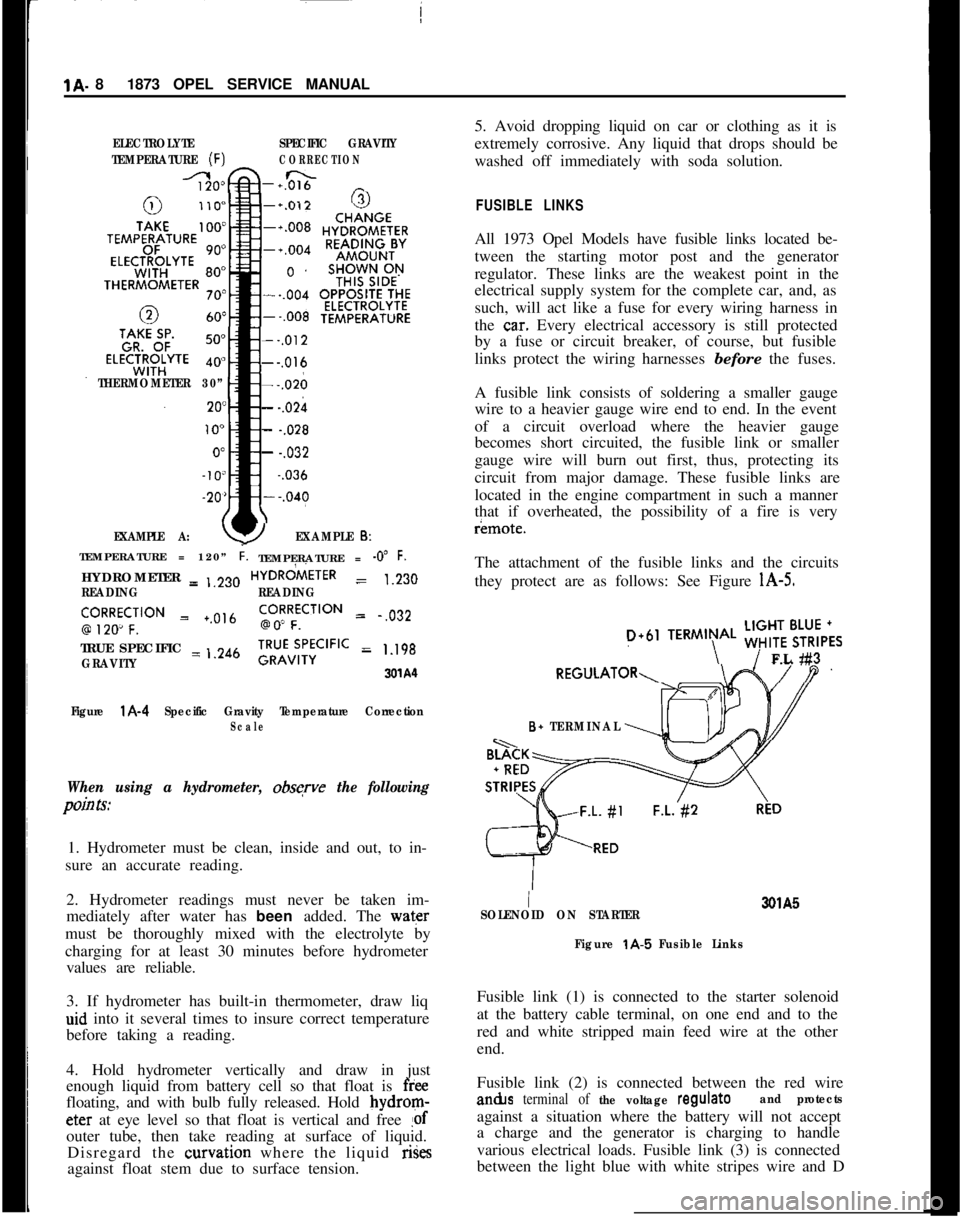

Correction can be made for temperature by adding

,004, usually referred to as 4 “points of gravity”, to

the hydrometer reading for every 10 degrees F. that

the electrolyte is above 80 degrees F. or subtracting004 for every 10 degrees F. that electrolyte is below

80 degrees F. Figure IA-4 shows the exact correctionfigure to use for any temperature above or below 80

degrees F., the three steps used in obtaining the cor-

rected or true specific gravity, and two examples

showing how it is figured.

Page 29 of 625

1A. 81873 OPEL SERVICE MANUALELECTROLYTESPECIFIC GRAVITY

TEMPERATURE

(F)CORRECTION

-+0&&n _

THERMOMETER 30”

EXAMPLE A:

--,012---,016---,026

- -.02h

- -.028

- -.032~

-.036

YEXAMPLE 6:TEMPERATURE = 120”

i.TEMPERATURE = -0” F.HYDROMETER = ,,230HYDRdiETER

= 1.230

READINGREADING

‘,9R2Ro~CF;‘“” = +.0,6go!RFfCilON = .,032

TRUE SPECIFIC = ,.246

GRAVITY;RU”v;,‘;CIFIC = 1.198

3xA‘l

Figure

l A-4 Specific Gravity Temperature CorrectionScale

When using a hydrometer, obsqve the following

pain Is:1. Hydrometer must be clean, inside and out, to in-

sure an accurate reading.

2. Hydrometer readings must never be taken im-

mediately after water has been added. The water

must be thoroughly mixed with the electrolyte by

charging for at least 30 minutes before hydrometer

values are reliable.

3. If hydrometer has built-in thermometer, draw liq

aid into it several times to insure correct temperature

before taking a reading.

4. Hold hydrometer vertically and draw in just

enough liquid from battery cell so that float is

freefloating, and with bulb fully released. Hold bydrom-eter at eye level so that float is vertical and free

!ofouter tube, then take reading at surface of liquid.

Disregard the curvation where the liquid rises

against float stem due to surface tension.5. Avoid dropping liquid on car or clothing as it is

extremely corrosive. Any liquid that drops should be

washed off immediately with soda solution.

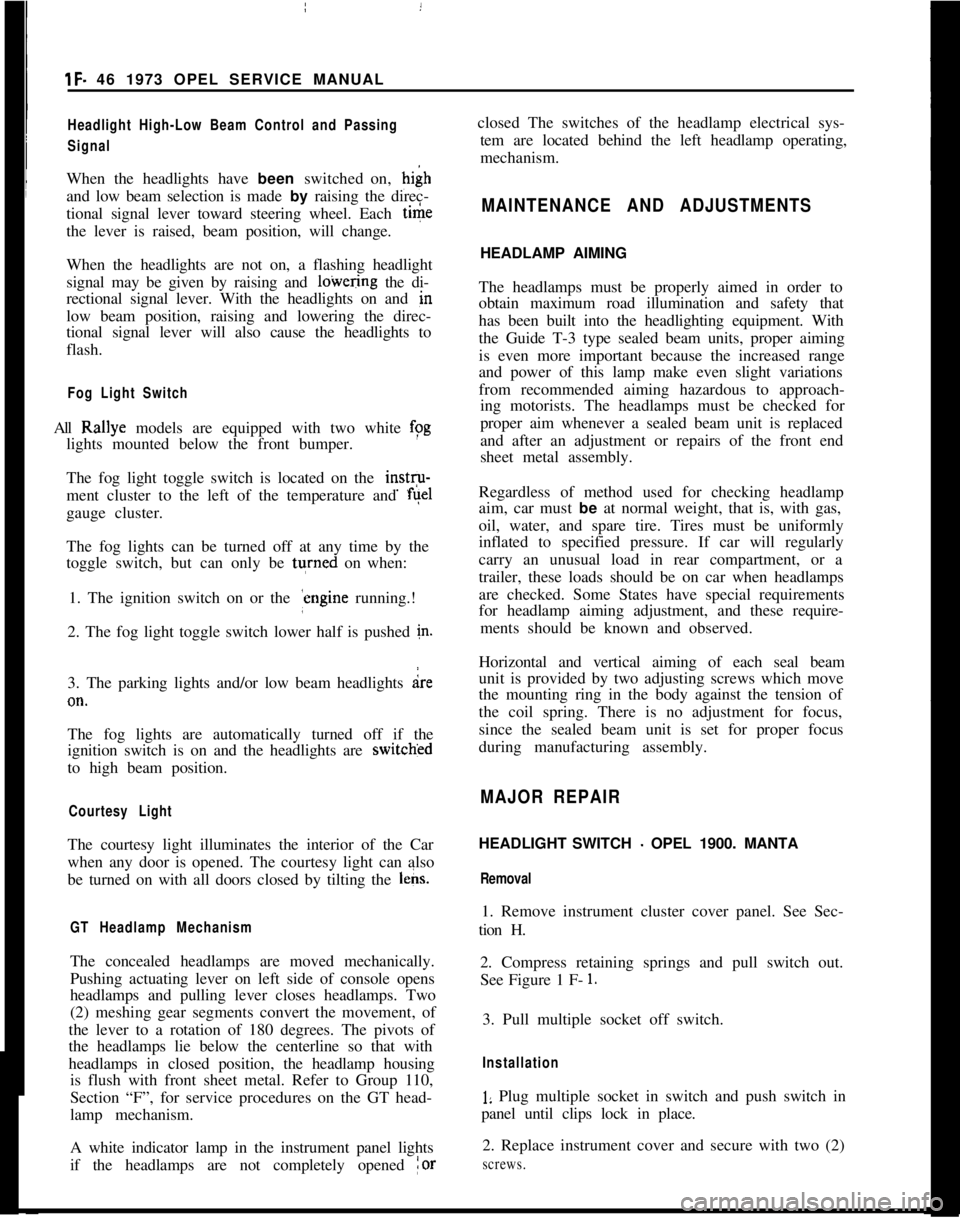

FUSIBLE LINKSAll 1973 Opel Models have fusible links located be-

tween the starting motor post and the generator

regulator. These links are the weakest point in the

electrical supply system for the complete car, and, as

such, will act like a fuse for every wiring harness in

the

ca.r. Every electrical accessory is still protected

by a fuse or circuit breaker, of course, but fusible

links protect the wiring harnesses before the fuses.

A fusible link consists of soldering a smaller gauge

wire to a heavier gauge wire end to end. In the event

of a circuit overload where the heavier gauge

becomes short circuited, the fusible link or smaller

gauge wire will burn out first, thus, protecting its

circuit from major damage. These fusible links are

located in the engine compartment in such a manner

that if overheated, the possibility of a fire is veryr¬e.

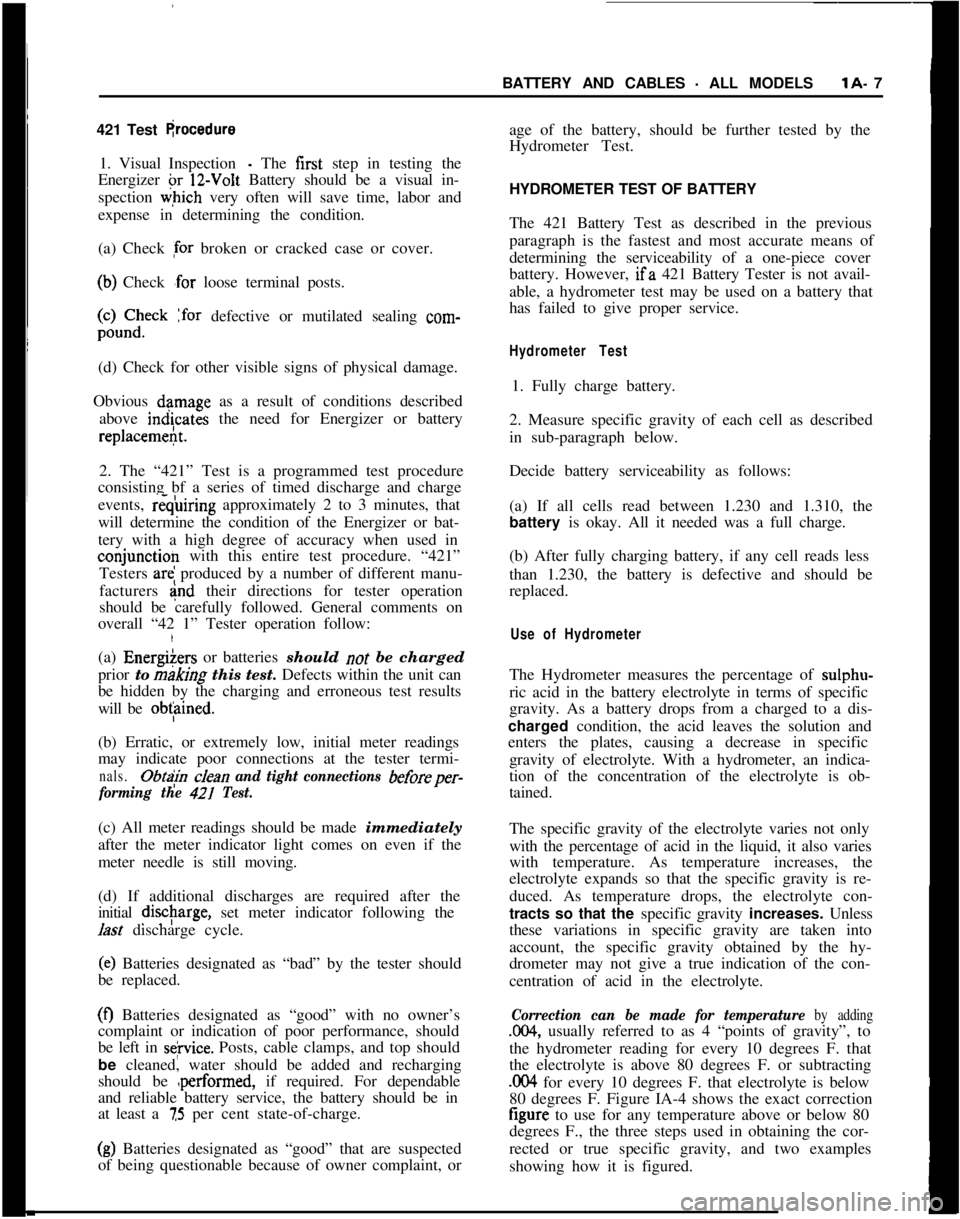

The attachment of the fusible links and the circuits

they protect are as follows: See Figure

l A-5.

D+61TERMIN\AL ;;!$6,,FL #3

B+ TERMINAL

I3QlA5

SOLENOID ON STARTER

Figure

t A-5 Fusible LinksFusible link (1) is connected to the starter solenoid

at the battery cable terminal, on one end and to the

red and white stripped main feed wire at the other

end.

Fusible link (2) is connected between the red wirean&s

terminal of the voltage regulateand protectsagainst a situation where the battery will not accept

a charge and the generator is charging to handle

various electrical loads. Fusible link (3) is connected

between the light blue with white stripes wire and D

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.