lock OPEL MERIVA 2017 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: MERIVA, Model: OPEL MERIVA 2017Pages: 251, PDF Size: 8.14 MB

Page 189 of 251

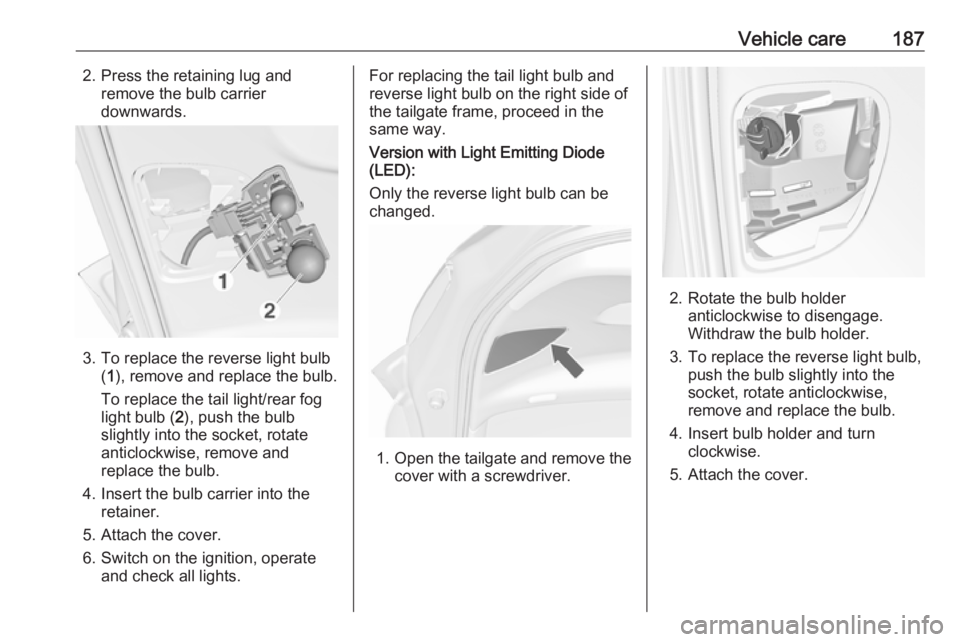

Vehicle care1872. Press the retaining lug andremove the bulb carrier

downwards.

3. To replace the reverse light bulb (1 ), remove and replace the bulb.

To replace the tail light/rear fog

light bulb ( 2), push the bulb

slightly into the socket, rotate

anticlockwise, remove and

replace the bulb.

4. Insert the bulb carrier into the retainer.

5. Attach the cover.

6. Switch on the ignition, operate and check all lights.

For replacing the tail light bulb and

reverse light bulb on the right side of

the tailgate frame, proceed in the

same way.

Version with Light Emitting Diode

(LED):

Only the reverse light bulb can be

changed.

1. Open the tailgate and remove the

cover with a screwdriver.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder.

3. To replace the reverse light bulb, push the bulb slightly into the

socket, rotate anticlockwise,

remove and replace the bulb.

4. Insert bulb holder and turn clockwise.

5. Attach the cover.

Page 190 of 251

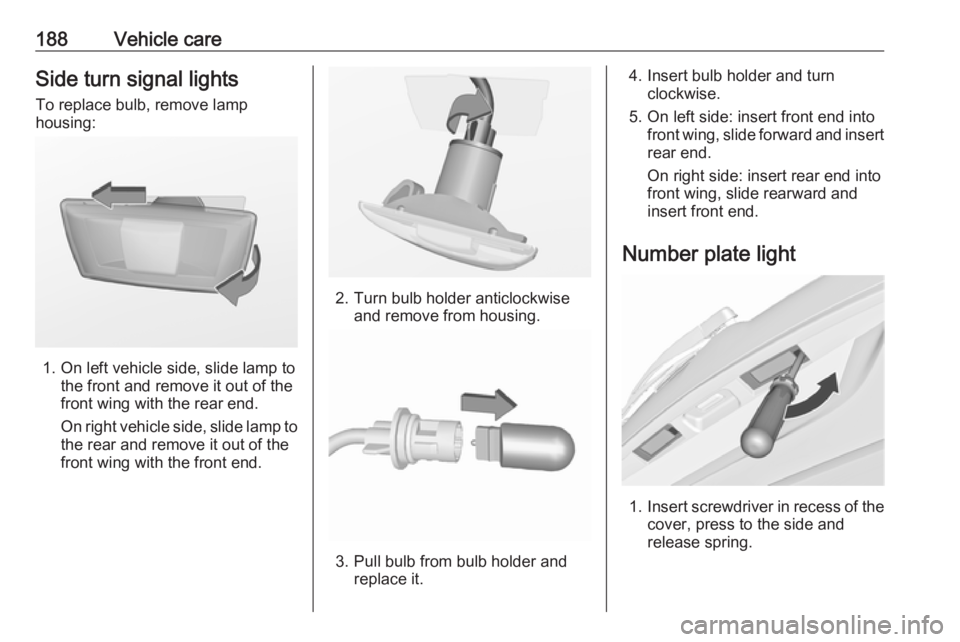

188Vehicle careSide turn signal lightsTo replace bulb, remove lamp

housing:

1. On left vehicle side, slide lamp to the front and remove it out of the

front wing with the rear end.

On right vehicle side, slide lamp to

the rear and remove it out of the front wing with the front end.

2. Turn bulb holder anticlockwise and remove from housing.

3. Pull bulb from bulb holder and replace it.

4. Insert bulb holder and turnclockwise.

5. On left side: insert front end into front wing, slide forward and insert

rear end.

On right side: insert rear end into

front wing, slide rearward and

insert front end.

Number plate light

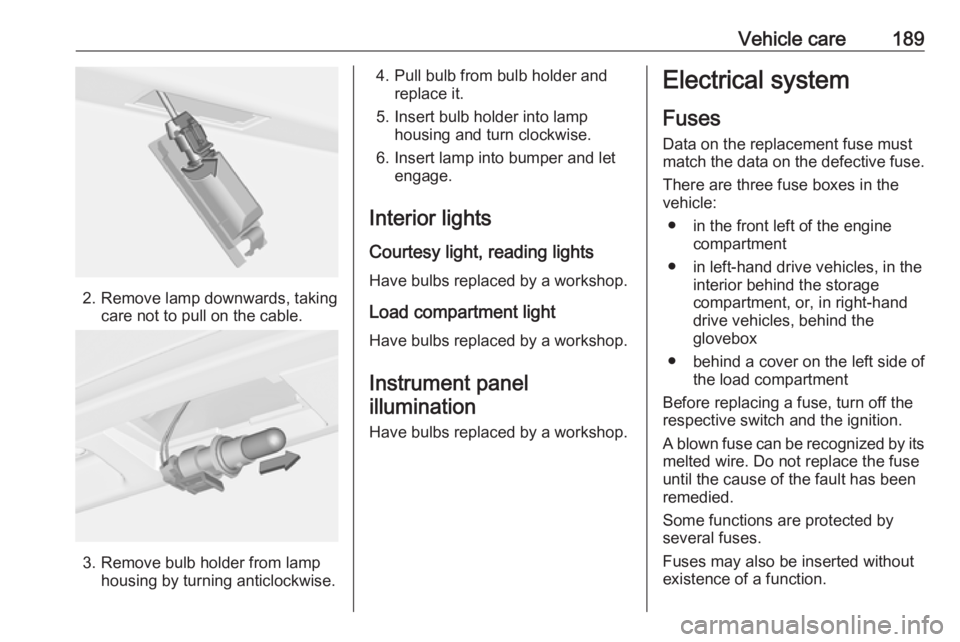

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

Page 191 of 251

Vehicle care189

2. Remove lamp downwards, takingcare not to pull on the cable.

3. Remove bulb holder from lamphousing by turning anticlockwise.

4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights

Courtesy light, reading lights Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panel illumination

Have bulbs replaced by a workshop.Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● in the front left of the engine compartment

● in left-hand drive vehicles, in the interior behind the storage

compartment, or, in right-hand

drive vehicles, behind the

glovebox

● behind a cover on the left side of the load compartment

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Page 195 of 251

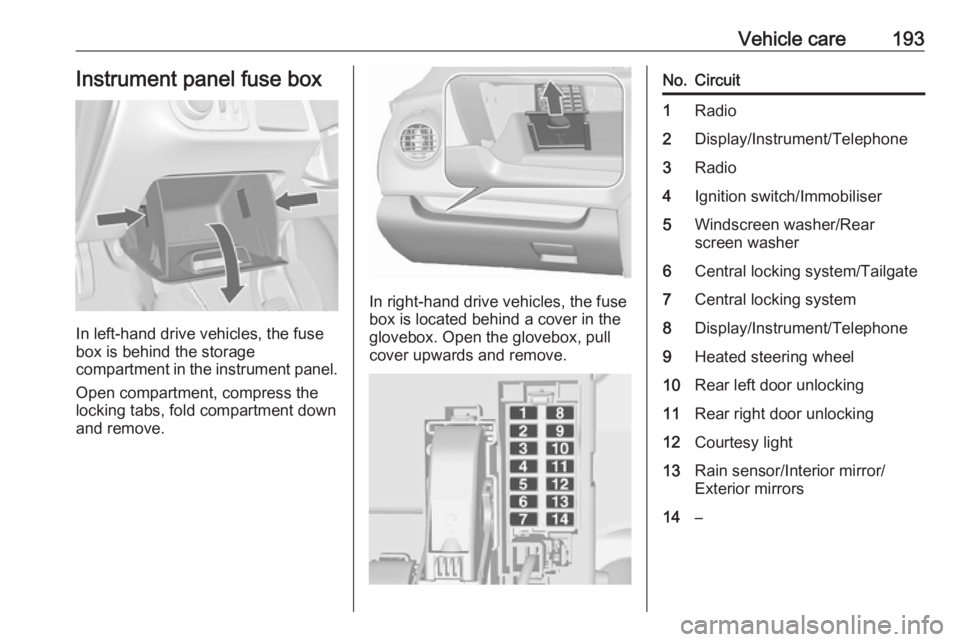

Vehicle care193Instrument panel fuse box

In left-hand drive vehicles, the fuse

box is behind the storage

compartment in the instrument panel.

Open compartment, compress the

locking tabs, fold compartment down and remove.

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox, pull

cover upwards and remove.

No.Circuit1Radio2Display/Instrument/Telephone3Radio4Ignition switch/Immobiliser5Windscreen washer/Rear

screen washer6Central locking system/Tailgate7Central locking system8Display/Instrument/Telephone9Heated steering wheel10Rear left door unlocking11Rear right door unlocking12Courtesy light13Rain sensor/Interior mirror/

Exterior mirrors14–

Page 204 of 251

202Vehicle care9Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel bolts, do not attach wheel

covers.

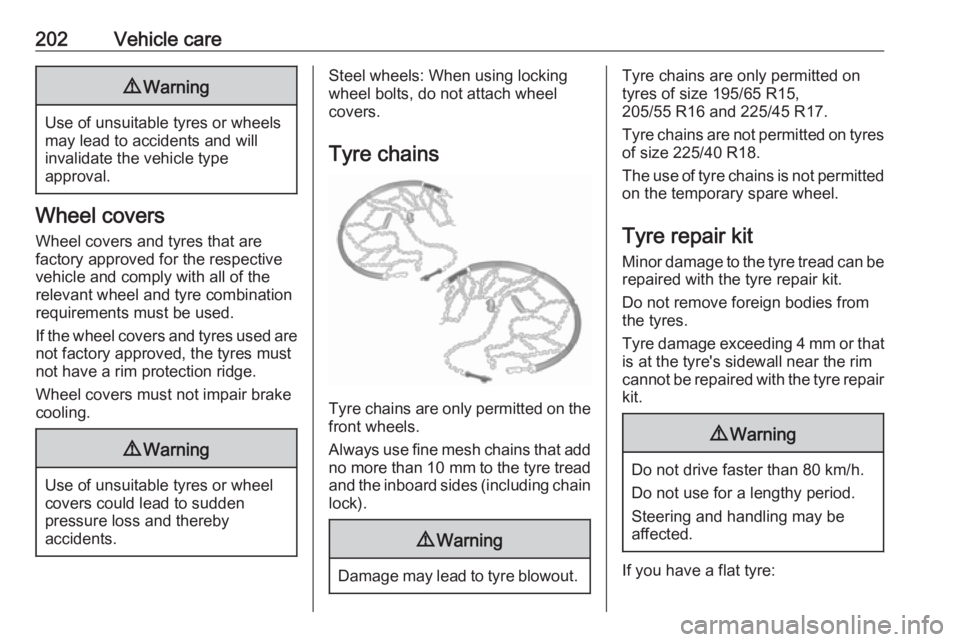

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 195/65 R15,

205/55 R16 and 225/45 R17.

Tyre chains are not permitted on tyres of size 225/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Page 211 of 251

Vehicle care209Fold out the wheel wrench and

install ensuring that it locates

securely and loosen each wheel

bolt by half a turn.

The wheels might be protected by locking wheel bolts. To loosen

these specific bolts first attach the

adapter onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

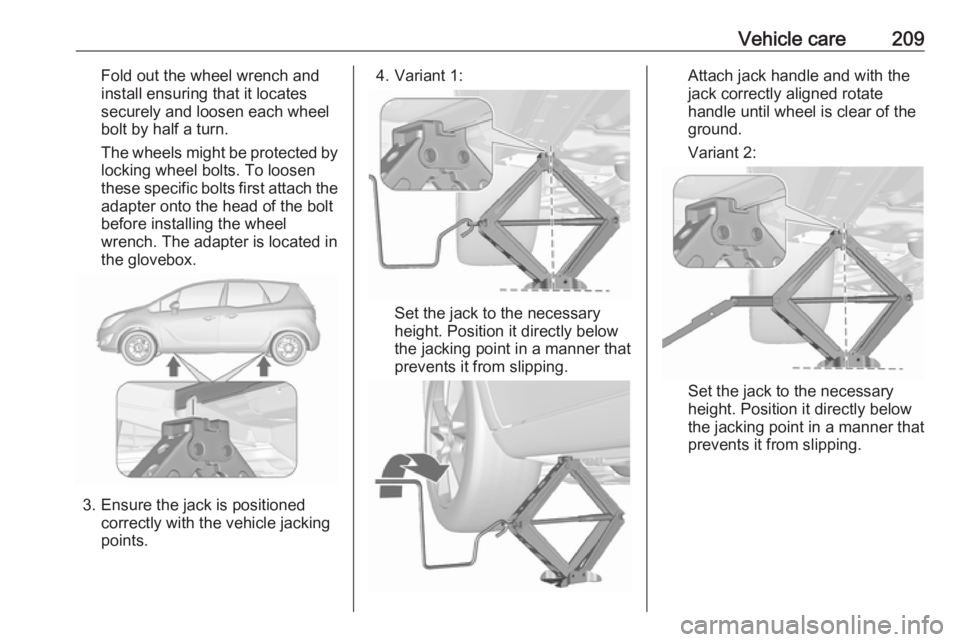

3. Ensure the jack is positioned correctly with the vehicle jacking

points.

4. Variant 1:

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

Variant 2:

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Page 212 of 251

210Vehicle care

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel bolts. 6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.

11. Stow the replaced wheel 3 210,

the vehicle tools 3 195 and the

adapter for the locking wheel bolts 3 61.

12. Check the tyre pressure of the installed tyre and also the wheel

bolt torque as soon as possible.

Have the defective tyre renewed or repaired.

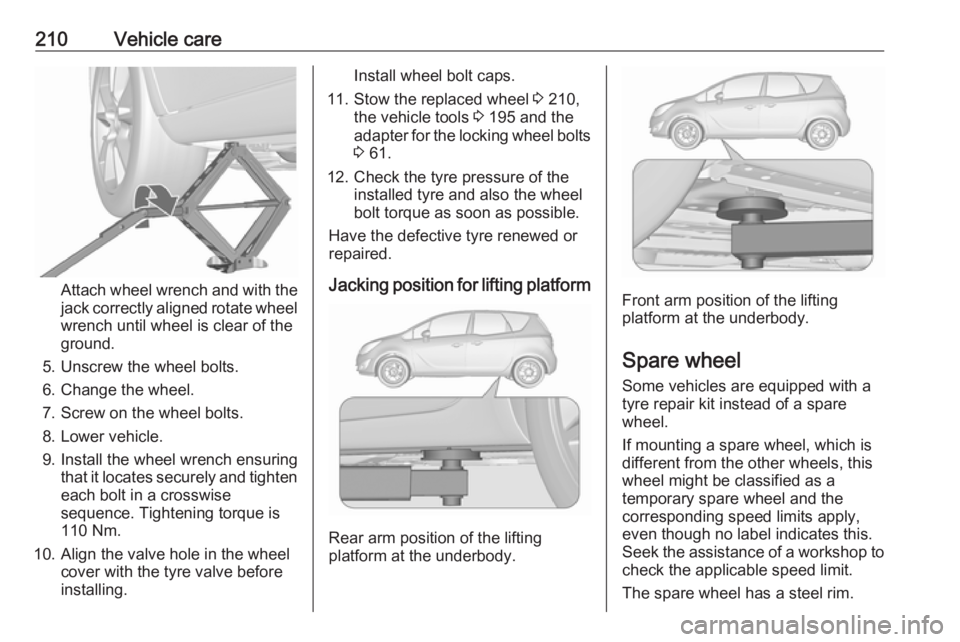

Jacking position for lifting platform

Rear arm position of the lifting

platform at the underbody.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Page 214 of 251

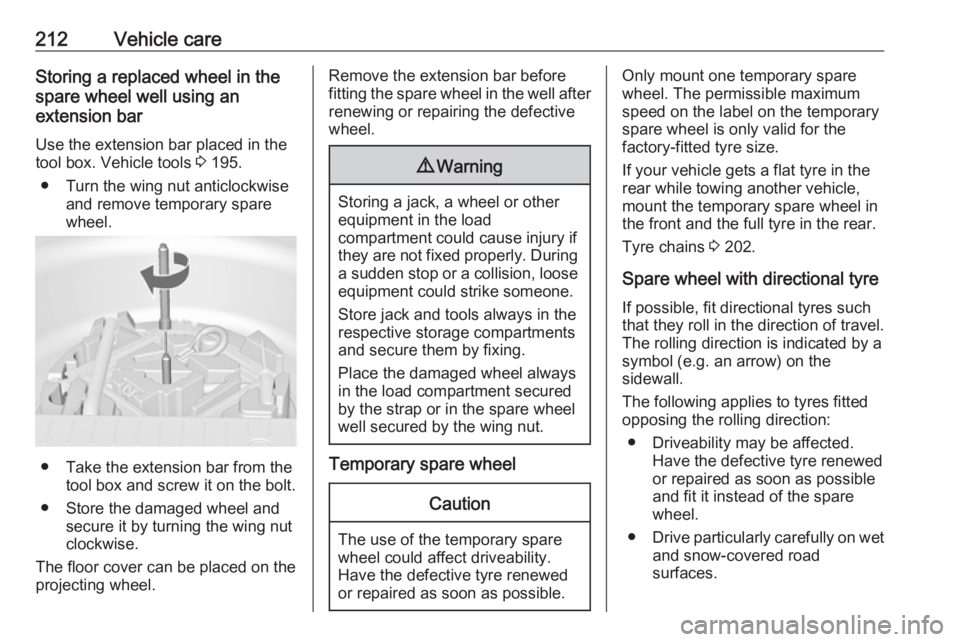

212Vehicle careStoring a replaced wheel in the

spare wheel well using an

extension bar

Use the extension bar placed in the

tool box. Vehicle tools 3 195.

● Turn the wing nut anticlockwise and remove temporary spare

wheel.

● Take the extension bar from the tool box and screw it on the bolt.

● Store the damaged wheel and secure it by turning the wing nut

clockwise.

The floor cover can be placed on the

projecting wheel.

Remove the extension bar before

fitting the spare wheel in the well after renewing or repairing the defective

wheel.9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, loose

equipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Place the damaged wheel always

in the load compartment secured

by the strap or in the spare wheel

well secured by the wing nut.

Temporary spare wheel

Caution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

If your vehicle gets a flat tyre in the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full tyre in the rear.

Tyre chains 3 202.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 216 of 251

214Vehicle care3. Connect the black lead to thenegative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of 1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

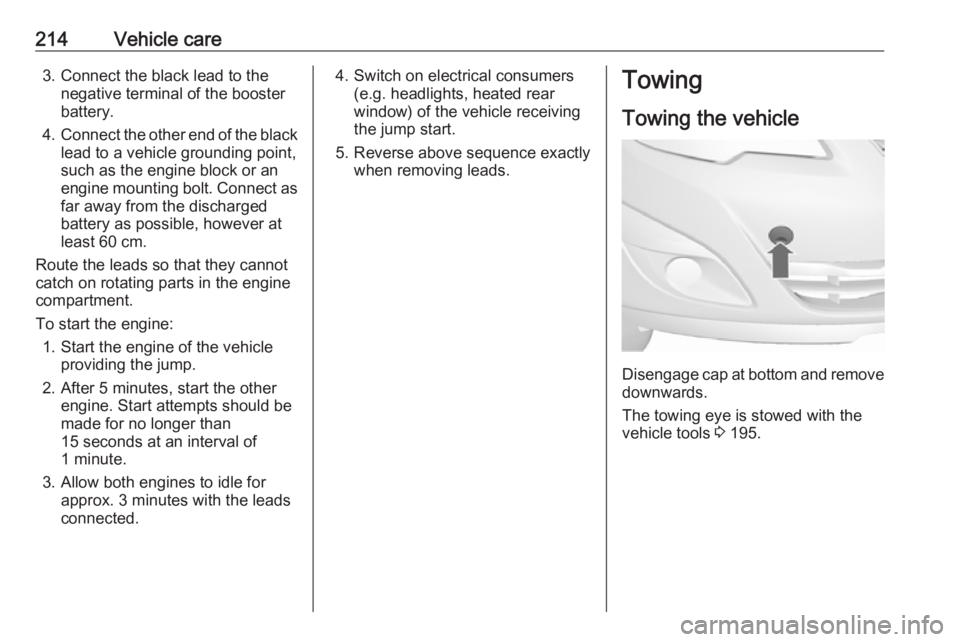

Towing the vehicle

Disengage cap at bottom and removedownwards.

The towing eye is stowed with the

vehicle tools 3 195.

Page 217 of 251

Vehicle care215

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Caution

Activate the child lock in both rear

doors if the rear seats are

occupied. Child locks 3 26.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap at the bottom and close

cap.

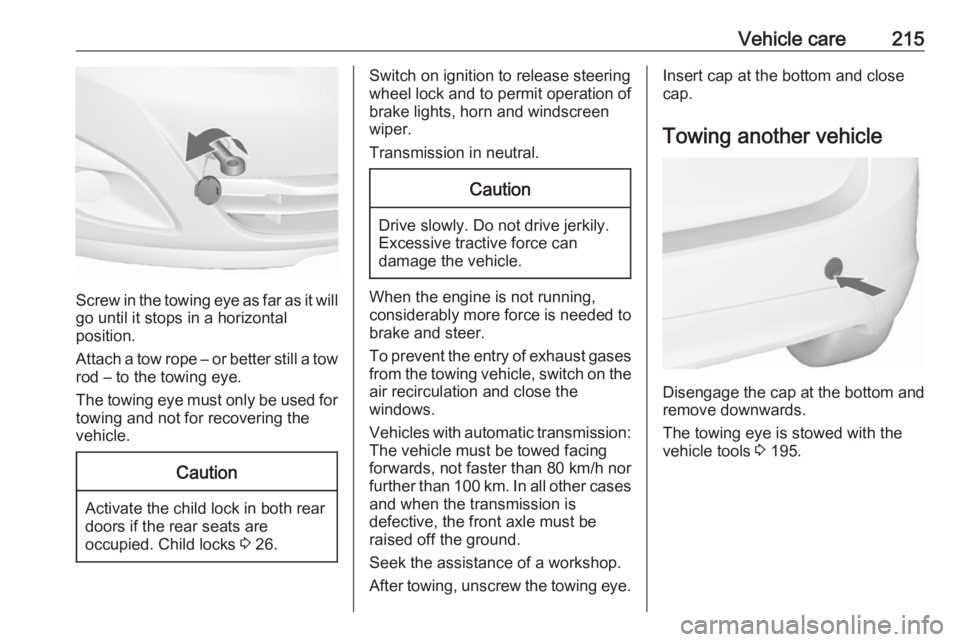

Towing another vehicle

Disengage the cap at the bottom and

remove downwards.

The towing eye is stowed with the

vehicle tools 3 195.