OPEL MOKKA X 2019 Manual user

Manufacturer: OPEL, Model Year: 2019, Model line: MOKKA X, Model: OPEL MOKKA X 2019Pages: 253, PDF Size: 6.86 MB

Page 171 of 253

Driving and operating169The lane departure warning system is

activated by pressing ). The

illuminated LED in the button

indicates that the system is switched

on.

When the control indicator ) in the

instrument cluster illuminates green,

the system is ready to operate.

The system is only operable at

vehicle speeds above 56 km/h and if

lane markings are available.

When the system recognises an

unintended lane change, the control

indicator ) changes to yellow and

flashes. Simultaneously a chime

sound is activated.

Deactivation

The system is deactivated by

pressing ), the LED in the button

extinguishes.

At speeds below 56 km/h the system

is inoperable.

Fault

The lane departure warning system

may not operate properly when:

● the windscreen is not clean

● there are adverse environmental conditions like heavy rain, snow,

direct sunlight or shadows

The system can not operate when no

lane marking is detected.Fuel

Fuel for petrol engines

Only use unleaded fuel that complies

with European standard EN 228 or

equivalent.

The engine is capable of running with

fuel that contains up to 10% ethanol

(e.g. named E10).

Use fuel with the recommended

octane rating. A lower octane rating can reduce engine power and torque

and slightly increases fuel

consumption.

Page 172 of 253

170Driving and operatingCaution

Do not use fuel or fuel additives

that contain metallic compounds

such as manganese-based

additives. This may cause engine

damage.

Caution

Use of fuel that does not comply to EN 228 or equivalent can lead to

deposits or engine damage.

Caution

Use of fuel with a lower octane

rating than the lowest possible

rating could lead to uncontrolled combustion and engine damage.

The engine-specific requirements

regarding octane rating are given in

the engine data overview 3 229. A

country-specific label at the fuel filler

flap can supersede the requirement.

Fuel additive

Fuel should contain detergent

additives that help prevent engine

and fuel system deposits from

forming. Clean fuel injectors and

intake valves will allow the emission

control system to work properly. In

certain countries fuel does not

contain sufficient quantities of

additive to keep fuel injectors and

intake valves clean. In these

countries a fuel additive is required for

some engines to make up for this lack

of detergency. Only use fuel additive

approved for the vehicle.

Adding fuel additive to the filled fuel

tank is required at least every 15,000 km or after one year, whichever

occurs first. For further information,

contact your workshop.

Prohibited fuels

Fuels containing oxygenates such as

ethers and ethanol, as well as

reformulated fuel, are available in

some cities. If these fuels comply with the previously described

specification, then they are

acceptable to use. However, E85(85% ethanol) and other fuels

containing more than 15% ethanol

must be used only in FlexFuel

vehicles.Caution

Do not use fuel containing

methanol. It can corrode metal

parts in the fuel system and also

damage plastic and rubber parts.

This damage would not be

covered by the vehicle warranty.

Some fuels, mainly high octane

racing fuels, can contain an octane

enhancing additive called

methylcyclopentadienyl manganese

tricarbonyl (MMT). Do not use fuels or fuel additives with MMT as they can

reduce spark plug life and affect

emission control system

performance. The malfunction

indicator light Z may illuminate 3 93.

If this occurs, seek the assistance of

a workshop.

Page 173 of 253

Driving and operating171Fuel for diesel engines

Only use diesel fuel that complies

with EN 590 and which has a sulphur

concentration of max. 10 ppm.

Fuels with a biodiesel (compliant with

EN 14214) content of max. 7% by

volume may be used (e.g. named

B7).

If travelling in countries outside the

European Union occasional use of Euro-Diesel fuel with a sulphur

concentration below 50 ppm is

possible.

Caution

Frequent usage of diesel fuel

containing more than 15 ppm

sulphur will cause severe engine

damage.

Caution

Use of fuel that does not comply to EN 590 or similar can lead to

engine powerloss, increased wear

or engine damage.

Do not use marine diesel oils, heating

oils, Aquazole and similar diesel-

water emulsions. Diesel fuels must

not be diluted with fuels for petrol

engines.

Low temperature operation At temperatures below 0 °C, some

diesel products with biodiesel blends may clog, freeze or gel, which mayaffect the fuel supply system. Starting

and engine operation may not work

properly. Make sure to fill winter

grade diesel fuel at ambient

temperatures below 0°C.

Arctic grade diesel fuel can be used

in extreme cold temperatures below

--20 °C. Using this fuel grade in warm

or hot climates is not recommended

and may cause engine stalling, poor

starting or damage on the fuel

injection system.

Fuel for liquid gas operation

Liquid gas is known as LPG

(Liquefied Petroleum Gas) or under its French name GPL (Gaz de Pétrole Liquéfié). LPG is also known as

Autogas.

LPG consists mainly of propane and

butane. The octane rating is between

105 and 115, depending on the

butane proportion. LPG is stored as a

liquid at a pressure of approx. five to

ten bar.

The boiling point depends on the

pressure and the mixing ratio. At

ambient pressure, it is between

-42 °C (pure propane) and -0.5 °C

(pure butane).

Page 174 of 253

172Driving and operatingCaution

The system works at an ambient

temperature of approx. -8 °C to

100 °C.

Full functioning of the LPG system can only be guaranteed with liquid

gas which complies with the minimum

requirements of DIN EN 589.

Fuel selector 3 86.

Refuelling

9 Danger

Before refuelling, switch off

ignition and any external heaters

with combustion chambers.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

A label with symbols at the fuel filler

flap is indicating the allowed fuel

types. In Europe the pump nozzles of the filling stations are marked with

these symbols. Refuel only the

allowed fuel type.

Caution

In case of misfuelling, do not

switch on ignition.

Fuel filler flap is located at right rear

side of vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

Page 175 of 253

Driving and operating173Petrol and Diesel refuelling

To open, turn the cap slowly

anticlockwise.

The fuel filler cap can be retained in

the bracket on the fuel filler flap.

Place the nozzle in straight position to the filler neck and press with slight

force to insert.

To refuel, switch on pump nozzle.

After automatic cut-off, the tank can be topped up by operating the pump

nozzle a maximum of two more times.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and allow it to engage.

Misfuel inhibitor

9 Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Diesel vehicle is equipped with a

misfuel inhibitor.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using the suitable fuel

nozzle or a funnel for emergency

refilling.

In case of an emergency, refill with a

canister. A funnel must be used to

open the cap of the filler neck.

Page 176 of 253

174Driving and operating

The funnel is stowed in the load

compartment.

Place the funnel in storage bin and

store into polybag.

Use the funnel to fill in the fuel into the

filler neck.

After topping-up, stow the funnel into

polybag in the load compartment.

Liquid gas refuelling

Follow the operating and safety

instructions of the filling station when

refuelling.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Opel Distributors and from Opel

Service Partners.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

DISH adapter: Austria, Bosnia-

Herzegovina, Bulgaria, Czech

Republic, Croatia, Denmark, Estonia, France, Greece, Hungary, Italy,

Latvia, Lithuania, Macedonia,

Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Sweden,

Switzerland, Turkey, Ukraine

Page 177 of 253

Driving and operating175

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

EURO adapter: Spain

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME adapter: Screw the nut of the

filling nozzle onto the adapter.

Engage the locking lever of the filler

nozzle.

DISH adapter: Place the filler nozzle

into the adapter. Engage the locking

lever of the filler nozzle.

Bayonet adapter: Place filler nozzle

on the adapter and turn one quarter

turn. Engage the locking lever of the

filler nozzle.

EURO adapter: Press the filler nozzle

onto the adapter. Engage the locking

lever of the filler nozzle.

Press the button at the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow in vehicle.

Page 178 of 253

176Driving and operatingFit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Fuel filler cap

Only use genuine fuel filler caps. Diesel-engined vehicles have special fuel filler caps.

Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage. E.g. in case of

four bulbs with a power of 5 W each,

the function only detects lamp outage when only a single 5 W lamp remains

or none remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case, use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle when

not in use.Driving characteristics and

towing tips

Before attaching a trailer, lubricate the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1000 kg, a speed of 80 km/h must not

be exceeded. The use of a stabiliser

is recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 235.

Page 179 of 253

Driving and operating177Trailer towingTrailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%.

The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 m above sea level.

Since engine power decreases as

altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).The permissible gross train weight

must not be exceeded. This weight is specified on the identification plate

3 224.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (75 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load

The permissible axle loads (see

identification plate or vehicle

documents) must not be exceeded.Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

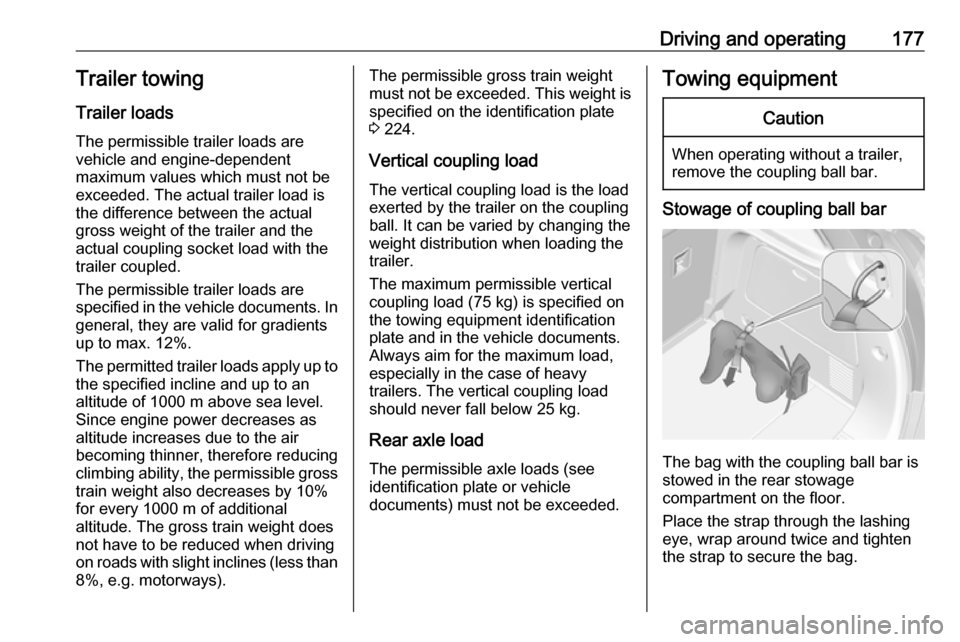

Stowage of coupling ball bar

The bag with the coupling ball bar is

stowed in the rear stowage

compartment on the floor.

Place the strap through the lashing

eye, wrap around twice and tighten

the strap to secure the bag.

Page 180 of 253

178Driving and operatingFitting the coupling ball bar

Disengage and fold down the socket.Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

● Unlock coupling ball bar by turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar