ECU OPEL MOVANO_B 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: MOVANO_B, Model: OPEL MOVANO_B 2017.5Pages: 261, PDF Size: 6.26 MB

Page 128 of 261

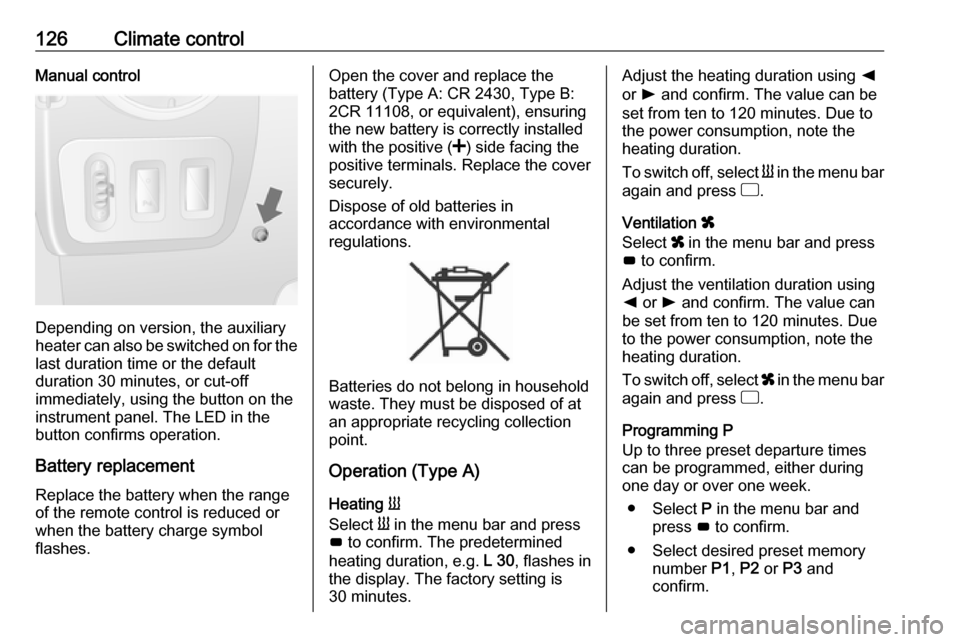

126Climate controlManual control

Depending on version, the auxiliary

heater can also be switched on for the

last duration time or the default

duration 30 minutes, or cut-off

immediately, using the button on the

instrument panel. The LED in the

button confirms operation.

Battery replacement

Replace the battery when the range

of the remote control is reduced or

when the battery charge symbol

flashes.

Open the cover and replace the

battery (Type A: CR 2430, Type B:

2CR 11108, or equivalent), ensuring

the new battery is correctly installed

with the positive ( <) side facing the

positive terminals. Replace the cover

securely.

Dispose of old batteries in

accordance with environmental

regulations.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Operation (Type A)

Heating Y

Select Y in the menu bar and press

G to confirm. The predetermined

heating duration, e.g. L 30, flashes in

the display. The factory setting is 30 minutes.

Adjust the heating duration using k

or l and confirm. The value can be

set from ten to 120 minutes. Due to

the power consumption, note the

heating duration.

To switch off, select Y in the menu bar

again and press d.

Ventilation x

Select x in the menu bar and press

G to confirm.

Adjust the ventilation duration using k or l and confirm. The value can

be set from ten to 120 minutes. Due

to the power consumption, note the

heating duration.

To switch off, select x in the menu bar

again and press d.

Programming P

Up to three preset departure times

can be programmed, either during

one day or over one week.

● Select P in the menu bar and

press G to confirm.

● Select desired preset memory number P1, P2 or P3 and

confirm.

Page 154 of 261

152Driving and operatingwarning may sound as a signal to

depress the brake pedal or apply the

parking brake.

Switch off engine if stopping for a

lengthy period, e.g. in traffic jams.

When the vehicle is parked and the

driver's door is opened, a warning

chime will sound if neutral is not

selected or the brake pedal has not

been depressed.

Engine braking

Automatic mode

When driving downhill, the manual

transmission automated does not

shift into higher gears until a fairly

high engine speed has been reached. It shifts down in good time when

braking.

Manual mode

To utilise the engine braking effect,

select a lower gear in good time when

driving downhill.Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud, snow or a hole. Move the

selector lever between R and A/M (or

between + and -) in a repeat pattern,

while applying light pressure to the

accelerator pedal. Do not race the

engine and avoid sudden

acceleration.

Parking

Apply the parking brake. The most

recently engaged gear (see

transmission display) remains

engaged. With N, no gear is engaged.

When the ignition is switched off, the

transmission no longer responds to

movement of the selector lever.

If the ignition is not switched off, or the

parking brake has not been applied, a

warning chime will sound upon

opening the driver's door.

Manual mode If a higher gear is selected when the

engine speed is too low, or a lower

gear when the speed is too high, theshift is not executed. This prevents

the engine from running at too low or too high an engine speed.

If engine speed is too low, the

transmission automatically shifts to a

lower gear.

If engine speed is too high, the

transmission only switches to a higher gear via kickdown.

Electronic driving programmes

Winter mode V

Page 179 of 261

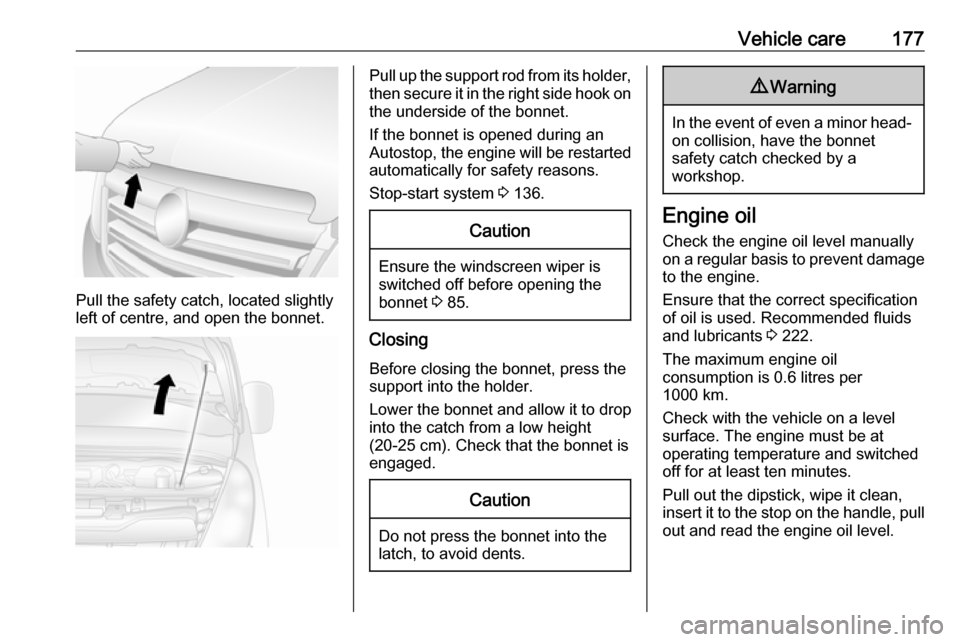

Vehicle care177

Pull the safety catch, located slightly

left of centre, and open the bonnet.

Pull up the support rod from its holder,

then secure it in the right side hook on the underside of the bonnet.

If the bonnet is opened during an Autostop, the engine will be restarted

automatically for safety reasons.

Stop-start system 3 136.Caution

Ensure the windscreen wiper is

switched off before opening the

bonnet 3 85.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to drop into the catch from a low height

(20-25 cm). Check that the bonnet is

engaged.

Caution

Do not press the bonnet into the

latch, to avoid dents.

9 Warning

In the event of even a minor head-

on collision, have the bonnet

safety catch checked by a

workshop.

Engine oil

Check the engine oil level manually on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 222.

The maximum engine oil

consumption is 0.6 litres per

1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least ten minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Page 180 of 261

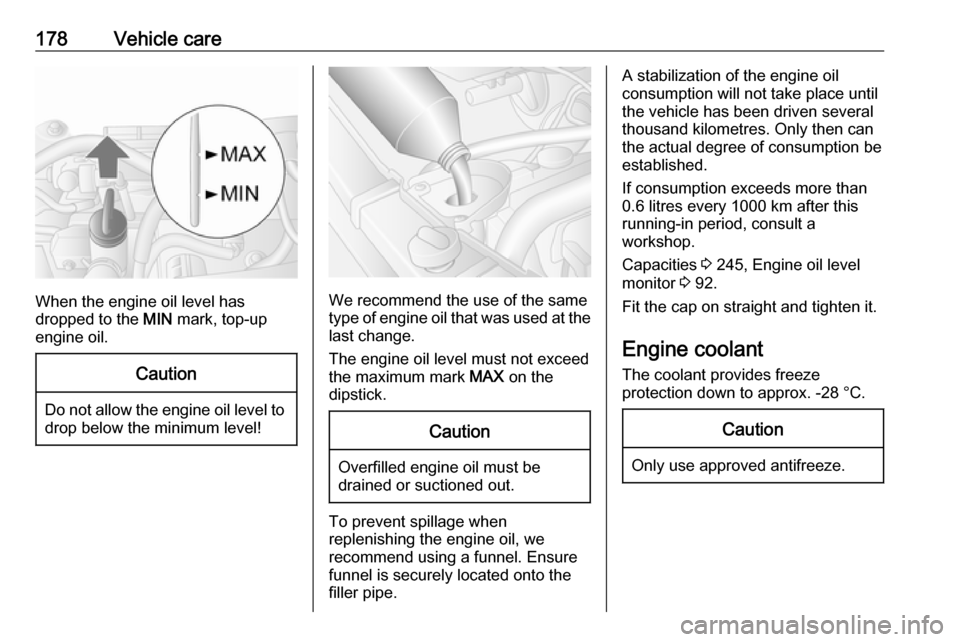

178Vehicle care

When the engine oil level has

dropped to the MIN mark, top-up

engine oil.

Caution

Do not allow the engine oil level to drop below the minimum level!

We recommend the use of the same

type of engine oil that was used at the

last change.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel. Ensure funnel is securely located onto the

filler pipe.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand kilometres. Only then can

the actual degree of consumption be

established.

If consumption exceeds more than

0.6 litres every 1000 km after this

running-in period, consult a

workshop.

Capacities 3 245, Engine oil level

monitor 3 92.

Fit the cap on straight and tighten it.

Engine coolant The coolant provides freeze

protection down to approx. -28 °C.Caution

Only use approved antifreeze.

Page 188 of 261

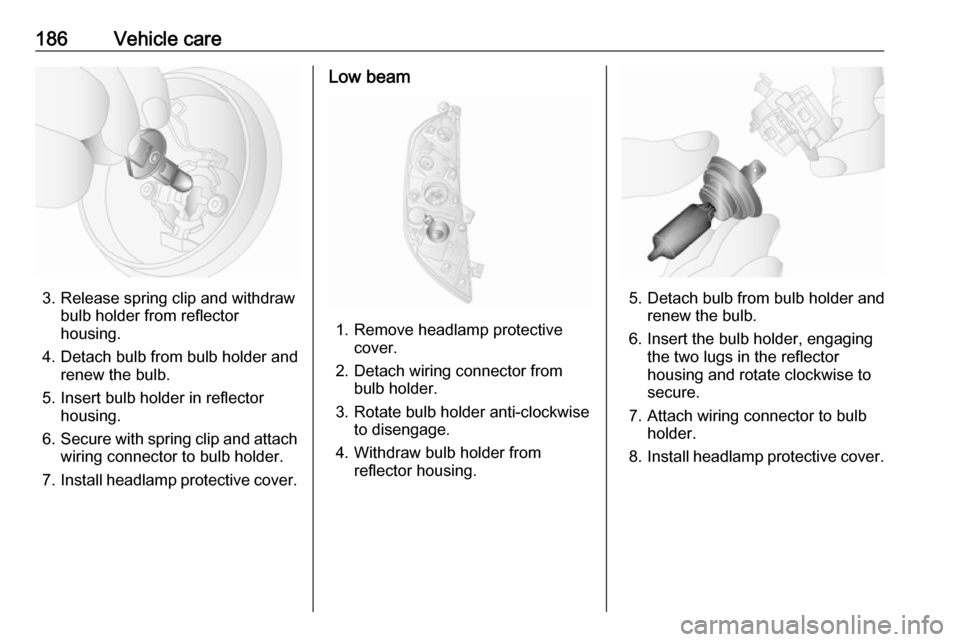

186Vehicle care

3. Release spring clip and withdrawbulb holder from reflector

housing.

4. Detach bulb from bulb holder and renew the bulb.

5. Insert bulb holder in reflector housing.

6. Secure with spring clip and attach

wiring connector to bulb holder.

7. Install headlamp protective cover.

Low beam

1. Remove headlamp protective

cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install headlamp protective cover.

Page 189 of 261

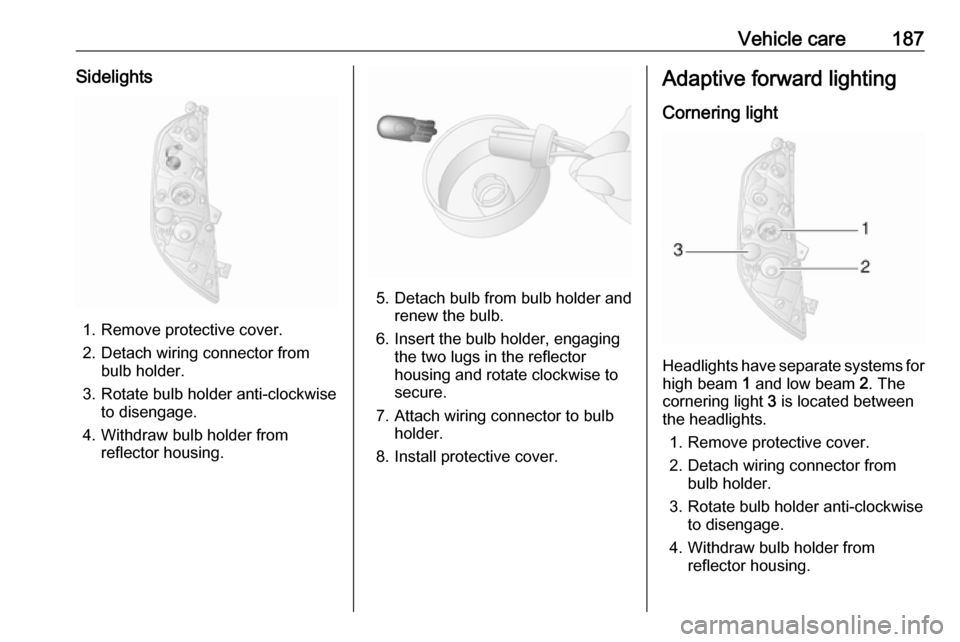

Vehicle care187Sidelights

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

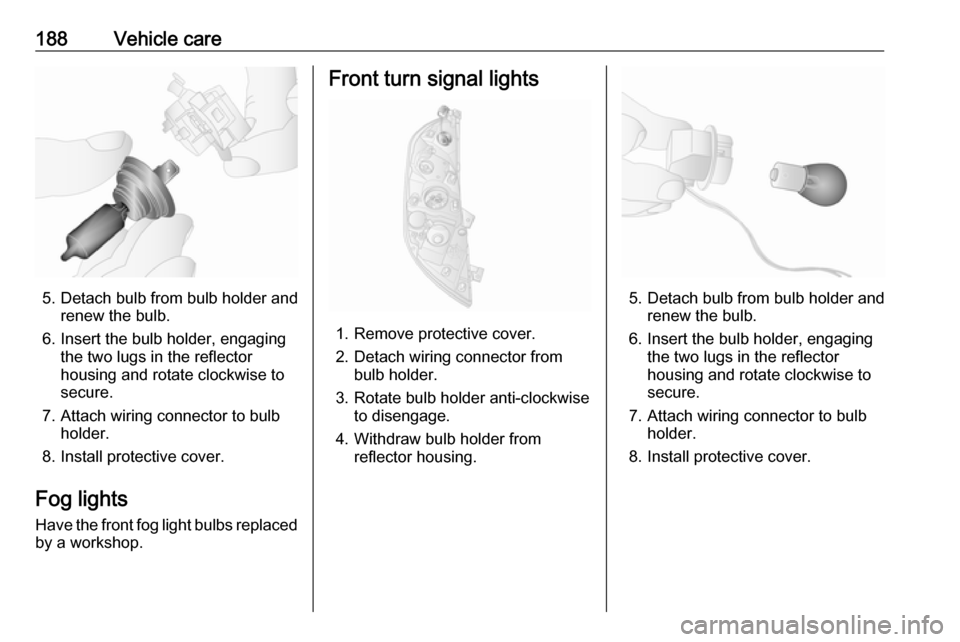

Adaptive forward lighting

Cornering light

Headlights have separate systems for high beam 1 and low beam 2. The

cornering light 3 is located between

the headlights.

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 190 of 261

188Vehicle care

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

Fog lights

Have the front fog light bulbs replaced by a workshop.

Front turn signal lights

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

Page 193 of 261

Vehicle care1915. Attach wiring connector to lampassembly.

6. Insert lamp assembly into aperture and push to the left to

secure.

Mirror turn signal lights 1. Move the lower mirror assembly from the front to access the screw.

2. Remove the screw using a torx screwdriver.

3.Remove bulb holder from the rear

of the lower mirror assembly.

4. Renew bulb.

5. Install bulb holder in lower mirror assembly.

6. Replace the screw.

Centre high-mounted brake light

1. Remove cover from the inside of the rear door.

2. Unscrew the nut from the locating

pin at the rear of the lamp

assembly.

3. Remove the lamp assembly from the aperture on the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove bulb holder from lamp assembly and renew bulb.

6. Install bulb holder in lamp assembly and reattach wiring

connector to lamp assembly.

7. Replace lamp assembly into aperture, ensuring that it is seated

correctly.

Page 210 of 261

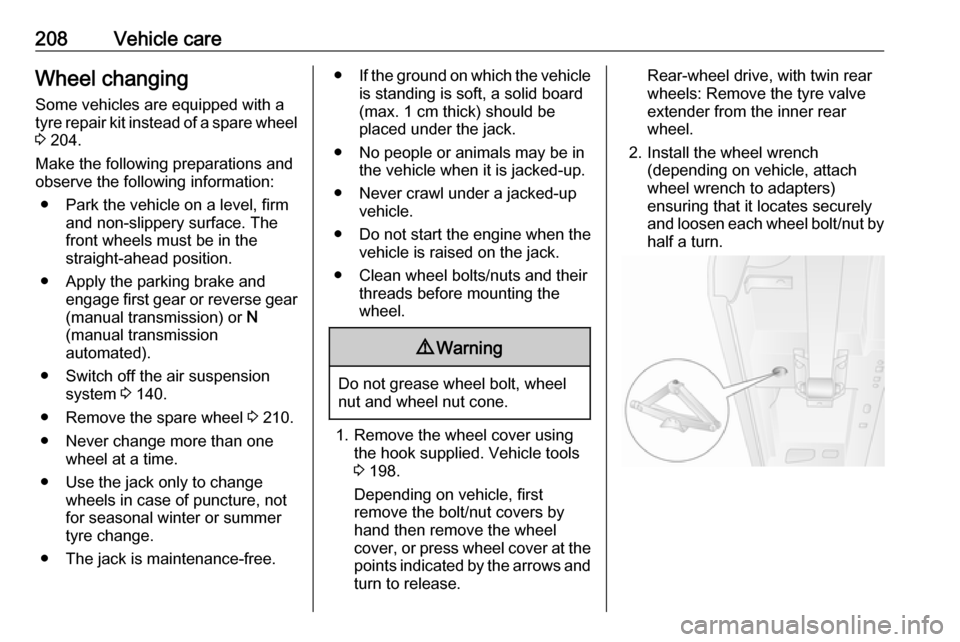

208Vehicle careWheel changingSome vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 204.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear

(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 140.

● Remove the spare wheel 3 210.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts/nuts and their threads before mounting thewheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 198.

Depending on vehicle, first

remove the bolt/nut covers by

hand then remove the wheel

cover, or press wheel cover at the points indicated by the arrows and

turn to release.

Rear-wheel drive, with twin rear

wheels: Remove the tyre valve

extender from the inner rear

wheel.

2. Install the wheel wrench (depending on vehicle, attach

wheel wrench to adapters)

ensuring that it locates securely

and loosen each wheel bolt/nut by half a turn.

Page 211 of 261

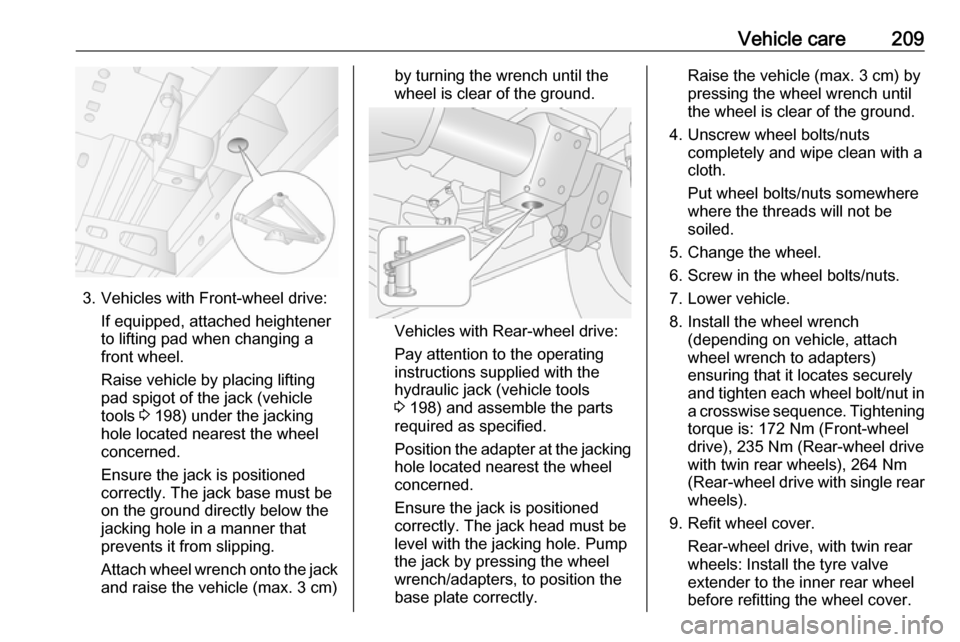

Vehicle care209

3. Vehicles with Front-wheel drive:If equipped, attached heightener

to lifting pad when changing a

front wheel.

Raise vehicle by placing lifting

pad spigot of the jack (vehicle

tools 3 198) under the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle (max. 3 cm)

by turning the wrench until the

wheel is clear of the ground.

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack (vehicle tools

3 198) and assemble the parts

required as specified.

Position the adapter at the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench/adapters, to position the

base plate correctly.

Raise the vehicle (max. 3 cm) by pressing the wheel wrench until

the wheel is clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench (depending on vehicle, attach

wheel wrench to adapters)

ensuring that it locates securely

and tighten each wheel bolt/nut in a crosswise sequence. Tighteningtorque is: 172 Nm (Front-wheel

drive), 235 Nm (Rear-wheel drive

with twin rear wheels), 264 Nm

(Rear-wheel drive with single rear

wheels).

9. Refit wheel cover. Rear-wheel drive, with twin rear

wheels: Install the tyre valve

extender to the inner rear wheel

before refitting the wheel cover.