ECU OPEL MOVANO_B 2017 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017, Model line: MOVANO_B, Model: OPEL MOVANO_B 2017Pages: 255, PDF Size: 6.12 MB

Page 175 of 255

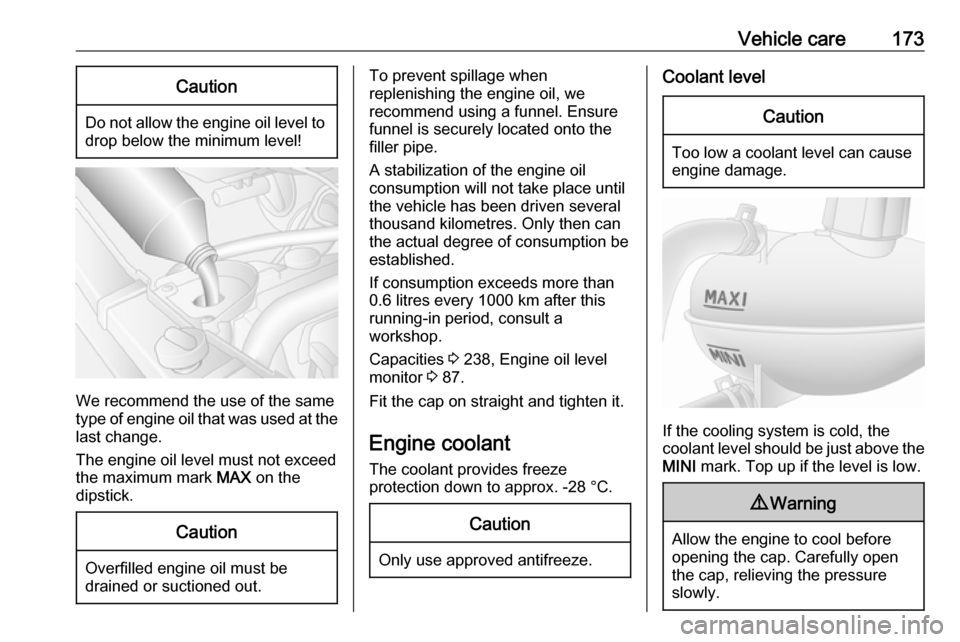

Vehicle care173Caution

Do not allow the engine oil level todrop below the minimum level!

We recommend the use of the same

type of engine oil that was used at the

last change.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel. Ensure funnel is securely located onto the

filler pipe.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand kilometres. Only then can

the actual degree of consumption be

established.

If consumption exceeds more than

0.6 litres every 1000 km after this

running-in period, consult a

workshop.

Capacities 3 238, Engine oil level

monitor 3 87.

Fit the cap on straight and tighten it.

Engine coolant The coolant provides freeze

protection down to approx. -28 °C.Caution

Only use approved antifreeze.

Coolant levelCaution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be just above the

MINI mark. Top up if the level is low.

9Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

Page 182 of 255

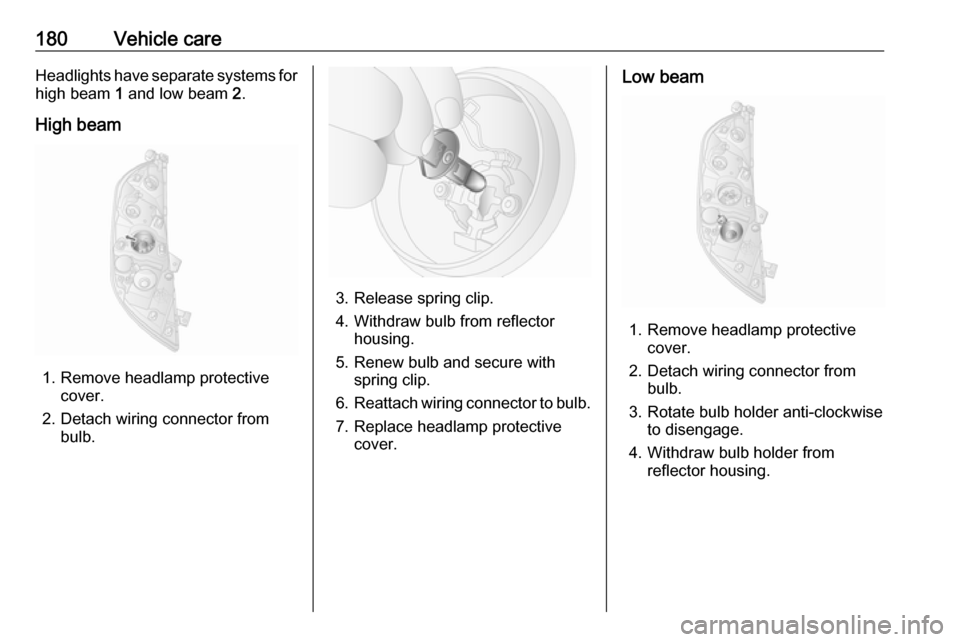

180Vehicle careHeadlights have separate systems forhigh beam 1 and low beam 2.

High beam

1. Remove headlamp protective cover.

2. Detach wiring connector from bulb.

3. Release spring clip.

4. Withdraw bulb from reflector housing.

5. Renew bulb and secure with spring clip.

6. Reattach wiring connector to bulb.

7. Replace headlamp protective cover.

Low beam

1. Remove headlamp protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 183 of 255

Vehicle care181

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace headlamp protective cover.

Sidelights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Page 184 of 255

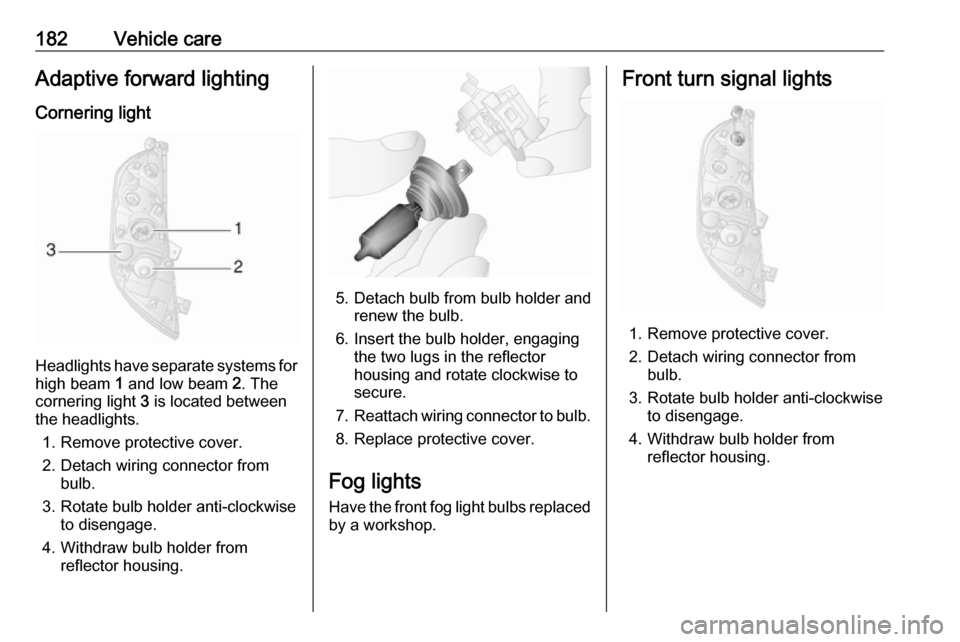

182Vehicle careAdaptive forward lightingCornering light

Headlights have separate systems forhigh beam 1 and low beam 2. The

cornering light 3 is located between

the headlights.

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Fog lights

Have the front fog light bulbs replaced by a workshop.

Front turn signal lights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 185 of 255

Vehicle care183

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

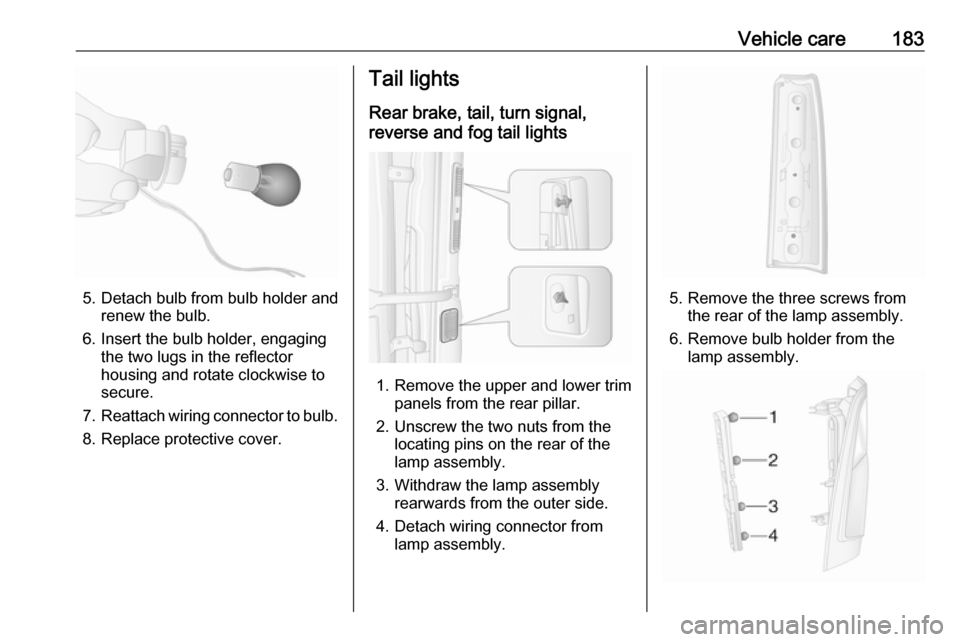

Tail lights

Rear brake, tail, turn signal,

reverse and fog tail lights

1. Remove the upper and lower trim panels from the rear pillar.

2. Unscrew the two nuts from the locating pins on the rear of the

lamp assembly.

3. Withdraw the lamp assembly rearwards from the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove the three screws from the rear of the lamp assembly.

6. Remove bulb holder from the lamp assembly.

Page 186 of 255

184Vehicle care7. Push bulb into socket slightly,rotate anti-clockwise, remove andrenew bulb.

Turn signal light ( 1)

Tail and brake light ( 2)

Reverse light ( 3)

Rear fog light, may be on one side

only ( 4)

8. Replace bulb holder in lamp assembly.

9. Replace the three screws on the rear of the lamp assembly.

10. Reattach wiring connector to lamp

assembly.

11. Replace lamp assembly from the outer side into original position,

ensuring that it is seated correctly.

12. Replace the two nuts onto the locating pins on the rear of the

lamp assembly.

13. Install the upper and lower trim panels to the rear pillar.Side turn signal lights

1. Push the lamp assembly to the right and pull at the left-hand side

of the lamp assembly to release

from the aperture.

2. Detach wiring connector from lamp assembly.

3. Remove bulb holder from lamp assembly by rotating 90° and

renew bulb.

4. Install bulb holder in lamp assembly.

5. Reattach wiring connector.

6. Install lamp assembly into aperture and push to the left to

secure.

Mirror turn signal lights 1. Move the lower mirror assembly from the front to access the screw.

2. Remove the screw using a torx screwdriver.

3. Remove bulb holder from the rear

of the lower mirror assembly.

4. Renew bulb.

5. Replace bulb holder.

6. Replace the screw.

Page 203 of 255

Vehicle care201not be driven. Seek the

assistance of a workshop.

21. Stow tyre repair kit under the front

seat.

Note

The driving characteristics of the repaired tyre are severely affected,therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 198.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear

(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 135.

● Remove the spare wheel 3 203.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts/nuts and their threads before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 192.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.

Page 204 of 255

202Vehicle care

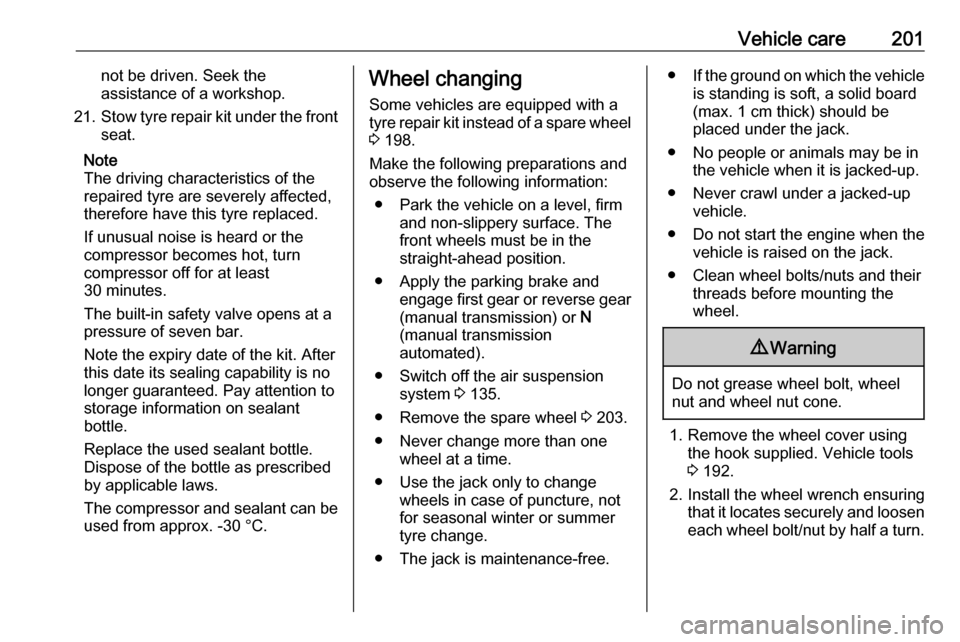

3. Vehicles with Front-wheel drive:Raise vehicle by placing lifting

pad spigot of the jack under the

jacking hole located nearest the

wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle by turning

the wrench until the wheel is clear of the ground.

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack and assemble the

parts required as specified.

Position the adapter at the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench, to position the base plate

correctly.

Raise the vehicle by pressing the wheel wrench until the wheel is

clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench ensuring that it locates securely and tighten

each wheel bolt/nut in a crosswise sequence. Tightening torque is:

172 Nm (Front-wheel drive),

235 Nm (Rear-wheel drive with

twin rear wheels), 264 Nm (Rear- wheel drive with single rear

wheels).

Page 205 of 255

Vehicle care2039. Refit wheel cover.Note

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel

cover).

10. Stow the replaced wheel 3 203

and the vehicle tools 3 192.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 239 and also the wheel bolt/nut

torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel Some vehicles are equipped with atyre repair kit instead of a spare wheel

3 198.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

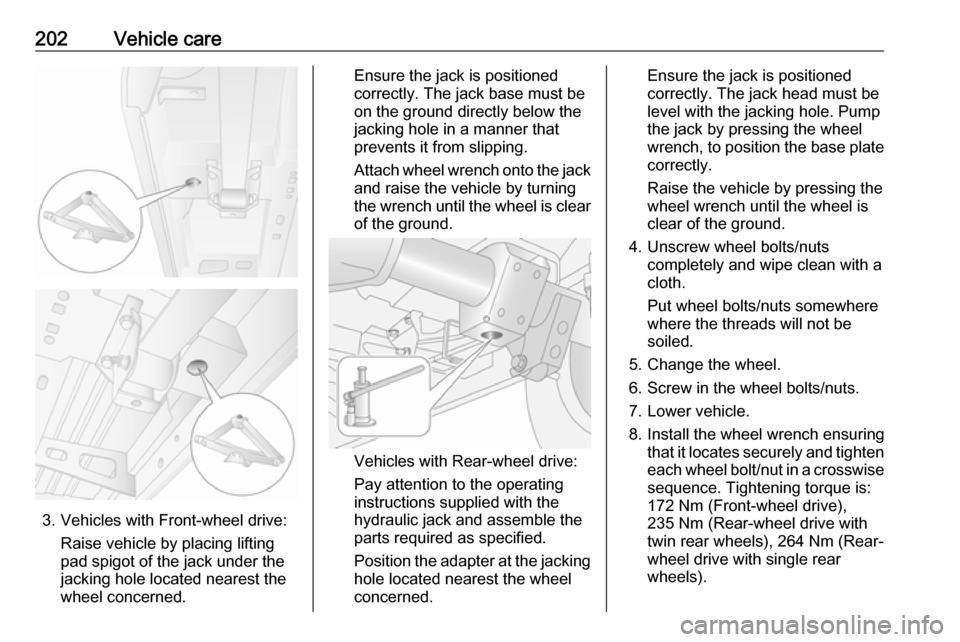

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapters

(depending on vehicle).

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

To release the spare wheel, loosen

cable by connecting the wheel

wrench and adapters (depending on

vehicle) to the slot position illustrated

and lower the wheel fully by turning

wrench clockwise.

Caution

Only use the wheel wrench and

adapters (depending on vehicle)

to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Page 206 of 255

204Vehicle care

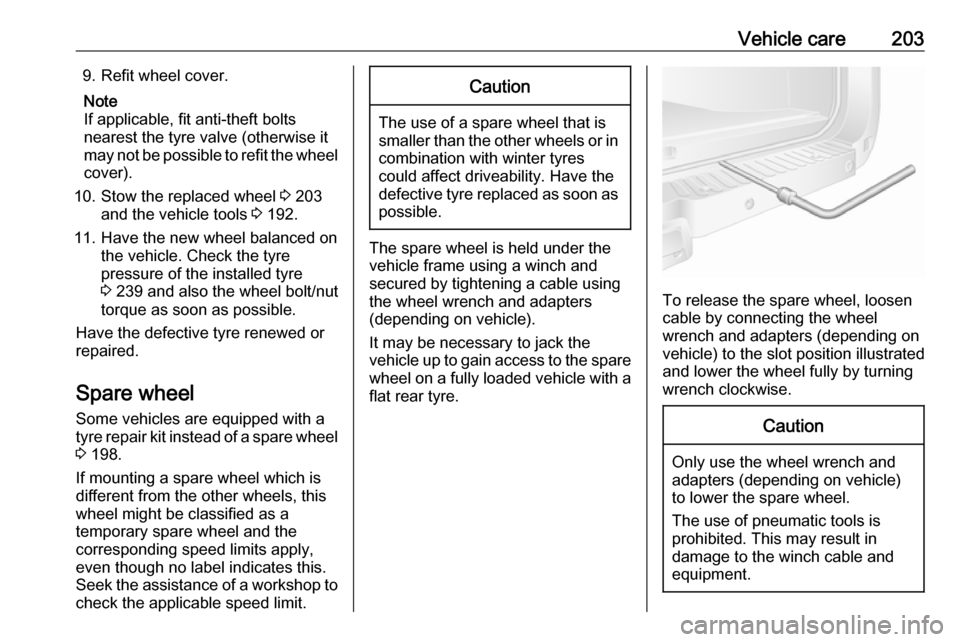

Place wheel upright, unclip retainer

from wheel rim and release the wheel

from the cable and connected

retainer by routing these components through the centre of the wheel.

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.When reinstalling a spare wheel, first

attach the mounting plate (twin rear

wheel vehicles) and secure with the

nut.

Place wheel upright, then route the

cable and connected retainer from

the front of the wheel (side with tyre

valve) and through the centre of the

wheel. Attach the retainer and clip it

into place, ensuring it is correctly

positioned and that the front of the

wheel (side with tyre valve) will be

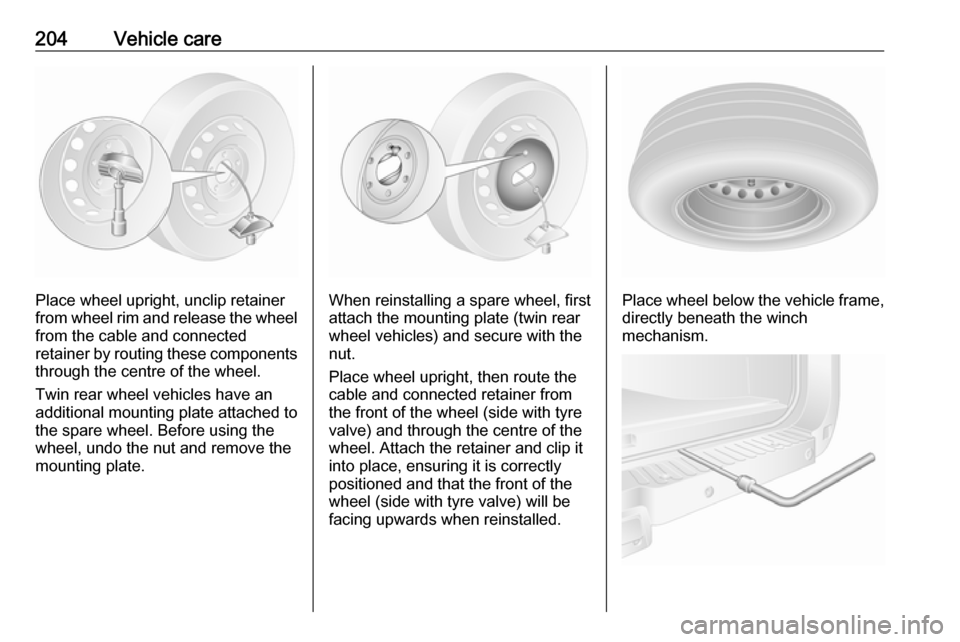

facing upwards when reinstalled.Place wheel below the vehicle frame,

directly beneath the winch

mechanism.