tyre pressure OPEL MOVANO_B 2018.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: MOVANO_B, Model: OPEL MOVANO_B 2018.5Pages: 271, PDF Size: 6.5 MB

Page 209 of 271

Vehicle care2079Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the

tyre information label and tyre

pressure chart are valid for cold tyres, which means at 20 °C. The pressure

increases by nearly 10 kPa (0.1 bar)

for a 10 °C temperature increase.

This must be considered when warm

tyres are checked.

Trailer towing

When towing a trailer with a fully laden vehicle, the tyre pressure must

be increased by 20 kPa/0.2 bar

(3.0 psi) and the maximum speed

limited to 100 km/h.

Trailer towing 3 177.

Rear-wheel drive, with twin rear

wheels

When inflating the outer tyre, the

inflation tube should be passed

between the two wheels.

Tyre pressure monitoringsystem

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The tyre pressure monitoring system

sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

Tyre pressure chart 3 252.

Page 210 of 271

208Vehicle careLow tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 104 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 252.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise w flashes for

several seconds then illuminates

continuously together with control

indicator A 3 101 and a

corresponding message appears in

the Driver Information Centre.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. For the further three wheels, the tyre pressure monitoring

system remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.

Driver Information Centre 3 106.

Vehicle messages 3 107.Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 102 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 252.

Tyre repair kit 3 211.

Spare wheel 3 216.

Wheel changing 3 214.

Relearn function

Page 211 of 271

Vehicle care209After a puncture has been repaired

and the driver has inflated the tyres to

the correct tyre pressure, the tyre

pressure monitoring system needs to

recalculate.

Tyre pressure 3 252.

Tyre repair kit 3 211.

During driving, select the tyre

pressure menu in the Driver

Information Centre by pressing button on end of wiper lever. Press and holdbutton for approx. five seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving at a speed

above 40 km/h may be required to

complete the relearn process. The system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is displayed in the Driver Information

Centre.

Driver Information Centre 3 106.

Vehicle messages 3 107.General information

The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 211.

Tyre chains 3 210.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, the

tyre pressure monitoring system

sensors must be dismounted and

serviced by a workshop.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2–3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Page 212 of 271

210Vehicle careChanging tyre and wheel

size

If tyres of a different size than thosefitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Tyre pressure monitoring system

3 207.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

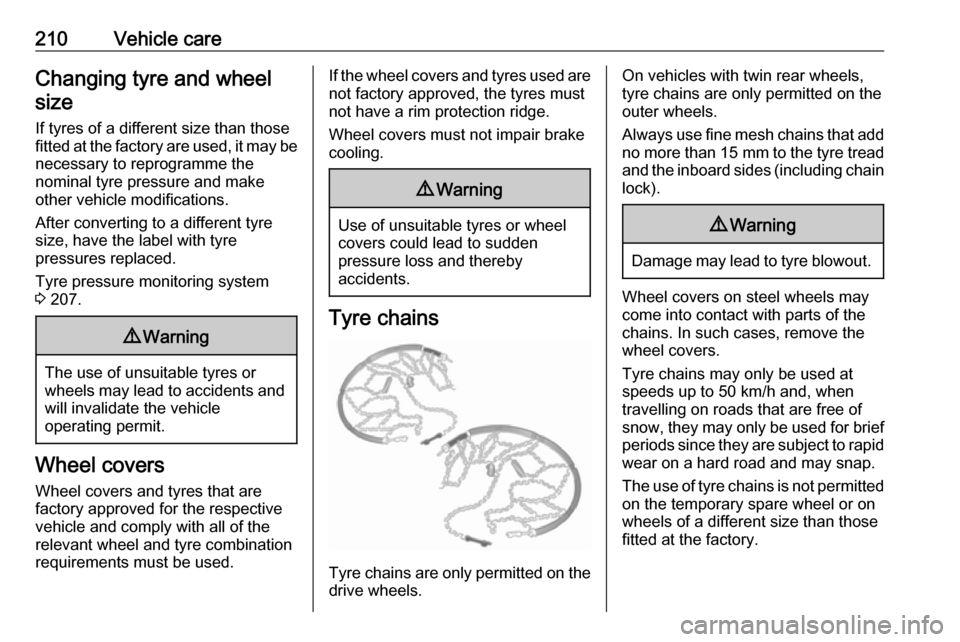

Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 50 km/h and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel or on

wheels of a different size than those

fitted at the factory.

Page 214 of 271

212Vehicle care9.Connect the red < power supply

lead on the compressor to the

jump start terminal 3 219.

Note

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine compartment.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

Note

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

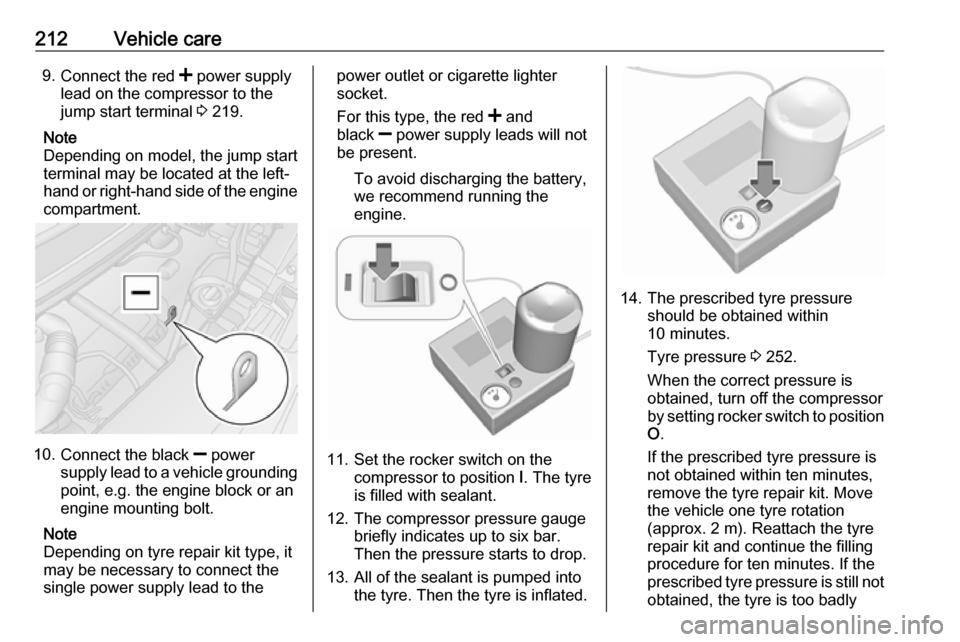

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to six bar.

Then the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.

14. The prescribed tyre pressureshould be obtained within

10 minutes.

Tyre pressure 3 252.

When the correct pressure is

obtained, turn off the compressor

by setting rocker switch to position O .

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 m). Reattach the tyre

repair kit and continue the filling

procedure for ten minutes. If the

prescribed tyre pressure is still not

obtained, the tyre is too badly

Page 215 of 271

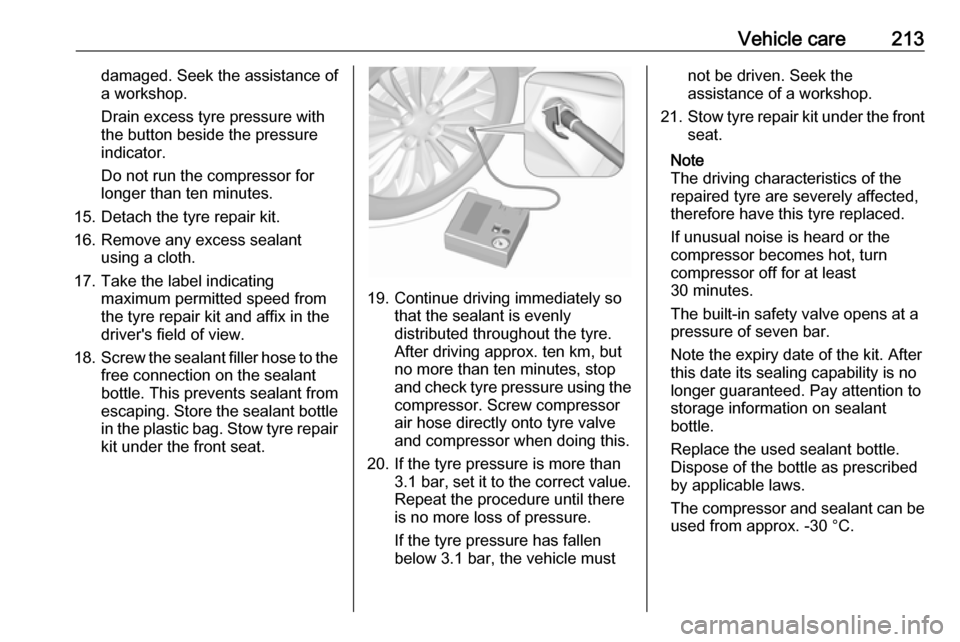

Vehicle care213damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than ten minutes.

15. Detach the tyre repair kit.

16. Remove any excess sealant using a cloth.

17. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the driver's field of view.

18. Screw the sealant filler hose to the

free connection on the sealant

bottle. This prevents sealant from

escaping. Store the sealant bottle in the plastic bag. Stow tyre repair

kit under the front seat.

19. Continue driving immediately so that the sealant is evenly

distributed throughout the tyre.

After driving approx. ten km, but

no more than ten minutes, stop

and check tyre pressure using the compressor. Screw compressor

air hose directly onto tyre valve

and compressor when doing this.

20. If the tyre pressure is more than 3.1 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 3.1 bar, the vehicle must

not be driven. Seek the

assistance of a workshop.

21. Stow tyre repair kit under the front

seat.

Note

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of seven bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

Page 218 of 271

216Vehicle careNote

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel cover).

10. Stow the replaced wheel 3 216

and the vehicle tools 3 204.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 252 and also the wheel bolt /

nut torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel Some vehicles are equipped with atyre repair kit instead of a spare wheel

3 211.

The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

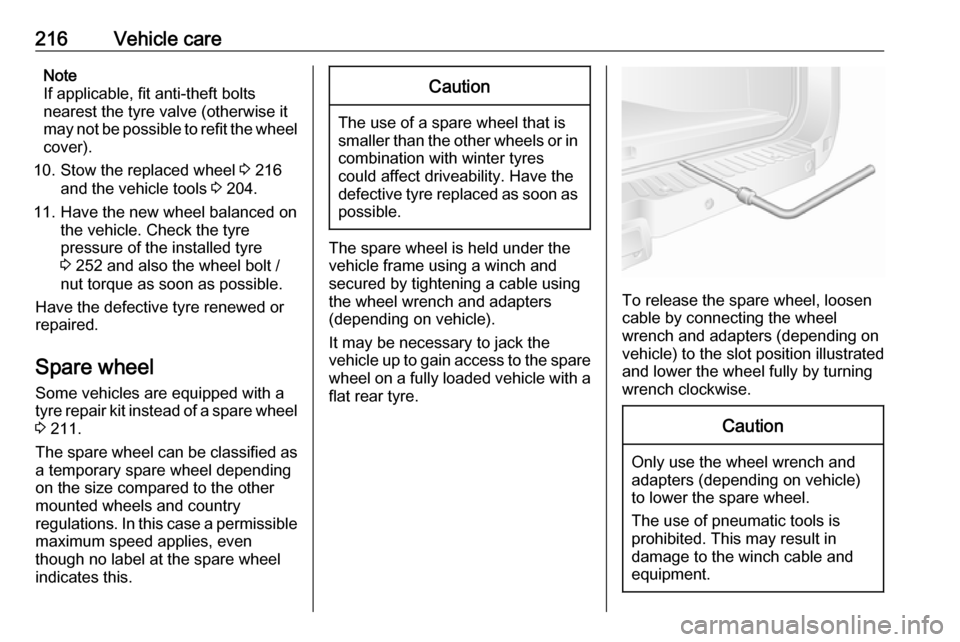

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapters

(depending on vehicle).

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

To release the spare wheel, loosen

cable by connecting the wheel

wrench and adapters (depending on

vehicle) to the slot position illustrated

and lower the wheel fully by turning

wrench clockwise.

Caution

Only use the wheel wrench and

adapters (depending on vehicle)

to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Page 226 of 271

224Vehicle carePaintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Unpainted plastic body parts must not be treated with wax or polishing

agents.

Matt filmed body parts or decor tapes must not be polished, to avoid

gleaming. Do not use hot wax

programmes in automatic car washes if the vehicle is equipped with theseparts.

Matt painted decor parts, e.g. mirror

housing cover, must not be polished.

Otherwise these parts would become

agleam or the colour would be

dissolved.

Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Remove dirt residues from smearing wiper blades by using a soft cloth and

window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage

Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.Underbody

Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check

the underbody and have it waxed if

necessary.

Bitumen / rubber materials could damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Towing equipment Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.

Page 232 of 271

230Technical dataTechnical dataVehicle identification..................230

Vehicle Identification Number ..230

Identification plate ...................231

Engine identification ................231

Vehicle data ............................... 232

Recommended fluids and lubricants ................................ 232

Engine data ............................. 233

Vehicle weight ......................... 235

Vehicle dimensions .................242

Capacities ................................ 250

Tyre pressures ........................ 252Vehicle identification

Vehicle IdentificationNumber

The Vehicle Identification Number

(VIN) is visible through the

windscreen.

The VIN is also displayed behind a

removable plastic cover on the front

right hand door step. Unclip the

covers using a flat blade screwdriver

to access.

Page 254 of 271

![OPEL MOVANO_B 2018.5 Manual user 252Technical dataTyre pressuresFront-wheel driveTyre pressure with full load10)11)EngineGross Vehicle WeightTyreFront

[kPa/bar] (psi)Rear

[kPa/bar] (psi)M9T2800215/65 R16 C 109/107R340/3.4 (49)360/3.6 OPEL MOVANO_B 2018.5 Manual user 252Technical dataTyre pressuresFront-wheel driveTyre pressure with full load10)11)EngineGross Vehicle WeightTyreFront

[kPa/bar] (psi)Rear

[kPa/bar] (psi)M9T2800215/65 R16 C 109/107R340/3.4 (49)360/3.6](/img/37/18910/w960_18910-253.png)

252Technical dataTyre pressuresFront-wheel driveTyre pressure with full load10)11)EngineGross Vehicle WeightTyreFront

[kPa/bar] (psi)Rear

[kPa/bar] (psi)M9T2800215/65 R16 C 109/107R340/3.4 (49)360/3.6 (52)3300215/65 R16 C 109/107R360/3.6 (52)430/4.3 (62)3500225/65 R16 C 112/110R380/3.8 (55)460/4.6 (68)3900225/65 R16 C 112/110R380/3.8 (55)460/4.6 (68)10) The spare wheel should be set to the highest applicable pressure shown in the table.

11) When towing a trailer with a fully laden vehicle, the tyre pressure must be increased by 20 kPa/0.2 bar (3.0 psi) and the maximum

speed limited to 100 km/h.Rear-wheel drive, with single rear wheelsTyre pressure with full load 11)EngineGross Vehicle WeightTyreFront

[kPa/bar] (psi)Rear

[kPa/bar] (psi)M9T3500235/65 R16 C 115/113R360/3.6 (52)450/4.5 (65)11) When towing a trailer with a fully laden vehicle, the tyre pressure must be increased by 20 kPa/0.2 bar (3.0 psi) and the maximum

speed limited to 100 km/h.