OPEL VECTRA 1988 Service Owner's Manual

Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 21 of 525

Refitting

10Refitting is a reversal of removal.

Fuel and temperature gauge

assembly -“high series” models

11The procedure is as described in

paragraphs 7 to 10 inclusive, except that the

gauge assembly is secured by four nuts.

Tachometer

12The procedure is as described in

paragraphs 7 to 10 inclusive except that the

tachometer is secured by three nuts (see

illustration).

Speedometer

Removal

13Proceed as described in paragraphs 7

and 8.

14Extract the four securing screws from the

rear of the panel (see illustration).

Refitting

15Refitting is a reversal of removal.

Printed circuit board

Removal

16Remove all bulbs and instruments, and

the voltage stabiliser, as described previously

in this Section.

17Carefully peel the printed circuit board

from the instrument panel.

Refitting

18Refitting is a reversal of removal, but

ensure that the printed circuit board is seated

correctly on the rear of the instrument panel.

20Trip computer components -

removal and refitting

2

1Disconnect the battery lead.

Display module

Removal

2Using a thin-bladed screwdriver, carefully

prise the module from the facia panel.

3Disconnect the wiring plug and withdraw

the module.

Refitting

4Refitting is a reversal of removal.

Display module illumination bulb

Removal

5Remove the display module, as described

previously in this Section.

6Using a length of rubber sleeving of similar

diameter, or an alternator tool, extract the

bulb by inserting the tool through the hole in

the side of the display module (see

illustration).

Refitting

7Refitting is a reversal of removal.

Operating switch

Removal

8Remove the rear section of the centre

console, as described in Chapter 11.

9Release the wiring plug from the switch

using a screwdriver.

10Lift the switch, then pull it down and out

from the centre console.

Refitting

11Refitting is a reversal of removal.

Outside air temperature sensor

Removal

12The sensor is located at the left-hand end

of the front bumper (see illustration).

13Prise the cover cap from the bumper, then

unclip the sensor, and disconnect the wiring

plug.

Refitting

14Refitting is a reversal of removal.

21Check control system

components - removal and

refitting

3

1Disconnect the battery negative lead.

Warning lamp bulbs

2The warning lamp bulbs are located in the

instrument panel, and removal and refitting

are described in Section 19.

Control module

Removal

3The control module is located behind the

passenger side of the facia, above the

glovebox.

4Remove the glovebox assembly, as

described in Chapter 11.

5Disconnect the control module wiring plug,

then release the control module from its

mounting and withdraw the unit.

Refitting

6Refitting is a reversal of removal.

Coolant level sensor

Removal

7The coolant level sensor is integral with the

coolant expansion tank cap.

8Disconnect the wiring from the top of the

cap, then unscrew the cap and withdraw it

from the expansion tank.

9If faulty, the complete cap assembly must

be renewed.

Refitting

10Refitting is a reversal of removal.

Washer fluid level sensor

Removal

11The sensor is mounted in the side of the

fluid reservoir.

12Disconnect the wiring from the sensor,

then unscrew the sensor from the fluid

reservoir. If the fluid level is above the level of

the sensor, be prepared for fluid spillage.

Refitting

13Refitting is a reversal of removal.

Body electrical systems 12•7

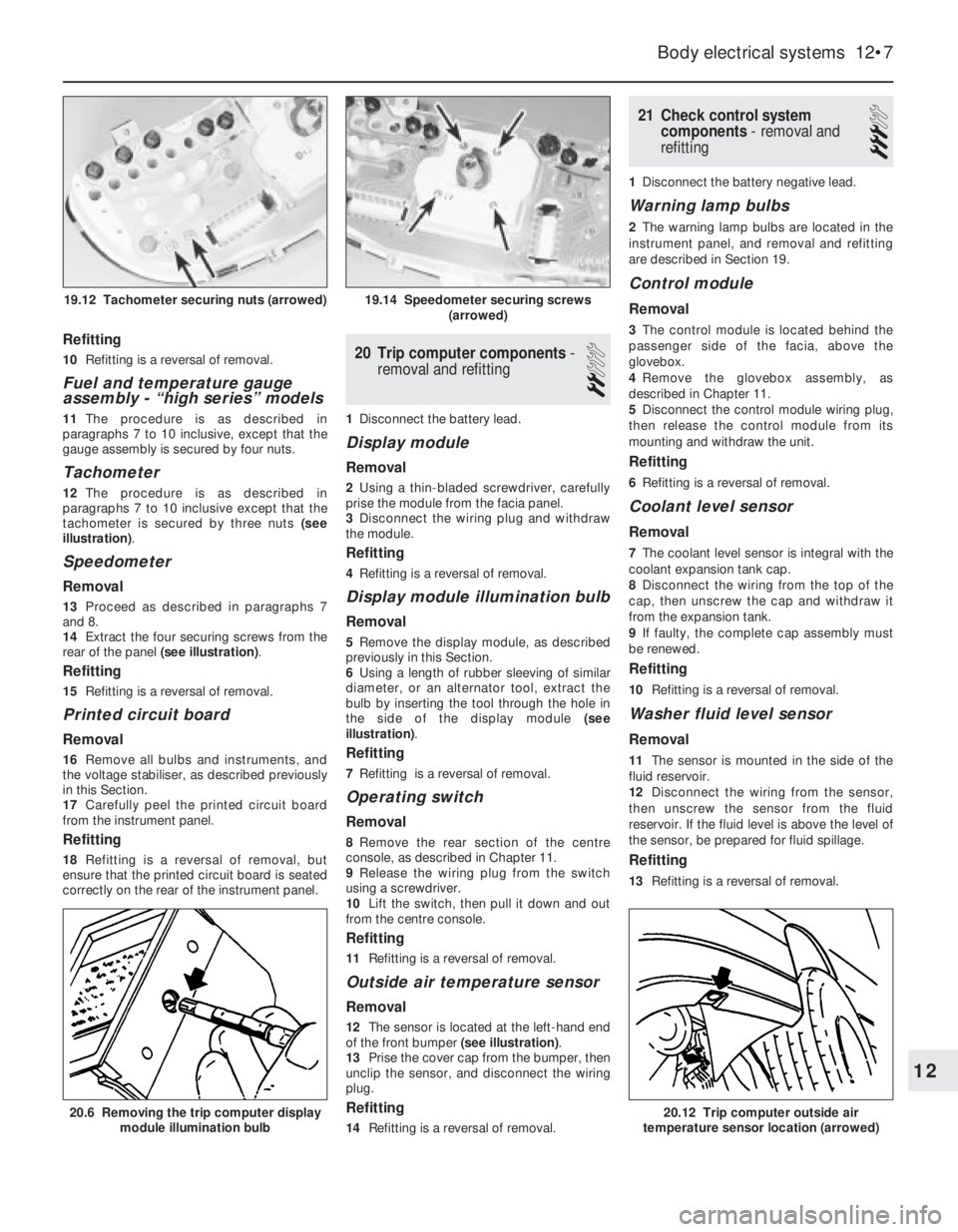

20.6 Removing the trip computer display

module illumination bulb20.12 Trip computer outside air

temperature sensor location (arrowed)

19.14 Speedometer securing screws

(arrowed)19.12 Tachometer securing nuts (arrowed)

12

Page 22 of 525

Brake fluid level sensor

14The procedure is as described for the

coolant level sensor in paragraphs 7 to 10

inclusive.

Engine oil level sensor

Removal

15Apply the handbrake, jack up the front of

the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

16On DOHC models, remove the engine

undershield, as described in Chapter 11.

17Disconnect the sensor wiring plug.

18Unscrew the three or four sensor securing

screws, as applicable, and withdraw the

sensor, manipulating the float through the hole

in the sump (see illustration). Recover the

sealing ring. Be prepared for some oil spillage.

19Examine the condition of the sealing ring,

and renew if necessary.

Refitting

20Refitting is a reversal of removal. On

completion, check, and if necessary top-up,

the engine oil level.

Bulb failure sensor

Removal

21The bulb failure sensor is mounted behind

the fuse/relay panel in the facia.

22Release the retaining clips from the lower

end of the fuse/relay panel, and tilt it forwards.23Reach up behind the fuse/relay panel, and

pull the sensor from its socket.

Refitting

24Refitting is a reversal of removal.

22Horn(s) - removal and refitting

2

1On models with a single horn, the horn is

located in front of the radiator. On models

with twin horns, the horns are located beneath

the washer fluid reservoir, at the left-hand end

of the front bumper.

Single horn

Removal

2Disconnect the battery negative lead.

3Remove the radiator grille panel, with

reference to Chapter 11.

4Disconnect the wiring from the rear of the

horn.

5Reach up behind the mounting bracket, and

unscrew the single nut securing the horn to the

bracket (see illustration). Withdraw the horn.

Refitting

6Refitting is a reversal of removal.

Twin horns

Removal

7Disconnect the battery negative lead.

8Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

9Remove the securing screws, and withdraw

the plastic cover (where fitted) from the

bumper/front wing to expose the horns.

10Remove the bolt securing the horn

mounting bracket to the bracket below the

washer fluid reservoir (see illustration).

11Withdraw the horns and disconnect the

wiring.

12If desired, the horns can be unbolted from

the bracket.

Refitting

13Refitting is a reversal of removal.

23Interior lamps - removal and

refitting

2

Removal

1Disconnect the battery negative lead.

2Using a thin-bladed screwdriver, prise the

lamp from its location and disconnect the

wiring (see illustration).

Refitting

3Refitting is a reversal of removal.

24Interior lamp bulbs - renewal

1

1Disconnect the battery negative lead.

Courtesy lamp

Note: Some later models are fitted with

courtesy lamps for the rear seat passengers,

as well as front.

Removal

2Using a thin-bladed screwdriver, prise the

lamp from its location and disconnect the

wiring.

3On models fitted with a courtesy lamp with

integral map reading lamps, the lens must be

levered from the housing for access to the

bulbs.

12•8Body electrical systems

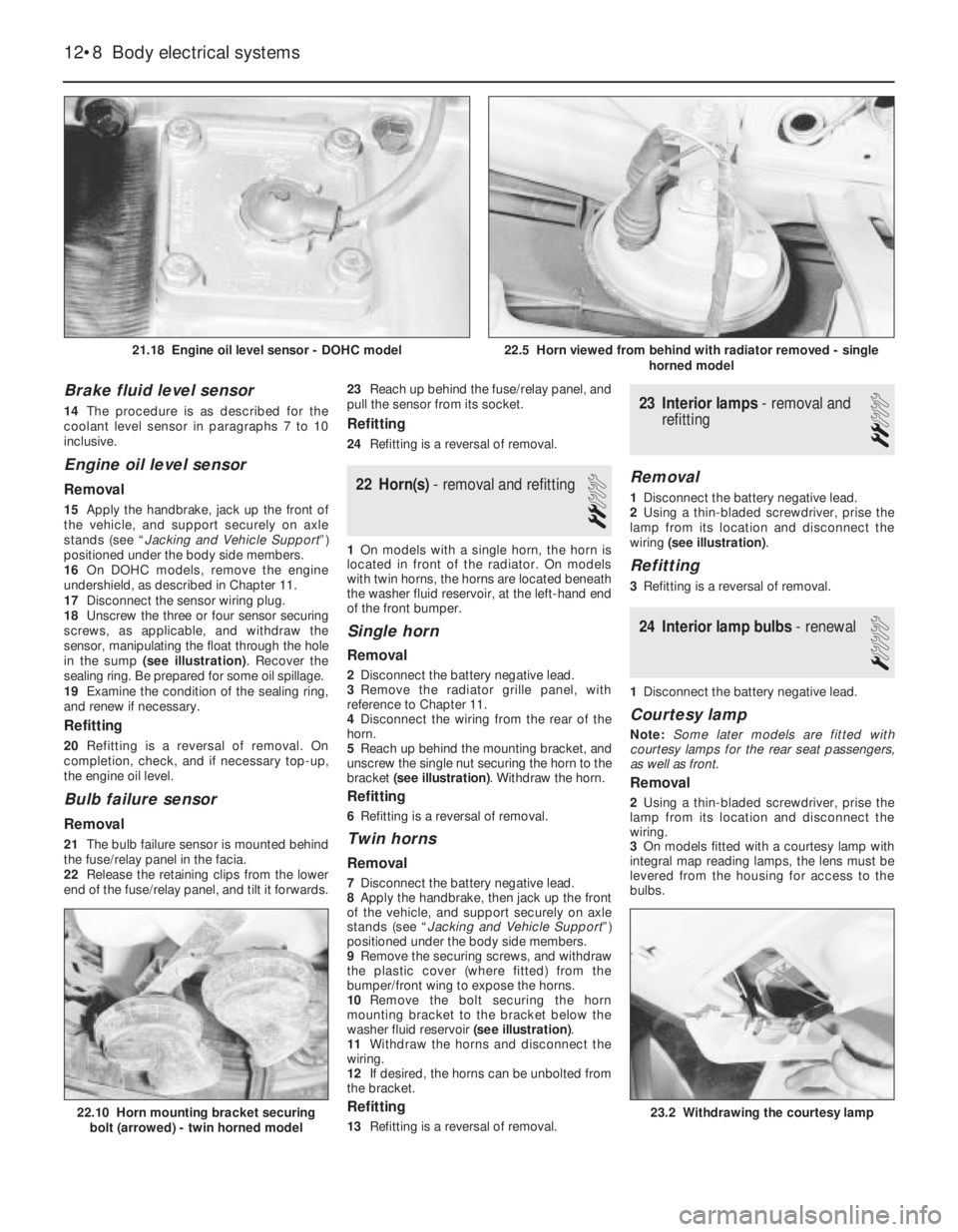

21.18 Engine oil level sensor - DOHC model

22.10 Horn mounting bracket securing

bolt (arrowed) - twin horned model23.2 Withdrawing the courtesy lamp

22.5 Horn viewed from behind with radiator removed - single

horned model

Page 23 of 525

4Remove the courtesy lamp bulbs by

carefully prising it from its location using a

thin-bladed screwdriver. Where applicable,

the map reading lamp bulbs are a push fit in

the bulbholders.

Refitting

5Refitting is a reversal of removal.

Glovebox lamp

Removal

6Using a thin-bladed screwdriver, prise the

lamp from its location and disconnect the

wiring.

7Carefully prise the bulb from the lamp.

Refitting

8Refitting is a reversal of removal.

Luggage compartment,

underbonnet and kerb lamps

Removal

9Using a thin-bladed screwdriver, prise the

lamp from its location; disconnect the wiring.

10Carefully prise the bulb from the lamp

(see illustration).

Refitting

11Refitting is a reversal of removal

Cigarette lighter illumination lamp

Removal

12Slide the ashtray/cigarette lighter

assembly from the facia, then disconnect the

wiring and pull the bulbholder from the rear of

the cigarette lighter housing.

13The bulb is a push fit in the bulbholder.

Refitting

14Refitting is a reversal of removal.

Clock illumination lamp

15Remove the clock, (Section 16).

16Twist the bulbholder and pull it from the

rear of the clock (see illustration).

17The bulb is a push fit in the bulbholder.

Trip computer display module

illumination lamp

18Refer to Section 20.

Heater control panel

illumination lamp

Removal

19Remove the heater control panel, as

described in Chapter 11. 20Pull the bulbholder from the rear of the

control panel (see illustration).

21The bulb is a push fit in the bulbholder.

Refitting

22Refitting is a reversal of removal.

Facia panel switch illumination

lamp

23If a bulb fails in one of the facia panel

switches, the complete switch assembly must

be renewed, as described in Section 7, as no

individual spare parts are available.

Vanity mirror illumination lamp

Removal

24Lower the sunvisor and, using a

thin-bladed screwdriver, prise out the mirror

and diffuser assembly. Pull the bulb(s) from

the spring contacts.

Refitting

25Refitting is a reversal of removal.

25Headlamp unit - removal and

refitting

2

Removal

1Remove the radiator grille panel, as

described in Chapter 11.

2Remove the front indicator lamp unit, as

described in Section 29.

3Remove the cover from the rear of the

headlamp unit, and disconnect the wiring

plugs from the bulbs.

4If applicable, disconnect the wiring plug

from the headlamp aim adjustment motor.

5Remove the three securing screws, and

withdraw the headlamp unit (see

illustrations). Feed the wiring through the

headlamp casing as it is removed.

6If required, the headlamp lens can be

removed by releasing the spring clips around

its edge.

Refitting

7Refitting is a reversal of removal.

8On completion, have the headlamp

alignment checked, with reference to

Section 27.

Body electrical systems 12•9

24.20 Heater control panel illumination

lamp bulbholder withdrawn

25.5C Withdrawing a headlamp unit25.5B Unscrewing an upper headlamp

securing screw

25.5A Unscrewing the lower headlamp

securing screw

24.16 Removing the clock illumination

lamp bulbholder24.10 Removing the underbonnet lamp

bulb

12

Page 24 of 525

27Headlamps -alignment

2

1Correct alignment of the headlamp beams

is most important, not only to ensure good

vision for the driver, but also to protect other

drivers from being dazzled.

2Accurate alignment should be carried out

using optical beam setting equipment.

3In an emergency, adjustments may be

made by turning the adjustment screws

shown (see illustrations). If an adjustment is

made, the alignment should be checked using

beam setting equipment at the earliest

opportunity.

4All 1992-on models are fitted with the

headlamp aim adjustment system, operated

through the facia-mounted switch (see

illustration).

a)Position ‘0’, is for correct alignment if just

the driving seat is occupied.

b)Position ‘1’, if all seats are occupied.

c)Position ‘2’, if all seats occupied and

luggage.

d)Position ‘3’, for just driver and luggage.

28Headlamp dim-dip system -

general, removal and refitting

3

General

1The system (where fitted) is governed by the

dim-dip control unit mounted either behind

and above the glovebox (early models), or

behind the main fuse panel (later models).

2The control unit uses the oil pressure

warning lamp circuit to ensure that, when theengine is running and the sidelamps are

switched on, reduced current is fed to the

headlamp dipped-beam circuits. This lights

the headlamps with approximately one-sixth

of their normal power so that the vehicle

cannot be driven using sidelamps alone.

3To locate the dim-dip control unit, open the

main fuse panel covering flap and unclip it

from its bottom and top mountings (Section 3).

Then use a torch to see whether the unit is

fastened to the plastic bracket behind the facia

and fuse panel. The unit is usually rectangular,

of black plastic, and can be identified by the

colours of the five wires leading to it (see

applicable wiring diagram).

Removal

4If the unit can be seen, remove the driver’s

side lower facia and footwell trim panels

(Chapter 11), then unscrew the four retaining

screws and lower the plastic bracket until the

control unit can be detached.

5If the unit cannot be seen, remove the

glovebox assembly (Chapter 11). The unit will

be fastened to the underside of the facia top

surface.

Refitting

6Refitting is the reverse of the removal

procedure.

26Headlamp aim adjustment

motor - removal and refitting

3

Removal

1Remove the headlamp, (Section 25).

2Twist the motor clockwise to release it from

the headlamp, then carefully disconnect the

motor from the balljoint (see illustrations).

Refitting

3Refitting is a reversal of removal, but ensure

that the motor is correctly engaged with the

balljoint.

12•10Body electrical systems

26.2A Headlamp aim adjustment motor

(headlamp removed)

27.4 The headlamp aim adjustment switch

- 1992-on models

27.3B Headlamp alignment adjustment screws - models with

electric aim adjustment

A Vertical adjustment screw B Horizontal adjustment screw27.3A Headlamp alignment adjustment screws - models without

electric aim adjustment

A Vertical adjustment screw B Horizontal adjustment screw

26.2B Headlamp aim adjuster balljoint

(arrowed)

Page 25 of 525

29Front indicator lamp unit -

removal and refitting

2

Removal

1Disconnect the battery negative lead.

2Remove the single indicator lamp unit

securing screw, which is accessible through

the hole in the upper body panel (see

illustration).

3Pull the lamp unit forwards to release it

from the body, then disconnect the wiring

plug (see illustration).

Refitting

4Refitting is a reversal of removal.

30Side repeater lamp -removal

and refitting

2

Removal

1Disconnect the battery negative lead.

2Remove the wheel arch liner, as described

in Chapter 11.

3Working in the engine compartment,

disconnect the wiring plug, and detach the

earth lead from the body panel.

4Working under the wheel arch, depress the

retaining tabs and manipulate the lamp

through the outside of the wing, pulling the

wiring and the grommet from the inner wing

panel.

5The lens can be removed from the lamp by

twisting it to release the retaining clips.

6Check the condition of the rubber sealing

ring, and renew if necessary.

Refitting

7Refitting is a reversal of removal.

31Front foglamp - removal,

refitting and adjustment

3

Removal

1Disconnect the battery negative lead.

2Removing (if necessary) the radiator grille

panel, as described in Chapter 11, disconnect

the appropriate foglamp wiring plug.

3Apply the handbrake, jack up the front of

the vehicle and support it securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

4If removing the driver’s side foglamp,

remove the securing screws and withdraw the

plastic cover from the bumper/front wing to

expose the lamp mountings.

5Unscrew the three securing bolts and

withdraw the lamp and wiring, the two bottom

bolts are obvious, but the third is well hidden

at the top of the lamp.

Refitting

6Refitting is a reversal of removal, but on

completion check the foglamp adjustment.

Adjustment

7The vertical aim of the foglamps can be

adjusted by turning the adjuster screw at the

rear of the lamp in the required direction. It will

be necessary to remove the plastic cover

(driver’s side only) from the bumper/front wing

to expose the adjuster screw (see

illustration).

32Rear lamp unit - removal and

refitting

2

Removal

1Disconnect the battery negative lead.

2Working in the luggage compartment,

remove the cover from the rear of the lamp.

3Release the top and bottom retaining clips,

and pull the bulbholder from the lamp.

Disconnect the wiring plug.

4Remove the securing screws, and withdraw

the lamp unit from outside the vehicle.

5Note that the lens cannot be renewed

separately, and if damaged, the complete

lamp unit must be renewed.

Refitting

6Refitting is a reversal of removal.

33Number plate lamp -removal

and refitting

2

Removal

1Disconnect the battery negative lead.

2Using a thin-bladed screwdriver, carefully

prise the lamp surround from the bumper.

3Pull the lamp from the bumper, and

disconnect the wiring.

Refitting

4Refitting is a reversal of removal.

34Exterior lamp bulbs - renewal

1

Note: The glass envelopes of the headlamp

and foglamp bulbs must not be touched with

the fingers. If the glass is accidentally

touched, it should be washed with methylated

spirits and dried with a soft cloth. Failure to

observe this procedure may result in

premature bulb failure

1Disconnect the battery negative lead.

Headlamps

Removal

2Working in the engine compartment,

release the retaining clip, and remove the

cover from the rear of the headlamp (see

illustration).

Body electrical systems 12•11

31.7 Foglamp aim adjustment screw

(arrowed)34.2 Removing the cover from the rear of

the headlamp

29.3 Disconnecting the front indicator

lamp unit wiring plug29.2 Unscrewing the front indicator lamp

unit securing screw

12

Page 26 of 525

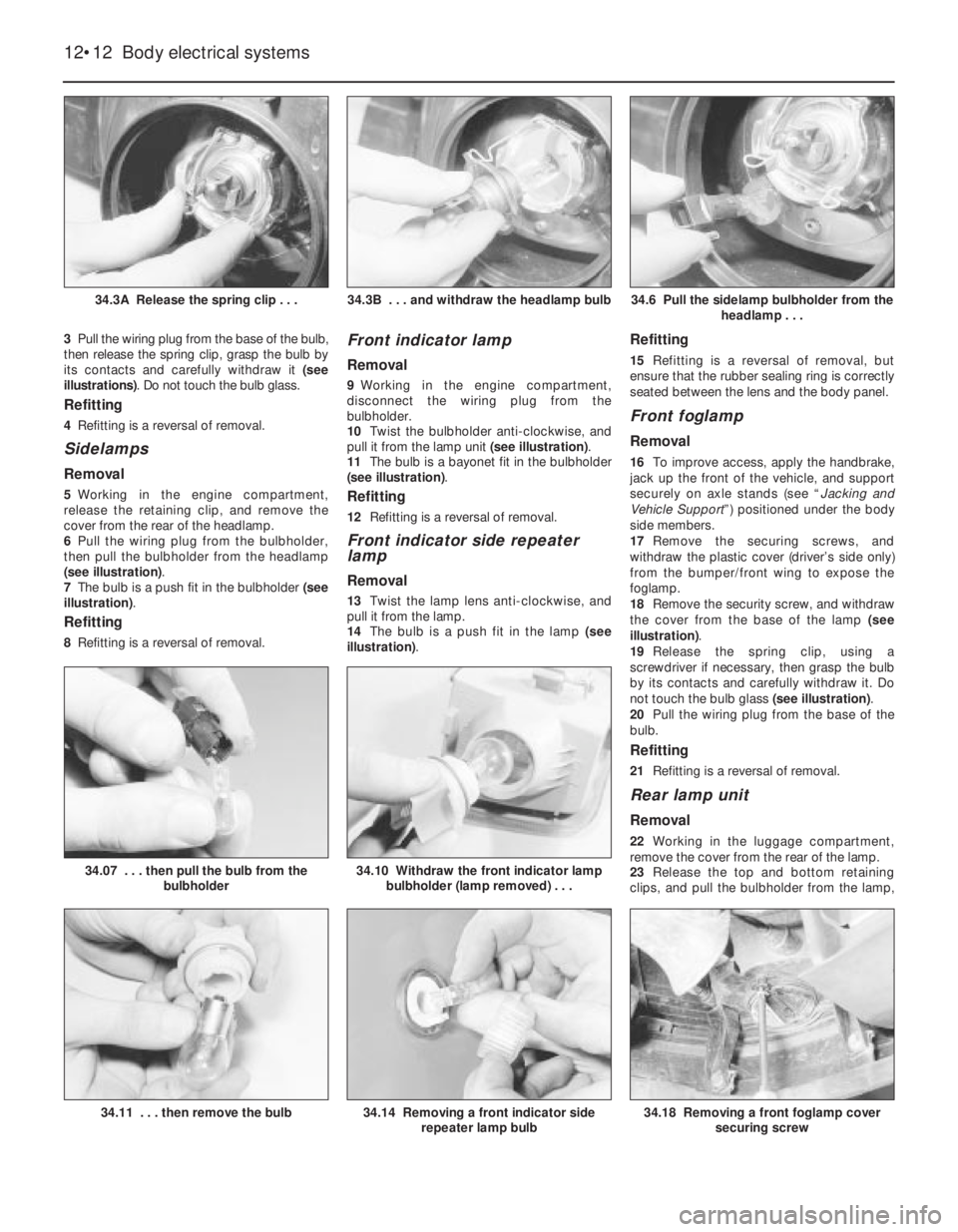

3Pull the wiring plug from the base of the bulb,

then release the spring clip, grasp the bulb by

its contacts and carefully withdraw it (see

illustrations). Do not touch the bulb glass.

Refitting

4Refitting is a reversal of removal.

Sidelamps

Removal

5Working in the engine compartment,

release the retaining clip, and remove the

cover from the rear of the headlamp.

6Pull the wiring plug from the bulbholder,

then pull the bulbholder from the headlamp

(see illustration).

7The bulb is a push fit in the bulbholder (see

illustration).

Refitting

8Refitting is a reversal of removal.

Front indicator lamp

Removal

9Working in the engine compartment,

disconnect the wiring plug from the

bulbholder.

10Twist the bulbholder anti-clockwise, and

pull it from the lamp unit (see illustration).

11The bulb is a bayonet fit in the bulbholder

(see illustration).

Refitting

12Refitting is a reversal of removal.

Front indicator side repeater

lamp

Removal

13Twist the lamp lens anti-clockwise, and

pull it from the lamp.

14The bulb is a push fit in the lamp (see

illustration).

Refitting

15Refitting is a reversal of removal, but

ensure that the rubber sealing ring is correctly

seated between the lens and the body panel.

Front foglamp

Removal

16To improve access, apply the handbrake,

jack up the front of the vehicle, and support

securely on axle stands (see “Jacking and

Vehicle Support”) positioned under the body

side members.

17Remove the securing screws, and

withdraw the plastic cover (driver’s side only)

from the bumper/front wing to expose the

foglamp.

18Remove the security screw, and withdraw

the cover from the base of the lamp (see

illustration).

19Release the spring clip, using a

screwdriver if necessary, then grasp the bulb

by its contacts and carefully withdraw it. Do

not touch the bulb glass (see illustration).

20Pull the wiring plug from the base of the

bulb.

Refitting

21Refitting is a reversal of removal.

Rear lamp unit

Removal

22Working in the luggage compartment,

remove the cover from the rear of the lamp.

23Release the top and bottom retaining

clips, and pull the bulbholder from the lamp,

12•12Body electrical systems

34.3A Release the spring clip . . .34.6 Pull the sidelamp bulbholder from the

headlamp . . .

34.18 Removing a front foglamp cover

securing screw

34.10 Withdraw the front indicator lamp

bulbholder (lamp removed) . . .34.07 . . . then pull the bulb from the

bulbholder

34.14 Removing a front indicator side

repeater lamp bulb34.11 . . . then remove the bulb

34.3B . . . and withdraw the headlamp bulb

Page 27 of 525

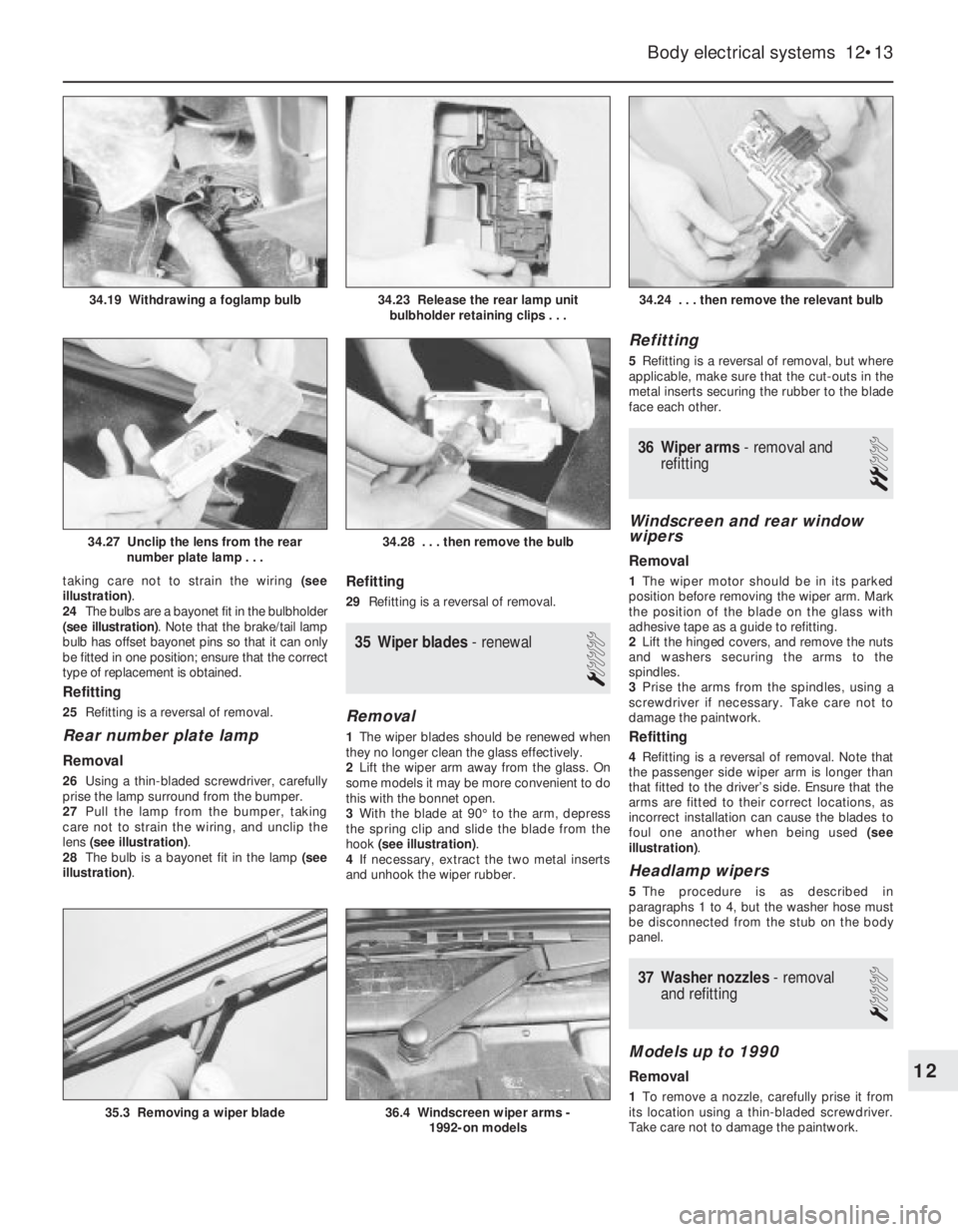

taking care not to strain the wiring (see

illustration).

24The bulbs are a bayonet fit in the bulbholder

(see illustration). Note that the brake/tail lamp

bulb has offset bayonet pins so that it can only

be fitted in one position; ensure that the correct

type of replacement is obtained.

Refitting

25Refitting is a reversal of removal.

Rear number plate lamp

Removal

26Using a thin-bladed screwdriver, carefully

prise the lamp surround from the bumper.

27Pull the lamp from the bumper, taking

care not to strain the wiring, and unclip the

lens (see illustration).

28The bulb is a bayonet fit in the lamp (see

illustration).

Refitting

29Refitting is a reversal of removal.

35Wiper blades -renewal

1

Removal

1The wiper blades should be renewed when

they no longer clean the glass effectively.

2Lift the wiper arm away from the glass. On

some models it may be more convenient to do

this with the bonnet open.

3With the blade at 90°to the arm, depress

the spring clip and slide the blade from the

hook (see illustration).

4If necessary, extract the two metal inserts

and unhook the wiper rubber.

Refitting

5Refitting is a reversal of removal, but where

applicable, make sure that the cut-outs in the

metal inserts securing the rubber to the blade

face each other.

36Wiper arms - removal and

refitting

2

Windscreen and rear window

wipers

Removal

1The wiper motor should be in its parked

position before removing the wiper arm. Mark

the position of the blade on the glass with

adhesive tape as a guide to refitting.

2Lift the hinged covers, and remove the nuts

and washers securing the arms to the

spindles.

3Prise the arms from the spindles, using a

screwdriver if necessary. Take care not to

damage the paintwork.

Refitting

4Refitting is a reversal of removal. Note that

the passenger side wiper arm is longer than

that fitted to the driver’s side. Ensure that the

arms are fitted to their correct locations, as

incorrect installation can cause the blades to

foul one another when being used (see

illustration).

Headlamp wipers

5The procedure is as described in

paragraphs 1 to 4, but the washer hose must

be disconnected from the stub on the body

panel.

37Washer nozzles - removal

and refitting

1

Models up to 1990

Removal

1To remove a nozzle, carefully prise it from

its location using a thin-bladed screwdriver.

Take care not to damage the paintwork.

Body electrical systems 12•13

34.24 . . . then remove the relevant bulb

36.4 Windscreen wiper arms -

1992-on models35.3 Removing a wiper blade

34.28 . . . then remove the bulb34.27 Unclip the lens from the rear

number plate lamp . . .

34.23 Release the rear lamp unit

bulbholder retaining clips . . .34.19 Withdrawing a foglamp bulb

12

Page 28 of 525

2Disconnect the washer hose and withdraw

the nozzle.

Refitting

3To refit, reconnect the washer hose to the

nozzle, and push the nozzle into its locating

hole.

4The nozzles can be adjusted by inserting a

pin into the jet, and swivelling it to the

required position.

1991-on models

5The nozzles on all later models are fitted

with twin jets.

6On some later models, the nozzles are

heated; the circuit is fed through fuse 29 and

is live whenever the ignition is switched on.

Current is regulated by a Positive

Temperature Coefficient (PTC) resistor that

takes outside temperature into account.

38Windscreen wiper motor and

linkage - removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arms, as described in

Section 36.

3Remove the windscreen cowl panel, as

described in Chapter 11.

4Disconnect the wiring plug from the motor

(see illustration). 5Unscrew the three bolts securing the

motor/linkage assembly to the body, then

withdraw the assembly (see illustrations).

6If desired, the motor can be removed from

the linkage by unscrewing the three securing

bolts. Do not attempt to dismantle the linkage.

Refitting

7Refitting is a reversal of removal.

39Tailgate wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Extract the securing screws, and remove

the rear tailgate trim panel.

4Disconnect the motor wiring plug.

5Unscrew the two motor securing bolts,

noting the earth leads under the bolt heads

(see illustration).

6Manipulate the motor assembly from the

tailgate.

Refitting

7Refitting is a reversal of removal, ensuring

that the cut-out in the drive spindle rubber

seal engages with the notch in the drive

spindle (see illustration).

40Headlamp wiper motor -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the wiper arm, as described in

Section 36.

3Remove the headlamp, as described in

Section 25.

4Disconnect the motor wiring plug.

5Unscrew the two bolts securing the motor

mounting bracket to the body panel, then

withdraw the motor (see illustrations).

Refitting

6Refitting is a reversal of removal.

12•14Body electrical systems

38.4 Disconnecting the windscreen wiper

motor wiring plug

38.5B . . . then withdraw the assembly

40.5B . . . and withdraw the motor40.5A Unscrew the headlamp wiper motor

securing bolts . . .39.7 Cut-out in tailgate wiper motor drive

spindle rubber seal must engage with

notch in drive spindle

39.5 Tailgate wiper motor assembly. Note

earth leads under heads of securing bolts

38.5A Unscrew the windscreen wiper

motor/linkage assembly securing bolts . .

Page 29 of 525

41Washer fluid reservoir -

removal and refitting

2

1Disconnect the battery negative lead.

Models without headlamp wash

Removal

2Disconnect the wiring from the washer

pump.

3Disconnect the washer fluid hose from the

pump. Be prepared for fluid spillage.

4Remove the screw(s) securing the reservoir

to the body, and withdraw the reservoir.

Refitting

5Refitting is a reversal of removal.

Models with headlamp wash

Removal

6On models with headlamp wash, the

reservoir is in two sections, the upper section,

which can be removed from the engine

compartment, and the lower section, which

must be removed from under the wheel arch.

7Disconnect the wiring from the headlamp

wash non-return valve in the top of the

reservoir.

8Disconnect the washer fluid hoses from the

non-return valve. Be prepared for fluid spillage.

9Remove the screw securing the upper

section of the reservoir to the wing panel.

10Loosen the plastic collar securing the

upper section of the reservoir to the lower

section, then withdraw the upper section of

the reservoir from the engine compartment.

11To remove the lower section of the

reservoir, continue as follows.

12Apply the handbrake, then jack up the

front of the vehicle, and support on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.

13Remove the securing screws, and

withdraw the plastic cover from thebumper/front wing to expose the lower

section of the reservoir.

14Remove the horns, (Section 22).

15Remove the wheel arch liner, (Chapter 11).

16Disconnect the wiring and the fluid hoses

from the washer pump. Be prepared for fluid

spillage.

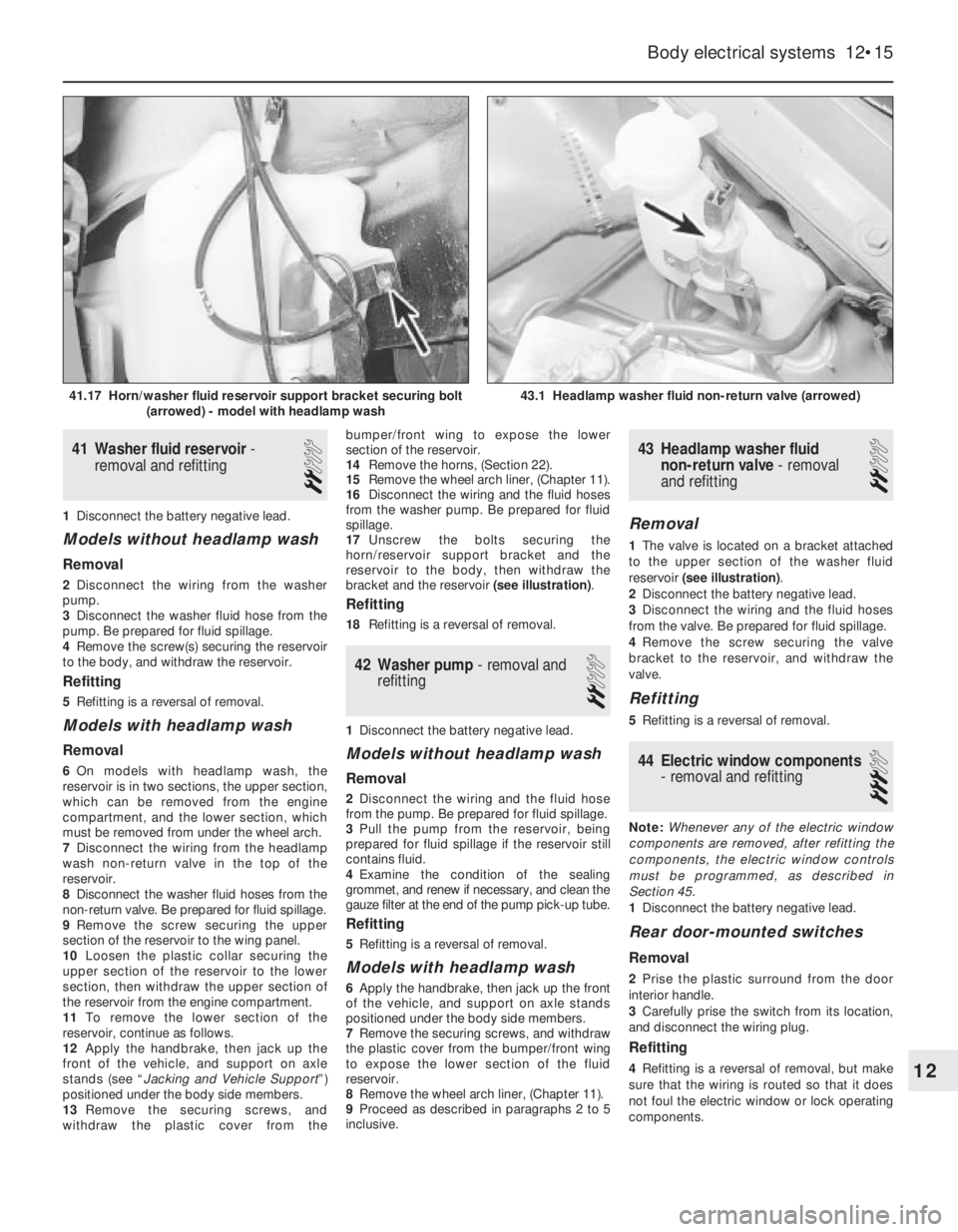

17Unscrew the bolts securing the

horn/reservoir support bracket and the

reservoir to the body, then withdraw the

bracket and the reservoir (see illustration).

Refitting

18Refitting is a reversal of removal.

42Washer pump -removal and

refitting

2

1Disconnect the battery negative lead.

Models without headlamp wash

Removal

2Disconnect the wiring and the fluid hose

from the pump. Be prepared for fluid spillage.

3Pull the pump from the reservoir, being

prepared for fluid spillage if the reservoir still

contains fluid.

4Examine the condition of the sealing

grommet, and renew if necessary, and clean the

gauze filter at the end of the pump pick-up tube.

Refitting

5Refitting is a reversal of removal.

Models with headlamp wash

6Apply the handbrake, then jack up the front

of the vehicle, and support on axle stands

positioned under the body side members.

7Remove the securing screws, and withdraw

the plastic cover from the bumper/front wing

to expose the lower section of the fluid

reservoir.

8Remove the wheel arch liner, (Chapter 11).

9Proceed as described in paragraphs 2 to 5

inclusive.

43Headlamp washer fluid

non-return valve -removal

and refitting

2

Removal

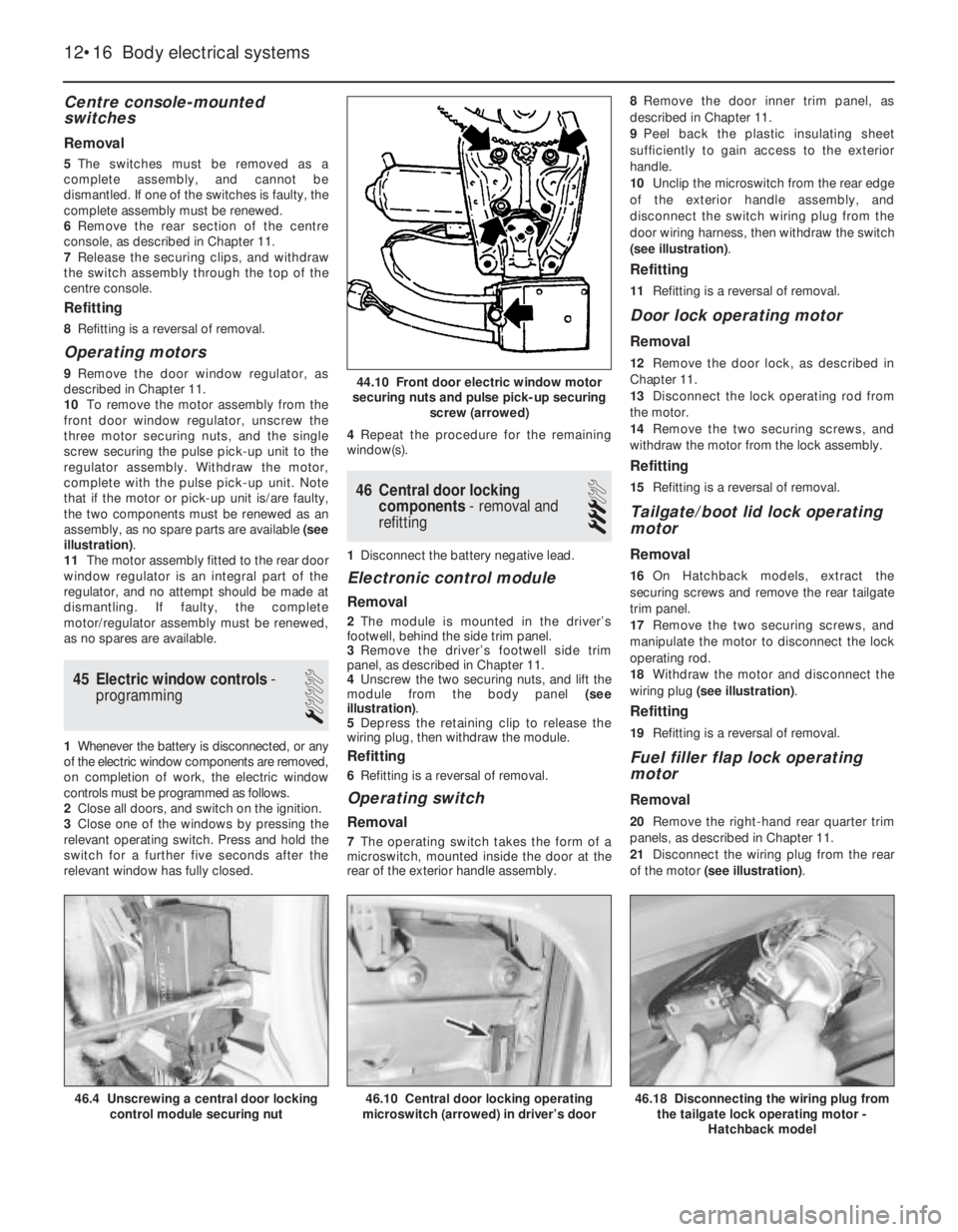

1The valve is located on a bracket attached

to the upper section of the washer fluid

reservoir (see illustration).

2Disconnect the battery negative lead.

3Disconnect the wiring and the fluid hoses

from the valve. Be prepared for fluid spillage.

4Remove the screw securing the valve

bracket to the reservoir, and withdraw the

valve.

Refitting

5Refitting is a reversal of removal.

44Electric window components

- removal and refitting

3

Note: Whenever any of the electric window

components are removed, after refitting the

components, the electric window controls

must be programmed, as described in

Section 45.

1Disconnect the battery negative lead.

Rear door-mounted switches

Removal

2Prise the plastic surround from the door

interior handle.

3Carefully prise the switch from its location,

and disconnect the wiring plug.

Refitting

4Refitting is a reversal of removal, but make

sure that the wiring is routed so that it does

not foul the electric window or lock operating

components.

Body electrical systems 12•15

43.1 Headlamp washer fluid non-return valve (arrowed)41.17 Horn/washer fluid reservoir support bracket securing bolt

(arrowed) - model with headlamp wash

12

Page 30 of 525

Centre console-mounted

switches

Removal

5The switches must be removed as a

complete assembly, and cannot be

dismantled. If one of the switches is faulty, the

complete assembly must be renewed.

6Remove the rear section of the centre

console, as described in Chapter 11.

7Release the securing clips, and withdraw

the switch assembly through the top of the

centre console.

Refitting

8Refitting is a reversal of removal.

Operating motors

9Remove the door window regulator, as

described in Chapter 11.

10To remove the motor assembly from the

front door window regulator, unscrew the

three motor securing nuts, and the single

screw securing the pulse pick-up unit to the

regulator assembly. Withdraw the motor,

complete with the pulse pick-up unit. Note

that if the motor or pick-up unit is/are faulty,

the two components must be renewed as an

assembly, as no spare parts are available (see

illustration).

11The motor assembly fitted to the rear door

window regulator is an integral part of the

regulator, and no attempt should be made at

dismantling. If faulty, the complete

motor/regulator assembly must be renewed,

as no spares are available.

45Electric window controls -

programming

1

1Whenever the battery is disconnected, or any

of the electric window components are removed,

on completion of work, the electric window

controls must be programmed as follows.

2Close all doors, and switch on the ignition.

3Close one of the windows by pressing the

relevant operating switch. Press and hold the

switch for a further five seconds after the

relevant window has fully closed.4Repeat the procedure for the remaining

window(s).

46Central door locking

components -removal and

refitting

3

1Disconnect the battery negative lead.

Electronic control module

Removal

2The module is mounted in the driver’s

footwell, behind the side trim panel.

3Remove the driver’s footwell side trim

panel, as described in Chapter 11.

4Unscrew the two securing nuts, and lift the

module from the body panel (see

illustration).

5Depress the retaining clip to release the

wiring plug, then withdraw the module.

Refitting

6Refitting is a reversal of removal.

Operating switch

Removal

7The operating switch takes the form of a

microswitch, mounted inside the door at the

rear of the exterior handle assembly.8Remove the door inner trim panel, as

described in Chapter 11.

9Peel back the plastic insulating sheet

sufficiently to gain access to the exterior

handle.

10Unclip the microswitch from the rear edge

of the exterior handle assembly, and

disconnect the switch wiring plug from the

door wiring harness, then withdraw the switch

(see illustration).

Refitting

11Refitting is a reversal of removal.

Door lock operating motor

Removal

12Remove the door lock, as described in

Chapter 11.

13Disconnect the lock operating rod from

the motor.

14Remove the two securing screws, and

withdraw the motor from the lock assembly.

Refitting

15Refitting is a reversal of removal.

Tailgate/boot lid lock operating

motor

Removal

16On Hatchback models, extract the

securing screws and remove the rear tailgate

trim panel.

17Remove the two securing screws, and

manipulate the motor to disconnect the lock

operating rod.

18Withdraw the motor and disconnect the

wiring plug (see illustration).

Refitting

19Refitting is a reversal of removal.

Fuel filler flap lock operating

motor

Removal

20Remove the right-hand rear quarter trim

panels, as described in Chapter 11.

21Disconnect the wiring plug from the rear

of the motor (see illustration).

12•16Body electrical systems

44.10 Front door electric window motor

securing nuts and pulse pick-up securing

screw (arrowed)

46.10 Central door locking operating

microswitch (arrowed) in driver’s door46.18 Disconnecting the wiring plug from

the tailgate lock operating motor -

Hatchback model46.4 Unscrewing a central door locking

control module securing nut