engine OPEL VECTRA 1988 Service Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 102 of 525

3Lift up the edge of the windscreen cowl

panel for access to the sensor.

4Disconnect the sensor wiring plug, and the

vacuum pipe.

5Pull the pressure sensor upwards to release

it from its bracket, and withdraw it from the

vehicle.

Refitting

6Refitting is a reversal of removal. However,

on Multec models no fuel vapour trap is fitted.

It is therefore essential that the sensor

vacuum hose is routed so that it falls steadily

from the sensor to the throttle body. This

precaution prevents any fuel droplets being

trapped in the sensor or hose, and allows

them to drain into the inlet port.

Oil temperature sensor

Removal

7The sensor is screwed into the inlet

manifold side of the cylinder block, next to the

starter motor’s right-hand end.

8The sensor can be reached quite easily

from above, but if it is to be removed from

beneath, ensure that the handbrake is

applied, and that the vehicle is securely

supported on axle stands (see “Jacking and

Vehicle Support”).

9Disconnect the battery negative lead.

10Disconnect the sensor wiring plug.

11Using a spanner, unscrew the sensor and

remove it (see illustration). Be prepared for

oil spillage, and plug the hole in the cylinder

block to prevent dirt ingress and further oil

loss.

Refitting

12Refitting is a reversal of removal.

Crankshaft speed/position

sensor (1.8 litre models)

Removal

13The sensor is located on the exhaust

manifold side of the engine, in the lower

cylinder block behind the oil pump.

14Disconnect the battery negative lead.

15Release the relevant outer timing belt

cover securing clips, and unclip the sensor

wiring from the timing belt cover.

16Disconnect the sensor wiring connector,

noting its location.

17Unscrew the securing bolt, and withdraw

the sensor from the cylinder block (see

illustration).

18Examine the sensor sealing ring, and

renew if necessary (see illustration).

Refitting

19Refitting is a reversal of removal, ensuring

that the sensor wiring is correctly located on

the timing belt cover, and that the wiring

connector is correctly located.

25Motronic system

components - removal and

refitting

3

Note: Refer to Section 3 before proceeding.

Procedures for removal and refitting of the

ignition system components and electronic

module are given elsewhere in the relevant

Sections of this Chapter. Removal and

refitting procedures for all fuel injection

system components are given in Chapter 4B

Coolant temperature sensor

Removal

1On all except 20 XEJ models, the sensor is

located in the end of the thermostat housing,

on the inlet manifold side of the engine.

2On 20 XEJ models, the sensor is located in

the thermostat housing, on the exhaust

manifold side of the engine.

3Disconnect the battery negative lead.

4Partially drain the cooling system, as

described in Chapter 3. 5Disconnect the sensor wiring plug (see

illustration).

6Using a spanner, unscrew the sensor and

withdraw it from the thermostat housing.

Refitting

7Refitting is a reversal of removal.

8On completion, top-up the cooling system,

as described in Chapter 3.

Knock sensor (DOHC models)

Removal

9The sensor is located at the lower inlet

manifold side of the cylinder block, below the

idle speed adjuster, and is only accessible

from below the vehicle.

10Disconnect the battery negative lead.

11Apply the handbrake, then jack up the

front of the vehicle, and support securely on

axle stands (see “Jacking and Vehicle

Support”) placed under the body side

members.

12Remove the engine undershield, as

described in Chapter 11.

13Disconnect the sensor wiring plug.

14Unscrew the securing bolt, and withdraw

the sensor from the cylinder block.

Refitting

15Refitting is a reversal of removal, but note

that the mating faces of the sensor and

cylinder block must be cleaned thoroughly

before fitting the sensor.

Engine electrical systems 5•15

24.17 Unscrewing the crankshaft

speed/position sensor securing bolt -

1.8 litre model

25.5 Disconnecting the coolant

temperature sensor wiring plug - 2.0 litre

model (alternator removed)24.18 Examine the crankshaft

speed/position sensor sealing ring -

1.8 litre model

24.11 Unscrewing the MSTS-i oil

temperature sensor - 1.6 litre model

(engine removed)24.1 MSTS-i manifold pressure sensor -

1.6 litre model

5

Page 103 of 525

26DIS module - removal and

refitting

3

Note: Refer to Section 3 before proceeding.

Removal

1Disconnect the battery negative lead.

2Disconnect the HT leads from the module

terminals noting their locations to ensure

correct refitting. Note that the HT lead cylinder

numbers are stamped on the module, next to

each terminal, and similar numbers appear on

each HT lead.

3Disconnect the module wiring plug.

4On X16 SZ engines, undo the three screws

and remove the module from the camshaft

housing. On C20 XE engines, undo the bolts

securing the DIS module mounting bracket tothe cylinder head and remove the module and

bracket. Note the installed position of DIS

module on its mounting bracket, undo the four

securing screws and separate the module

from the bracket.

Refitting

5Refitting is a reversal of removal.

27Camshaft phase sensor (C20

XE engine) -removal and

refitting

3

Note: Refer to Section 3 before proceeding.

Removal

1The camshaft phase sensor is mounted on

the end of the cylinder head in the position

normally occupied by the distributor.2Disconnect the battery negative lead.

3Disconnect the wiring plug then undo the

phase sensor securing bolts.

4Withdraw the phase sensor from the

cylinder head, then undo the bolt and remove

the phase sensor disc from the end of the

camshaft.

Refitting

5Refitting is a reversal of removal.

5•16Engine electrical systems

Page 104 of 525

11

Torque wrench settingNm lbf ft

Front seat rails to floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Seat belt fixings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 26

1 General description

The bodyshell and floorpan are of pressed

steel, and form an integral part of the vehicle’s

structure, without the need for a separate

chassis.

Various areas are strengthened, to provide

for suspension, steering and engine mounting

points, and load distribution.

Extensive corrosion protection is applied to

all new vehicles. Various anti-corrosion

preparations are used, including galvanising

and PVC under-sealing. Protective wax is

injected into the box sections and other

hollow cavities.

Extensive use is made of plastic for

peripheral components, such as the radiator

grille, bumpers and wheel trims, and for much

of the interior trim.Interior fittings are to a high standard on all

models, and a wide range of optional

equipment is available throughout the range.

Except for the rear quarter windows, all

fixed glass is bonded in position, using a

special adhesive. Any work in this area should

be entrusted to a Vauxhall dealer or glass

replacement specialist.

2 Bodywork and underframe -

maintenance

1

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those partsof the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing preferably with a lot of

water, from a hose. This will remove all the

loose solids that may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way to remove any

accumulated mud that will retain moisture and

tend to encourage rust. Oddly enough, the

best time to clean the underframe and wheel

arches is in wet weather when the mud is

thoroughly wet and soft. In very wet weather

the underframe is usually cleaned of large

accumulations automatically and this is a

good time for inspection.

Periodically, except on vehicles with a

Chapter 11

Bodywork and fittings

Bodywork and underframe - maintenance . . . . . . . . . . . . . . . . . . . . . .2

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet lock components - removal and refitting . . . . . . . . . . . . . . . . .7

Bonnet lock release cable - removal and refitting . . . . . . . . . . . . . . . .8

Boot lid (Saloon models) - removal and refitting . . . . . . . . . . . . . . . . .9

Boot lid lock (Saloon models) - removal and refitting . . . . . . . . . . . . .10

Boot lid lock cylinder (Saloon models) - removal and refitting . . . . . .11

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .38

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Door check arm - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .22

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .19

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . .17

Door interior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Door lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .20

Door mirror - removal, overhaul and refitting . . . . . . . . . . . . . . . . . . .27

Door window - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .25

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . .26

Engine undershield (DOHC models) - removal and refitting . . . . . . . .32

Facia panels - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .37

Fuel filler flap - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .33General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Interior trim panels - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . .36

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Radiator grille panel - removal and refitting . . . . . . . . . . . . . . . . . . . .29

Rear quarter windows - removal and refitting . . . . . . . . . . . . . . . . . .24

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Seat belt tensioners - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Seats (without tensioners) - removal and refitting . . . . . . . . . . . . . . .40

Seats, front (with seat belt tensioners) - removal and refitting . . . . . .43

Sunroof - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Tailgate (Hatchback models) - removal and refitting . . . . . . . . . . . . .12

Tailgate lock (Hatchback models) - removal and refitting . . . . . . . . .13

Tailgate lock cylinder (Hatchback models) - removal and refitting . .14

Tailgate strut (Hatchback models) - removal and refitting . . . . . . . . .15

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . .3

Wheel arch liners - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Windscreen and rear window - removal and refitting . . . . . . . . . . . . .23

Windscreen cowl panel - removal and refitting . . . . . . . . . . . . . . . . .30

11•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 105 of 525

wax-based underbody protective coating, it is

a good idea to have the whole of the

underframe of the vehicle steam cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam cleaning is available at

many garages and is necessary for removal of

the accumulation of oily grime that sometimes

is allowed to become thick in certain areas.

The dirt can then be simply hosed off. Note

that these methods should not be used on

vehicles with wax-based underbody

protective coating or the coating will be

removed. Such vehicles should be inspected

annually, preferably just before winter, when

the underbody should be washed down and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc., as an additional safeguard against rust

damage where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish,

will give added protection against chemical

pollutants in the air. If the paintwork sheen

has dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish.

Always check that the door and ventilator

opening drain holes and pipes are completely

clear so that water can be drained out. Bright

work should be treated in the same way as

paint work. Windscreens and windows can be

kept clear of the smeary film that often

appears, by using a glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

3Upholstery and carpets -

maintenance

1

Mats and carpets should be brushed or

vacuum cleaned regularly to keep them free of

grit. If they are badly stained remove them

from the vehicle for scrubbing or sponging

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light coloured upholstery) use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the

material. Do not forget to keep the headlining

clean in the same way as the upholstery.

When using liquid cleaners inside the vehicle

do not over-wet the surfaces being cleaned.Excessive damp could get into the seams and

padded interior causing stains, offensive

odours or even rot. If the inside of the vehicle

gets wet accidentally it is worthwhile taking

some trouble to dry it out properly, particularly

where carpets are involved. Do not leave oil or

electric heaters inside the vehicle for this

purpose.

4Minor body damage - repair

3

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of

the scratch with a paintwork renovator, to

remove loose paint from the scratch and to

clear the surrounding bodywork of wax polish.

Rinse the area with clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden: then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste and apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique

is required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust inhibiting paint, to prevent the

formation of rust in the future. Using a rubber

or nylon applicator fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste that is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smooth

cotton rag around the top of a finger. Dip the

finger in cellulose thinners and then quickly

sweep it across the surface of the

stopper-paste in the scratch; this will ensure

that the surface of the stopper-paste is

slightly hollowed. The scratch can now be

painted over as described earlier in this

Section.

Repair of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point that is about 8 in (3 mm) below the level

of the surrounding bodywork. In cases where

the dent is very shallow anyway, it is not worthtrying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a block of wood firmly against the

outside of the panel to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being

“belled-out”.

Should the dent be in a section of the

bodywork that has a double skin or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area particularly in the deeper section.

Then screw long self-tapping screws into the

holes just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a good “key” for the

filler paste.

To complete the repair see the Section on

filling and re-spraying.

Repair of rust holes or gashes in

bodywork

Remove all paint from the affected area and

from an inch or so of the surrounding “sound”

bodywork, using an abrasive pad or a wire

brush on a power drill. If these are not

available a few sheets of abrasive paper will

do the job just as effectively. With the paint

removed you will be able to gauge the severity

of the corrosion and therefore decide whether

to renew the whole panel (if this is possible) or

to repair the affected area. New body panels

are not as expensive as most people think

and it is often quicker and more satisfactory

to fit a new panel than to attempt to repair

large areas of corrosion.

Remove all fittings from the affected area

except those which will act as a guide to the

original shape of the damaged bodywork (e.g.

headlamp shells, etc.). Then, using tin snips or

a hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards to

create a slight depression for the filler paste.

Wire brush the affected area to remove the

powdery rust from the surface of the

remaining metal. Paint the affected area with

rust inhibiting paint. If the back of the rusted

area is accessible treat this also.

Before filling can take place it will be

necessary to block the hole in some way. This

can be achieved by using aluminium or plastic

mesh, or aluminium tape.

11•2Bodywork and fittings

Page 107 of 525

6Bonnet - removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2On models fitted with an underbonnet lamp,

disconnect the battery negative lead, then

prise the lamp from the bonnet and disconnect

the wiring. If the bonnet is to be refitted, to aid

routing of the wiring on refitting, tie a length of

string to the end of the wiring. Then withdraw

the wiring through the bonnet and untie the

string, leaving it in position in the bonnet.

3Similarly, disconnect the windscreen

washer fluid hose from the connector in the

bonnet, but tie the string to the connector, to

prevent it from slipping into an inaccessible

position in the bonnet.

4Mark the position of the hinges on the

bonnet.

5With the help of an assistant, support the

weight of the bonnet, then unscrew the

securing bolts from the hinges, and lift the

bonnet from the vehicle (see illustration). If the

bonnet is to be refitted, rest it carefully on rags

or cardboard, to avoid damaging the paint.

6If a new bonnet is to be fitted, transfer all

the serviceable fittings (rubber buffers, lock

striker, etc.), to it.

7If desired, the bonnet hinges can be

removed from the vehicle, after unscrewing

the three bolts in each case securing them to

the upper flanges of the front wings.

Refitting

8Refitting is a reversal of removal,

remembering the following points.

9Align the hinges with the previously made

marks on the bonnet.10If the original bonnet is being refitted,

draw the windscreen washer fluid hose, and

where applicable, the underbonnet lamp

wiring, through the bonnet using the string.

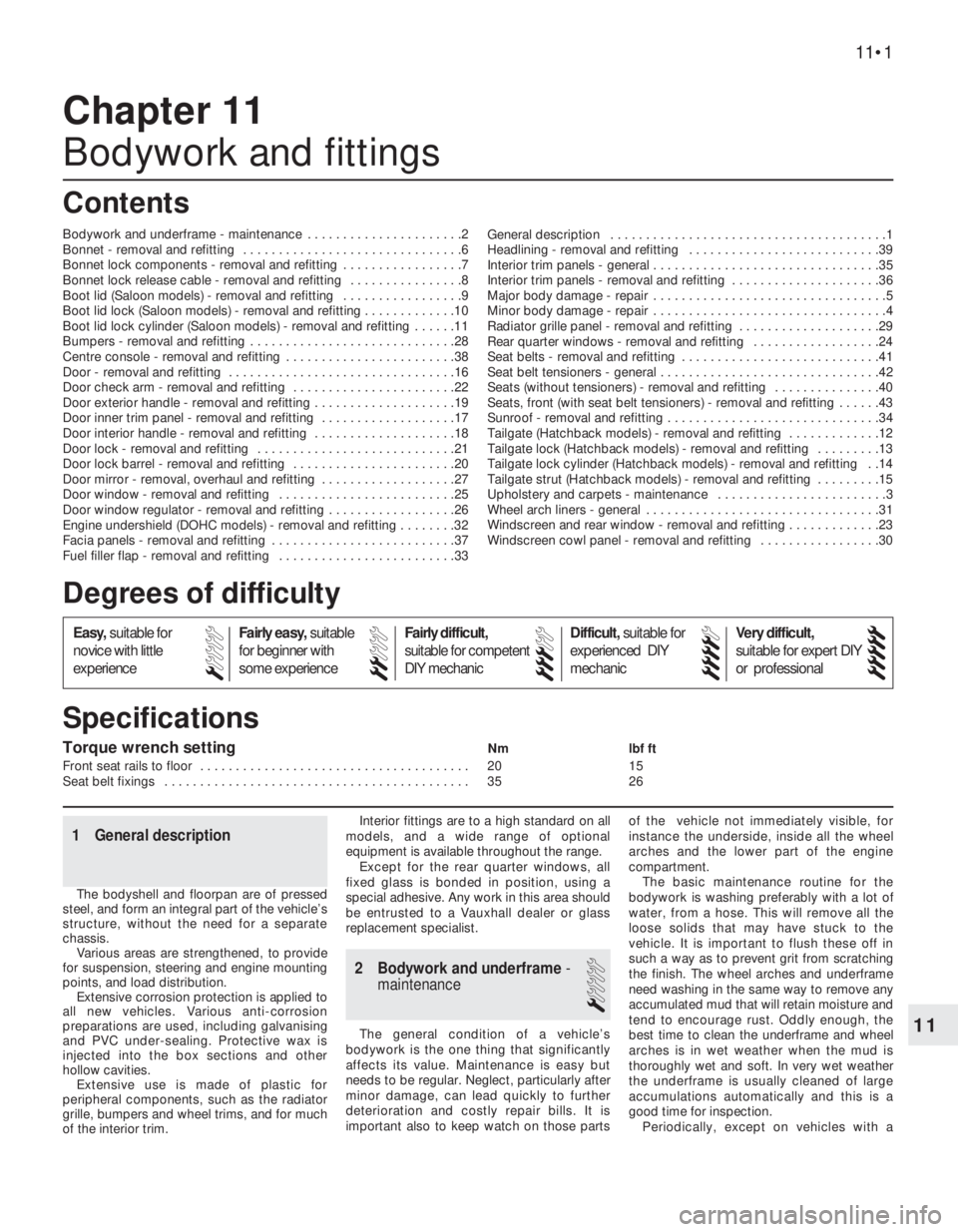

11If the lock striker has been disturbed,

adjust it to the dimension shown (see

illustration), then tighten the locknut.

12If necessary, adjust the hinge bolts and

the front rubber buffers until a good fit is

obtained with the bonnet shut.

7Bonnet lock components -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2The bonnet lock hook is riveted to the

bonnet, and removal involves drilling out the

rivet. Secure the hook assembly with a new

rivet when refitting.

3To remove the bonnet lock striker from the

bonnet, loosen the locknut, then unscrew the

striker and recover the washers and spring.

When refitting, adjust the striker dimension as

described in Section 6, paragraph 11, before

tightening the locknut.

4To remove the locking spring, disconnect

the end of the bonnet release cable from the

spring. Then unhook the end of the spring

from the slot in the front body panel, and

manipulate the spring out through the top of

the panel, taking care not to damage the paint.

Refitting

5Refitting is a reversal of removal.

6On completion, close the bonnet and check

that the lock and the bonnet release

mechanism operate satisfactorily.

8Bonnet lock release cable -

removal and refitting

2

Removal

1Open the bonnet, and support it in the fully

open position.

2Unscrew the release cable clip from the

front body panel.

3Disconnect the end of the release cable

from the locking spring under the front body

panel.

4Disconnect the release cable from the

release handle in the driver’s footwell. If

necessary, remove the release handle from its

retainer for access to the cable end.

5Pull the cable assembly through the

grommet in the engine compartment

bulkhead into the engine compartment.

6Release the cable from any remaining clips

and cable-ties, and withdraw it from the

engine compartment.

Refitting

7Refitting is a reversal of removal, but ensure

that the cable is correctly routed, and on

completion check the release mechanism for

satisfactory operation.

9Boot lid (Saloon models) -

removal and refitting

2

Removal

1Open the bonnet lid fully.

2On models with central locking, disconnect

the battery negative lead then disconnect the

wiring from the lock solenoid. If the boot lid is

11•4Bodywork and fittings

6.5 Lifting the bonnet from the vehicle

6.11 Bonnet lock striker adjustment

X = 40.0 to 45.0 mm (1.57 to 1.77 in) measured from bonnet panel to washer (9)

7 Locknut8 Spring9 Washer10 Striker pinTo aid refitting mark the

position of the bonnet

before removal.

Page 116 of 525

4Certain models may have additional

underbody shields and splashguards fitted,

which may be attached to the wheel arch liners.

32Engine undershield (DOHC

models) - removal and

refitting

2

Removal

1Apply the handbrake, then jack up the front

of the vehicle, and support on axle stands

(see “Jacking and Vehicle Support”).

2Extract the two securing screws, and

remove the oil filter access panel.

3Working around the edges of the splash

shield, remove the self tapping screws that

secure the shield to the body, noting that

some of the screws also secure the wheel

arch liners.

4With the help of an assistant, pull the shield

from the vehicle, and place it to one side to

avoid damage.

Refitting

5Refitting is a reversal of removal.

33Fuel filler flap -removal and

refitting

2

Removal

1Open the flap for access to the four screws

securing the flap to the rear wing.2Remove the securing screws, and withdraw

the flap.

Refitting

3Refitting is a reversal of removal.

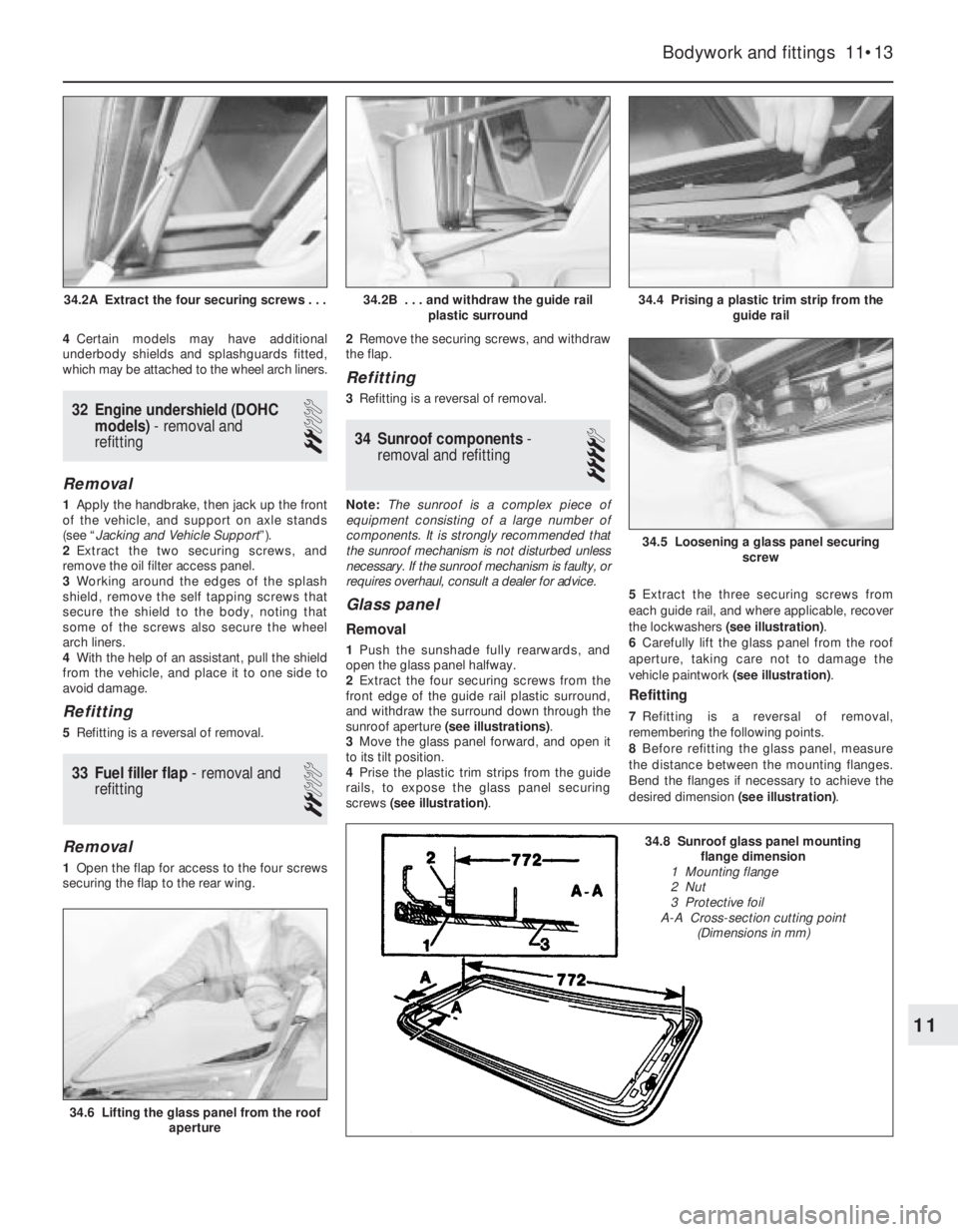

34Sunroof components -

removal and refitting

4

Note:The sunroof is a complex piece of

equipment consisting of a large number of

components. It is strongly recommended that

the sunroof mechanism is not disturbed unless

necessary. If the sunroof mechanism is faulty, or

requires overhaul, consult a dealer for advice.

Glass panel

Removal

1Push the sunshade fully rearwards, and

open the glass panel halfway.

2Extract the four securing screws from the

front edge of the guide rail plastic surround,

and withdraw the surround down through the

sunroof aperture (see illustrations).

3Move the glass panel forward, and open it

to its tilt position.

4Prise the plastic trim strips from the guide

rails, to expose the glass panel securing

screws (see illustration).5Extract the three securing screws from

each guide rail, and where applicable, recover

the lockwashers (see illustration).

6Carefully lift the glass panel from the roof

aperture, taking care not to damage the

vehicle paintwork (see illustration).

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Before refitting the glass panel, measure

the distance between the mounting flanges.

Bend the flanges if necessary to achieve the

desired dimension (see illustration).

Bodywork and fittings 11•13

34.4 Prising a plastic trim strip from the

guide rail

34.6 Lifting the glass panel from the roof

aperture

34.5 Loosening a glass panel securing

screw

34.2B . . . and withdraw the guide rail

plastic surround34.2A Extract the four securing screws . . .

11

34.8 Sunroof glass panel mounting

flange dimension

1 Mounting flange

2 Nut

3 Protective foil

A-A Cross-section cutting point

(Dimensions in mm)

Page 126 of 525

4C

Torque wrench settingsNm lbf ft

AIR non-return valve to pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 22

AIR pipe support bracket to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

AIR pipe to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

AIR pipe to support bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

AIR pump bracket to protective shield . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

AIR pump to wheel arch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

AIR pump to insulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

AIR valves to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Carbon canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

EGR valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Heat shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 22

Chapter 4 Part C:

Fuel and exhaust systems - exhaust and emissions

AIR cut-off valve - removal, testing and refitting . . . . . . . . . . . . . . . . .7

AIR pipe and non-return valve - removal and refitting . . . . . . . . . . . . .9

AIR pump assembly (Simtec system) - removal and refitting . . . . . . . .6

AIR switchover valve - removal and refitting . . . . . . . . . . . . . . . . . . . .8

Carbon canister - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .11

Catalytic converter - description, general and precautions . . . . . . . .10

EGR module (X 16 SZ models) - removal and refitting . . . . . . . . . . . . .5EGR valve (Multec system models) - testing, removal and refitting . . .3

EGR valve (Simtec system) - testing, removal and refitting . . . . . . . . .4

Emissions control systems - general . . . . . . . . . . . . . . . . . . . . . . . . . .1

Exhaust gas recirculation (EGR) system - general . . . . . . . . . . . . . . . .2

Exhaust manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . .13

Exhaust system - checking, removal and refitting . . . . . . . . . . . . . . .14

Oxygen sensor (catalytic converter models) - removal and refitting .12

4C•1

Specifications Contents

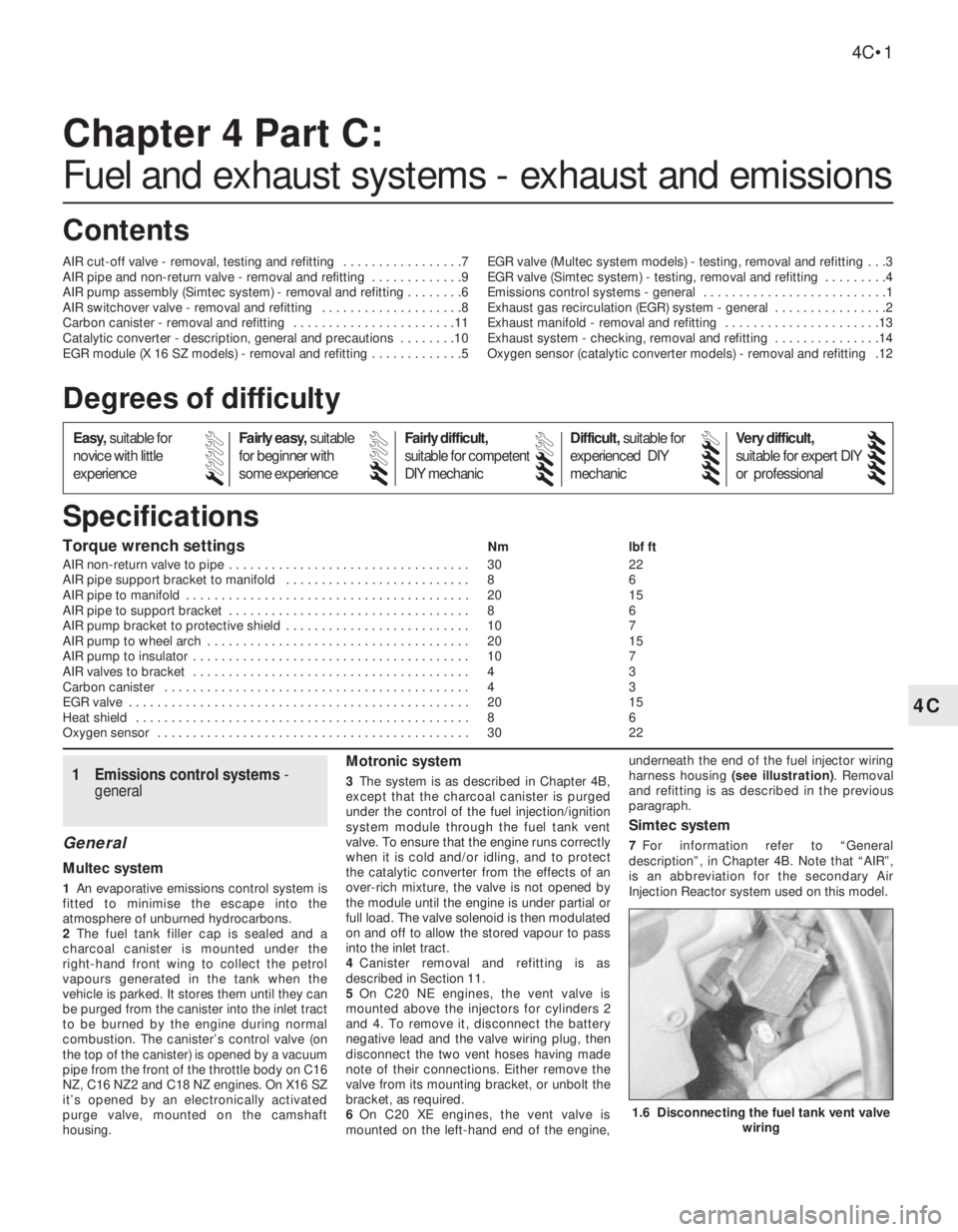

1 Emissions control systems -

general

General

Multec system

1An evaporative emissions control system is

fitted to minimise the escape into the

atmosphere of unburned hydrocarbons.

2The fuel tank filler cap is sealed and a

charcoal canister is mounted under the

right-hand front wing to collect the petrol

vapours generated in the tank when the

vehicle is parked. It stores them until they can

be purged from the canister into the inlet tract

to be burned by the engine during normal

combustion. The canister’s control valve (on

the top of the canister) is opened by a vacuum

pipe from the front of the throttle body on C16

NZ, C16 NZ2 and C18 NZ engines. On X16 SZ

it’s opened by an electronically activated

purge valve, mounted on the camshaft

housing.

Motronic system

3The system is as described in Chapter 4B,

except that the charcoal canister is purged

under the control of the fuel injection/ignition

system module through the fuel tank vent

valve. To ensure that the engine runs correctly

when it is cold and/or idling, and to protect

the catalytic converter from the effects of an

over-rich mixture, the valve is not opened by

the module until the engine is under partial or

full load. The valve solenoid is then modulated

on and off to allow the stored vapour to pass

into the inlet tract.

4Canister removal and refitting is as

described in Section 11.

5On C20 NE engines, the vent valve is

mounted above the injectors for cylinders 2

and 4. To remove it, disconnect the battery

negative lead and the valve wiring plug, then

disconnect the two vent hoses having made

note of their connections. Either remove the

valve from its mounting bracket, or unbolt the

bracket, as required.

6On C20 XE engines, the vent valve is

mounted on the left-hand end of the engine,underneath the end of the fuel injector wiring

harness housing (see illustration). Removal

and refitting is as described in the previous

paragraph.

Simtec system

7For information refer to “General

description”, in Chapter 4B. Note that “AIR”,

is an abbreviation for the secondary Air

Injection Reactor system used on this model.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1.6 Disconnecting the fuel tank vent valve

wiring

Page 127 of 525

2Exhaust gas recirculation

(EGR) system - general

The system reintroduces small amounts of

exhaust gas into the combustion cycle to

reduce the generation of oxides of nitrogen

(NOx).

On C16 NZ, C16 NZ2 and C18 NZ engines,

the volume of exhaust gas reintroduced is

governed by manifold vacuum, through the

EGR valve mounted on the inlet manifold.

When the valve is opened small amounts of

exhaust gas are allowed to enter the inlet

tract, passing through ports in the cylinder

head.

On X16 SZ engines the EGR valve is

operated by an EGR module, mounted on the

left-hand side of the engine compartment

behind the battery. This module amplifies

signals received from the fuel system ECU

and operates the EGR valve electronically

providing precise control of exhaust gas

recirculation under all engine conditions.

3EGR valve (Multec system

models) - testing, removal and

refitting

2

Testing

1On C16 NZ, C16 NZ2 and C18 NZ engines,

it is recommended that the system is checked

annually, by checking the movement of the

valve’s diaphragm carrier plate as follows.

Note that the carrier plate is visible only

through the apertures in the underside of the

valve, so a battery-operated torch and small

mirror may be useful. On X16 SZ engines,

Vauxhall test equipment is necessary to check

the EGR system.

2With the engine fully warmed up to normal

operating temperature and idling, briefly open

and close the throttle. The carrier plate should

move upwards as the manifold vacuum

changes. When the engine is idling smoothly

again, press the carrier plate upwards (do this

very carefully, so that the plate is not distorted or

the diaphragm damaged). The idle speed should

drop significantly (approximately 100 rpm).

3If the valve does not respond as described,

it must be cleaned.

Removal

4Pull off the hose from the valve, then unbolt

the valve and remove it (see illustrations).

Clean away all carbon using a wire brush and

a pointed tool, but take care not to damage

the valve seat. Renew the valve gasket to

prevent induction leaks.

Refitting

5Refit the valve and reconnect the hose,

then recheck the system’s performance; if

there is no improvement, the valve must be

renewed.

4EGR valve (Simtec system) -

testing, removal and refitting

3

Note: A new gasket will be required when

refitting the valve.

Removal

1Disconnect the battery negative lead.

2Remove wiring harness and vacuum hose.

3Mark position of the valve, to ensure

correct relocation.

4Undo the 3 bolts, and remove the valve

from the dual spark ignition coil’s coolant

flange.

Refitting

5Clean the sealing surfaces of the valve and

flange.

6Refit the valve with a new gasket and line

up the marks made before removal (see

illustration).

5EGR module (X16 SZ

models) - removal and

refitting

2

Removal

1Disconnect the knock module from its

bracket (refer to Chapter 4B, if necessary),

and place to one side.

2Remove wiring plug from module. Remove

module from bracket.

Refitting

3Refitting is a reversal of removal.

6AIR pump assembly (Simtec

system) - removal and refitting

3

Removal

1Chock the rear wheels, jack up the front of

the vehicle and support it on axle stands

placed under the body side members (see

“Jacking and Vehicle Support”)

2Remove the left hand front wheel and inner

wheel arch lining.

3Loosen the hose clamp and remove the air

duct hose from the pump.

4Disconnect the battery negative lead.

5Undo the securing nuts and remove the

pump assembly from its location. Disconnect

the wiring plug.

6Remove the wiring plug from the pump’s

bracket.

7Mark the position of the pump on it’s

bracket before separating.

8Remove the fixing bolts and disconnect the

pump from it’s insulator.

9The insulator can also be checked by

removing the 3 nuts, securing the protective

shield. Before removing, mark the shield and

insulator. Replace if necessary.

10Check the pump’s air cleaner for damage.

Refitting

11Refitting is a reversal of removal. Ensure

correct alignment of the components.

7AIR cut-off valve - removal,

testing and refitting

3

Removal

1Before removal, mark on the cut-off valve,

the direction of flow towards the non-return

valve (see illustration).

2Disconnect and remove the air duct and

vacuum hoses.

3Undo the switchover valve’s bolts and

move to one side.

4C•2Fuel and exhaust systems - exhaust and emissions

3.4 Disconnecting the vacuum hose from

the exhaust gas recirculation valve

4.6 EGR valve

1 Valve 2 Gasket

3.4B Withdrawing the exhaust gas

recirculation valve

Page 128 of 525

4The cut-off valve can now be removed from

the bracket.

Testing

5To test the cut-off valve a vacuum hand

pump with gauge will be required. If available,

connect to the cut-off valve and ensure that

air through-flow aperture is fully open.

Refitting

6Refitting is a reversal of removal. Ensure

valve is fitted in the correct direction.

8AIR switchover valve -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect wiring plug from the valve.

3Mark the location of the vacuum hoses

before removing them from the valve.

4After disconnecting the hoses undo the two

bolts, and remove them from its bracket.

Refitting

5Refitting is a reversal of removal. Ensure

hoses are fitted correctly (see illustration).

9AIR pipe and non-return

valve - removal and refitting

3

Note:New air pipe washers will be required

when refitting.

Removal

1Remove the non-return valve air duct hose.

2Undo the bolts engine lifting eye bracket,

and turn the bracket on to its left hand side.

3Remove the pipe support bracket by

releasing its three bolts.

4Remove the heat shield that is secured by

two bolts.

5The air pipe can now be removed by

releasing the two securing bolts.

6If necessary the non-return valve can now

be disconnected.

7Carefully clamp the pipe using a vice with

protective jaws. Unbolt the valve from the

pipe, clean and inspect for damage.

Refitting

8Before refitting, coat the threads of the non-

return valve with sealing compound (i.e.

Vauxhall part no. 90094714).

9Use new washers when refitting the pipe,

(take care as the washers have sharp edges).

Coat the pipe mounting bolts with assembly

paste (i.e. Vauxhall part no. 90513210), before

refitting.

10Refitting is a reversal of removal.

Retighten to correct torque as shown in Spec-

ifications.

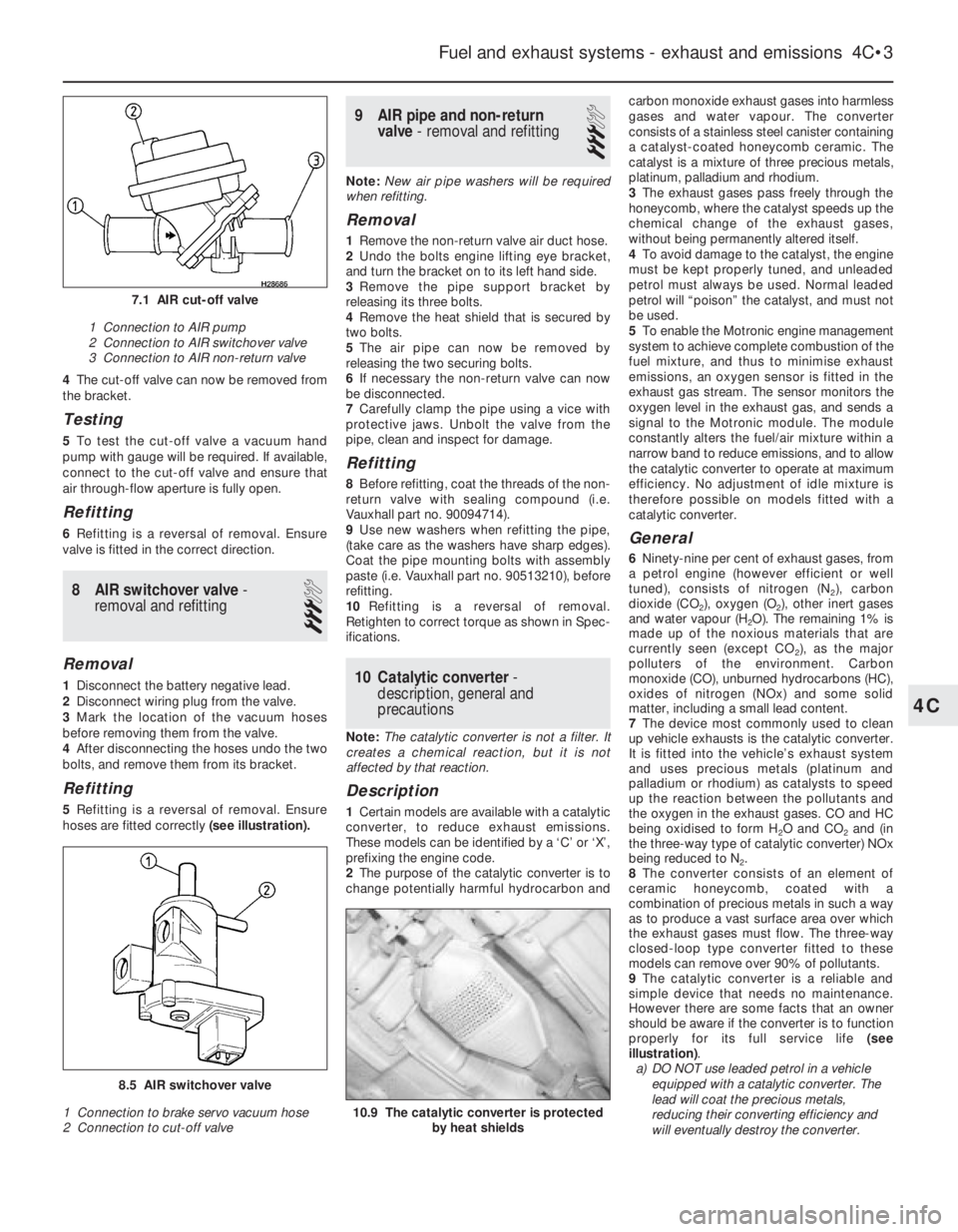

10Catalytic converter -

description, general and

precautions

Note: The catalytic converter is not a filter. It

creates a chemical reaction, but it is not

affected by that reaction.

Description

1Certain models are available with a catalytic

converter, to reduce exhaust emissions.

These models can be identified by a ‘C’ or ‘X’,

prefixing the engine code.

2The purpose of the catalytic converter is to

change potentially harmful hydrocarbon andcarbon monoxide exhaust gases into harmless

gases and water vapour. The converter

consists of a stainless steel canister containing

a catalyst-coated honeycomb ceramic. The

catalyst is a mixture of three precious metals,

platinum, palladium and rhodium.

3The exhaust gases pass freely through the

honeycomb, where the catalyst speeds up the

chemical change of the exhaust gases,

without being permanently altered itself.

4To avoid damage to the catalyst, the engine

must be kept properly tuned, and unleaded

petrol must always be used. Normal leaded

petrol will “poison” the catalyst, and must not

be used.

5To enable the Motronic engine management

system to achieve complete combustion of the

fuel mixture, and thus to minimise exhaust

emissions, an oxygen sensor is fitted in the

exhaust gas stream. The sensor monitors the

oxygen level in the exhaust gas, and sends a

signal to the Motronic module. The module

constantly alters the fuel/air mixture within a

narrow band to reduce emissions, and to allow

the catalytic converter to operate at maximum

efficiency. No adjustment of idle mixture is

therefore possible on models fitted with a

catalytic converter.

General

6Ninety-nine per cent of exhaust gases, from

a petrol engine (however efficient or well

tuned), consists of nitrogen (N

2), carbon

dioxide (CO

2), oxygen (O2), other inert gases

and water vapour (H

2O). The remaining 1% is

made up of the noxious materials that are

currently seen (except CO

2), as the major

polluters of the environment. Carbon

monoxide (CO), unburned hydrocarbons (HC),

oxides of nitrogen (NOx) and some solid

matter, including a small lead content.

7The device most commonly used to clean

up vehicle exhausts is the catalytic converter.

It is fitted into the vehicle’s exhaust system

and uses precious metals (platinum and

palladium or rhodium) as catalysts to speed

up the reaction between the pollutants and

the oxygen in the exhaust gases. CO and HC

being oxidised to form H

2O and CO2and (in

the three-way type of catalytic converter) NOx

being reduced to N

2.

8The converter consists of an element of

ceramic honeycomb, coated with a

combination of precious metals in such a way

as to produce a vast surface area over which

the exhaust gases must flow. The three-way

closed-loop type converter fitted to these

models can remove over 90% of pollutants.

9The catalytic converter is a reliable and

simple device that needs no maintenance.

However there are some facts that an owner

should be aware if the converter is to function

properly for its full service life (see

illustration).

a)DO NOT use leaded petrol in a vehicle

equipped with a catalytic converter. The

lead will coat the precious metals,

reducing their converting efficiency and

will eventually destroy the converter.

Fuel and exhaust systems - exhaust and emissions 4C•3

10.9 The catalytic converter is protected

by heat shields

8.5 AIR switchover valve

1 Connection to brake servo vacuum hose

2 Connection to cut-off valve

7.1 AIR cut-off valve

1 Connection to AIR pump

2 Connection to AIR switchover valve

3 Connection to AIR non-return valve

4C

Page 129 of 525

b)Always keep the ignition and fuel systems

well maintained according to the

manufacturers schedule (see “Routine

maintenance” and the relevant Chapter).

In particular, ensure that the air cleaner

filter element, the fuel filter and the spark

plugs are renewed at the correct intervals.

If the inlet air/fuel mixture is allowed to

become too rich due to neglect, the

unburned surplus will enter and burn in

the catalytic converter, overheating the

element and eventually destroying the

converter.

c)If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured. The

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

d)The engine control indicator (the outline

of an engine with a lightning symbol

superimposed), will light when the ignition

is switched on and the engine is started,

then it will go out. While it may light briefly

while the engine is running, it should go

out again immediately and stays unlit. If it

lights and stays on while the engine is

running, seek the advice of a Vauxhall

dealer as soon as possible. A fault has

occurred in the fuel injection/ignition

system that, apart from increasing fuel

consumption and impairing the engine’s

performance, may damage the catalytic

converter.

e)DO NOT push or tow-start the vehicle.

This will soak the catalytic converter in

unburned fuel causing it to overheat when

the engine does start see (b) above.

f)DO NOT switch off the ignition at high

engine speeds. If the ignition is switched

off at anything above idle speed,

unburned fuel will enter the (very hot)

catalytic converter, with the possible risk

of its igniting on the element and

damaging the converter.

g)DO NOT use fuel or engine oil additives.

These may contain substances harmful to

the catalytic converter.

h)DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke. The unburned

carbon deposits will clog the converter

passages and reduce its efficiency; in

severe cases the element will overheat.

i)Remember that the catalytic converter

operates at very high temperatures hence

the heat shields on the vehicle’s under-

body and the casing will become hot

enough to ignite combustible materials

that brush against it. DO NOT, therefore,

park the vehicle in dry undergrowth, over

long grass or over piles of dead leaves.

j)Remember that the catalytic converter is

FRAGlLE. Do not strike it with tools during

servicing work. Take great care when

working on the exhaust system. Ensure

that the converter is well clear of any

jacks or other lifting gear used to raise thevehicle. Do not drive the vehicle over

rough ground, road humps, etc., in such a

way as to ground the exhaust system.

k)In some cases, particularly when the

vehicle is new and/or is used for

stop/start driving, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles and

seems to be due to the small amount of

sulphur found in some petrol’s reacting

with hydrogen in the exhaust to produce

hydrogen sulphide (CS) gas. While this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the

vehicle has covered a few thousand miles

the problem should disappear. In the

meanwhile a change of driving style or of

the brand of petrol may effect a solution.

l)The catalytic converter, used on a

well-maintained and well-driven vehicle,

should last for between 50 000 and 100

000 miles. From this point on, careful

checks should be made at all specified

service intervals of the CO level to ensure

that the converter is still operating

efficiently. If the converter is no longer

effective it must be renewed.

11Carbon canister - removal

and refitting

3

Removal

1Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members

(see “Jacking and Vehicle Support”).

2Remove the front right hand wheel and

wheel arch liner.

3Note the hose and pipe connections to the

canister, or label them, to ensure that they are

reconnected to their original unions, then

disconnect them (see illustration). Unscrew

the two nuts securing the canister mounting

bracket to the vehicle body.

Refitting

4Refitting is a reversal of removal, however

ensure correct fitment of hose and pipes.

12Oxygen sensor (catalytic

converter models) - removal

and refitting

3

Note: This sensor is also known as a Lambda

sensor.

Removal

1Disconnect the battery negative lead.

2Disconnect the oxygen sensor wiring plug,

which is located behind the coolant expansion

tank.

3Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands placed under the body side members.

4On DOHC models, remove the engine

undershield, as described in Chapter 11.

5On models fitted with Multec injection

system, the sensor is screwed into the

exhaust manifold. Trace the wiring from the

sensor itself to the connector (either clipped

to the radiator cooling fan shroud or behind

the coolant expansion tank). Release it from

any clips or ties; disconnect the wiring before

unscrewing the sensor.

6On other models, unscrew the oxygen

sensor from the front section of the exhaust

system (see illustration). It is advisable to

wear gloves, as the exhaust system will be

extremely hot.

7Withdraw the oxygen sensor and its wiring,

taking care not to burn the wiring on the

exhaust system. If the sensor is to be re-used,

take care that the sealing ring is not lost, and

that the sensor is not dropped.

Refitting

8If a new sensor is being fitted, it will be

supplied with the threads coated in a special

grease to prevent it seizing in the exhaust

system.

9If the original sensor is being refitted,

ensure that the screw thread is clean. Coat

the thread with a lithium based copper grease

(i.e. Vauxhall Part No. 90295397).

10Refitting is a reversal of removal. Check

the exhaust system for leakage when the

engine is re-started.

4C•4Fuel and exhaust systems - exhaust and emissions

12.6 Oxygen sensor location in front

section of exhaust system - DOHC models

11.3 Charcoal canister

A Vent to atmosphere

B Vapour feed hose from filler pipe

C Vapour exhaust hose to inlet tract

D Control valve vacuum pipe from

throttle body