engine OPEL VECTRA 1988 Service Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 158 of 525

4B

13Manipulate the air inlet tube to release the

securing lugs from the front body panel. This

is a tricky operation, and patience will be

required. For improved access, the headlamp

can be removed, as described in Chapter 12.

Refitting

14Refitting of all components is a reversal of

removal, noting that the air cleaner element

fits with the rubber locating flange uppermost.

5Air box - removal and refitting

2

Removal

1The air box, if fitted, is secured by two or

three bolts to the top of the throttle body.

Take note of the routing and connections of

the inlet air temperature control system

vacuum pipes.

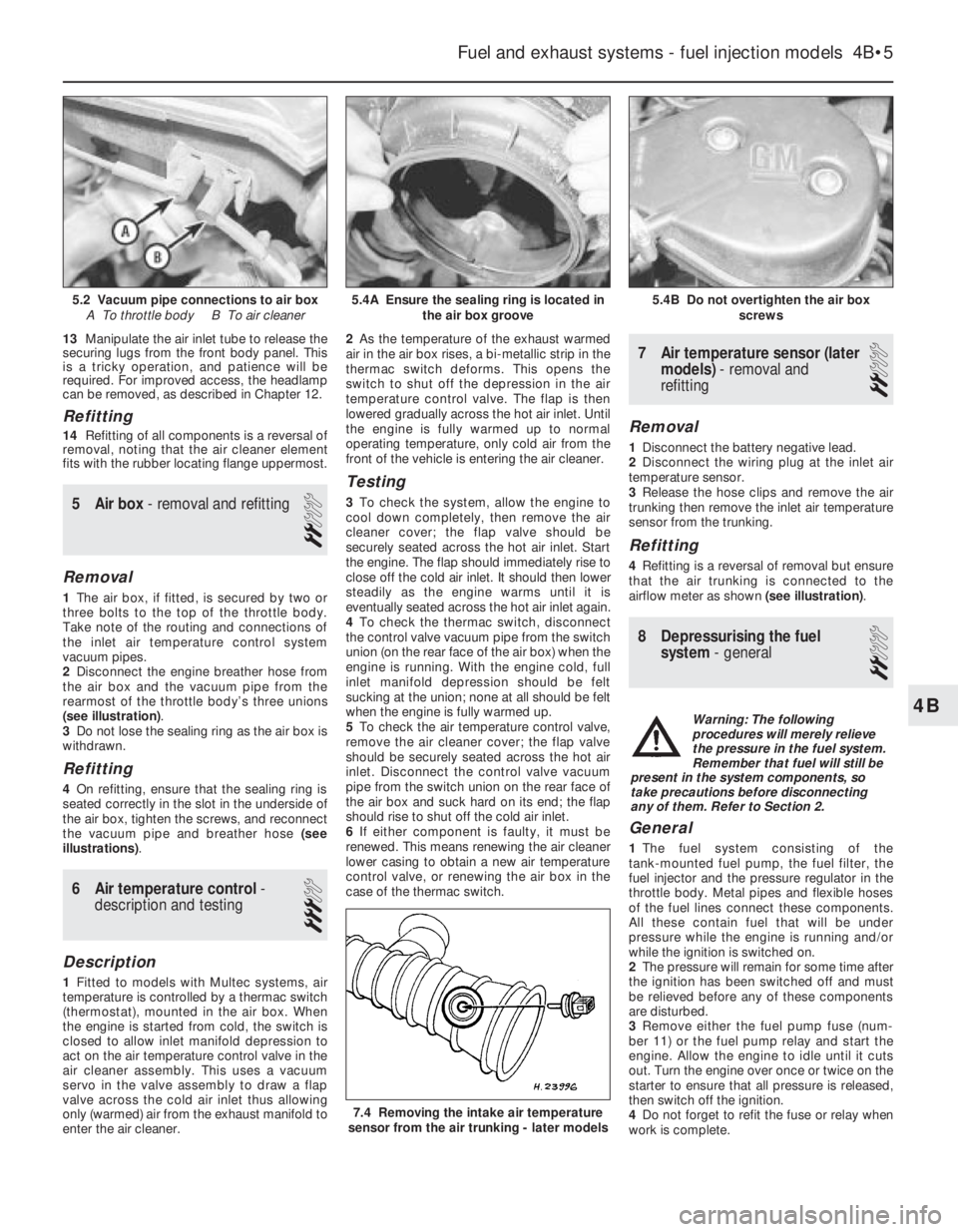

2Disconnect the engine breather hose from

the air box and the vacuum pipe from the

rearmost of the throttle body’s three unions

(see illustration).

3Do not lose the sealing ring as the air box is

withdrawn.

Refitting

4On refitting, ensure that the sealing ring is

seated correctly in the slot in the underside of

the air box, tighten the screws, and reconnect

the vacuum pipe and breather hose (see

illustrations).

6Air temperature control -

description and testing

3

Description

1Fitted to models with Multec systems, air

temperature is controlled by a thermac switch

(thermostat), mounted in the air box. When

the engine is started from cold, the switch is

closed to allow inlet manifold depression to

act on the air temperature control valve in the

air cleaner assembly. This uses a vacuum

servo in the valve assembly to draw a flap

valve across the cold air inlet thus allowing

only (warmed) air from the exhaust manifold to

enter the air cleaner.2As the temperature of the exhaust warmed

air in the air box rises, a bi-metallic strip in the

thermac switch deforms. This opens the

switch to shut off the depression in the air

temperature control valve. The flap is then

lowered gradually across the hot air inlet. Until

the engine is fully warmed up to normal

operating temperature, only cold air from the

front of the vehicle is entering the air cleaner.

Testing

3To check the system, allow the engine to

cool down completely, then remove the air

cleaner cover; the flap valve should be

securely seated across the hot air inlet. Start

the engine. The flap should immediately rise to

close off the cold air inlet. It should then lower

steadily as the engine warms until it is

eventually seated across the hot air inlet again.

4To check the thermac switch, disconnect

the control valve vacuum pipe from the switch

union (on the rear face of the air box) when the

engine is running. With the engine cold, full

inlet manifold depression should be felt

sucking at the union; none at all should be felt

when the engine is fully warmed up.

5To check the air temperature control valve,

remove the air cleaner cover; the flap valve

should be securely seated across the hot air

inlet. Disconnect the control valve vacuum

pipe from the switch union on the rear face of

the air box and suck hard on its end; the flap

should rise to shut off the cold air inlet.

6If either component is faulty, it must be

renewed. This means renewing the air cleaner

lower casing to obtain a new air temperature

control valve, or renewing the air box in the

case of the thermac switch.

7Air temperature sensor (later

models) - removal and

refitting

2

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plug at the inlet air

temperature sensor.

3Release the hose clips and remove the air

trunking then remove the inlet air temperature

sensor from the trunking.

Refitting

4Refitting is a reversal of removal but ensure

that the air trunking is connected to the

airflow meter as shown (see illustration).

8Depressurising the fuel

system - general

2

General

1The fuel system consisting of the

tank-mounted fuel pump, the fuel filter, the

fuel injector and the pressure regulator in the

throttle body. Metal pipes and flexible hoses

of the fuel lines connect these components.

All these contain fuel that will be under

pressure while the engine is running and/or

while the ignition is switched on.

2The pressure will remain for some time after

the ignition has been switched off and must

be relieved before any of these components

are disturbed.

3Remove either the fuel pump fuse (num-

ber 11) or the fuel pump relay and start the

engine. Allow the engine to idle until it cuts

out. Turn the engine over once or twice on the

starter to ensure that all pressure is released,

then switch off the ignition.

4Do not forget to refit the fuse or relay when

work is complete.

Fuel and exhaust systems - fuel injection models 4B•5

5.4B Do not overtighten the air box

screws

7.4 Removing the intake air temperature

sensor from the air trunking - later models

5.4A Ensure the sealing ring is located in

the air box groove5.2 Vacuum pipe connections to air box

A To throttle body B To air cleaner

Warning: The following

procedures will merely relieve

the pressure in the fuel system.

Remember that fuel will still be

present in the system components, so

take precautions before disconnecting

any of them. Refer to Section 2.

Page 159 of 525

9Fuel filter (‘Out-of-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel filter is located on the fuel pump

bracket under the rear of the vehicle. Either on

the right-hand side of the spare wheel well or

in front of the fuel tank, depending on model

(see illustrations).

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the filter is removed.

4Clamp the fuel hoses on either side of the

filter, to minimise fuel loss when the hoses are

disconnected.

5Loosen the clamp screws, and disconnect

the fuel hoses from the filter. Be prepared for

fuel spillage, and take adequate fire

precautions.

6Loosen the clamp bolt(s), and withdraw the

fuel filter from its bracket. Note the orientation

of the flow direction arrow on the body of the

filter, and the position of the “AUS” (out)

marking on the filter end face.

Refitting

7Refitting is a reversal of removal, ensuring

that the flow direction markings are correctly

orientated.

8Run the engine and check for leaks on

completion. If leakage is evident, stop the

engine immediately, and rectify the problem

without delay.

10Fuel filter (‘In-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1Depressurise the fuel system (Section 8).

2Chock the front wheels, jack up the rear of

the vehicle and support it on axle stands

placed under the body side members. (see

“Jacking and Vehicle Support”). The fuel filter

is located at the rear of the fuel tank, on the

right-hand side.3Unclip the fuel hose from the filter mounting

bracket.

4Note carefully any markings on the fuel filter

casing. There should be at least an arrow

(showing the direction of fuel flow) pointing in

the direction of the fuel supply hose leading to

the engine compartment. There may also be

the words “EIN” (in) and “AUS” (out)

embossed in the appropriate end of the

casing.

5Clamp the fuel filter hoses, then slacken the

clips and disconnect the hoses.

6Undo the single screw to release the

mounting bracket, then open the clamp with a

screwdriver to remove the fuel filter (see

illustration).

Refitting

7Fit the new fuel filter using a reversal of the

removal procedure, but ensure that the fuel

flow direction arrow or markings point in the

correct direction. Switch on the ignition and

check carefully for leaks; if any signs of

leakage are detected, the problem must be

rectified before the engine is started.

11Fuel pump - testing

2

Testing

1If the fuel pump is functioning, it should be

possible to hear it “buzzing” by listening

under the rear of the vehicle when the ignition

is switched on. Unless the engine is started,

the fuel pump should switch off after

approximately one second. If the noise

produced is excessive, this may be due to a

faulty fuel flow damper. The damper can be

renewed referring to Section 18, if necessary.

2If the pump appears to have failed

completely, check the appropriate fuse and

relay.

3To test the fuel pump, special equipment is

required, and it is recommended that any

suspected faults are referred to a Vauxhall

dealer.

12Fuel pump (‘Out-of-tank’ fuel

pump models) - removal and

refitting

3

Note: Refer to Section 2 before proceeding

Removal

1The fuel pump is located on a bracket

under the rear of the vehicle, either on the

right-hand side of the spare wheel well or in

front of the fuel tank on other models.

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the damper is

removed.

4Disconnect the wiring plug(s) from the fuel

pump (see illustration).

5Clamp the fuel hoses on either side of the

damper, to minimise fuel loss when the hoses

are disconnected.

6Loosen the clamp screws, and disconnect

the fuel hoses from the pump. Be prepared for

fuel spillage, and take adequate fire

precautions.

7Loosen the clamp bolt, and slide the pump

from its bracket.

Refitting

8Refitting is a reversal of removal, ensuring

that the pump is fitted the correct way round

in its bracket. Push the pump into the rubber

clamping sleeve as far as the rim on the pump

body (see illustration).

4B•6Fuel and exhaust systems - fuel injection models

9.1A Fuel filter (arrowed) - ‘out of tank’,

fuel pump models10.6 Fuel filter - ‘in tank’, fuel pump type

A Clamp screwB Hose clips

12.4 Disconnecting a fuel pump wiring

plug - ‘out of tank’, fuel pump model

9.1B Fuel component assembly - ‘out of

tank’, fuel pump models

1 Fuel filter

2 Fuel flow damper3 Fuel pump

Page 160 of 525

4B

9Run the engine and check for leaks on

completion. If leakage is evident, stop the

engine immediately, and rectify the problem

without delay.

13Fuel pump (‘In-tank’ fuel

pump models) - removal and

refitting

3

Removal

1Depressurise the fuel system (Section 8),

then remove and refit the fuel filler cap to

ensure that the pressure is equalised inside

and outside the tank.

2Disconnect the battery negative terminal.

3Fold forwards the rear seat cushion. Peel

back the floor covering beneath it, then

remove the cover plug from the vehicle floor

to reach the pump mountings (see

illustration).

4Noting exactly how it is connected, and

making your own marks or notes to ensure

that it can be reconnected the same way

round, disconnect the wiring plug from the

pump.

5Release the securing clip and disconnect

the fuel hose from the pump. Clamp or plug

the hose to prevent the loss of fuel and the

entry of dirt.

6Undo the pump mounting bracket screws,

then withdraw the mounting bracket and

pump assembly from the tank. Note the

position of the sealing ring and discard it, then

cover the tank opening as a safety measure

and to prevent the entry of dirt.

7If the pump is to be renewed, first move it to

a clean working area and carry out the

following.

8Prise off the filter at the base of the pump

assembly, then release the securing clamp

and disconnect the mounting

bracket-to-pump fuel hose.

9Making your own marks or notes to ensure

that they can be reconnected the same way

round, unsolder the wires connecting the

pump to the mounting bracket.

10Press the pump out of the rubber sleeve.

Refitting

11Reassembly and refitting are the reverse

of the removal and dismantling procedures,

noting the following points.a)Ensure that the pump is seated correctly

in the sleeve and that the hose is securely

fastened.

b)Ensure that the wires are correctly

reconnected and securely soldered.

c)Always renew the pump mounting

bracket’s sealing ring.

d)Apply a few drops of sealing compound

(i.e. Vauxhall part no. 90485251) to the

threads of the screws, then tighten them

securely, but take care not to distort the

sealing ring.

14Fuel pump relay - renewal

2

The relay is mounted in the engine

compartment relay box (Chapter 12). Where

more than one relay is fitted, the fuel pump

relay is the one with the black base.

15Fuel tank filler pipe - removal

and refitting

3

Removal

1Syphon out any remaining fuel in the tank

into a clean container that is designed for

carrying petrol and is clearly marked as such.

2Raise the bottom edge of the seal

surrounding the filler neck and undo the single

securing screw beneath.

3Chock the front wheels, jack up the rear of

the vehicle and support it securely on axle

stands (see “Jacking and Vehicle Support”)

placed under the body side members.

4Unscrew the single filler pipe mounting bolt

from the underbody, then work along the

length of the pipe, cutting or releasing any

clips or ties securing other pipes or hoses to

it. Releasing their clips, disconnect the filler

and vent hoses from the pipe’s lower end and

the small-bore vent hoses from the unions at

its upper end.

5Having ensured that all components have

been removed or disconnected which mightprevent its removal, manoeuvre the pipe away

from the vehicle’s underside.

6To check the operation of the pipe’s

anti-leak valve, invert the filler pipe and fill the

lower union (now uppermost) with petrol. If

the valve is functioning correctly, no petrol will

leak from the other union. If petrol leaks from

the other union the valve is faulty and the

complete filler pipe must be renewed.

Refitting

7Refitting is the reverse of the removal

procedure, noting the following.

a)Check the condition of all hoses and

clips, renewing any components that are

found to be worn or damaged

b)When reconnecting the small-bore vent

hoses to the unions at the pipe’s upper

end, connect the hose from the charcoal

canister to the uppermost union and the

vent hose from the tank itself to the lower

union (see illustration).

c)Replacing any that were cut on removal

use the clips or ties provided to secure

any other pipes or hoses to the filler pipe.

d)Check carefully for signs of leaks on

refilling the tank; if any signs of leakage

are detected, the problem must be

rectified immediately.

16Fuel tank - removal and

refitting

4

Note: Refer to Section 2 before proceeding

Removal

SOHC models

1The procedure is similar as for models with

carburettors. Refer to Chapter 4A, however

note the following:

a)Depressurise the fuel system (Section 8).

b)On models with C16 NZ and X16 SZ

engines, disconnect the exhaust system

from the manifold.

c)When working on the fuel tank sender

unit, note that there is only one hose to be

disconnected.

Fuel and exhaust systems - fuel injection models 4B•7

15.7 Vent hose connections at fuel tank

filler pipe

A Charcoal canister hose

B Tank vent hose

13.3 Fuel pump - ‘in-tank’, fuel pump

model

A Wiring connector

B Fuel hose clampC Mounting bracket

screws

12.8 Fuel pump clamping sleeve should

rest against rim (arrowed)

Page 161 of 525

d)Disconnect the fuel pump hose and wiring

as described in Section 12.

e)When releasing the tank mounting straps,

note that the fuel filter must either be

moved aside or removed completely,

whichever is most convenient

f)One of the fuel hoses connects to a pipe

in the side of the tank.

DOHC models

2Disconnect the battery negative lead.

3Siphon out any remaining fuel in the tank

through the filler pipe. Siphon the fuel into a

clean metal container that can be sealed.

4Chock the front wheels, then jack up the

rear of the vehicle, and support on axle stands

placed under the body side members (see

“Jacking and Vehicle Support”).

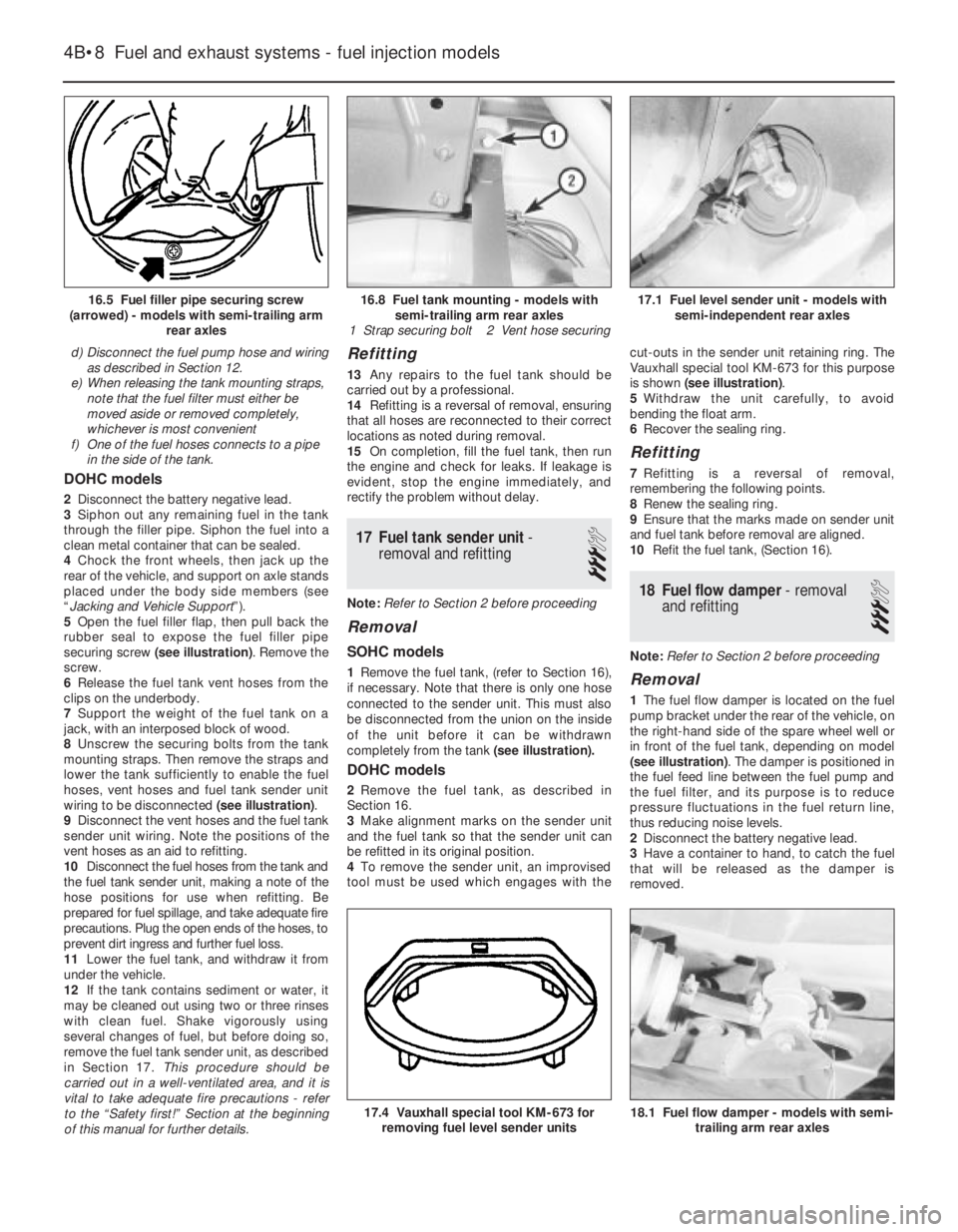

5Open the fuel filler flap, then pull back the

rubber seal to expose the fuel filler pipe

securing screw (see illustration). Remove the

screw.

6Release the fuel tank vent hoses from the

clips on the underbody.

7Support the weight of the fuel tank on a

jack, with an interposed block of wood.

8Unscrew the securing bolts from the tank

mounting straps. Then remove the straps and

lower the tank sufficiently to enable the fuel

hoses, vent hoses and fuel tank sender unit

wiring to be disconnected (see illustration).

9Disconnect the vent hoses and the fuel tank

sender unit wiring. Note the positions of the

vent hoses as an aid to refitting.

10Disconnect the fuel hoses from the tank and

the fuel tank sender unit, making a note of the

hose positions for use when refitting. Be

prepared for fuel spillage, and take adequate fire

precautions. Plug the open ends of the hoses, to

prevent dirt ingress and further fuel loss.

11Lower the fuel tank, and withdraw it from

under the vehicle.

12If the tank contains sediment or water, it

may be cleaned out using two or three rinses

with clean fuel. Shake vigorously using

several changes of fuel, but before doing so,

remove the fuel tank sender unit, as described

in Section 17. This procedure should be

carried out in a well-ventilated area, and it is

vital to take adequate fire precautions - refer

to the “Safety first!” Section at the beginning

of this manual for further details.

Refitting

13Any repairs to the fuel tank should be

carried out by a professional.

14Refitting is a reversal of removal, ensuring

that all hoses are reconnected to their correct

locations as noted during removal.

15On completion, fill the fuel tank, then run

the engine and check for leaks. If leakage is

evident, stop the engine immediately, and

rectify the problem without delay.

17Fuel tank sender unit -

removal and refitting

3

Note:Refer to Section 2 before proceeding

Removal

SOHC models

1Remove the fuel tank, (refer to Section 16),

if necessary. Note that there is only one hose

connected to the sender unit. This must also

be disconnected from the union on the inside

of the unit before it can be withdrawn

completely from the tank (see illustration).

DOHC models

2Remove the fuel tank, as described in

Section 16.

3Make alignment marks on the sender unit

and the fuel tank so that the sender unit can

be refitted in its original position.

4To remove the sender unit, an improvised

tool must be used which engages with thecut-outs in the sender unit retaining ring. The

Vauxhall special tool KM-673 for this purpose

is shown (see illustration).

5Withdraw the unit carefully, to avoid

bending the float arm.

6Recover the sealing ring.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Renew the sealing ring.

9Ensure that the marks made on sender unit

and fuel tank before removal are aligned.

10Refit the fuel tank, (Section 16).

18Fuel flow damper - removal

and refitting

3

Note:Refer to Section 2 before proceeding

Removal

1The fuel flow damper is located on the fuel

pump bracket under the rear of the vehicle, on

the right-hand side of the spare wheel well or

in front of the fuel tank, depending on model

(see illustration). The damper is positioned in

the fuel feed line between the fuel pump and

the fuel filter, and its purpose is to reduce

pressure fluctuations in the fuel return line,

thus reducing noise levels.

2Disconnect the battery negative lead.

3Have a container to hand, to catch the fuel

that will be released as the damper is

removed.

4B•8Fuel and exhaust systems - fuel injection models

16.5 Fuel filler pipe securing screw

(arrowed) - models with semi-trailing arm

rear axles17.1 Fuel level sender unit - models with

semi-independent rear axles

18.1 Fuel flow damper - models with semi-

trailing arm rear axles17.4 Vauxhall special tool KM-673 for

removing fuel level sender units

16.8 Fuel tank mounting - models with

semi-trailing arm rear axles

1 Strap securing bolt 2 Vent hose securing

Page 162 of 525

4B

4Clamp the fuel hoses on either side of the

damper, to minimise fuel loss when the hoses

are disconnected.

5Loosen the clamp screws, and disconnect

the fuel hoses from the damper. Be prepared

for fuel spillage, and take adequate fire

precautions.

6Unscrew the securing nut, and withdraw

the damper from the bracket.

Refitting

7Refitting is a reversal of removal.

8Run the engine and check for leaks on

completion. If leakage is evident; stop the

engine immediately, and rectify the problem

without delay.

19Throttle cable - removal,

refitting and adjustment

3

Removal

1This procedure is basically the same as

described in Chapter 4A, but note the

following.

2Not all models are fitted with an air box.

Ignore references to it, if not applicable.

3For “carburettor” substitute “throttle body”,

and note that the cable bracket is bolted to

the inlet manifold.

4The throttle cable end may connect to a

balljoint on the throttle valve lever, which is

retained by a clip (see illustration).

5If fitted, remove the air box. Refer to

Section 5, if necessary.

6Where fitted, use a pair of needle-nosed

pliers to extract the wire spring clip securing

the cable end balljoint to the throttle linkage.

Prise the cable end off the linkage.

7Withdraw the clip and pull the cable outer

seating grommet out of the cable bracket,

then release the cable as far as the bulkhead

(see illustration).

8Working inside the passenger

compartment, remove the driver’s footwell

trim panel, refer to Chapter 11, if necessary.

9Release the end of the cable’s inner wire

from the “keyhole” fitting at the top of the

throttle pedal by easing back the spring and

prising the cable end out of the slot.10Prise the grommet out of the bulkhead

and tie a length of string to the cable.

11Noting carefully its routing, withdraw the

cable through the bulkhead into the engine

compartment; untie the string, leaving it in

place, when the pedal end of the cable

appears.

Refitting

12Refitting is the reverse of the removal

procedure, noting the following points.

a)First ensure that the cable is correctly

routed, then draw it through the bulkhead

aperture using the string.

b)Ensure that the bulkhead grommet is

correctly seated.

c)Connect the cable end to the throttle

linkage. Seat the cable outer grommet in

the bracket and pull it through so that the

cable inner wire is just taut when the

throttle linkage is held fully closed. Fit the

clip to secure the cable outer in that

position.

d)Check the throttle operation and cable

adjustment, as described below.

Adjustment

13Refer to Chapter 4A, but for “carburettor”

substitute “throttle body”. If applicable, the air

box must be removed.

14First check that the pedal is at a

convenient height for the driver. This setting

can be adjusted by turning the pedal stop

screw (it will be necessary to remove the

footwell trim panel to reach the screw).

Remember that the pedal must be left with

enough travel for the throttle valve to open

fully. Also check that the pedal pivot bushes

are in good condition.

15Returning to the engine compartment,

check that the linkage pivots and balljoints are

unworn and operate smoothly throughout

their full travel. When the throttle valve is fully

closed and the throttle pedal is released, there

should be hardly any free play in the cable

inner wire.

16If adjustment is required, extract the clip

securing the cable outer seating grommet in

the cable bracket and replace it in the

appropriate groove, so that the cable outer is

repositioned correctly.17With an assistant operating the throttle

pedal from the driver’s seat. Check that when

the pedal is fully depressed, the throttle valve

is fully open. If there is insufficient pedal travel

to permit this, unscrew the pedal stop screw,

then reset the cable at the throttle linkage.

18When cable adjustment is correct, refit all

disturbed components.

20Idle mixture - checking and

adjustment

3

Note: No adjustment of idle mixture is

possible on models fitted with a catalytic

converter, and no adjustment of idle speed is

possible with the Motronic system. Refer to

Section 2 before proceeding. A tachometer

and an exhaust gas analyser (CO meter) will be

required to carry out adjustment on models

fitted with Motronic systems.

Multec systems

Checking

1If the CO level reading is incorrect (or if any

other symptom is encountered which causes

you to suspect a fault) always check first that

the air cleaner element is clean. Check also

that the spark plugs are in good condition and

correctly gapped. Ensure that the engine

breather and vacuum hoses are clear and

undamaged. Check that there are no leaks in

the air inlet trunking. Check the throttle body

and the manifolds for damage. Ensure that the

throttle cable is correctly adjusted (see Section

19). If the engine is running very roughly, check

the compression pressures (Chapter 2A) and

remember the possibility that one of the

hydraulic tappets might be faulty, producing

an incorrect valve clearance. Check also that

all wiring is in good condition, with securely

fastened connectors. Check that the fuel filter

has been renewed at the recommended

intervals and that the exhaust system is

entirely free of air leaks which might upset the

operation of the catalytic converter, if fitted.

Adjustment

2The idle mixture is controlled entirely by the

ECU and there is no provision at all for any

form of adjustment. Furthermore, accurate

checking is not possible without the use of

Vauxhall test equipment in conjunction with a

good-quality, carefully calibrated exhaust gas

analyser.

3While it may be possible for owners with

access to such analysers to check the

mixture, the results should be regarded as no

more than a rough guide. If the mixture is

thought to be incorrect, the vehicle should be

taken to a Vauxhall dealer for checking. If the

CO level exceeds the specified value the

system must be checked thoroughly by an

experienced mechanic using the Vauxhall test

equipment until the fault is eliminated and the

defective component renewed.

Fuel and exhaust systems - fuel injection models 4B•9

19.7 Throttle cable end grommet in

bracket on inlet manifold19.4 Disconnecting the throttle cable end

from the throttle valve lever - SOHC model

Page 163 of 525

4Where applicable, the only test of the

catalytic converter’s efficiency is to check the

level of CO in the exhaust gas. This is

measured at the tailpipe with the engine

running (with no load) at 3000 rpm. If the CO

level exceeds the specified value, the Vauxhall

test equipment must be used to check the

entire fuel injection/ignition system. If the

engine is mechanically sound, once the

system has been eliminated, the fault must lie

in the converter, which must be renewed.

Motronic systems

Checking

5In order to check the idle mixture adjustment,

the following conditions must be met:

a)The engine must be at normal operating

temperature

b)All electrical consumers (cooling fan,

heater blower, headlamps etc.) must be

switched off

c)The spark plug gaps must be correctly

adjusted see Chapter 1

d)The throttle cable free play must be

correctly adjusted - see Section 19

e)The air inlet trunking must be free from

leaks, and the air filter must be clean

Adjustment

6Connect a tachometer and an exhaust gas

analyser to the vehicle in accordance with the

equipment manufacturer’s instructions.

7Start the engine and turn it at 2000 rpm for

approximately 30 seconds, then allow it to

idle. Check that the idle speed is within the

specified limits. No adjustment of idle speed

is possible, and if outside the specified limits,

the problem should be referred to a dealer.

8With the idle speed correct, check the CO

level in the exhaust gas. If it is outside the

specified limits, adjust by means of the idle

mixture adjustment screw in the airflow meter

or air mass meter, as applicable. In

production, the screw is covered by a

tamperproof plug; ensure that no local or

national laws are being broken before

removing the plug.9If the cooling fan cuts in during the

adjustment procedure, stop the adjustments,

and proceed when the cooling fan stops.

10When the idle mixture is correctly set,

stop the engine and disconnect the test

equipment.

Simtec systems

11Adjustment is not possible on these

models.

21Fuel pressure regulator -

removal and refitting

3

Note:Refer to Section 2 before proceeding

Removal

SOHC models (except Multec systems)

1Disconnect the battery negative lead.

2For improved access, remove the idle

speed adjuster as described in Section 22.

Disconnect the wiring harness housing from

the fuel injectors and move it to one side,

taking care not to strain the wiring. Pull up on

the wiring harness housing, and compress the

wiring plug retaining clips to release the

harness housing from the injectors.

3Position a wad of rag beneath the pressure

regulator, to absorb the fuel that will be

released as the regulator is removed.

4Loosen the clamp screws and disconnect

the fuel hoses from the regulator. Be prepared

for fuel spillage, and take adequate fire

precautions.

5Disconnect the vacuum pipe from the top

of the pressure regulator and withdraw the

regulator.

SOHC models (with Multec system)

6Depressurise the fuel system, as described

in Section 8.

7Remove the air box. Refer to Section 5, if

necessary.

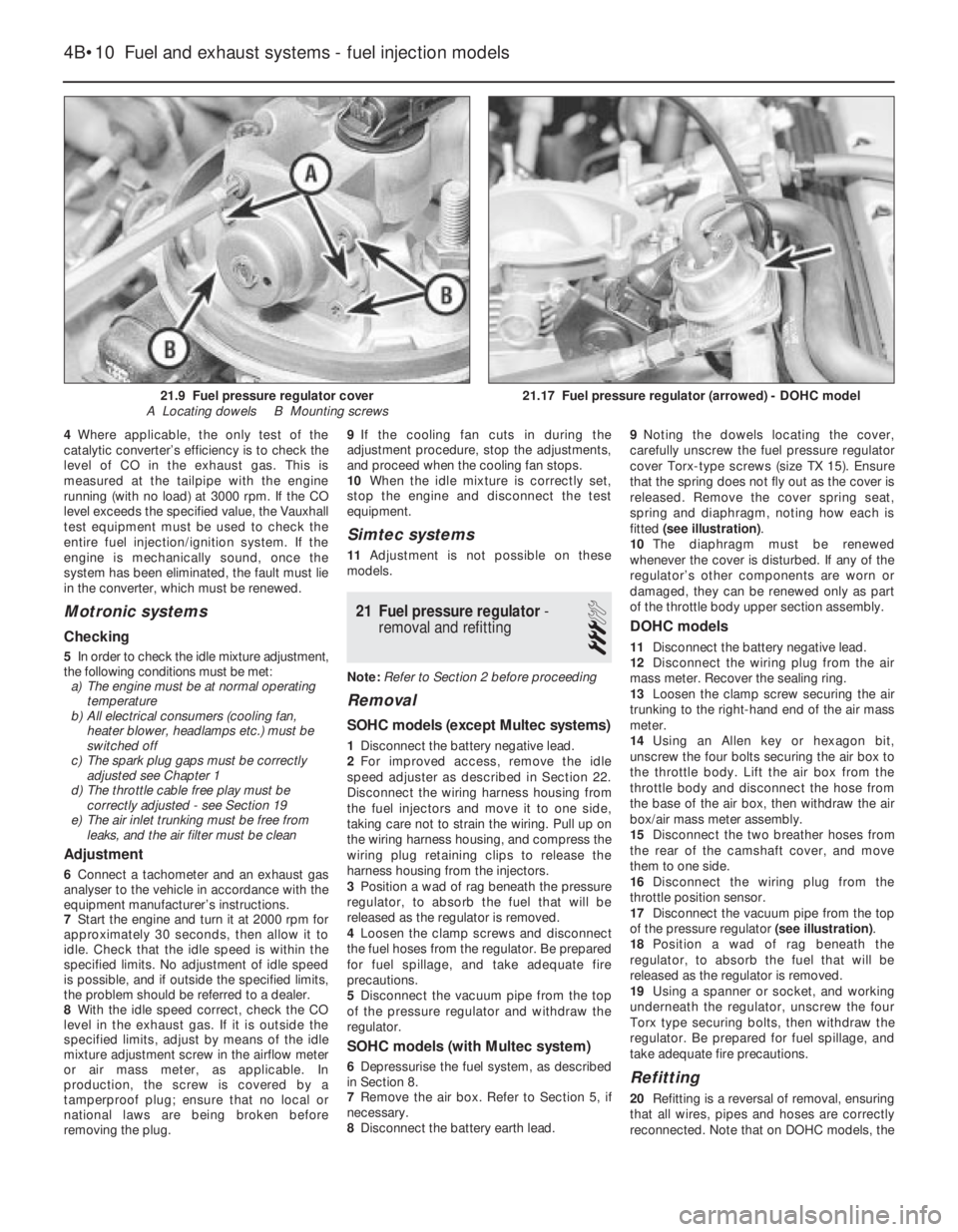

8Disconnect the battery earth lead.9Noting the dowels locating the cover,

carefully unscrew the fuel pressure regulator

cover Torx-type screws (size TX 15). Ensure

that the spring does not fly out as the cover is

released. Remove the cover spring seat,

spring and diaphragm, noting how each is

fitted (see illustration).

10The diaphragm must be renewed

whenever the cover is disturbed. If any of the

regulator’s other components are worn or

damaged, they can be renewed only as part

of the throttle body upper section assembly.

DOHC models

11Disconnect the battery negative lead.

12Disconnect the wiring plug from the air

mass meter. Recover the sealing ring.

13Loosen the clamp screw securing the air

trunking to the right-hand end of the air mass

meter.

14Using an Allen key or hexagon bit,

unscrew the four bolts securing the air box to

the throttle body. Lift the air box from the

throttle body and disconnect the hose from

the base of the air box, then withdraw the air

box/air mass meter assembly.

15Disconnect the two breather hoses from

the rear of the camshaft cover, and move

them to one side.

16Disconnect the wiring plug from the

throttle position sensor.

17Disconnect the vacuum pipe from the top

of the pressure regulator (see illustration).

18Position a wad of rag beneath the

regulator, to absorb the fuel that will be

released as the regulator is removed.

19Using a spanner or socket, and working

underneath the regulator, unscrew the four

Torx type securing bolts, then withdraw the

regulator. Be prepared for fuel spillage, and

take adequate fire precautions.

Refitting

20Refitting is a reversal of removal, ensuring

that all wires, pipes and hoses are correctly

reconnected. Note that on DOHC models, the

4B•10Fuel and exhaust systems - fuel injection models

21.17 Fuel pressure regulator (arrowed) - DOHC model21.9 Fuel pressure regulator cover

A Locating dowels B Mounting screws

Page 164 of 525

regulator vacuum pipe should be routed over

the top of the camshaft cover breather hoses.

21On models with the Multec system note

also the following:

a)Fit the new diaphragm so that it locates in

the throttle body groove.

b)Ensure that the spring and spring seat are

correctly engaged with each other and

with the diaphragm and regulator cover.

Then press the cover over its locating

dowels and hold it in place while the

screws are tightened.

c)Tighten the screws carefully to the

specified torque wrench setting.

22On completion, check the regulator for

leaks, pressurising the system by switching

the ignition on and off several times, before

the engine is started.

22Idle speed adjuster - removal

and refitting

3

Note:Idle speed adjustment on models fitted

with Multec systems, is not possible, as it is

controlled by the ECU. Refer to Section 1.

Removal

SOHC models (except Multec system)

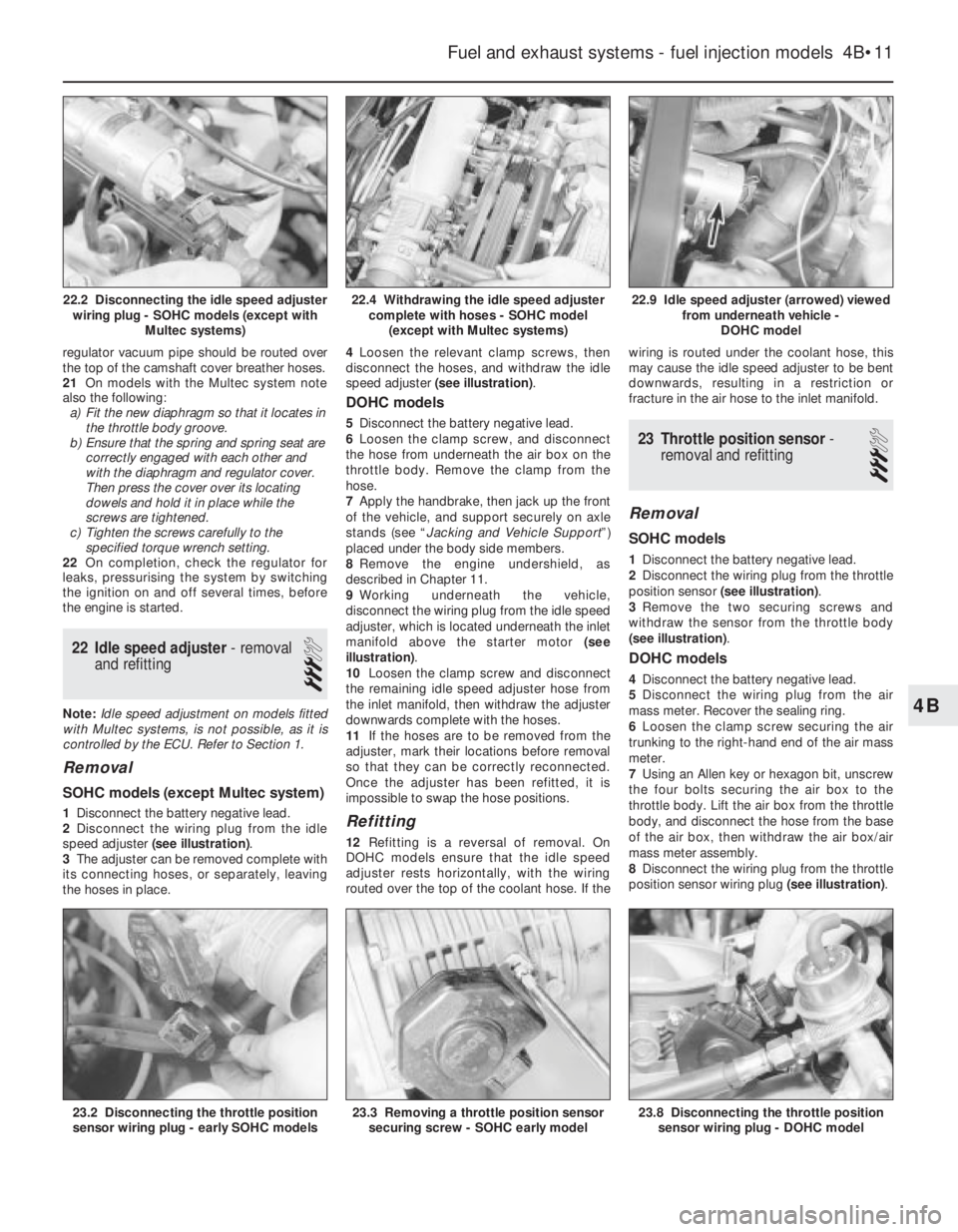

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the idle

speed adjuster (see illustration).

3The adjuster can be removed complete with

its connecting hoses, or separately, leaving

the hoses in place.4Loosen the relevant clamp screws, then

disconnect the hoses, and withdraw the idle

speed adjuster (see illustration).

DOHC models

5Disconnect the battery negative lead.

6Loosen the clamp screw, and disconnect

the hose from underneath the air box on the

throttle body. Remove the clamp from the

hose.

7Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

placed under the body side members.

8Remove the engine undershield, as

described in Chapter 11.

9Working underneath the vehicle,

disconnect the wiring plug from the idle speed

adjuster, which is located underneath the inlet

manifold above the starter motor (see

illustration).

10Loosen the clamp screw and disconnect

the remaining idle speed adjuster hose from

the inlet manifold, then withdraw the adjuster

downwards complete with the hoses.

11If the hoses are to be removed from the

adjuster, mark their locations before removal

so that they can be correctly reconnected.

Once the adjuster has been refitted, it is

impossible to swap the hose positions.

Refitting

12Refitting is a reversal of removal. On

DOHC models ensure that the idle speed

adjuster rests horizontally, with the wiring

routed over the top of the coolant hose. If thewiring is routed under the coolant hose, this

may cause the idle speed adjuster to be bent

downwards, resulting in a restriction or

fracture in the air hose to the inlet manifold.

23Throttle position sensor -

removal and refitting

3

Removal

SOHC models

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the throttle

position sensor (see illustration).

3Remove the two securing screws and

withdraw the sensor from the throttle body

(see illustration).

DOHC models

4Disconnect the battery negative lead.

5Disconnect the wiring plug from the air

mass meter. Recover the sealing ring.

6Loosen the clamp screw securing the air

trunking to the right-hand end of the air mass

meter.

7Using an Allen key or hexagon bit, unscrew

the four bolts securing the air box to the

throttle body. Lift the air box from the throttle

body, and disconnect the hose from the base

of the air box, then withdraw the air box/air

mass meter assembly.

8Disconnect the wiring plug from the throttle

position sensor wiring plug (see illustration).

Fuel and exhaust systems - fuel injection models 4B•11

22.9 Idle speed adjuster (arrowed) viewed

from underneath vehicle -

DOHC model

23.8 Disconnecting the throttle position

sensor wiring plug - DOHC model23.3 Removing a throttle position sensor

securing screw - SOHC early model23.2 Disconnecting the throttle position

sensor wiring plug - early SOHC models

22.4 Withdrawing the idle speed adjuster

complete with hoses - SOHC model

(except with Multec systems)22.2 Disconnecting the idle speed adjuster

wiring plug - SOHC models (except with

Multec systems)

4B

Page 167 of 525

23Disconnect the wiring harness housing

from the fuel injectors, and move it to one

side, taking care not to strain the wiring. Pull

up on the wiring harness housing, and

compress the wiring plug retaining clips to

release the housing from the injectors.

24Unscrew and remove the two fuel rail

securing nuts, and withdraw the fuel rail

complete with fuel injectors from the inlet

manifold. Note the position of the earth leads

on the fuel rail securing studs (see

illustration).

25To remove an injector from the fuel rail,

prise out the metal securing clip using a

screwdriver, then pull the injector from the fuel

rail

Refitting

26Refitting is as described in paragraphs 8

to 11 inclusive.

29Fuel injector (Multec system)

- removal and refitting

3

Removal

1Depressurise the fuel system (see Sec

tion 8).

2Remove the air box (see Section 5).

3Disconnect the battery earth lead.

4Disconnect the wiring plug from the fuel

injector (see illustration).

5Undo the Torx-type screw (size TX 20)

securing the fuel injector retainer to the top ofthe throttle body, remove the retainer and lift

out the injector (see illustration). Remove

and discard the injector sealing rings.

Refitting

6Refitting is the reverse of the removal

procedure, noting the following points.

a)Always renew both sealing rings; apply a

smear of grease to each to ease injector

refitting (see illustration).

b)Refit the injector so that its wiring

terminals point to the rear of the vehicle;

locate the edge of the retainer securely in

the groove at the top of the injector.

c)Apply a few drops of a thread-locking

compound to the screw threads, then

tighten it carefully to the specified torque

wrench setting.

d)Switch on the ignition and check carefully

for signs of fuel leaks; if any signs of

leakage are detected, the problem must

be rectified before the engine is started.

30Fuel injector (Multec system)

- testing

3

1A simple test of the injector’s windings is

possible for those who have a multi-meter of

sufficient sensitivity. First disconnect the

injector wiring plug as described in Section 29,

then connect the meter (set to the appropriate

resistance scale) across the injector’s

terminals and note the reading obtained.

2On C18 NZ engines, the reading should be

within the specified tolerance; similar results

can be expected on C16NZ, C16NZ2, and

X16 SZ engines.

3If the reading differs significantly from the

specified value, indicating either shorted or

open circuit windings, the injector must be

renewed.

4Note that this is only a test of the injector’s

electrical condition; it does not test its spray

pattern or performance. If the injector is

thought to be faulty it is always worth trying a

well known injector-cleaning treatment. If this

fails, the vehicle must be taken to a Vauxhall

dealer for full testing on the special test

equipment.

31Throttle body (except Multec

system) - removal and refitting

3

Note:Refer to Section 2 before proceeding. A

new throttle body gasket must be used on

refitting

SOHC

Removal

1Disconnect the battery negative lead.

2Loosen the clamp screws securing the air

trunking to the throttle body and the airflow

meter, then withdraw the air trunking.

3Loosen the clamp screw, and disconnect

the idle speed adjuster hose from the throttle

body.

4Disconnect the camshaft cover breather

hose from the throttle body.

5Disconnect the coolant hoses from the

throttle body. Be prepared for coolant

spillage, and clamp or plug the open ends of

the hoses, to prevent further coolant loss.

6Disconnect the wiring plug from the throttle

position sensor.

7Release the securing clip, then disconnect

the throttle cable end balljoint from the throttle

valve lever.

8Slide the throttle cable grommet from the

bracket on the inlet manifold, then unhook the

throttle return spring from the bracket (see

illustration).

9Make a final check to ensure that all relevant

hoses and wires have been disconnected and

moved clear of the throttle body.

4B•14Fuel and exhaust systems - fuel injection models

28.24 Earth leads secured to fuel rail stud

(arrowed) - DOHC model29.5 Unscrewing the injector retainer Torx

screw

31.8 Unhook the throttle return spring

from the bracket on the inlet manifold

(inlet manifold removed for clarity)29.6 Renew injector sealing rings

(arrowed)

29.4 Disconnecting the fuel injector wiring

plug - Multec systems

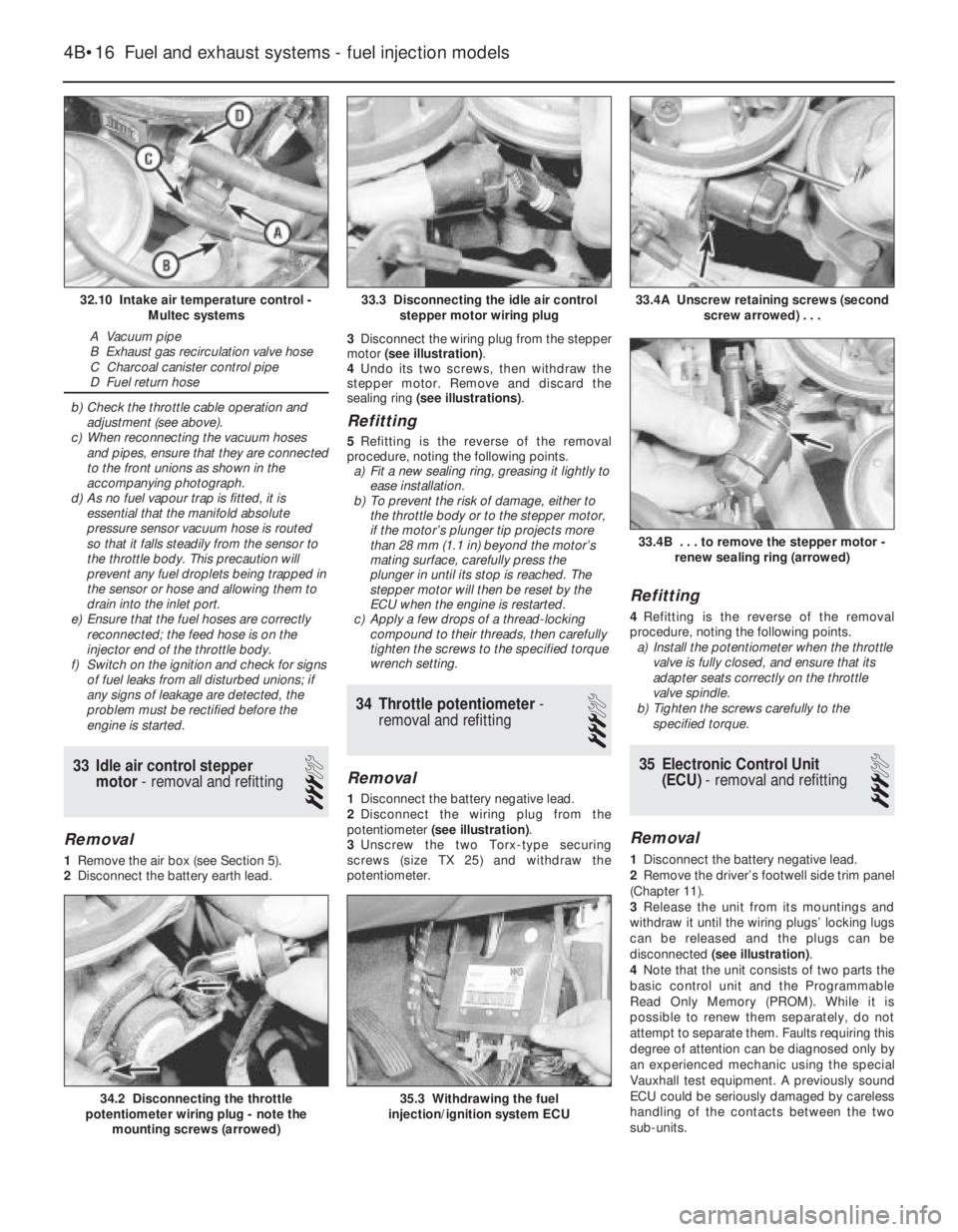

Page 169 of 525

b)Check the throttle cable operation and

adjustment (see above).

c)When reconnecting the vacuum hoses

and pipes, ensure that they are connected

to the front unions as shown in the

accompanying photograph.

d)As no fuel vapour trap is fitted, it is

essential that the manifold absolute

pressure sensor vacuum hose is routed

so that it falls steadily from the sensor to

the throttle body. This precaution will

prevent any fuel droplets being trapped in

the sensor or hose and allowing them to

drain into the inlet port.

e)Ensure that the fuel hoses are correctly

reconnected; the feed hose is on the

injector end of the throttle body.

f)Switch on the ignition and check for signs

of fuel leaks from all disturbed unions; if

any signs of leakage are detected, the

problem must be rectified before the

engine is started.

33Idle air control stepper

motor - removal and refitting

3

Removal

1Remove the air box (see Section 5).

2Disconnect the battery earth lead.3Disconnect the wiring plug from the stepper

motor (see illustration).

4Undo its two screws, then withdraw the

stepper motor. Remove and discard the

sealing ring (see illustrations).

Refitting

5Refitting is the reverse of the removal

procedure, noting the following points.

a)Fit a new sealing ring, greasing it lightly to

ease installation.

b)To prevent the risk of damage, either to

the throttle body or to the stepper motor,

if the motor’s plunger tip projects more

than 28 mm (1.1 in) beyond the motor’s

mating surface, carefully press the

plunger in until its stop is reached. The

stepper motor will then be reset by the

ECU when the engine is restarted.

c)Apply a few drops of a thread-locking

compound to their threads, then carefully

tighten the screws to the specified torque

wrench setting.

34Throttle potentiometer -

removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the

potentiometer (see illustration).

3Unscrew the two Torx-type securing

screws (size TX 25) and withdraw the

potentiometer.

Refitting

4Refitting is the reverse of the removal

procedure, noting the following points.

a)Install the potentiometer when the throttle

valve is fully closed, and ensure that its

adapter seats correctly on the throttle

valve spindle.

b)Tighten the screws carefully to the

specified torque.

35Electronic Control Unit

(ECU) - removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the driver’s footwell side trim panel

(Chapter 11).

3Release the unit from its mountings and

withdraw it until the wiring plugs’ locking lugs

can be released and the plugs can be

disconnected (see illustration).

4Note that the unit consists of two parts the

basic control unit and the Programmable

Read Only Memory (PROM). While it is

possible to renew them separately, do not

attempt to separate them. Faults requiring this

degree of attention can be diagnosed only by

an experienced mechanic using the special

Vauxhall test equipment. A previously sound

ECU could be seriously damaged by careless

handling of the contacts between the two

sub-units.

4B•16Fuel and exhaust systems - fuel injection models

32.10 Intake air temperature control -

Multec systems

A Vacuum pipe

B Exhaust gas recirculation valve hose

C Charcoal canister control pipe

D Fuel return hose

33.4A Unscrew retaining screws (second

screw arrowed) . . .

35.3 Withdrawing the fuel

injection/ignition system ECU34.2 Disconnecting the throttle

potentiometer wiring plug - note the

mounting screws (arrowed)

33.4B . . . to remove the stepper motor -

renew sealing ring (arrowed)

33.3 Disconnecting the idle air control

stepper motor wiring plug

Page 170 of 525

Refitting

5Refitting is a reversal of the removal

procedure, ensuring that the wiring plugs are

correctly reconnected and that the unit is

located securely.

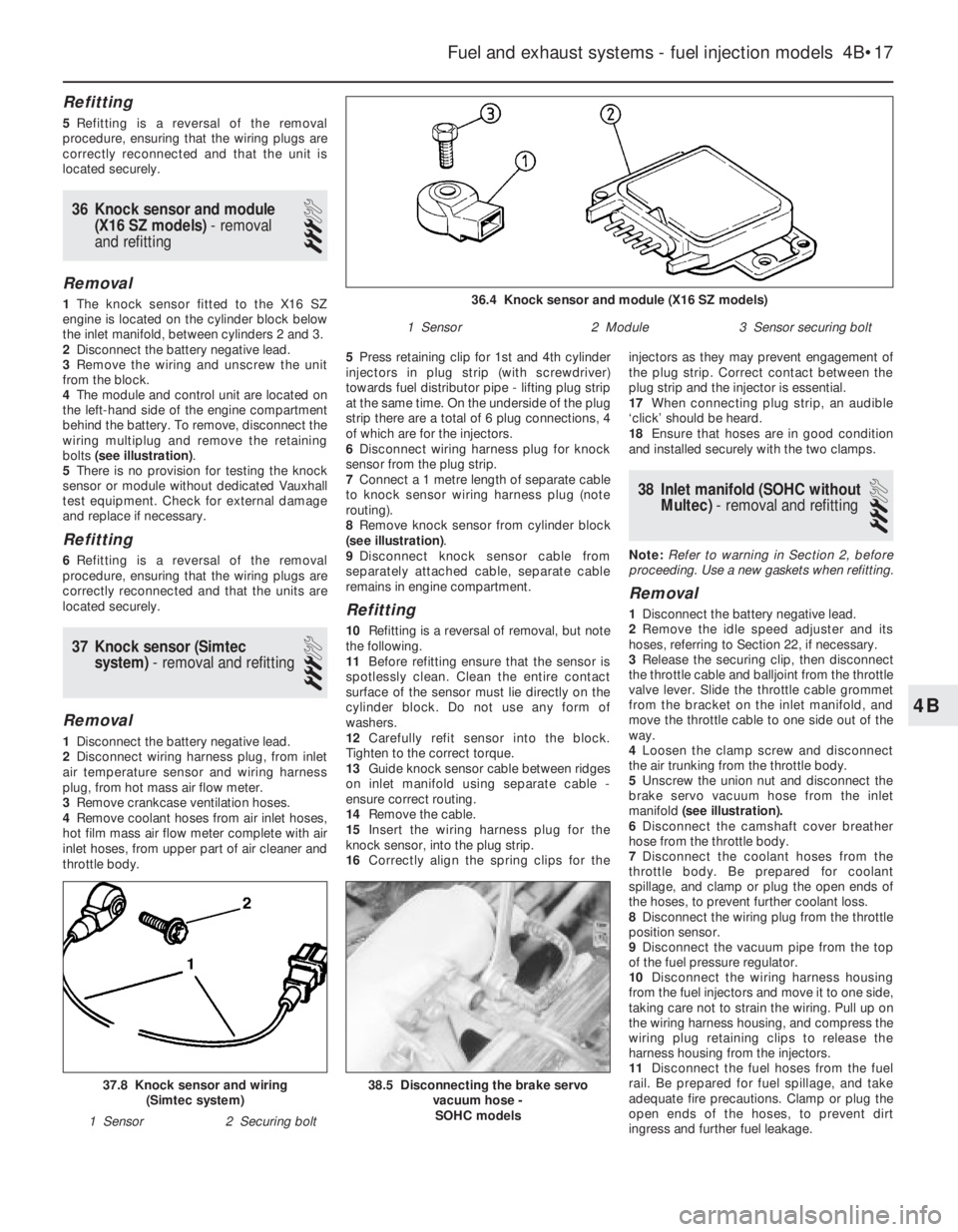

36Knock sensor and module

(X16 SZ models) - removal

and refitting

3

Removal

1The knock sensor fitted to the X16 SZ

engine is located on the cylinder block below

the inlet manifold, between cylinders 2 and 3.

2Disconnect the battery negative lead.

3Remove the wiring and unscrew the unit

from the block.

4The module and control unit are located on

the left-hand side of the engine compartment

behind the battery. To remove, disconnect the

wiring multiplug and remove the retaining

bolts (see illustration).

5There is no provision for testing the knock

sensor or module without dedicated Vauxhall

test equipment. Check for external damage

and replace if necessary.

Refitting

6Refitting is a reversal of the removal

procedure, ensuring that the wiring plugs are

correctly reconnected and that the units are

located securely.

37Knock sensor (Simtec

system) - removal and refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect wiring harness plug, from inlet

air temperature sensor and wiring harness

plug, from hot mass air flow meter.

3Remove crankcase ventilation hoses.

4Remove coolant hoses from air inlet hoses,

hot film mass air flow meter complete with air

inlet hoses, from upper part of air cleaner and

throttle body.5Press retaining clip for 1st and 4th cylinder

injectors in plug strip (with screwdriver)

towards fuel distributor pipe - lifting plug strip

at the same time. On the underside of the plug

strip there are a total of 6 plug connections, 4

of which are for the injectors.

6Disconnect wiring harness plug for knock

sensor from the plug strip.

7Connect a 1 metre length of separate cable

to knock sensor wiring harness plug (note

routing).

8Remove knock sensor from cylinder block

(see illustration).

9Disconnect knock sensor cable from

separately attached cable, separate cable

remains in engine compartment.

Refitting

10Refitting is a reversal of removal, but note

the following.

11Before refitting ensure that the sensor is

spotlessly clean. Clean the entire contact

surface of the sensor must lie directly on the

cylinder block. Do not use any form of

washers.

12Carefully refit sensor into the block.

Tighten to the correct torque.

13Guide knock sensor cable between ridges

on inlet manifold using separate cable -

ensure correct routing.

14Remove the cable.

15Insert the wiring harness plug for the

knock sensor, into the plug strip.

16Correctly align the spring clips for theinjectors as they may prevent engagement of

the plug strip. Correct contact between the

plug strip and the injector is essential.

17When connecting plug strip, an audible

‘click’ should be heard.

18Ensure that hoses are in good condition

and installed securely with the two clamps.

38Inlet manifold (SOHC without

Multec) - removal and refitting

3

Note:Refer to warning in Section 2, before

proceeding. Use a new gaskets when refitting.

Removal

1Disconnect the battery negative lead.

2Remove the idle speed adjuster and its

hoses, referring to Section 22, if necessary.

3Release the securing clip, then disconnect

the throttle cable and balljoint from the throttle

valve lever. Slide the throttle cable grommet

from the bracket on the inlet manifold, and

move the throttle cable to one side out of the

way.

4Loosen the clamp screw and disconnect

the air trunking from the throttle body.

5Unscrew the union nut and disconnect the

brake servo vacuum hose from the inlet

manifold(see illustration).

6Disconnect the camshaft cover breather

hose from the throttle body.

7Disconnect the coolant hoses from the

throttle body. Be prepared for coolant

spillage, and clamp or plug the open ends of

the hoses, to prevent further coolant loss.

8Disconnect the wiring plug from the throttle

position sensor.

9Disconnect the vacuum pipe from the top

of the fuel pressure regulator.

10Disconnect the wiring harness housing

from the fuel injectors and move it to one side,

taking care not to strain the wiring. Pull up on

the wiring harness housing, and compress the

wiring plug retaining clips to release the

harness housing from the injectors.

11Disconnect the fuel hoses from the fuel

rail. Be prepared for fuel spillage, and take

adequate fire precautions. Clamp or plug the

open ends of the hoses, to prevent dirt

ingress and further fuel leakage.

Fuel and exhaust systems - fuel injection models 4B•17

38.5 Disconnecting the brake servo

vacuum hose -

SOHC models37.8 Knock sensor and wiring

(Simtec system)

1 Sensor2 Securing bolt

36.4 Knock sensor and module (X16 SZ models)

1 Sensor2 Module3 Sensor securing bolt

4B