sensor OPEL VECTRA 1988 Service Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 171 of 525

12Unscrew and remove the top alternator

mounting nut and bolt.

13Make a final check to ensure that all

relevant hoses, pipes and wires have been

disconnected.

14Unscrew the securing nuts, and withdraw

the manifold from the cylinder head. Recover

the gasket (see illustrations).

15It is possible that some of the manifold

studs may be unscrewed from the cylinder

head when the manifold securing nuts are

unscrewed. In this event, the studs should be

screwed back into the cylinder head once the

manifold has been removed, using two

manifold nuts locked together.

16If desired, the ancillary components can

be removed from the manifold, referring to the

relevant Chapter.

Refitting

17Refitting is a reversal of removal,

remembering the following points.

18Where applicable refit any ancillary

components to the manifold, with reference to

relevant Sections of Chapters 4A or 4B.

19If the alternator mounting bracket has

been unbolted from the manifold, refit it

before refitting the manifold, as access to the

securing bolt is extremely limited once the

manifold is in place.

20Refit the manifold using a new gasket,

and tighten the securing nuts to the specified

torque.

21Ensure that all relevant hoses, pipes and

wires are correctly reconnected.

22On completion, check and if necessary

top-up the coolant level, (Chapter 3).

23Check and if necessary adjust the throttle

cable free play, as described in Chapters 4A

or 4B, as applicable.

24If any of the fuel system components have

been disturbed or renewed, check and if

necessary adjust the idle mixture, as

described in Chapters 4A or 4B, as applicable.

39Inlet manifold (SOHCwith

Multec) - removal and refitting

3

Removal

1Depressurise the fuel system Section 8).

2Remove the air box (see Section 5).

3Disconnect the battery negative lead.

4Either remove the throttle body assembly

(see Section 32), or disconnect the throttle

cable, wiring, fuel and vacuum hoses and

pipes to allow the manifold to be removed

with the throttle body.

5Drain the cooling system (see Chapter 3).

6Continue as described in Chapter 4A,

Section 26, paragraph 4 onwards.

Refitting

7Refitting is the reverse of the removal

procedure; renew all gaskets and seals

disturbed.

40Inlet manifold (DOHC

models) - removal and

refitting

3

Removal

1Disconnect the battery negative lead.

2Disconnect the wiring plug from the air

mass meter. Recover the sealing ring.

3Loosen the clamp screw securing the air

trunking to the right-hand end of the air mass

meter.

4Using an Allen key or hexagon bit, unscrew

the four bolts securing the air box to the

throttle body. Lift the air box from the throttle

body, and disconnect the hose from the base

of the air box then withdraw the air box/air

mass meter assembly.

5Disconnect the wiring plug from the throttle

position sensor.

6Slide the throttle cable end from the throttle

valve lever. Then pull the cable end grommet

from the bracket on the inlet manifold and

move the throttle cable to one side out of the

way.

7Disconnect the two breather hoses from the

rear of the camshaft cover. Disconnect the

larger hose from the throttle body, and

remove the hose completely.

8Position a wad of rag beneath one of the

fuel hose unions on the fuel rail, to absorb the

fuel that will be released as the union is

disconnected.

9Slowly loosen the fuel hose union, to

gradually relieve the pressure in the fuel feed

line, then disconnect the hose from the fuel

rail. Be prepared for fuel spillage, and take

adequate fire precautions. Plug the end of the

fuel hose, to prevent dirt ingress and further

fuel leakage.

10Repeat paragraphs 9 and 10 for the

remaining fuel hose-to-fuel rail union.

11Disconnect the vacuum pipe from the top

of the fuel pressure regulator.

12Disconnect the wiring harness housing

from the fuel injectors and move it to one side,

taking care not to strain the wiring. Pull up on

the wiring harness housing, and compress the

wiring plug retaining clips to release the

housing from the injectors.

13Unscrew the union nut, and disconnectthe brake servo vacuum hose from the left-

hand side of the inlet manifold (see

illustration).

14Unscrew the retaining nut, and remove

the fuel hose bracket from the left-hand side

of the throttle body.

15Unscrew the securing nuts, and

disconnect the earth leads from the fuel rail

securing studs at either end of the fuel rail.

16Unscrew the securing bolt, and remove

the cable/hose bracket from the left-hand end

of the inlet manifold.

17Remove the idle speed adjuster, as

described in Section 22.

18Unscrew and remove the top alternator

mounting nut and bolt.

19Make a final check to ensure that all

relevant hoses, pipes and wires have been

disconnected.

20Unscrew the securing nuts, and withdraw

the manifold from the cylinder head. Recover

the gasket.

21It is possible that some of the manifold

studs may be unscrewed from the cylinder

head when the manifold securing nuts are

unscrewed. In this event, the studs should be

screwed back into the cylinder head once the

manifold has been removed, using two

manifold nuts locked together.

22If desired, the ancillary components can

be removed from the manifold, with reference

to the relevant Sections of Chapters 4A or 4B.

Refitting

23Refitting is a reversal of the removal

procedure.

4B•18Fuel and exhaust systems - fuel injection models

38.14A Unscrew the securing nuts

40.13 Brake servo vacuum hose

connection at inlet manifold (arrowed) -

DOHC models

38.14B ...and withdraw the inlet manifold -

SOHC models

Page 176 of 525

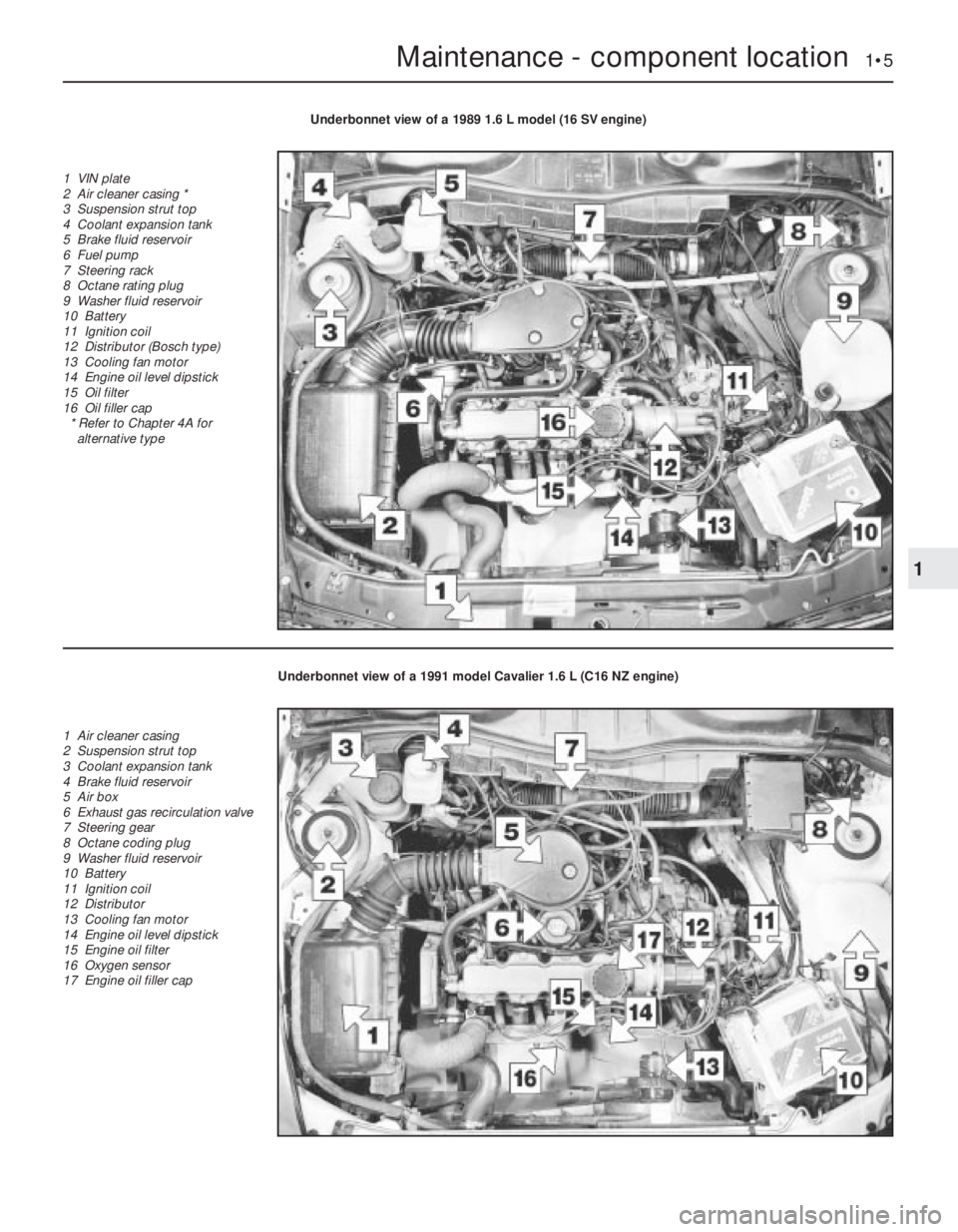

Maintenance - component location 1•5

1

Underbonnet view of a 1989 1.6 L model (16 SV engine)

1 VIN plate

2 Air cleaner casing *

3 Suspension strut top

4 Coolant expansion tank

5 Brake fluid reservoir

6 Fuel pump

7 Steering rack

8 Octane rating plug

9 Washer fluid reservoir

10 Battery

11 Ignition coil

12 Distributor (Bosch type)

13 Cooling fan motor

14 Engine oil level dipstick

15 Oil filter

16 Oil filler cap

* Refer to Chapter 4A for

alternative type

Underbonnet view of a 1991 model Cavalier 1.6 L (C16 NZ engine)

1 Air cleaner casing

2 Suspension strut top

3 Coolant expansion tank

4 Brake fluid reservoir

5 Air box

6 Exhaust gas recirculation valve

7 Steering gear

8 Octane coding plug

9 Washer fluid reservoir

10 Battery

11 Ignition coil

12 Distributor

13 Cooling fan motor

14 Engine oil level dipstick

15 Engine oil filter

16 Oxygen sensor

17 Engine oil filler cap

Page 179 of 525

1Introduction

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master maintenance

schedule, followed by Sections dealing specifically

with each task in the schedule. Visual checks,

adjustments, component renewal and other helpful

items are included. Refer to the accompanying

illustrations of the engine compartment and the

underside of the vehicle for the locations of the

various components.

Servicing your vehicle according to the

mileage/time maintenance schedule and the

following Sections will provide a planned

maintenance programme, which should result in a

long and reliable service life. This is a comprehensiveplan, so maintaining some items but not others at

the specified service intervals, will not produce the

same results.

As you service your vehicle, you will

discover that many of the procedures can -

and should - be grouped together, because of

the particular procedure being performed, or

because of the proximity of two otherwise-

unrelated components to one another. For

example, if the vehicle is raised for any

reason, the exhaust can be inspected at the

same time as the suspension and steering

components.

The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

Sections relevant to the work to be carried

out, then make a list and gather all the parts

and tools required. If a problem is found, seek

advice from a parts specialist, or a dealer

service department.

2Intensive maintenance

If, from the time the vehicle is new, routine

maintenance schedule is followed closely,

frequent checks made of fluid levels and high-

wear items, as recommended, the engine will

be kept in relatively good running condition.

The need for additional work will be minimised

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

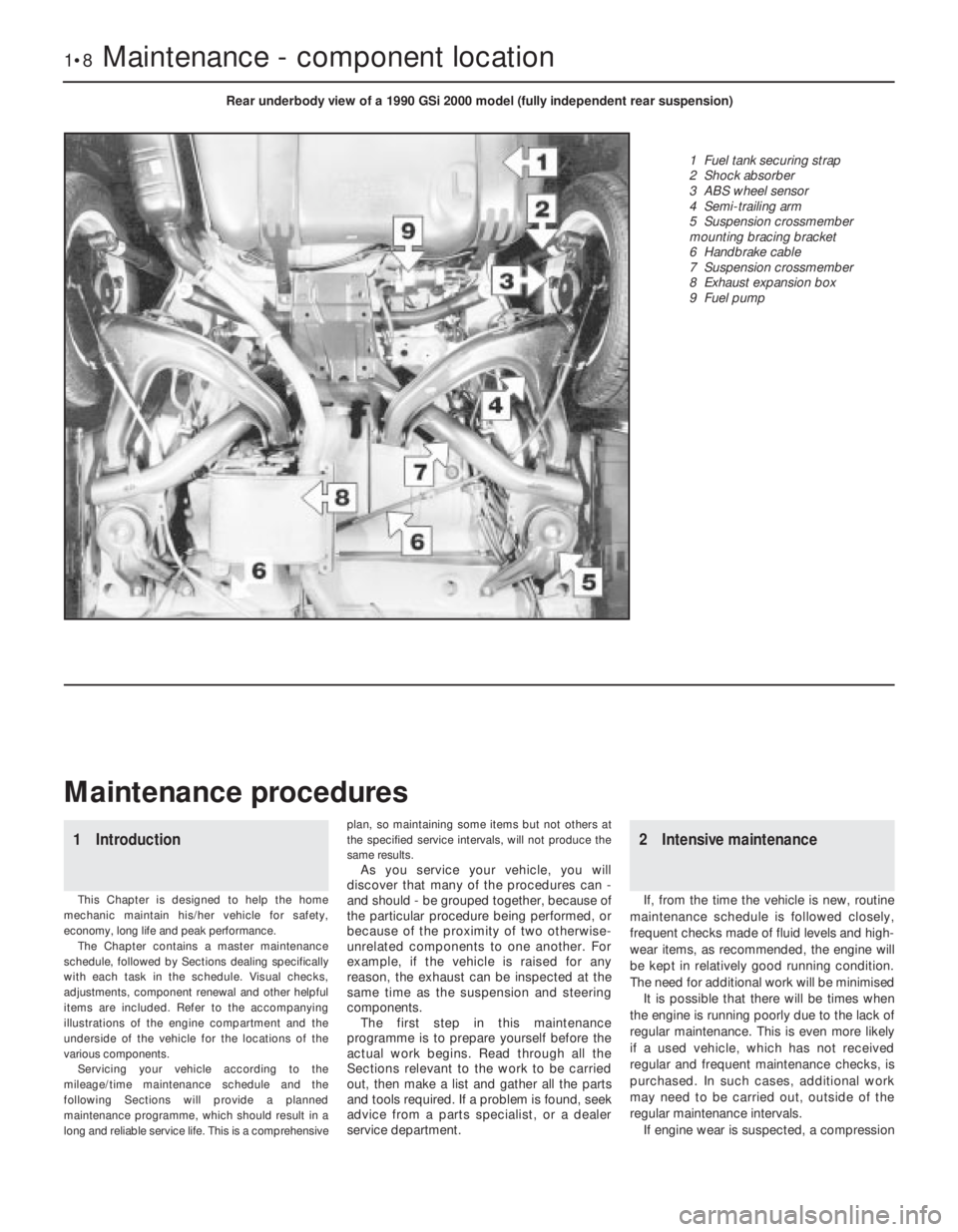

1•8Maintenance - component location

Rear underbody view of a 1990 GSi 2000 model (fully independent rear suspension)

1 Fuel tank securing strap

2 Shock absorber

3 ABS wheel sensor

4 Semi-trailing arm

5 Suspension crossmember

mounting bracing bracket

6 Handbrake cable

7 Suspension crossmember

8 Exhaust expansion box

9 Fuel pump

Maintenance procedures

Page 189 of 525

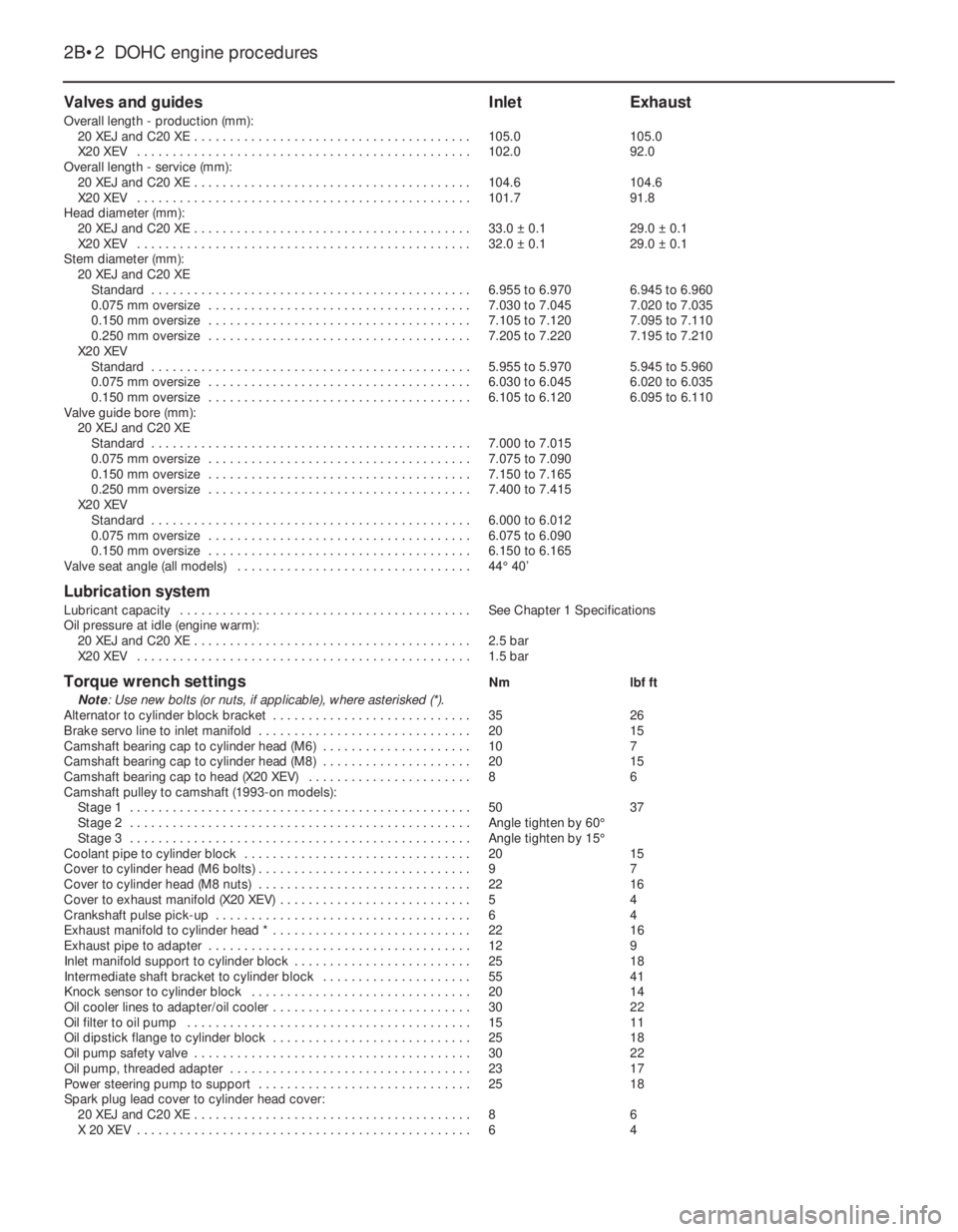

Valves and guidesInletExhaust

Overall length - production (mm):

20 XEJ and C20 XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105.0105.0

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102.092.0

Overall length - service (mm):

20 XEJ and C20 XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.6104.6

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101.791.8

Head diameter (mm):

20 XEJ and C20 XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.0 ±0.129.0 ±0.1

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32.0 ±0.129.0 ±0.1

Stem diameter (mm):

20 XEJ and C20 XE

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.955 to 6.9706.945 to 6.960

0.075 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.030 to 7.0457.020 to 7.035

0.150 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.105 to 7.1207.095 to 7.110

0.250 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.205 to 7.2207.195 to 7.210

X20 XEV

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.955 to 5.9705.945 to 5.960

0.075 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.030 to 6.0456.020 to 6.035

0.150 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.105 to 6.1206.095 to 6.110

Valve guide bore (mm):

20 XEJ and C20 XE

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.000 to 7.015

0.075 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.075 to 7.090

0.150 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.150 to 7.165

0.250 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.400 to 7.415

X20 XEV

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.000 to 6.012

0.075 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.075 to 6.090

0.150 mm oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.150 to 6.165

Valve seat angle (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44°40’

Lubrication system

Lubricant capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1 Specifications

Oil pressure at idle (engine warm):

20 XEJ and C20 XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5 bar

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 bar

Torque wrench settingsNmlbf ft

Note: Use new bolts (or nuts, if applicable), where asterisked (*).

Alternator to cylinder block bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . .3526

Brake servo line to inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

Camshaft bearing cap to cylinder head (M6) . . . . . . . . . . . . . . . . . . . . .107

Camshaft bearing cap to cylinder head (M8) . . . . . . . . . . . . . . . . . . . . .2015

Camshaft bearing cap to head (X20 XEV) . . . . . . . . . . . . . . . . . . . . . . .86

Camshaft pulley to camshaft (1993-on models):

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5037

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 60°

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15°

Coolant pipe to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

Cover to cylinder head (M6 bolts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Cover to cylinder head (M8 nuts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Cover to exhaust manifold (X20 XEV) . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Crankshaft pulse pick-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Exhaust manifold to cylinder head * . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Exhaust pipe to adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Inlet manifold support to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . .2518

Intermediate shaft bracket to cylinder block . . . . . . . . . . . . . . . . . . . . .5541

Knock sensor to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2014

Oil cooler lines to adapter/oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Oil filter to oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1511

Oil dipstick flange to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Oil pump safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Oil pump, threaded adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2317

Power steering pump to support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Spark plug lead cover to cylinder head cover:

20 XEJ and C20 XE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

X 20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

2B•2DOHC engine procedures

Page 194 of 525

pitting. If evident, the cylinder head and all

bearing caps must be renewed as a matched

set, as there is no provision for refacing if the

bearing caps cannot be renewed individually.

8The camshaft(s) should show no marks or

scoring on the journal or cam lobe surfaces. if

evident, renew the camshaft(s).

9It is advisable to renew the camshaft front

oil seal(s) as a matter of course. Prise the old

seal(s) from the front of the camshaft(s) and

discard them.

Refitting

10Begin refitting by liberally coating the

contact faces of the hydraulic valve lifters and

the camshaft(s) with molybdenum disulphide

paste.

11Coat the mating faces of the front and

rear bearing caps with sealing compound and

refit the bearing caps in their original positions

as noted during removal.

12Tighten the camshaft bearing cap nuts to

the specified torque in half-turn stages, as

when loosening the nuts. Note that when

refitting the exhaust camshaft, the two smaller

rear bearing cap securing nuts should be

tightened after all the main camshaft bearing

cap nuts have been tightened. Note also that

the two smaller nuts should be tightened to a

lower torque wrench setting than the main

nuts.

13Turn the camshaft until the locating peg

for the camshaft sprocket is uppermost, then

lubricate the lips of a rear camshaft front oil

seal with a little grease, and fit the oil seal,

using a tube or socket of similar diameter with

a washer and the camshaft sprocket bolt.

Screw the camshaft sprocket bolt into the end

of the camshaft to draw the oil seal into

position on its shoulder.

14Repeat the procedure for the remaining

camshaft.

15Refit the distributor with reference to

Chapter 5. Fit a new timing belt and the

camshaft sprockets, then adjust the timing

belt as described in Section 4 or 5, as

applicable.

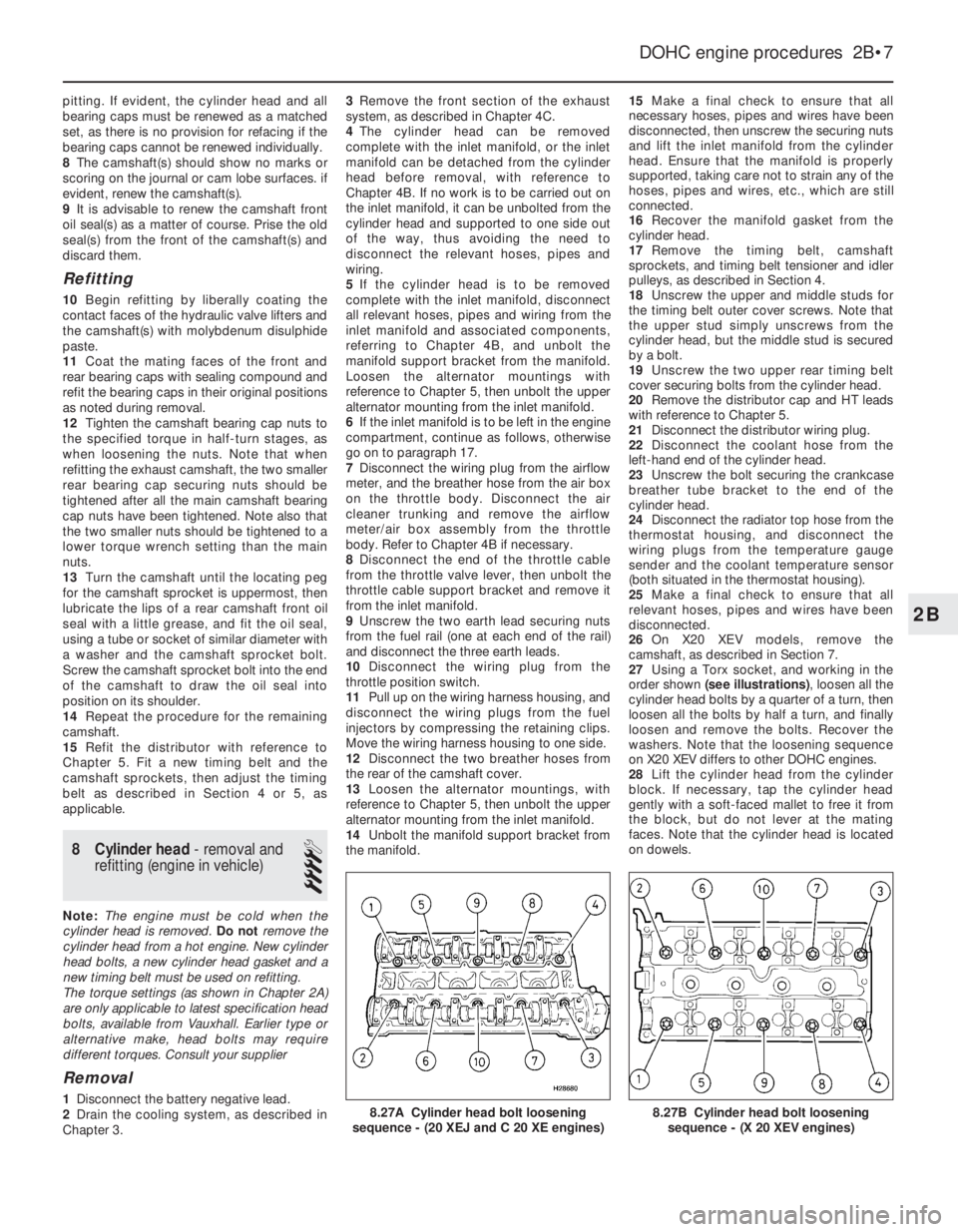

8Cylinder head -removal and

refitting (engine in vehicle)

4

Note: The engine must be cold when the

cylinder head is removed. Do not remove the

cylinder head from a hot engine. New cylinder

head bolts, a new cylinder head gasket and a

new timing belt must be used on refitting.

The torque settings (as shown in Chapter 2A)

are only applicable to latest specification head

bolts, available from Vauxhall. Earlier type or

alternative make, head bolts may require

different torques. Consult your supplier

Removal

1Disconnect the battery negative lead.

2Drain the cooling system, as described in

Chapter 3.3Remove the front section of the exhaust

system, as described in Chapter 4C.

4The cylinder head can be removed

complete with the inlet manifold, or the inlet

manifold can be detached from the cylinder

head before removal, with reference to

Chapter 4B. If no work is to be carried out on

the inlet manifold, it can be unbolted from the

cylinder head and supported to one side out

of the way, thus avoiding the need to

disconnect the relevant hoses, pipes and

wiring.

5If the cylinder head is to be removed

complete with the inlet manifold, disconnect

all relevant hoses, pipes and wiring from the

inlet manifold and associated components,

referring to Chapter 4B, and unbolt the

manifold support bracket from the manifold.

Loosen the alternator mountings with

reference to Chapter 5, then unbolt the upper

alternator mounting from the inlet manifold.

6If the inlet manifold is to be left in the engine

compartment, continue as follows, otherwise

go on to paragraph 17.

7Disconnect the wiring plug from the airflow

meter, and the breather hose from the air box

on the throttle body. Disconnect the air

cleaner trunking and remove the airflow

meter/air box assembly from the throttle

body. Refer to Chapter 4B if necessary.

8Disconnect the end of the throttle cable

from the throttle valve lever, then unbolt the

throttle cable support bracket and remove it

from the inlet manifold.

9Unscrew the two earth lead securing nuts

from the fuel rail (one at each end of the rail)

and disconnect the three earth leads.

10Disconnect the wiring plug from the

throttle position switch.

11Pull up on the wiring harness housing, and

disconnect the wiring plugs from the fuel

injectors by compressing the retaining clips.

Move the wiring harness housing to one side.

12Disconnect the two breather hoses from

the rear of the camshaft cover.

13Loosen the alternator mountings, with

reference to Chapter 5, then unbolt the upper

alternator mounting from the inlet manifold.

14Unbolt the manifold support bracket from

the manifold.15Make a final check to ensure that all

necessary hoses, pipes and wires have been

disconnected, then unscrew the securing nuts

and lift the inlet manifold from the cylinder

head. Ensure that the manifold is properly

supported, taking care not to strain any of the

hoses, pipes and wires, etc., which are still

connected.

16Recover the manifold gasket from the

cylinder head.

17Remove the timing belt, camshaft

sprockets, and timing belt tensioner and idler

pulleys, as described in Section 4.

18Unscrew the upper and middle studs for

the timing belt outer cover screws. Note that

the upper stud simply unscrews from the

cylinder head, but the middle stud is secured

by a bolt.

19Unscrew the two upper rear timing belt

cover securing bolts from the cylinder head.

20Remove the distributor cap and HT leads

with reference to Chapter 5.

21Disconnect the distributor wiring plug.

22Disconnect the coolant hose from the

left-hand end of the cylinder head.

23Unscrew the bolt securing the crankcase

breather tube bracket to the end of the

cylinder head.

24Disconnect the radiator top hose from the

thermostat housing, and disconnect the

wiring plugs from the temperature gauge

sender and the coolant temperature sensor

(both situated in the thermostat housing).

25Make a final check to ensure that all

relevant hoses, pipes and wires have been

disconnected.

26On X20 XEV models, remove the

camshaft, as described in Section 7.

27Using a Torx socket, and working in the

order shown (see illustrations), loosen all the

cylinder head bolts by a quarter of a turn, then

loosen all the bolts by half a turn, and finally

loosen and remove the bolts. Recover the

washers. Note that the loosening sequence

on X20 XEV differs to other DOHC engines.

28Lift the cylinder head from the cylinder

block. If necessary, tap the cylinder head

gently with a soft-faced mallet to free it from

the block, but do not lever at the mating

faces. Note that the cylinder head is located

on dowels.

DOHC engine procedures 2B•7

8.27B Cylinder head bolt loosening

sequence - (X 20 XEV engines)8.27A Cylinder head bolt loosening

sequence - (20 XEJ and C 20 XE engines)

2B

Page 203 of 525

Torque wrench settings (continued)Nmlbf ft

Big-end bearing cap: *

C16 NZ2, 1.8 and 2.0 litre:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3526

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 45º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15º

Camshaft housing cover to housing . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Camshaft pulley to camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Camshaft thrust plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Coolant outlet to thermostat housing:

C 16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Coolant pump to cylinder block:

1.4 and 1.6 litre, (except C 16 NZ2) (M6) . . . . . . . . . . . . . . . . . . . . . .86

C16 NZ2, 1.8 and 2.0 litre (M8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Crankshaft sensor wheel:

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1310

Cylinder head to cylinder block: *

1.4 and 1.6 litre, (except C16 NZ2):

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 60º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 60º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 60º

C16 NZ2, 1.8 and 2.0 litre:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 90º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 90º

Drivebelt (ribbed) pulley/timing belt drive to crankshaft: *

1.4 and 1.6 litre, (except C16 NZ2):

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 45º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15º

Drivebelt pulley to timing belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

Drivebelt (ribbed) tensioner to cylinder block . . . . . . . . . . . . . . . . . . . . .2015

Drivebelt (ribbed) tensioner to support:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1813

Engine bracket to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

Engine bracket to transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

Engine mounting bracket to engine bracket . . . . . . . . . . . . . . . . . . . . . .6044

Engine mounting to engine mounting bracket . . . . . . . . . . . . . . . . . . . .6548

Engine mounting to front axle housing . . . . . . . . . . . . . . . . . . . . . . . . . .4030

Engine mounting to power steering pump support . . . . . . . . . . . . . . . .6044

Engine mounting to side member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6548

Exhaust manifold to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Exhaust pipe to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Flexplate to crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

Flywheel to crankshaft: *

1.4 and 1.6 litre, (except C16 NZ2):

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3526

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 30º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15º

C16 NZ2, 1.8 and 2.0 litre:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6548

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 30º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15º

Front timing belt cover to rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Fuel pump to camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1813

Guide sleeve, release bearing to transmission . . . . . . . . . . . . . . . . . . . .2216

Heat shield sleeves to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Inlet manifold to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Knock sensor to cylinder block (X16 SZ) . . . . . . . . . . . . . . . . . . . . . . . .1310

Main bearing cap: *

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5037

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 45º

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15º

Oil filter to oil pump/cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

2A•6SOHC engine procedures

Page 204 of 525

Oil pick-up pipe bracket to cylinder block . . . . . . . . . . . . . . . . . . . . . . .64

Oil pick-up pipe to oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Oil pipes to radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2216

Oil pressure switch to oil pump:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . .3022

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4030

Oil pressure relief valve to oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Oil pump cover to oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Oil pump to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Oxygen sensor to exhaust manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Power steering pump bracket to support:

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1813

Power steering pump to support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Right engine mounting to subframe . . . . . . . . . . . . . . . . . . . . . . . . . . . .6548

Shackle to alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Starter to cylinder block (M10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Starter to cylinder block (M12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

Sump:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . . .86

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1511

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Support to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3526

Temperature sender to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . .2015

Thermostat housing:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . . .107

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1511

Timing belt tensioner to oil pump:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Timing belt cover to oil pump/camshaft housing:

1.4 and 1.6 litre, (except C16 NZ2) . . . . . . . . . . . . . . . . . . . . . . . . . . .129

C16 NZ2, 1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Timing belt drive gear to crankshaft:

C16 NZ2, 1.8 and 2.0 litre:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13096

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by between 40º to 50º

Transmission to engine (M10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Transmission to engine (M12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

1General description

General

The engine is of four-cylinder, in-line single

or double overhead camshaft type (depending

on model), mounted transversely at the front

of the vehicle.

The crankshaft runs in five shell-type

bearings, and the centre bearing incorporates

a thrust bearing shell to control crankshaft

endfloat.

The connecting rods are attached to the

crankshaft by horizontally split shell-type

big-end bearings. On single overhead

camshaft (SOHC) models, the pistons are

attached to the connecting rods by gudgeon

pins, which are an interference fit in the

connecting rod small-end bore. The

aluminium alloy pistons are fitted with three

piston rings: two compression rings and an oil

control ring.

The camshaft on SOHC engines is driven

from the crankshaft by a toothed composite

rubber belt. Each cylinder has two valves (oneinlet and one exhaust), operated through

rocker arms that are supported at their pivot

ends by hydraulic self-adjusting valve lifters

(tappets).

The inlet and exhaust valves are each

closed by a single valve spring, and operate in

guides pressed into the cylinder head.

A gear-type oil pump is located in a housing

attached to the front of the cylinder block, and

is driven directly from the crankshaft. A

full-flow type oil filter is fitted.

The distributor is driven directly from the

end of the camshaft. On carburettor models,

the mechanical fuel pump is operated from

the front end of the camshaft. The coolant

pump is located at the front of the cylinder

block, and is driven by the timing belt.

Chapter 2A describes the SOHC engine

repair procedures. Many repairs and specifi-

cations to the DOHC engine are similar to the

2.0 litre SOHC. However where they differ,

details can be found in Chapter 2B.

Engine identification codes -

general

Before ordering spare parts, or carrying out

any repair or overhaul operations on the

engine, it is essential to identify the exactengine type being worked on. Later engines,

although outwardly similar in appearance,

often have significant differences in repair

procedures, even though they may be of the

same displacement and model year.

The following sub-Sections in this Chapter

are mainly specific to engine type, as will be

noted from the sub-Section headings. Check

the engine identification code first, which is

located on a horizontal surface on the exhaust

manifold side of the cylinder block, at the

distributor end. On later engines, the code is

on the cylinder block-to-transmission flange,

next to the engine oil dipstick.

2Crankcase ventilation

system - description and

maintenance

2

Description

1A crankcase ventilation system is fitted to

all models, but the systems differ in detail

depending on the model concerned.

2Oil fumes and blow-by gases (combustion

gases that have passed by the piston rings)

are drawn from the crankcase into the area of

SOHC engine procedures 2A•7

2A

Page 206 of 525

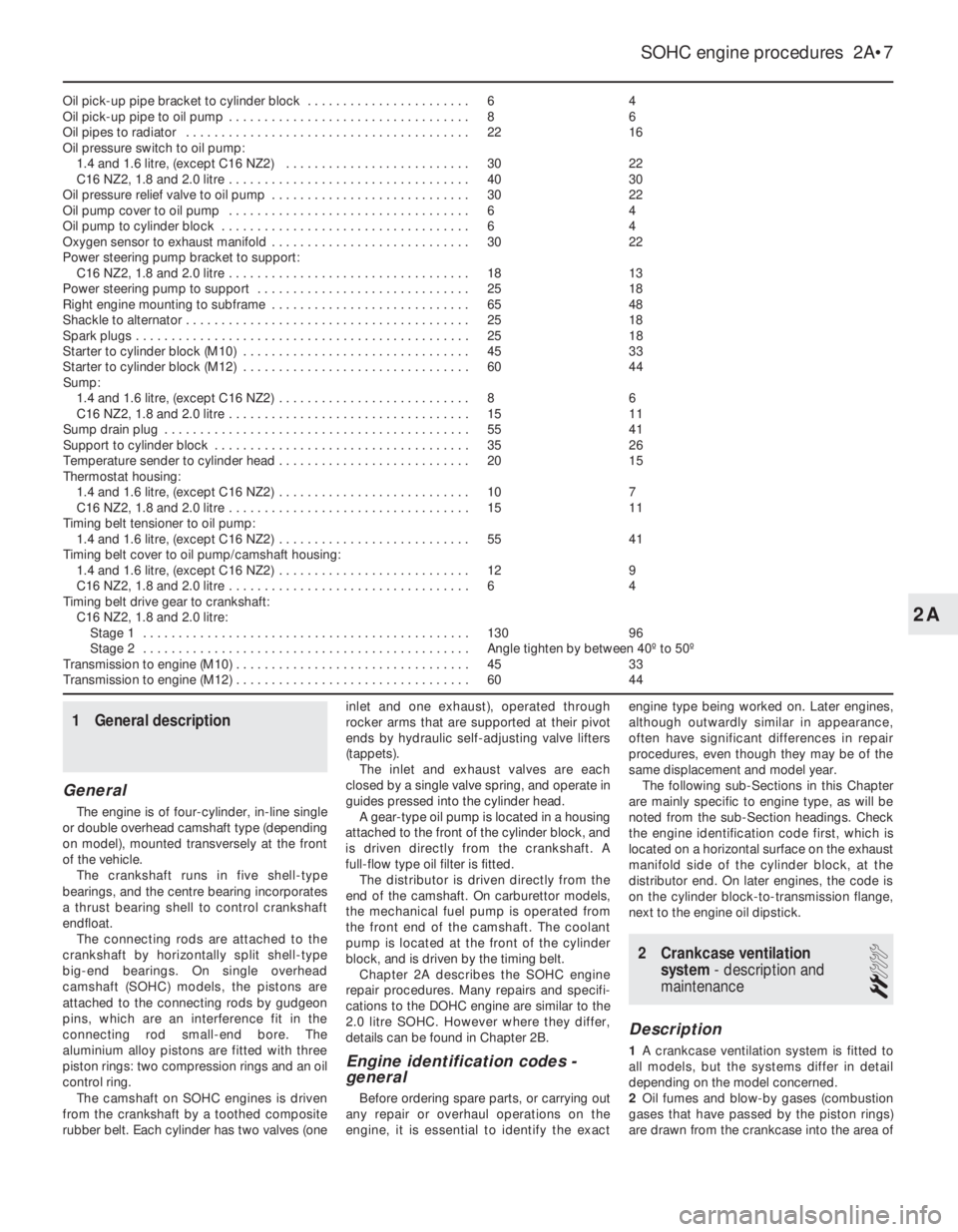

12Disconnect the pressure sensor vacuum

pipe from the carburettor (see illustration).

13Remove the coolant hose(s) from the inlet

manifold and/or throttle body, as applicable.

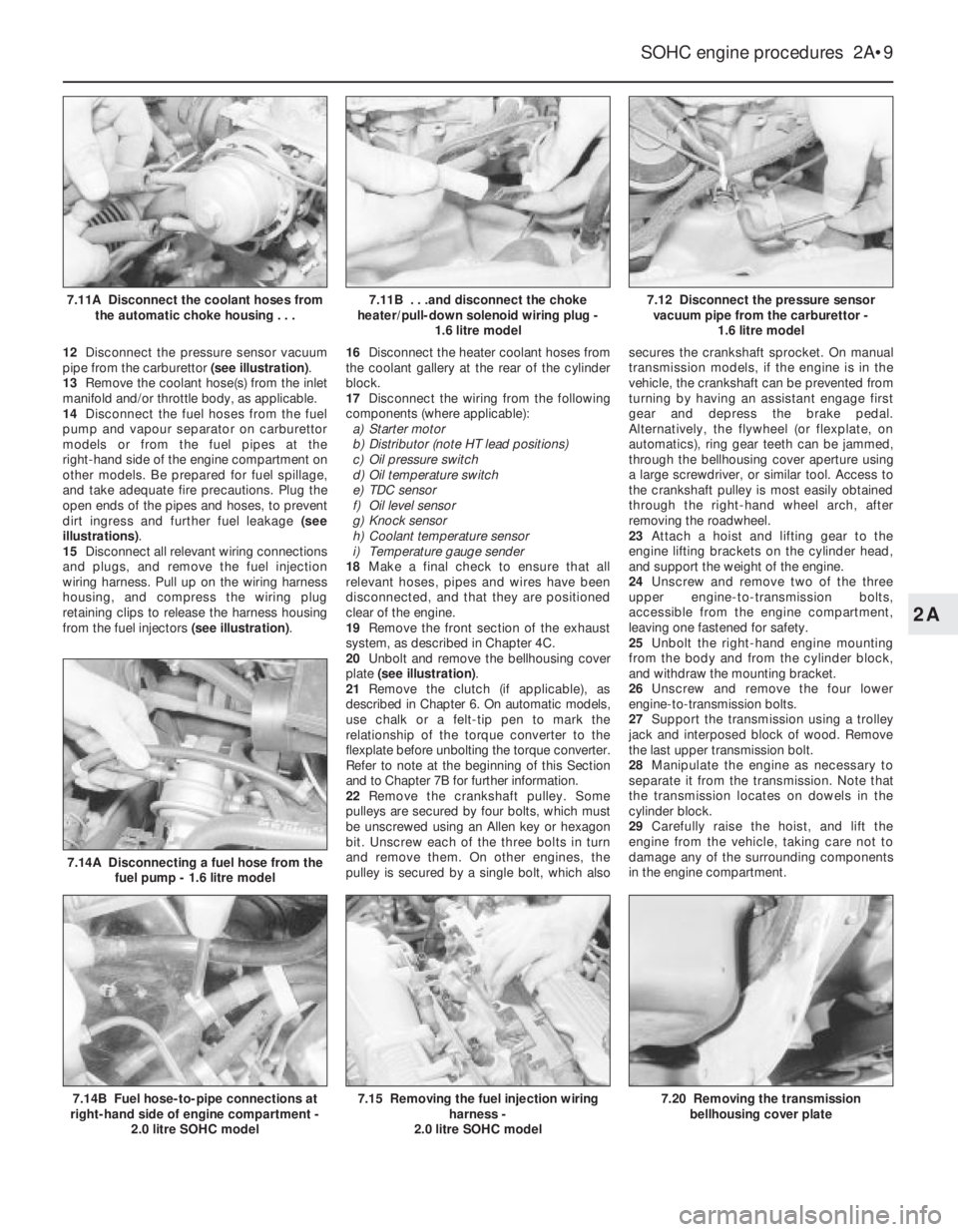

14Disconnect the fuel hoses from the fuel

pump and vapour separator on carburettor

models or from the fuel pipes at the

right-hand side of the engine compartment on

other models. Be prepared for fuel spillage,

and take adequate fire precautions. Plug the

open ends of the pipes and hoses, to prevent

dirt ingress and further fuel leakage (see

illustrations).

15Disconnect all relevant wiring connections

and plugs, and remove the fuel injection

wiring harness. Pull up on the wiring harness

housing, and compress the wiring plug

retaining clips to release the harness housing

from the fuel injectors (see illustration).16Disconnect the heater coolant hoses from

the coolant gallery at the rear of the cylinder

block.

17Disconnect the wiring from the following

components (where applicable):

a)Starter motor

b)Distributor (note HT lead positions)

c)Oil pressure switch

d)Oil temperature switch

e)TDC sensor

f)Oil level sensor

g)Knock sensor

h)Coolant temperature sensor

i)Temperature gauge sender

18Make a final check to ensure that all

relevant hoses, pipes and wires have been

disconnected, and that they are positioned

clear of the engine.

19Remove the front section of the exhaust

system, as described in Chapter 4C.

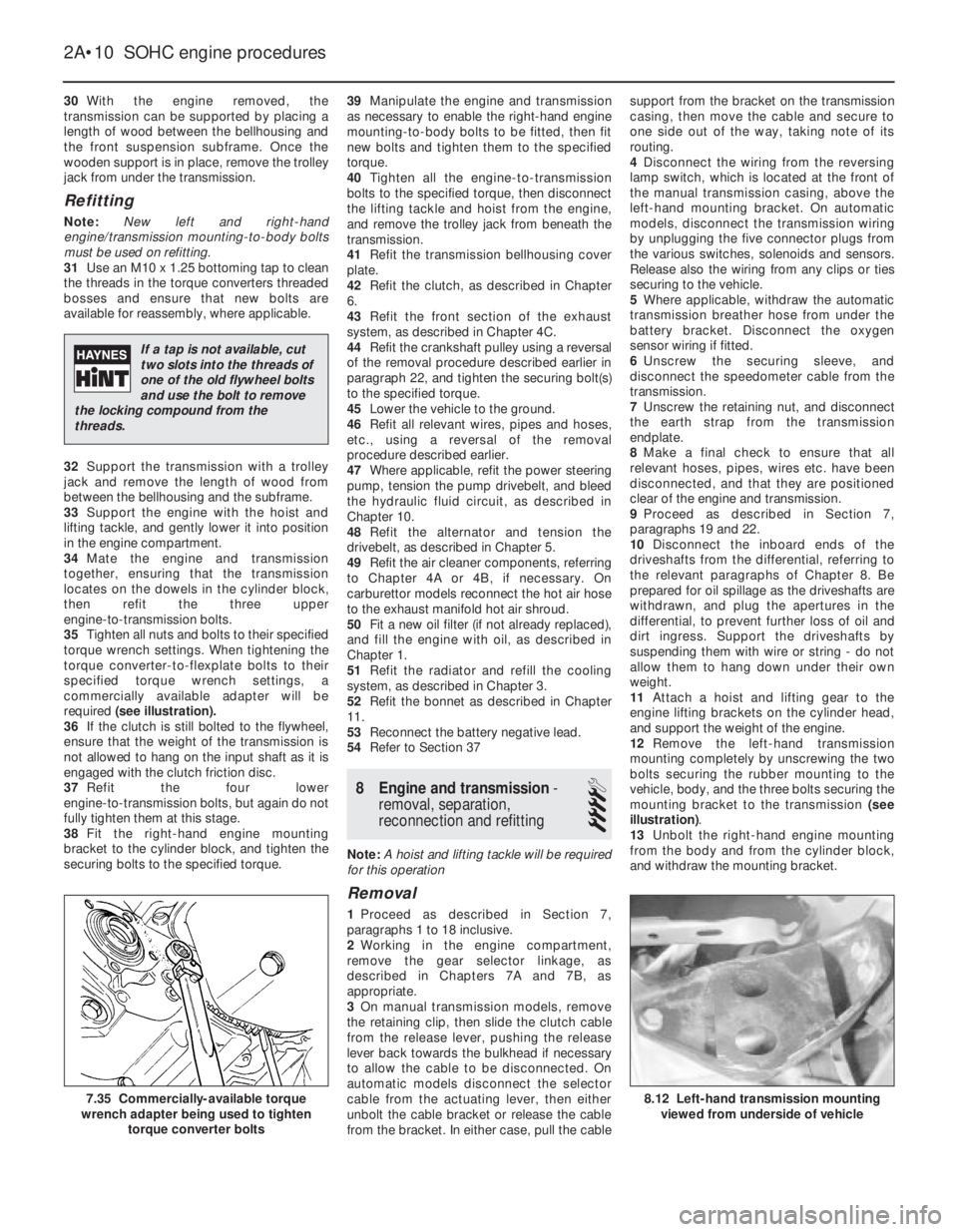

20Unbolt and remove the bellhousing cover

plate (see illustration).

21Remove the clutch (if applicable), as

described in Chapter 6. On automatic models,

use chalk or a felt-tip pen to mark the

relationship of the torque converter to the

flexplate before unbolting the torque converter.

Refer to note at the beginning of this Section

and to Chapter 7B for further information.

22Remove the crankshaft pulley. Some

pulleys are secured by four bolts, which must

be unscrewed using an Allen key or hexagon

bit. Unscrew each of the three bolts in turn

and remove them. On other engines, the

pulley is secured by a single bolt, which alsosecures the crankshaft sprocket. On manual

transmission models, if the engine is in the

vehicle, the crankshaft can be prevented from

turning by having an assistant engage first

gear and depress the brake pedal.

Alternatively, the flywheel (or flexplate, on

automatics), ring gear teeth can be jammed,

through the bellhousing cover aperture using

a large screwdriver, or similar tool. Access to

the crankshaft pulley is most easily obtained

through the right-hand wheel arch, after

removing the roadwheel.

23Attach a hoist and lifting gear to the

engine lifting brackets on the cylinder head,

and support the weight of the engine.

24Unscrew and remove two of the three

upper engine-to-transmission bolts,

accessible from the engine compartment,

leaving one fastened for safety.

25Unbolt the right-hand engine mounting

from the body and from the cylinder block,

and withdraw the mounting bracket.

26Unscrew and remove the four lower

engine-to-transmission bolts.

27Support the transmission using a trolley

jack and interposed block of wood. Remove

the last upper transmission bolt.

28Manipulate the engine as necessary to

separate it from the transmission. Note that

the transmission locates on dowels in the

cylinder block.

29Carefully raise the hoist, and lift the

engine from the vehicle, taking care not to

damage any of the surrounding components

in the engine compartment.

SOHC engine procedures 2A•9

7.12 Disconnect the pressure sensor

vacuum pipe from the carburettor -

1.6 litre model

7.20 Removing the transmission

bellhousing cover plate7.15 Removing the fuel injection wiring

harness -

2.0 litre SOHC model7.14B Fuel hose-to-pipe connections at

right-hand side of engine compartment -

2.0 litre SOHC model

7.14A Disconnecting a fuel hose from the

fuel pump - 1.6 litre model

7.11B . . .and disconnect the choke

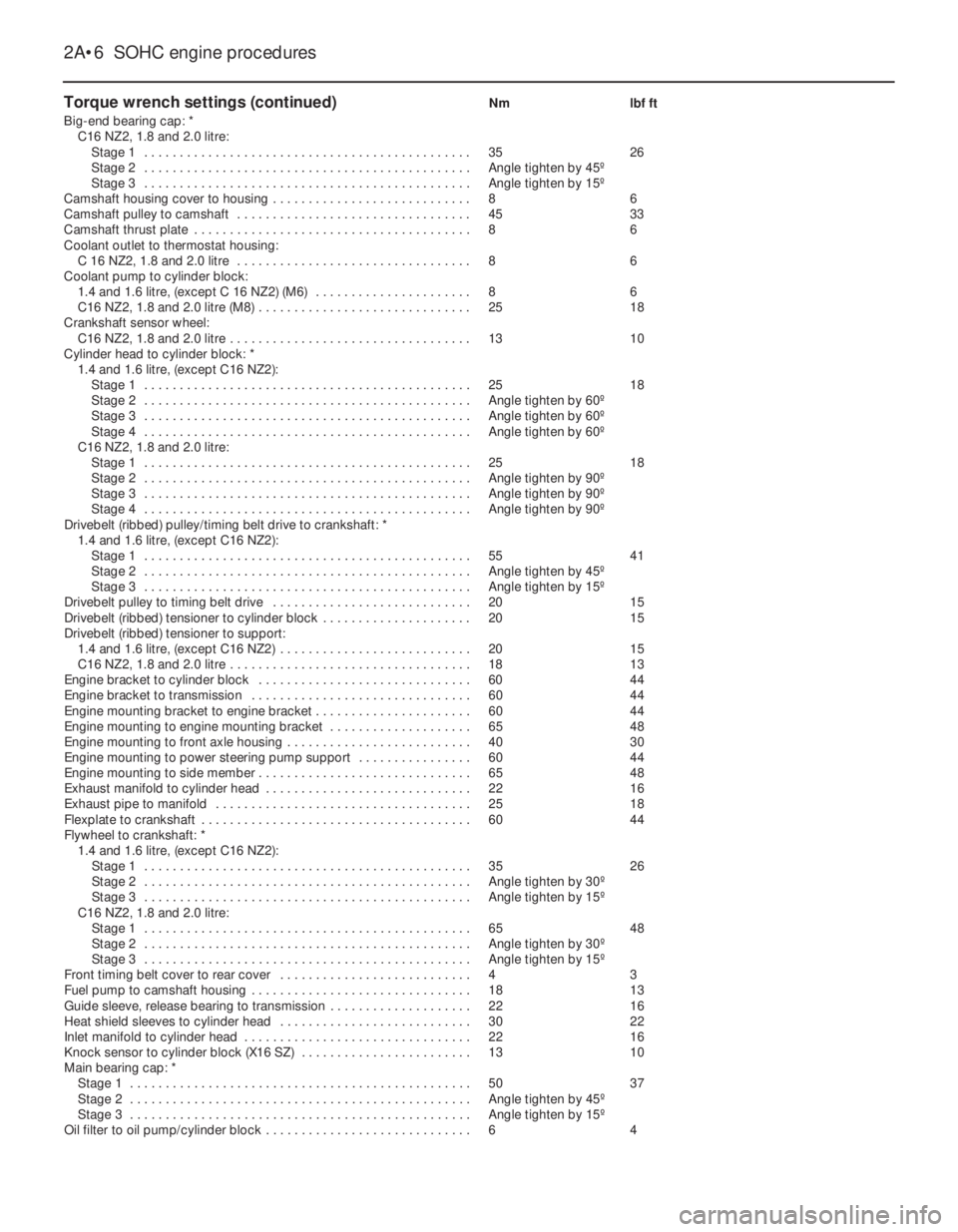

heater/pull-down solenoid wiring plug -

1.6 litre model7.11A Disconnect the coolant hoses from

the automatic choke housing . . .

2A

Page 207 of 525

30With the engine removed, the

transmission can be supported by placing a

length of wood between the bellhousing and

the front suspension subframe. Once the

wooden support is in place, remove the trolley

jack from under the transmission.

Refitting

Note: New left and right-hand

engine/transmission mounting-to-body bolts

must be used on refitting.

31Use an M10 x 1.25 bottoming tap to clean

the threads in the torque converters threaded

bosses and ensure that new bolts are

available for reassembly, where applicable.

32Support the transmission with a trolley

jack and remove the length of wood from

between the bellhousing and the subframe.

33Support the engine with the hoist and

lifting tackle, and gently lower it into position

in the engine compartment.

34Mate the engine and transmission

together, ensuring that the transmission

locates on the dowels in the cylinder block,

then refit the three upper

engine-to-transmission bolts.

35Tighten all nuts and bolts to their specified

torque wrench settings. When tightening the

torque converter-to-flexplate bolts to their

specified torque wrench settings, a

commercially available adapter will be

required (see illustration).

36If the clutch is still bolted to the flywheel,

ensure that the weight of the transmission is

not allowed to hang on the input shaft as it is

engaged with the clutch friction disc.

37Refit the four lower

engine-to-transmission bolts, but again do not

fully tighten them at this stage.

38Fit the right-hand engine mounting

bracket to the cylinder block, and tighten the

securing bolts to the specified torque.39Manipulate the engine and transmission

as necessary to enable the right-hand engine

mounting-to-body bolts to be fitted, then fit

new bolts and tighten them to the specified

torque.

40Tighten all the engine-to-transmission

bolts to the specified torque, then disconnect

the lifting tackle and hoist from the engine,

and remove the trolley jack from beneath the

transmission.

41Refit the transmission bellhousing cover

plate.

42Refit the clutch, as described in Chapter

6.

43Refit the front section of the exhaust

system, as described in Chapter 4C.

44Refit the crankshaft pulley using a reversal

of the removal procedure described earlier in

paragraph 22, and tighten the securing bolt(s)

to the specified torque.

45Lower the vehicle to the ground.

46Refit all relevant wires, pipes and hoses,

etc., using a reversal of the removal

procedure described earlier.

47Where applicable, refit the power steering

pump, tension the pump drivebelt, and bleed

the hydraulic fluid circuit, as described in

Chapter 10.

48Refit the alternator and tension the

drivebelt, as described in Chapter 5.

49Refit the air cleaner components, referring

to Chapter 4A or 4B, if necessary. On

carburettor models reconnect the hot air hose

to the exhaust manifold hot air shroud.

50Fit a new oil filter (if not already replaced),

and fill the engine with oil, as described in

Chapter 1.

51Refit the radiator and refill the cooling

system, as described in Chapter 3.

52Refit the bonnet as described in Chapter

11.

53Reconnect the battery negative lead.

54Refer to Section 37

8Engine and transmission -

removal, separation,

reconnection and refitting

4

Note: A hoist and lifting tackle will be required

for this operation

Removal

1Proceed as described in Section 7,

paragraphs 1 to 18 inclusive.

2Working in the engine compartment,

remove the gear selector linkage, as

described in Chapters 7A and 7B, as

appropriate.

3On manual transmission models, remove

the retaining clip, then slide the clutch cable

from the release lever, pushing the release

lever back towards the bulkhead if necessary

to allow the cable to be disconnected. On

automatic models disconnect the selector

cable from the actuating lever, then either

unbolt the cable bracket or release the cable

from the bracket. In either case, pull the cablesupport from the bracket on the transmission

casing, then move the cable and secure to

one side out of the way, taking note of its

routing.

4Disconnect the wiring from the reversing

lamp switch, which is located at the front of

the manual transmission casing, above the

left-hand mounting bracket. On automatic

models, disconnect the transmission wiring

by unplugging the five connector plugs from

the various switches, solenoids and sensors.

Release also the wiring from any clips or ties

securing to the vehicle.

5Where applicable, withdraw the automatic

transmission breather hose from under the

battery bracket. Disconnect the oxygen

sensor wiring if fitted.

6Unscrew the securing sleeve, and

disconnect the speedometer cable from the

transmission.

7Unscrew the retaining nut, and disconnect

the earth strap from the transmission

endplate.

8Make a final check to ensure that all

relevant hoses, pipes, wires etc. have been

disconnected, and that they are positioned

clear of the engine and transmission.

9Proceed as described in Section 7,

paragraphs 19 and 22.

10Disconnect the inboard ends of the

driveshafts from the differential, referring to

the relevant paragraphs of Chapter 8. Be

prepared for oil spillage as the driveshafts are

withdrawn, and plug the apertures in the

differential, to prevent further loss of oil and

dirt ingress. Support the driveshafts by

suspending them with wire or string - do not

allow them to hang down under their own

weight.

11Attach a hoist and lifting gear to the

engine lifting brackets on the cylinder head,

and support the weight of the engine.

12Remove the left-hand transmission

mounting completely by unscrewing the two

bolts securing the rubber mounting to the

vehicle, body, and the three bolts securing the

mounting bracket to the transmission (see

illustration).

13Unbolt the right-hand engine mounting

from the body and from the cylinder block,

and withdraw the mounting bracket.

2A•10SOHC engine procedures

8.12 Left-hand transmission mounting

viewed from underside of vehicle7.35 Commercially-available torque

wrench adapter being used to tighten

torque converter bolts

If a tap is not available, cut

two slots into the threads of

one of the old flywheel bolts

and use the bolt to remove

the locking compound from the

threads.

Page 208 of 525

14Working under the vehicle, unscrew and

remove the two nuts securing the

engine/transmission rear mounting to the front

subframe, and the three bolts securing the

mounting bracket to the transmission, then

withdraw the mounting bracket (see

illustrations).

15Carefully swing the engine/transmission

assembly across the engine compartment as

necessary, to allow the assembly to be lifted

vertically from the vehicle by raising the hoist.

Take care not to damage any of the

surrounding components in the engine

compartment.

Separation

16With the engine/transmission assembly

removed, support the assembly on blocks of

wood positioned on a workbench, or failing

that, on a clean area of the workshop floor.

17Clean away any external dirt using

paraffin or a water-soluble solvent and a stiff

brush.

18Unbolt and remove the transmission

bellhousing cover plate.

19Ensure that both engine and transmission

are adequately supported, then unscrew and

remove the engine-to-transmission bolts.

20Carefully withdraw the transmission from

the engine, ensuring that the weight of the

transmission is not allowed to hang on the

input shaft while it is engaged with the clutch

friction disc. Note that the transmission

locates on dowels positioned in the cylinder

block.

21On automatic models unbolt the

transmission bellhousing cover plate (three

bolts), then use chalk or a felt-tip pen to mark

the relationship of the torque converter to the

flexplate before unbolting the torque

converter. Note:If the torque converter is

removed (even partially) from the transmission,

a considerable amount of the fluid inside it will

leak out. To prevent this, when prising the

transmission off its locating dowels and

removing it, be careful to keep the torque

converter pressed firmly into the transmission.

If the transmission is to be removed for some

time, retain the torque converter by bolting a

strip of metal across the bellhousing mating

surface. Applying a spanner to the crankshaft

pulley/sprocket bolt, rotate the crankshaft

until the first bolt appears, then use ascrewdriver or similar to jam the flexplate ring

gear teeth to prevent it from rotating as the

bolt is unscrewed. Unscrew each of the three

bolts in turn and remove them.

Reconnection

22Before beginning the refitting operations,

check that the two original bolts that secured

the left-hand transmission rubber mounting to

the vehicle body rotate freely in their threaded

bores in the body. If necessary, re-cut the

threaded bores using an M10 x 1.25 mm tap.

23Where applicable, if the clutch assembly

has been removed from the flywheel, it will

prove easier to refit after the transmission has

been refitted.

24On automatics, if any fluid was spilled from

the torque converter, be careful to refill it as

much as possible. Wipe clean the converter’s

spigot to prevent damage to the transmission’s

input shaft oil seal as the converter is installed,

and ensure that the converter engages

correctly on the fluid pump shaft.

25If the transmission has been renewed, be

careful to flush clean the radiator fluid cooler

passages. Vauxhall recommend the use of

low-pressure compressed air, but this will

require great care to avoid deforming the

radiator.

26Be very careful to ensure that all

components are scrupulously clean, to avoid

the risk of dirt getting into the system.

27Use an M10 x 1.25 bottoming tap to clean

the threads in the torque converters threaded

bosses and ensure that new bolts are

available for reassembly, where applicable.

28Tighten all nuts and bolts to their specified

torque wrench settings.

29Refer also to Section 7, paragraphs 35

and 36.

30Carefully offer the transmission to the

engine until the bellhousing is located on the

dowels in the cylinder block, then refit the

engine-to-transmission bolts, and tighten

them to the specified torque.

31Refit the transmission bellhousing cover

plate.

Refitting

32Working under the vehicle, refit the rear

engine/transmission mounting to the

transmission, using new locking plates under

the bolt heads, and tighten the bolts to the

specified torque.

33Fit the two bolts securing the engine/

transmission rear mounting to the front

subframe, but do not fully tighten at this stage.

34Fit the right-hand engine mounting

bracket to the cylinder block, and tighten the

securing bolts to the specified torque.

35Fit new right-hand engine

mounting-to-body bolts, but do not fully

tighten them at this stage.

36Fit the left-hand transmission mounting

bracket to the transmission, and tighten the

securing bolts to the specified torque.

37Fit new left-hand transmission

mounting-to-body bolts, and tighten them to

the specified torque.

38Tighten the right-hand engine mounting-

to-body bolts and the engine/transmission

rear mounting-to-front subframe bolts to their

specified torques, then remove the lifting

tackle and hoist from the engine.

39Where applicable, the clutch can now be

fitted, and the transmission input shaft can be

pressed into engagement with the splined hub

of the clutch friction disc, (see Chapter 5).

40Reconnect the inboard ends of the

driveshafts to the differential, with reference

to the relevant paragraphs of Chapter 8, and

using new snap rings.

41Refit the front section of the exhaust

system, as described in Chapter 4C.

42Refit the crankshaft pulley, using a

reversal of the removal procedure described

in Section 7, paragraph 22, and tighten the

securing bolt(s) to the specified torque.

43On automatic models, connect the wires

to the various switches, solenoids and

sensors. Replace the transmission breather

hose and oxygen sensor (if fitted).

44Reconnect the transmission earth strap,

and tighten the securing nut.

45Lower the vehicle to the ground.

46Reconnect the speedometer cable to the

transmission, and tighten the securing sleeve.

47Reconnect the reversing lamp wiring.

48On manual transmission models, refit the

clutch cable to the bracket on the

transmission casing, then reconnect the cable

to the release lever, and adjust the cable as

described in Chapter 6. Ensure that the cable

is routed as noted during removal.

49Refit the gear selector linkage, as

described in Chapter 7A, if applicable.

50Proceed as described in Section 7,

paragraphs 41 to 52 inclusive.

51Top-up the transmission oil level, as

described in Chapters 7A and 7B.

52Adjust the selector cable on completion,

and refill the transmission with fluid (see

above).

53Reconnect the battery negative lead.

54Refer to Section 37

SOHC engine procedures 2A•11

8.14B Rear engine/transmission mounting-

to-transmission bolts (arrowed)8.14A Rear engine/transmission

mounting-to-front subframe nuts

2A

If a tap is not available, cut

two slots into the threads of

one of the old flywheel bolts

and use the bolt to remove

the locking compound from the threads.