OPEL VECTRA 1988 Service Manual Online

Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 81 of 525

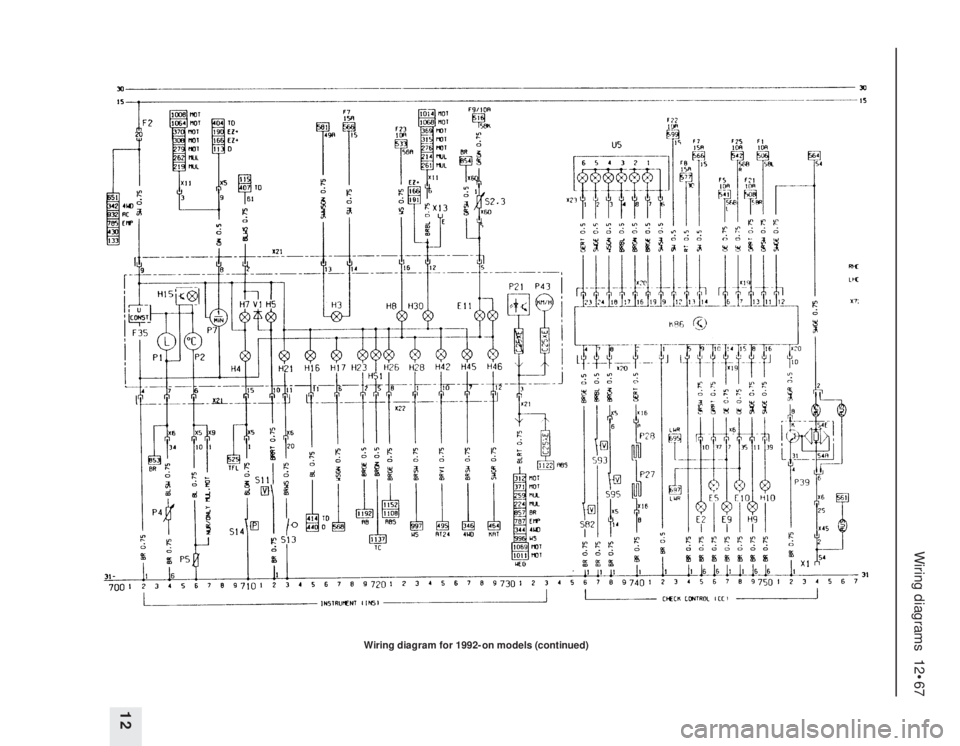

Wiring diagrams 12•67

12

Wiring diagram for 1992-on models (continued)

Page 82 of 525

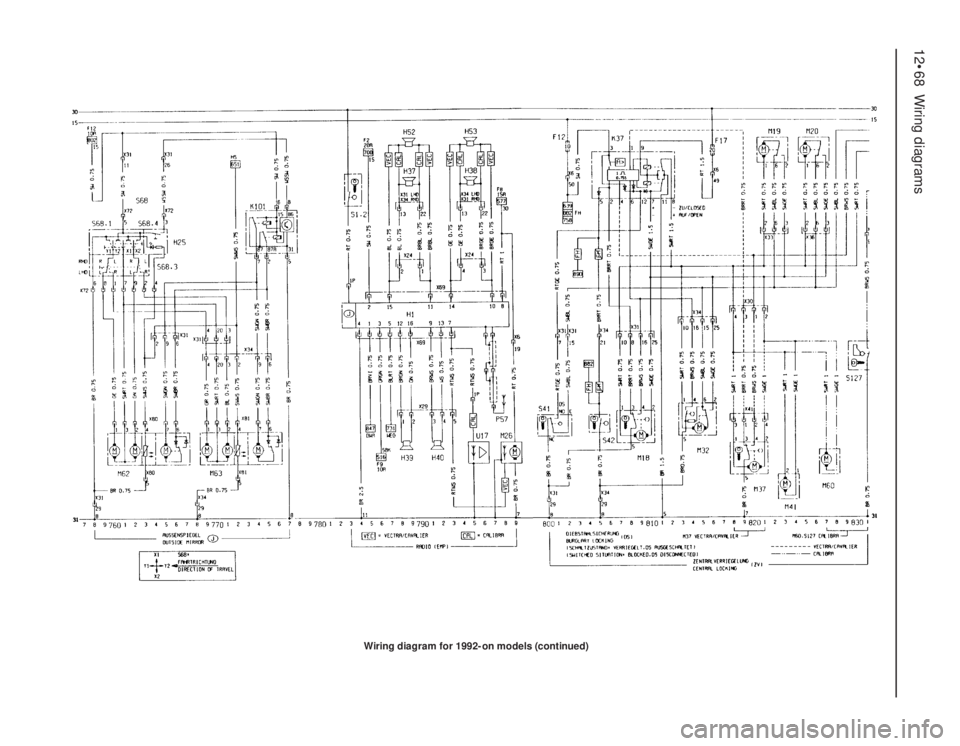

12•68Wiring diagrams

Wiring diagram for 1992-on models (continued)

Page 83 of 525

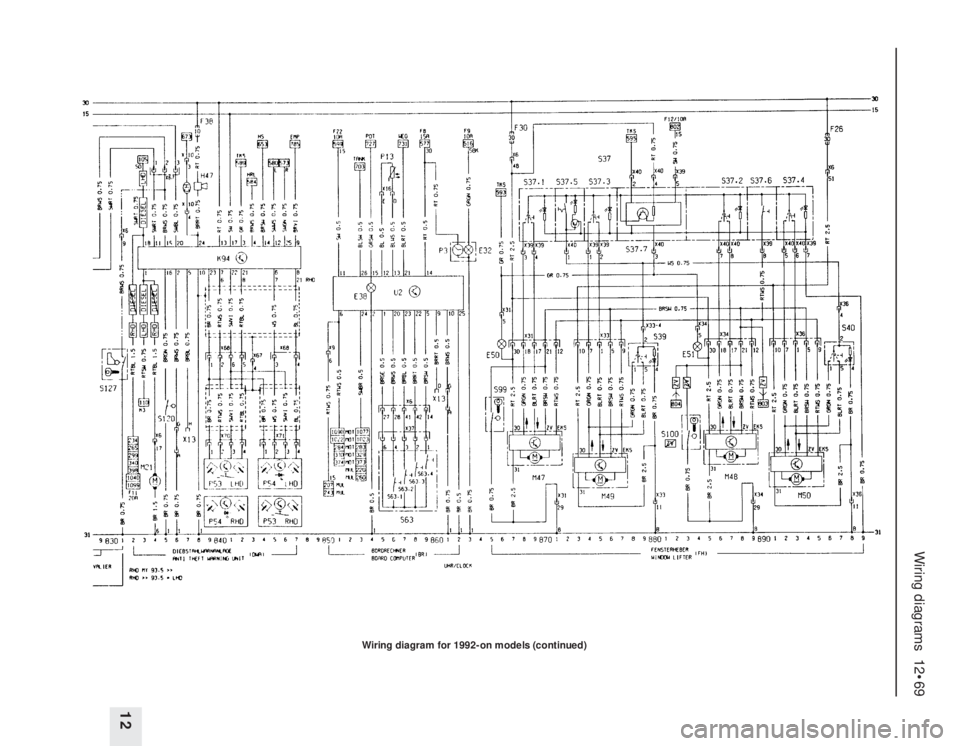

Wiring diagrams 12•69

12

Wiring diagram for 1992-on models (continued)

Page 84 of 525

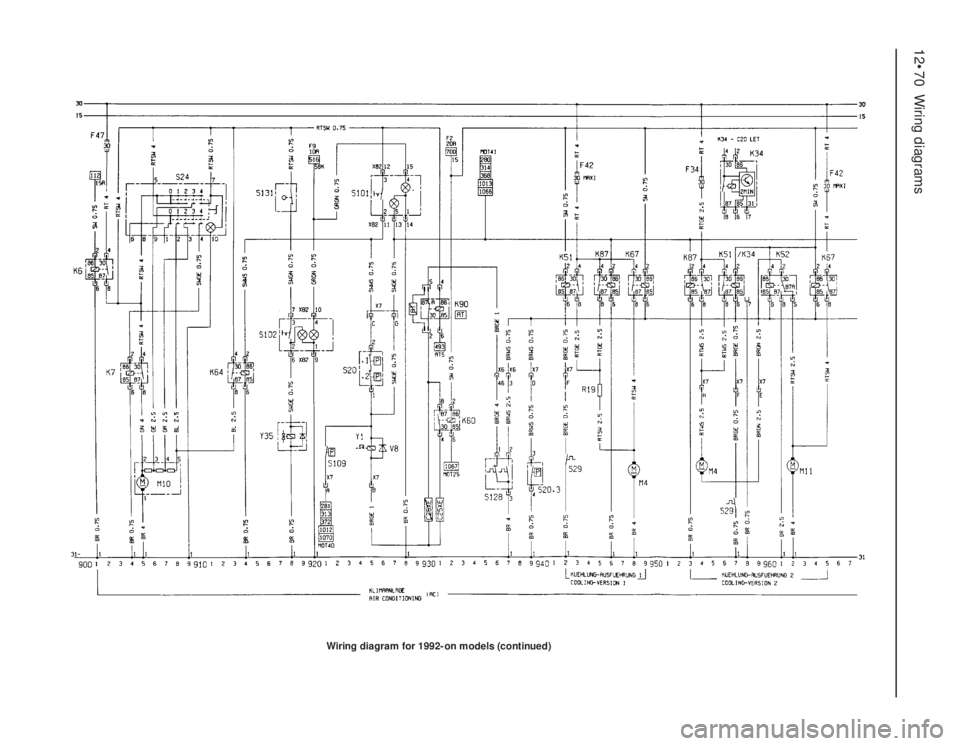

12•70Wiring diagrams

Wiring diagram for 1992-on models (continued)

Page 85 of 525

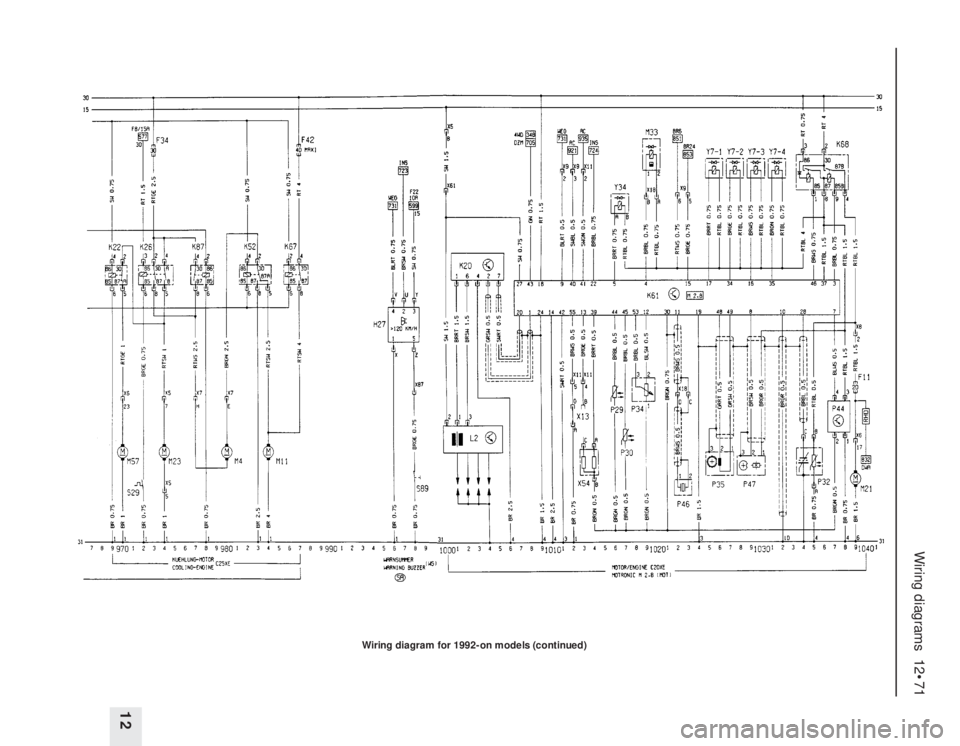

Wiring diagrams 12•71

12

Wiring diagram for 1992-on models (continued)

Page 86 of 525

12•72Wiring diagrams

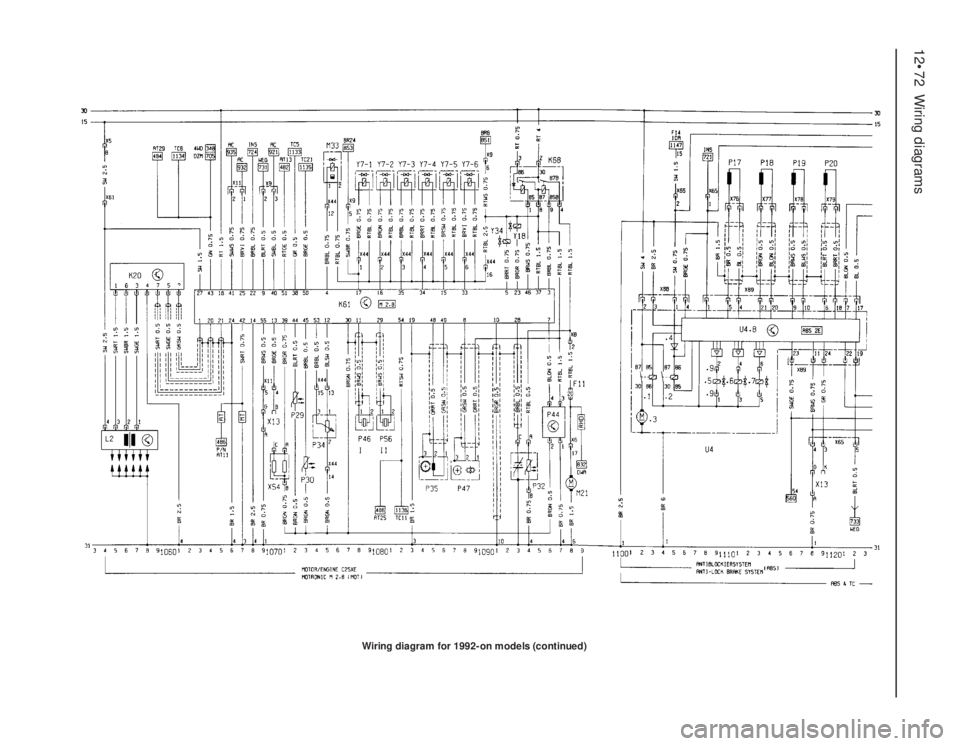

Wiring diagram for 1992-on models (continued)

Page 87 of 525

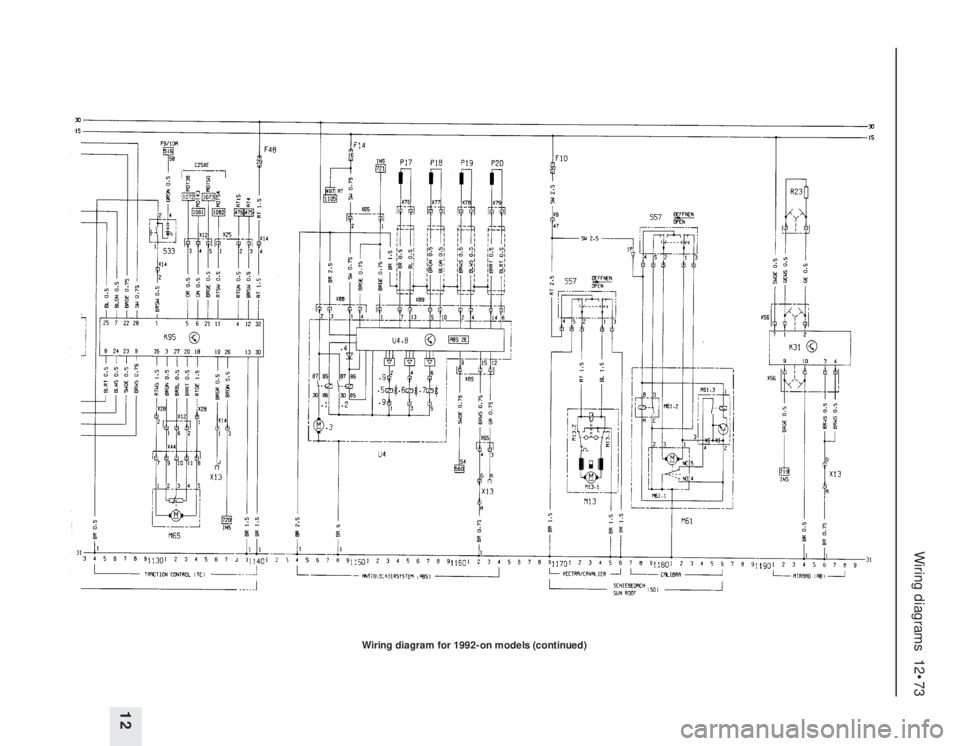

Wiring diagrams 12•73

12

Wiring diagram for 1992-on models (continued)

Page 88 of 525

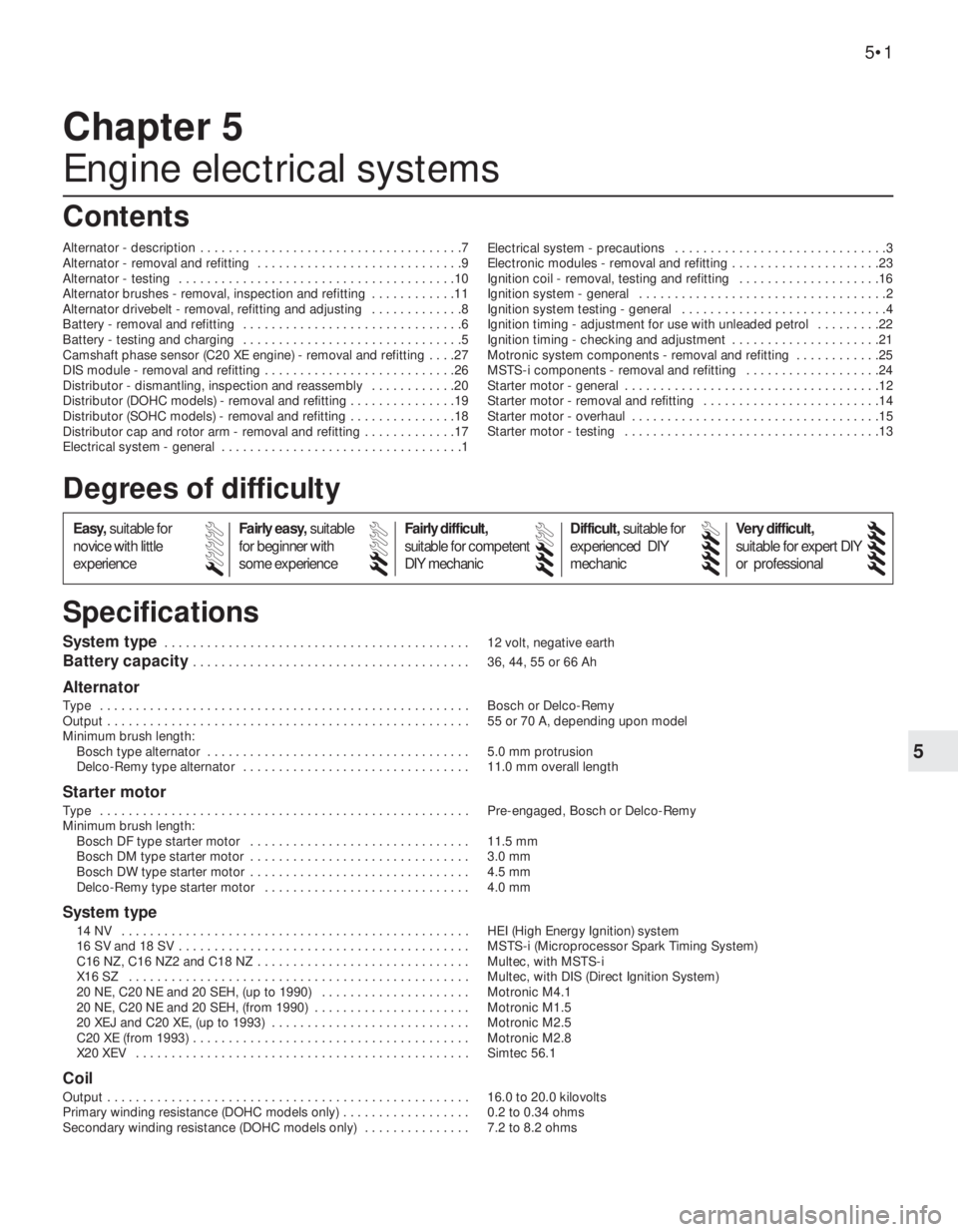

5

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volt, negative earth

Battery capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36, 44, 55 or 66 Ah

Alternator

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch or Delco-Remy

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 or 70 A, depending upon model

Minimum brush length:

Bosch type alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 mm protrusion

Delco-Remy type alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.0 mm overall length

Starter motor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pre-engaged, Bosch or Delco-Remy

Minimum brush length:

Bosch DF type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.5 mm

Bosch DM type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 mm

Bosch DW type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 mm

Delco-Remy type starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 mm

System type

14 NV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HEI (High Energy Ignition) system

16 SV and 18 SV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MSTS-i (Microprocessor Spark Timing System)

C16 NZ, C16 NZ2 and C18 NZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multec, with MSTS-i

X16 SZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multec, with DIS (Direct Ignition System)

20 NE, C20 NE and 20 SEH, (up to 1990) . . . . . . . . . . . . . . . . . . . . . Motronic M4.1

20 NE, C20 NE and 20 SEH, (from 1990) . . . . . . . . . . . . . . . . . . . . . . Motronic M1.5

20 XEJ and C20 XE, (up to 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motronic M2.5

C20 XE (from 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motronic M2.8

X20 XEV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Simtec 56.1

Coil

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.0 to 20.0 kilovolts

Primary winding resistance (DOHC models only) . . . . . . . . . . . . . . . . . . 0.2 to 0.34 ohms

Secondary winding resistance (DOHC models only) . . . . . . . . . . . . . . . 7.2 to 8.2 ohms

Chapter 5

Engine electrical systems

Alternator - description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Alternator - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Alternator brushes - removal, inspection and refitting . . . . . . . . . . . .11

Alternator drivebelt - removal, refitting and adjusting . . . . . . . . . . . . .8

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Battery - testing and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Camshaft phase sensor (C20 XE engine) - removal and refitting . . . .27

DIS module - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Distributor - dismantling, inspection and reassembly . . . . . . . . . . . .20

Distributor (DOHC models) - removal and refitting . . . . . . . . . . . . . . .19

Distributor (SOHC models) - removal and refitting . . . . . . . . . . . . . . .18

Distributor cap and rotor arm - removal and refitting . . . . . . . . . . . . .17

Electrical system - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Electrical system - precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electronic modules - removal and refitting . . . . . . . . . . . . . . . . . . . . .23

Ignition coil - removal, testing and refitting . . . . . . . . . . . . . . . . . . . .16

Ignition system - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Ignition system testing - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Ignition timing - adjustment for use with unleaded petrol . . . . . . . . .22

Ignition timing - checking and adjustment . . . . . . . . . . . . . . . . . . . . .21

Motronic system components - removal and refitting . . . . . . . . . . . .25

MSTS-i components - removal and refitting . . . . . . . . . . . . . . . . . . .24

Starter motor - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .14

Starter motor - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Starter motor - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 89 of 525

Distributor

Direction of rotor arm rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Anti-clockwise (viewed from cap)

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-4-2 (No 1 cylinder at timing belt end of engine)

Dwell angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatically controlled by electronic module (not adjustable)

Ignition timing

14 NV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5°BTDC

16 SV, X 16 SZ, C 16 NZ, C 16 NZ2 and C 18 NZ . . . . . . . . . . . . . . . .10°BTDC *

18 SV and 2.0 litres models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 12°BTDC *

* Ignition timing electronically controlled no adjustment possible

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1 Specifications

Torque wrench settingNmlbf ft

Alternator mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Camshaft phase sensor disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Camshaft phase sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1511

‘Compact’ series alternator lower mounting bolt . . . . . . . . . . . . . . . . . .3526

‘Compact’ series alternator upper mounting bolts . . . . . . . . . . . . . . . . .2015

DIS module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Inductive pulse pick-up to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Starter motor mounting bracket-to-cylinder block . . . . . . . . . . . . . . . . .2518

Starter motor mounting:

1.4 and 1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

1.8 and 2.0 litre models:

Engine side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Transmission side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7555

1Electrical system - general

1The electrical system is of the 12 volt

negative earth type, and consists of a 12 volt

battery, alternator with integral voltage

regulator, starter motor, and related electrical

accessories, components and wiring.

2The battery is of the maintenance-free

“sealed for life” type, and is charged by an

alternator, which is belt-driven from the

crankshaft pulley. The starter motor is of the

pre-engaged type, incorporating an integral

solenoid. On starting, the solenoid moves the

drive pinion into engagement with the flywheel

ring gear before the starter motor is

energised. Once the engine has started, a

one-way clutch prevents the motor armature

being driven by the engine until the pinion

disengages from the flywheel.

3It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.4Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

5Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

6If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

7Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

8The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

9Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

2Ignition system - general

1The ignition system is responsible for

igniting the air/fuel mixture in each cylinder at

the correct moment, in relation to engine

speed and load. A number of different types

of ignition systems are fitted to models within

the range. Ranging from a basic breakerless

electronic system, to a fully integrated engine

management system controlling both ignition

and fuel injection systems. Each system isdescribed in further detail later in this Section.

2The ignition system is based on feeding low

tension voltage from the battery to the coil,

where it is converted to high tension voltage.

The high tension voltage is powerful enough

to jump the spark plug gap in the cylinders

many times a second under high compression

pressures, providing that the system is in

good condition. The low tension (or primary)

circuit consists of the battery, the lead to the

ignition switch. The lead from the ignition

switch to the low tension coil windings and

the supply terminal on the electronic module.

The lead from the low tension coil windings to

the control terminal on the electronic module.

The high tension (or secondary) circuit

consists of the high tension coil windings, the

HT (high tension) lead from the coil to the

distributor cap, the rotor arm, the HT leads to

the spark plugs, and the spark plugs.

3The system functions in the following

manner. Current flowing through the low

tension coil windings produces a magnetic

field around the high tension windings. As the

engine rotates, a sensor produces an

electrical impulse that is amplified in the

electronic module and used to switch off the

low tension circuit.

4The subsequent collapse of the magnetic

field over the high tension windings produces

a high tension voltage, which is then fed to the

relevant spark plug through the distributor

cap and rotor arm. The low tension circuit is

automatically switched on again by the

electronic module, to allow the magnetic field

to build up again before the firing of the next

spark plug. The ignition is advanced and

retarded automatically, to ensure that the

spark occurs at the correct instant with the

engine speed and load.

5•2Engine electrical systems

Caution: Before carrying out

any work on the vehicle

electrical system, read through

the precautions given in the

“Safety first!” Section at the beginning of

this manual, and in Section 3 of this

Chapter.

Page 90 of 525

HEI (High Energy Ignition)

system

5This comprises of a breakerless distributor

and an electronic switching/amplifier module

along with the coil and spark plugs.

6The electrical impulse that is required to

switch off the low tension circuit is generated

by a magnetic trigger coil in the distributor. A

trigger wheel rotates within a magnetic stator,

the magnetic field being provided by a

permanent magnet. The magnetic field across

the two poles (stator arm and trigger wheel) is

dependent on the air gap between the two

poles. When the air gap is at its minimum, the

trigger wheel arm is directly opposite the

stator arm, and this is the trigger point. As the

magnetic flux between the stator arm and

trigger wheel varies, a voltage is induced in the

trigger coil mounted below the trigger wheel.

This voltage is sensed and then amplified by

the electronic module, and used to switch off

the low tension circuit. There is one trigger arm

and one stator arm for each cylinder.

7The ignition advance is a function of the

distributor, and is controlled both

mechanically and by a vacuum-operated

system. The mechanical governor mechanism

consists of two weights that move out from

the distributor shaft due to centrifugal force as

the engine speed rises. As the weights move

outwards, they rotate the trigger wheel

relative to the distributor shaft and so

advance the spark. The weights are held in

position by two light springs, and it is the

tension of the springs that is largely

responsible for correct spark advancement.

8The vacuum control consists of a

diaphragm, one side of which is connected by

way of a small-bore hose to the carburettor,

and the other side to the distributor.

Depression in the inlet manifold and

carburettor, which varies with engine speed

and throttle position, causes the diaphragm to

move, so moving the baseplate and

advancing or retarding the spark. A fine

degree of control is achieved by a spring in

the diaphragm assembly.

MSTS-i (Microprocessor-

controlled Spark Timing System)

9This system comprises a “Hall-effect”

distributor (or a crankshaft speed/position

sensor on X 16 SZ models), a manifold pressure

sensor, an oil temperature sensor, and a

module, along with the coil and spark plugs.

10On 1.6 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a sensor in the

distributor. A trigger vane rotates in the gap

between a permanent magnet and the sensor.

The trigger vane has four cut-outs, one for

each cylinder. When one of the trigger vane

cut-outs is in line with the sensor, magnetic

flux can pass between the magnet and the

sensor. When a trigger vane segment is in line

with the sensor, the magnetic flux is diverted

through the trigger vane away from thesensor. The sensor senses the change in

magnetic flux, and sends an impulse to the

MSTS-i module, which switches off the low

tension circuit.

11On 1.8 litre models, the electrical impulse

that is required to switch off the low tension

circuit is generated by a crankshaft

speed/position sensor, which is activated by a

toothed wheel on the crankshaft. The toothed

wheel has 35 equally spaced teeth, with a gap

in the 36th position. The gap is used by the

sensor to determine the crankshaft position

relative to TDC (top dead centre) of No 1 piston.

12Engine load information is supplied to the

MSTS-i module by a pressure sensor, which

is connected to the carburettor by a vacuum

pipe. Additional information is supplied by an

oil temperature sensor. The module selects

the optimum ignition advance setting based

on the information received from the sensors.

The degree of advance can thus be constantly

varied to suit the prevailing engine conditions.

Multec, with MSTS-i

13The ignition system is fully electronic in

operation and incorporates the Electronic

Control Unit (ECU) mounted in the driver’s

footwell. A distributor (driven off the camshaft

left-hand end and incorporating the amplifier

module) as well as the octane coding plug,

the spark plugs, HT leads, ignition HT coil and

associated wiring.

14The ECU controls both the ignition system

and the fuel injection system, integrating the

two in a complete engine management

system. Refer to Chapters 4B and 4C for

further information that is not detailed here.

15For ignition the ECU receives information

in the form of electrical impulses or signals

from the distributor (giving it the engine speed

and crankshaft position), from the coolant

temperature sensor (giving it the engine

temperature) and from the manifold absolute

pressure sensor (giving it the load on the

engine). In addition, the ECU receives input

from the octane coding plug (to provide

ignition timing appropriate to the grade of fuel

used) and from, where fitted, the automatic

transmission control unit (to smooth gear

changing by retarding the ignition as changes

are made).

16All these signals are compared by the

ECU with set values pre-programmed

(mapped) into its memory. Considering this

information, the ECU selects the ignition

timing appropriate to those values and

controls the ignition HT coil by way of the

amplifier module accordingly.

17The system is so sensitive that, at idle

speed, the ignition timing may be constantly

changing; this should be remembered if trying

to check the ignition timing.

18The system fitted to C18 NZ models, is

similar to that described above, except that

the amplifier module is separate. The ECU

determines engine speed and crankshaft

position using a sensor mounted in the

right-hand front end of the engine’s cylinderblock; this registers with a 58-toothed disc

mounted on the crankshaft so that the gap left

by the missing two teeth provides a reference

point, so enabling the ECU to recognise TDC.

19Note that this simplifies the distributor’s

function, which is merely to distribute the HT

pulse to the appropriate spark plug; it has no

effect whatsoever on the ignition timing.

DIS (Direct Ignition System)

20On all X16 SZ engines, and on C20 XE

(DOHC) engines from 1993-on, a DIS (Direct

Ignition System) module is used in place of

the distributor and coil. On the X16 SZ engine

the DIS module is attached to the camshaft

housing in the position normally occupied by

the distributor. On the C20 XE engine, a

camshaft phase sensor is attached to the

cylinder head at the non-driven end of the

exhaust camshaft, in the position normally

occupied by the distributor. The DIS module

is attached, by a bracket, to the cylinder head

at the non-driven end of the inlet camshaft.

21The DIS module consists of two ignition

coils and an electronic control module housed

in a cast casing. Each ignition coil supplies

two spark plugs with HT voltage. One spark is

provided in a cylinder with its piston on the

compression stroke, and one spark is

provided to a cylinder with its piston on the

exhaust stroke. This means that a “wasted

spark” is supplied to one cylinder during each

ignition cycle, but this has no detrimental

effect. This system has the advantage that

there are no moving parts (therefore there is

no wear), and the system is largely

maintenance-free.

Motronic M4.1 and M1.5

22This system controls both the ignition and

the fuel injection systems.

23The Motronic module receives information

from a crankshaft speed/position sensor, an

engine coolant temperature sensor mounted

in the thermostat housing. A throttle position

sensor, an airflow meter, and on models fitted

with a catalytic converter, an oxygen sensor

mounted in the exhaust system (Chapter 4C).

24The module provides outputs to control

the fuel pump, fuel injectors, idle speed and

ignition circuit. Using the inputs from the

various sensors, the module computes the

optimum ignition advance, and fuel injector

pulse duration, to suit the prevailing engine

conditions. This system gives very accurate

control of the engine under all conditions,

improving fuel consumption and driveability,

and reducing exhaust gas emissions.

25Further details of the fuel injection system

components are given in Chapter 4B.

Motronic M2.5 and M2.8

26The system is similar to that described for

SOHC models, with the following differences.

27Along with the crankshaft speed/position

sensor, a “Hall-effect” distributor is used

(similar to that described in this Section, with

the MSTS-i system).

Engine electrical systems 5•3

5