OPEL VECTRA 1988 Service Owners Manual

Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 91 of 525

28The system also incorporates a separate

ignition amplifier module that transmits

amplified signals from the main system

module to trigger the HT pulse from the

ignition coil. The module is mounted on the

ignition coil’s bracket/baseplate.

29Additionally, the Motronic module

receives information from a cylinder

block-mounted knock sensor, which senses

“knocking” (or pre-ignition) just as it begins to

occur, enabling the module to retard the

ignition timing, thus preventing engine

damage.

Simtec 56.1

30This system uses increased amount of

electronic components instead of mechanical

parts as sensors and actuators with the

Simtec engine management system. This

provides more precise operating data as well

as greater problem free motoring.

31The control unit is equipped with

electronic ignition control. Called ‘Micropro-

cessor Spark Timing System, inductive

triggered’, (or MSTS-i), and means that the

mechanical high voltage distributor is no

longer needed. It is located behind the trim

panel, on the right-hand side footwell (door

pillar).

32The ignition coil is replaced by a dual

spark ignition coil, which is switched directly

by the output stages in the control unit.

33A camshaft sensor will maintain

emergency operation, should the crankshaft

inductive pulse pick-up, malfunction. These

sense TDC (‘Top Dead Centre’), crankshaft

angle and engine speed. The signals are used

by the control unit to calculate ignition point

and for fuel injection.

34The ‘hot film airflow meter’ determines the

mass of air taken in by the engine. The system

uses this information to calculate the correct

amount of fuel needed for injection in the

engine.

35The air inlet temperature sensor (NTC), is

fitted in the air inlet duct between the air

cleaner and the hot mass air flow meter.

36A controlled canister purge valve is

actuated by the system. The tank ventilation is

monitored closely with the Lambda control (or

oxygen sensor) and adaptation by the

computer within the control unit.

37A knock control system is also fitted. This

eliminates the need for octane number

adjustment, as it is performed automatically

through the control unit.

3Electrical system -

precautions

1It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. Along with the precautions

given in the “Safety first!” Section at the

beginning of this manual, take note of the

following points when working on the system.

2Always remove rings, watches, etc. before

working on the electrical system. Even with

the battery disconnected, discharge could

occur if a component live terminal is earthed

through a metal object. This could cause a

shock or nasty burn.

3Do not reverse the battery connections.

Components such as the alternator, or any

other component having semi-conductor

circuitry, could be irreparably damaged.

4If the engine is being started using jump

leads and a slave battery, connect the

batteries positive to positive and negative to

negative. This also applies when connecting a

battery charger.

5Never disconnect the battery terminals, or

alternator multi-plug connector, when the

engine is running.

6The battery leads and alternator wiring

must be disconnected before carrying out any

electric welding on the vehicle.

7Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

8Engine management modules are very

sensitive components, and certain

precautions must be taken, to avoid damage

to the module when working on a vehicle

equipped with an engine management

system, as follows.

9When carrying out welding operations on

the vehicle using electric welding equipment,

the battery and alternator should be

disconnected.

10Although underbonnet-mounted modules

will tolerate normal underbonnet conditions,

they can be adversely affected by excess heat

or moisture. If using welding equipment or

pressure washing equipment near the

module, take care not to direct heat, or jets of

water or steam, at the module. If this cannot

be avoided, remove the module from the

vehicle, and protect its wiring plug with a

plastic bag.

11Before disconnecting any wiring, or

removing components, always ensure that the

ignition is switched off.

12Do not attempt to improvise fault

diagnosis procedures using a test lamp or

multimeter, as irreparable damage could be

caused to the module.13After working on ignition/engine

management system components, ensure

that all wiring is correctly reconnected before

reconnecting the battery or switching on the

ignition.

14Any ignition system that uses a

“Hall-effect” generator in the distributor,

cannot be tested. Test equipment that uses

its own power source (e.g. an ohmmeter),

when connected to the distributor or the

“Hall-effect” generator, will be damaged.

4Ignition system testing -

general

3

Note: Refer to Section 3 before proceeding.

Always switch off the ignition before

disconnecting or connecting any component

and when using a multi-meter to check

resistances. Any voltmeter or multi-meter

used to test ignition system components must

have an impedance of 10 meg ohms or

greater

1Electronic ignition system components are

normally very reliable. Most faults are far more

likely to be due to loose or dirty connections,

or to “tracking” of HT voltage due to dirt,

dampness or damaged insulation than to

component failure. Always check all wiring

thoroughly before condemning an electrical

component and work methodically to

eliminate all other possibilities before deciding

that a particular component is faulty.

2The old practice of checking for a spark by

holding the live end of a HT lead a short

distance away from the engine is not

recommended. Not only is there a high risk of

a powerful electric shock, but the ignition coil

or amplifier module will be damaged.

Similarly, never try to “diagnose” misfires by

pulling off one HT lead at a time. Note also

that the ECU is at risk if the system is

triggered with an open (i.e., not properly

earthed) HT circuit; ECU’s are very expensive

to replace, so take care!

3If you are in any doubt as to your skill and

ability to test an ignition system component or

if you do not have the required equipment,

take the vehicle to a suitably equipped

Vauxhall dealer. It is better to pay the labour

charges involved in having the vehicle

checked by an expert than to risk damage to

the system or to yourself.

4If the engine either will not turn over at all,

or only turns very slowly, check the battery

and starter motor. Connect a voltmeter across

the battery terminals (meter positive probe to

battery positive terminal) and disconnect the

ignition coil HT lead from the distributor cap

and earth. Note the voltage reading obtained

while turning over the engine on the starter for

(no more than) ten seconds. If the reading

obtained is less than approximately 9.5 volts,

check the battery, battery connections, starter

motor and charging system.

5•4Engine electrical systems

Warning: The HT voltage

generated by an electronic

ignition system is extremely

high and, in certain

circumstances, could prove fatal. Take

care to avoid receiving electric shocks

from the HT side of the ignition system.

Do not handle HT leads, or touch the

distributor or coil, when the engine is

running. If tracing faults in the HT circuit,

use well-insulated tools to manipulate live

leads

Page 92 of 525

5If the engine turns over at normal speed but

will not start, check the HT circuit by

connecting a timing light and turning the

engine over on the starter motor. If the light

flashes, voltage is reaching the spark plugs,

so these should be checked first. If the light

does not flash, check the HT leads

themselves followed by the distributor cap,

carbon brush and rotor arm.

6If there is a spark, check the fuel system for

faults as far as possible (Chapters 4A or 4B).

7If there is still no spark, check the voltage at

the ignition coil “+” or “15” terminal; it should

be the same as the battery voltage (i.e., at

least 11.7 volts). If the voltage at the coil is

more than 1 volt less than that at the battery,

check the connections back through the

ignition switch to the battery and its earth until

the fault is found. Note, however, that the

ECU controls the coil’s feed; do not attempt

to “test” the ECU with anything other than the

correct test equipment, which will be available

only to a Vauxhall dealer. If any of the wires

are to be checked which lead to the ECU,

always first unplug the relevant connector

from the ECU so that there is no risk of the

ECU being damaged by the application of

incorrect voltages from test equipment.

8If the feed to the ignition coil is sound,

check the coil’s primary and secondary

windings (refer to Section 16). Renew the coil

if faulty, but check the condition of the LT

connections themselves before doing so, to

ensure that the fault is not due to dirty or

poorly fastened connectors.

9If the ignition coil is in good condition, the

fault may be within the amplifier module or the

distributor on the C16 NZ and C16 NZ2

engines, or the amplifier or the crankshaft

speed/position sensor on the C18 NZ engine.

A quick check of these components can be

made by connecting a low-wattage bulb

across the ignition coil’s (disconnected) LT

terminals. If the bulb flickers or flashes when

the engine is turned over, the amplifier and

distributor (C16 NZ and C16 NZ2 engines), or

amplifier and crankshaft speed/position

sensor (C18 NZ engine), are sound.

10If this is the case, the entire LT circuit is in

good condition; the fault, if it lies in the

ignition system, must be in the HT circuit

components. These should be checked

carefully, as outlined above.

11If the indicator or bulb does not flash, the

fault is in either the amplifier or the distributor

(C16 NZ and C16 NZ2 engines), or the

amplifier or crankshaft speed/position sensor

(C18 NZ engine). Owners should note,

however, that by far the commonest cause of

“failure” of either of these is a poor

connection, either between the components

themselves or in the LT circuit wiring

connections. If such a fault is suspected, the

vehicle must be taken to a suitably equipped

Vauxhall dealer for testing; no information is

available to eliminate these components by

other means.12An irregular misfire suggests either a

loose connection or intermittent fault on the

primary circuit, or a HT fault on the coil side of

the rotor arm.

13With the ignition switched off, check

carefully through the system ensuring that all

connections are clean and securely fastened.

If the equipment is available, check the LT

circuit as described in paragraphs 7 to 11

above.

14Check that the HT coil, the distributor cap

and the HT leads are clean and dry. Check the

leads and the spark plugs (by substitution, if

necessary), then check the distributor cap,

carbon brush and rotor arm.

15Regular misfiring is almost certainly due to

a fault in the distributor cap, HT leads or spark

plugs. Use a timing light (paragraph 5, above)

to check whether HT voltage is present at all

leads.

16If HT voltage is not present on any

particular lead, the fault will be in that lead or

in the distributor cap. If HT is present on all

leads, the fault will be in the spark plugs;

check and renew them if there is any doubt

about their condition.

17If no HT voltage is present, check the

ignition coil; its secondary windings may be

breaking down under load.

18If all components have been checked for

signs of obvious faults but the system is still

thought to be faulty, take the vehicle to a

Vauxhall dealer for testing on special

equipment.

5Battery - testing and charging

2

Note: Refer to Section 3 before proceeding.

Testing

1Topping-up and testing of the electrolyte in

each cell is not possible. The condition of the

battery can therefore only be tested by

observing the battery condition indicator.

2The battery condition indicator is fitted in

the top of the battery casing, and indicates

the condition of the battery from its colour. If

the indicator shows green, then the battery is

in a good state of charge. If the indicator turns

darker, eventually to black, then the battery

requires charging, as described later in this

Section. If the indicator shows clear/yellow,

then the electrolyte level in the battery is too

low to allow further use, and the battery

should be renewed.

Charging

3Do not attempt to charge, load or jump start

a battery when the indicator shows

clear/yellow. If the battery is to be charged,

remove it from the vehicle and charge it as

follows.

4The maintenance-free type battery takes

considerably longer to fully recharge than the

standard type, the time taken being

dependent on the extent of discharge.5A constant-voltage type charger is required,

to be set, when connected, to 13.9 to 14.9

volts with a charger current below 25 amps.

6If the battery is to be charged from a fully

discharged state (less than 12.2 volts output),

have it recharged by a Vauxhall dealer or

battery specialist, as the charge rate will be

high and constant supervision during charging

is necessary.

6Battery - removal and refitting

2

Note: Refer to Section 3 before proceeding.

Removal

1The battery is located at the left-hand front

corner of the engine compartment.

2Disconnect the lead(s) at the negative

(earth) terminal by unscrewing the retaining

nut and removing the terminal clamp.

3Disconnect the positive terminal lead(s) in

the same way.

4Unscrew the clamp bolt sufficiently to

enable the battery to be lifted from its

location. Keep the battery in an upright

position, to avoid spilling electrolyte on the

bodywork.

Refitting

5Refitting is a reversal of removal, but smear

petroleum jelly on the terminals when

reconnecting the leads, and always connect

the positive lead first and the negative lead

last.

7Alternator - description

1A Delco-Remy or Bosch alternator may be

fitted, depending on model and engine

capacity. The maximum output of the

alternator varies accordingly.

2The alternator is belt-driven from the

crankshaft pulley. Cooling is provided by a

fan, mounted outside the casing on the end of

the rotor shaft. An integral voltage regulator is

incorporated, to control the output voltage.

3The alternator provides a charge to the

battery even at very low engine speed, and

consists of a coil-wound stator in which a

rotor rotates. The rotor shaft is supported in

ball-bearings, and slip rings are used to

conduct current to and from the field coils

through the carbon brushes.

4The alternator generates ac (alternating

current), which is rectified by an internal diode

circuit to dc (direct current) for supply to the

battery.

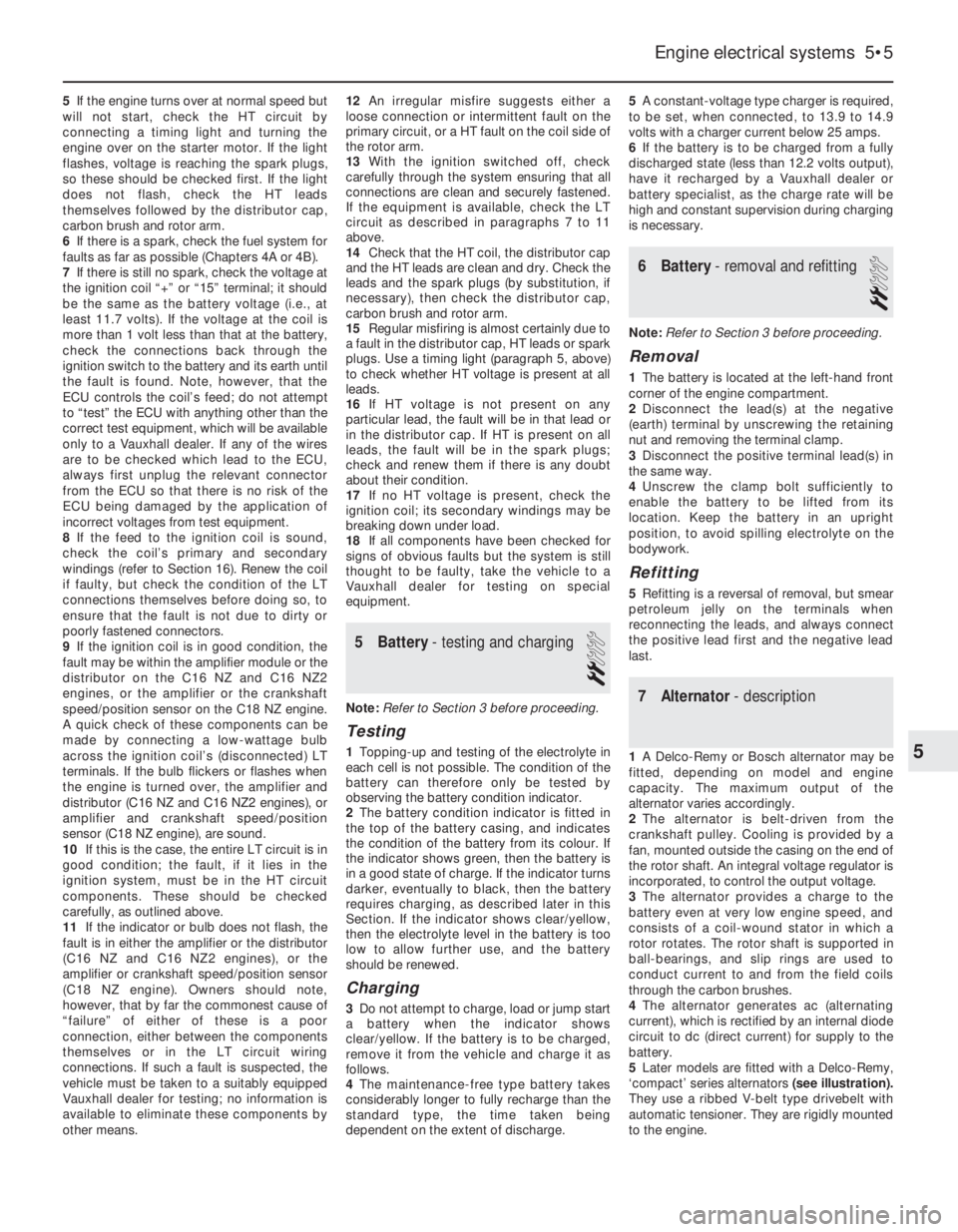

5Later models are fitted with a Delco-Remy,

‘compact’ series alternators (see illustration).

They use a ribbed V-belt type drivebelt with

automatic tensioner. They are rigidly mounted

to the engine.

Engine electrical systems 5•5

5

Page 93 of 525

8Alternator drivebelt -

removal, refitting and adjusting

2

V-belt type (not-ribbed)

Removal

1Disconnect the air inlet trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

2Correct tensioning of the drivebelt will

ensure that it has a long life. Beware,

however, of overtightening, as this can cause

excessive wear in the alternator.

3The belt should be inspected regularly, and

if it is found to be worn, frayed or cracked, it

should be renewed as a precaution against

breakage in service. It is advisable to carry a

spare drivebelt of the correct type in the

vehicle always.

4On models with power steering, the

alternator drivebelt also drives the power

steering pump.

5To remove the belt, on 1.8 and 2.0 litre

models first remove the power steering pump

drivebelt, as described in Chapter 10.

6Loosen the two alternator mounting nuts

and bolts sufficiently to allow the alternator to

be pivoted in towards the engine.

7Slide the belt from the pulleys.

Refitting

8Ensure that the correct type of belt is used,

if it is being renewed. Fit the belt around the

pulleys. Take up the slack in the belt byswinging the alternator away from the engine

and lightly tightening the mounting nuts and

bolts.

Adjusting

9Although special tools are available for

measuring the belt tension, a good

approximation can be achieved if the belt is

tensioned so that there is approximately 13.0

mm (0.5 in) of free movement under firm

thumb pressure at the mid-point of the

longest run between pulleys.

10With the mounting bolts just holding the

unit, lever the alternator away from the engine

using a wooden lever at the mounting bracket

end until the correct tension is achieved. Then

tighten the mounting nuts and bolts. On no

account lever at the free end of the alternator,

as serious internal damage could be caused.11Where applicable, refit and tension the

power steering pump drivebelt, as described

in Chapter 10.

12Refit the air inlet trunking.

13When a new belt has been fitted, it will

probably stretch slightly when it is first run,

and the tension should be rechecked and if

necessary adjusted after approximately 250

miles (400 km).

Ribbed V-belt type

General

14Later models equipped with power

steering are fitted with a ribbed V-belt type

drivebelt in conjunction with an automatic

tensioning roller. Once the belt is installed, no

further adjustment is necessary as the correct

tension is maintained by the automatic

tensioning roller. Removal and refitting

procedures are as follows.

Removal

15For improved access, remove the air

cleaner assembly and air inlet trunking.

16If the original drivebelt is to be refitted, mark

the rotational direction on the belt with chalk.

17Using a spanner or socket on the

automatic tensioning roller hexagon, turn the

tensioning roller clockwise (as viewed from the

right-hand side of the car) and hold it in this

position. With the drivebelt tension released,

slip the drivebelt off the pulleys, then allow the

tensioner to return to its original position.

18Support the engine under the sump with a

jack and interposed block of wood.

19From under the car, unbolt the right-hand

engine mounting block from the body.

20Lower the engine support jack just

sufficiently to allow the drivebelt to be

withdrawn from between the mounting block

and the body.

Refitting

21Slip the new drivebelt between the

mounting block and body then raise the

engine, by means of the jack, to its original

position.

22Clean the threads of the mounting block

retaining bolts, apply locking fluid, and refit

the bolts. Tighten the bolts to the specified

torque (see Chapter 2A).

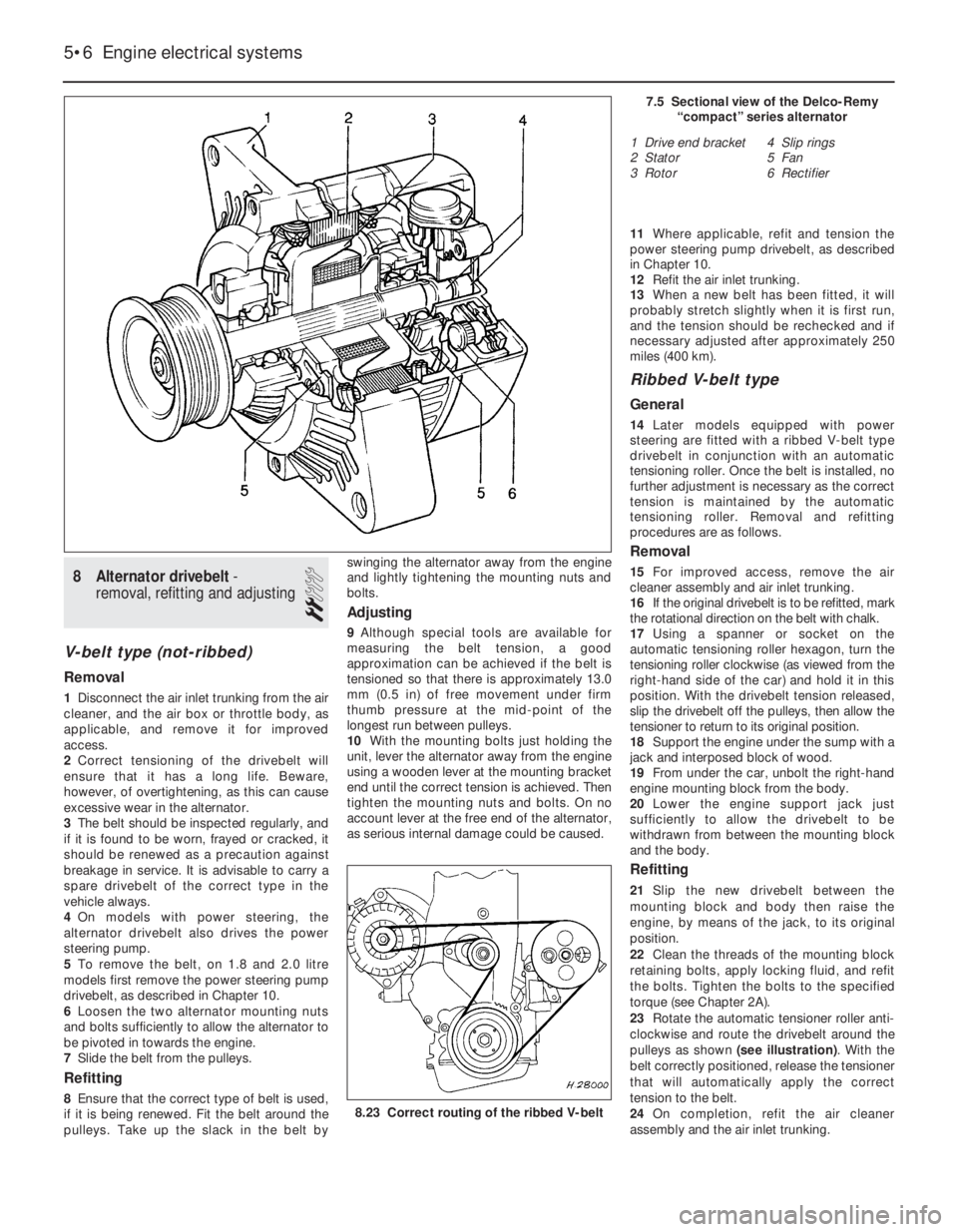

23Rotate the automatic tensioner roller anti-

clockwise and route the drivebelt around the

pulleys as shown (see illustration). With the

belt correctly positioned, release the tensioner

that will automatically apply the correct

tension to the belt.

24On completion, refit the air cleaner

assembly and the air inlet trunking.

5•6Engine electrical systems

7.5 Sectional view of the Delco-Remy

“compact” series alternator

1 Drive end bracket

2 Stator

3 Rotor4 Slip rings

5 Fan

6 Rectifier

8.23 Correct routing of the ribbed V-belt

Page 94 of 525

9Alternator-removal and

refitting

3

Note: Refer to Section 3 before proceeding

Except ‘compact’ series

alternators

Removal

1Disconnect the battery leads.

2Disconnect the air trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

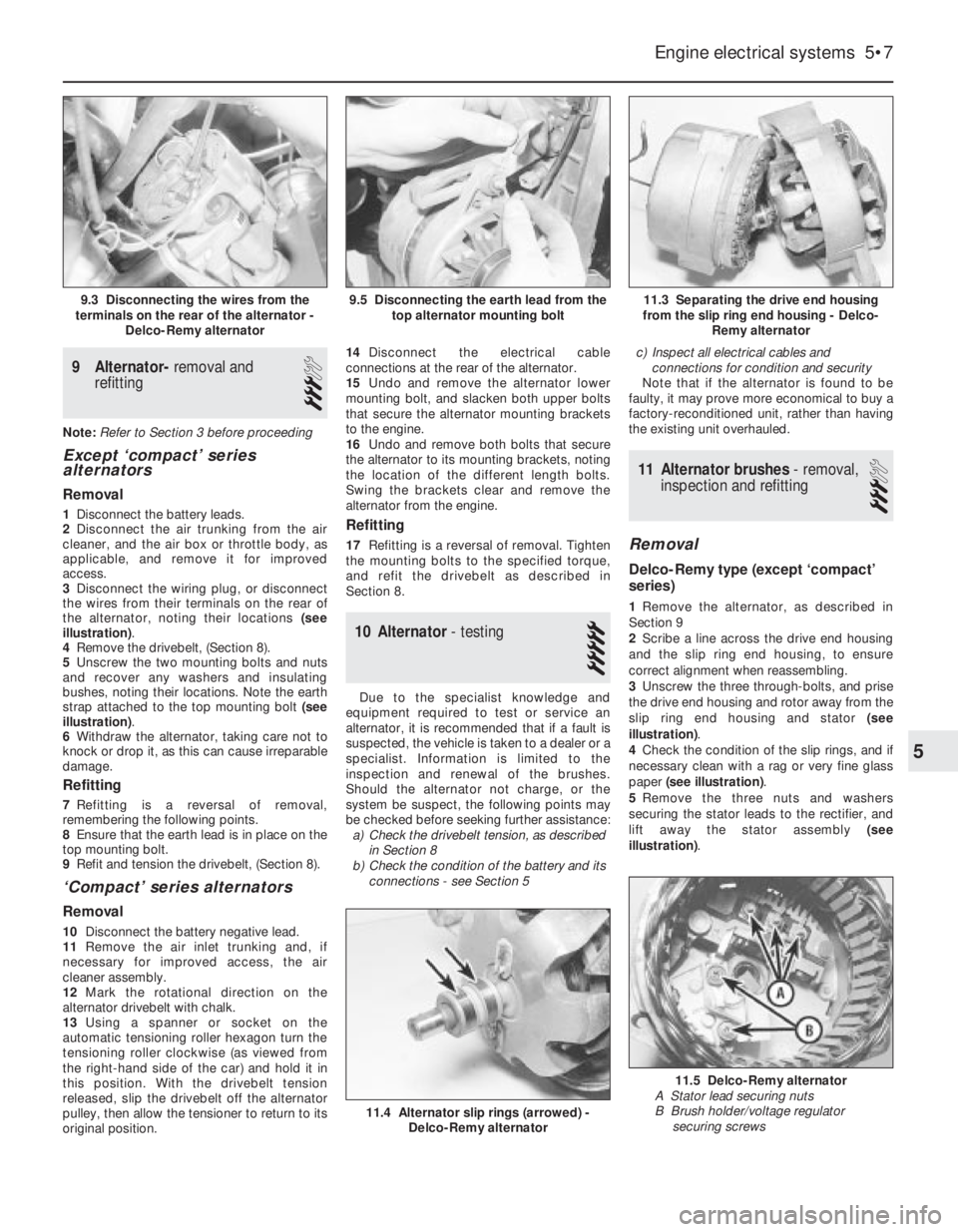

3Disconnect the wiring plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (see

illustration).

4Remove the drivebelt, (Section 8).

5Unscrew the two mounting bolts and nuts

and recover any washers and insulating

bushes, noting their locations. Note the earth

strap attached to the top mounting bolt (see

illustration).

6Withdraw the alternator, taking care not to

knock or drop it, as this can cause irreparable

damage.

Refitting

7Refitting is a reversal of removal,

remembering the following points.

8Ensure that the earth lead is in place on the

top mounting bolt.

9Refit and tension the drivebelt, (Section 8).

‘Compact’ series alternators

Removal

10Disconnect the battery negative lead.

11Remove the air inlet trunking and, if

necessary for improved access, the air

cleaner assembly.

12Mark the rotational direction on the

alternator drivebelt with chalk.

13Using a spanner or socket on the

automatic tensioning roller hexagon turn the

tensioning roller clockwise (as viewed from

the right-hand side of the car) and hold it in

this position. With the drivebelt tension

released, slip the drivebelt off the alternator

pulley, then allow the tensioner to return to its

original position.14Disconnect the electrical cable

connections at the rear of the alternator.

15Undo and remove the alternator lower

mounting bolt, and slacken both upper bolts

that secure the alternator mounting brackets

to the engine.

16Undo and remove both bolts that secure

the alternator to its mounting brackets, noting

the location of the different length bolts.

Swing the brackets clear and remove the

alternator from the engine.

Refitting

17Refitting is a reversal of removal. Tighten

the mounting bolts to the specified torque,

and refit the drivebelt as described in

Section 8.

10Alternator -testing

5

Due to the specialist knowledge and

equipment required to test or service an

alternator, it is recommended that if a fault is

suspected, the vehicle is taken to a dealer or a

specialist. Information is limited to the

inspection and renewal of the brushes.

Should the alternator not charge, or the

system be suspect, the following points may

be checked before seeking further assistance:

a)Check the drivebelt tension, as described

in Section 8

b)Check the condition of the battery and its

connections -see Section 5c)Inspect all electrical cables and

connections for condition and security

Note that if the alternator is found to be

faulty, it may prove more economical to buy a

factory-reconditioned unit, rather than having

the existing unit overhauled.

11Alternator brushes -removal,

inspection and refitting

3

Removal

Delco-Remy type (except ‘compact’

series)

1Remove the alternator, as described in

Section 9

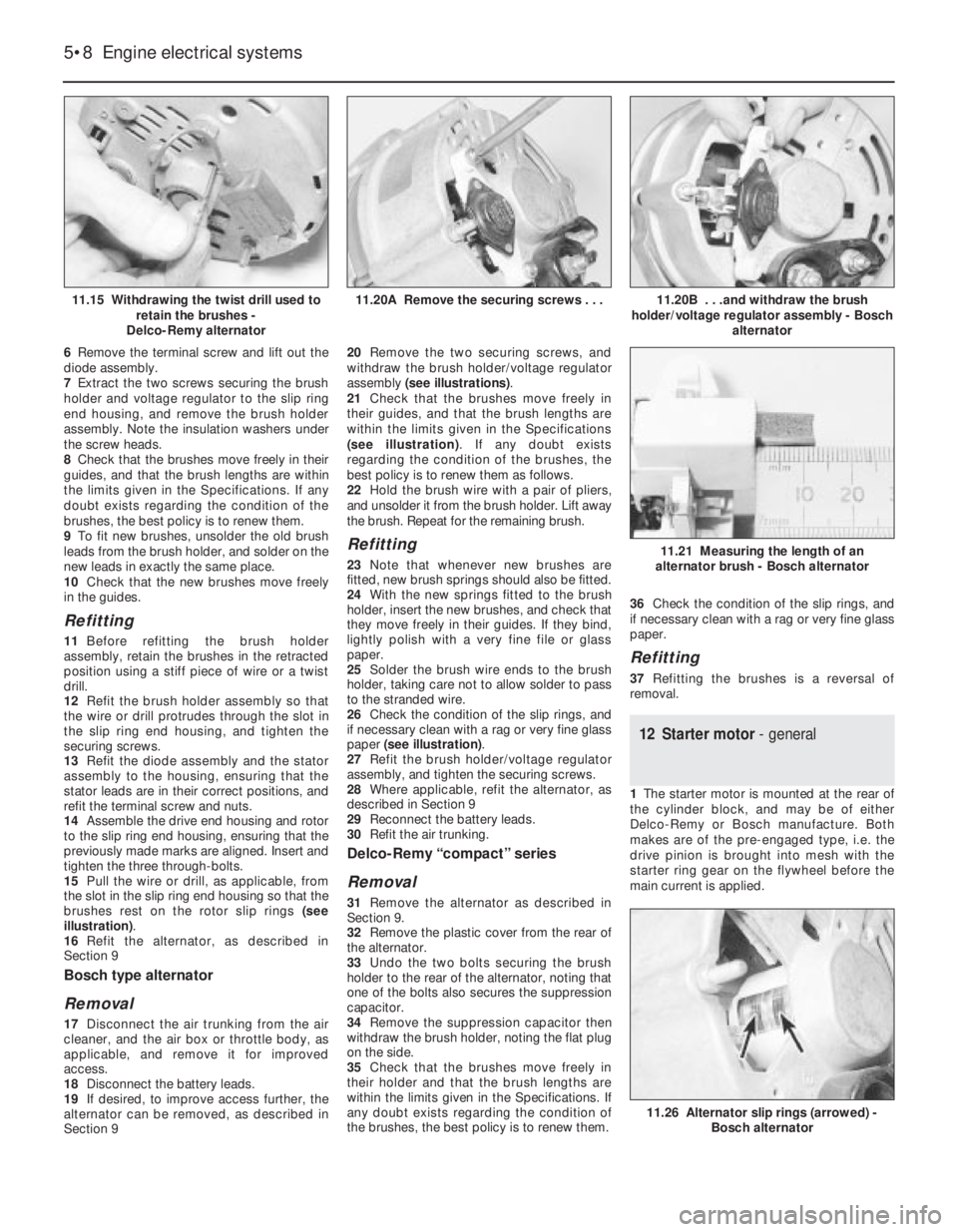

2Scribe a line across the drive end housing

and the slip ring end housing, to ensure

correct alignment when reassembling.

3Unscrew the three through-bolts, and prise

the drive end housing and rotor away from the

slip ring end housing and stator (see

illustration).

4Check the condition of the slip rings, and if

necessary clean with a rag or very fine glass

paper (see illustration).

5Remove the three nuts and washers

securing the stator leads to the rectifier, and

lift away the stator assembly (see

illustration).

Engine electrical systems 5•7

11.3 Separating the drive end housing

from the slip ring end housing - Delco-

Remy alternator

11.4 Alternator slip rings (arrowed) -

Delco-Remy alternator

11.5 Delco-Remy alternator

A Stator lead securing nuts

B Brush holder/voltage regulator

securing screws

9.5 Disconnecting the earth lead from the

top alternator mounting bolt9.3 Disconnecting the wires from the

terminals on the rear of the alternator -

Delco-Remy alternator

5

Page 95 of 525

6Remove the terminal screw and lift out the

diode assembly.

7Extract the two screws securing the brush

holder and voltage regulator to the slip ring

end housing, and remove the brush holder

assembly. Note the insulation washers under

the screw heads.

8Check that the brushes move freely in their

guides, and that the brush lengths are within

the limits given in the Specifications. If any

doubt exists regarding the condition of the

brushes, the best policy is to renew them.

9To fit new brushes, unsolder the old brush

leads from the brush holder, and solder on the

new leads in exactly the same place.

10Check that the new brushes move freely

in the guides.

Refitting

11Before refitting the brush holder

assembly, retain the brushes in the retracted

position using a stiff piece of wire or a twist

drill.

12Refit the brush holder assembly so that

the wire or drill protrudes through the slot in

the slip ring end housing, and tighten the

securing screws.

13Refit the diode assembly and the stator

assembly to the housing, ensuring that the

stator leads are in their correct positions, and

refit the terminal screw and nuts.

14Assemble the drive end housing and rotor

to the slip ring end housing, ensuring that the

previously made marks are aligned. Insert and

tighten the three through-bolts.

15Pull the wire or drill, as applicable, from

the slot in the slip ring end housing so that the

brushes rest on the rotor slip rings (see

illustration).

16Refit the alternator, as described in

Section 9

Bosch type alternator

Removal

17Disconnect the air trunking from the air

cleaner, and the air box or throttle body, as

applicable, and remove it for improved

access.

18Disconnect the battery leads.

19If desired, to improve access further, the

alternator can be removed, as described in

Section 920Remove the two securing screws, and

withdraw the brush holder/voltage regulator

assembly (see illustrations).

21Check that the brushes move freely in

their guides, and that the brush lengths are

within the limits given in the Specifications

(see illustration). If any doubt exists

regarding the condition of the brushes, the

best policy is to renew them as follows.

22Hold the brush wire with a pair of pliers,

and unsolder it from the brush holder. Lift away

the brush. Repeat for the remaining brush.

Refitting

23Note that whenever new brushes are

fitted, new brush springs should also be fitted.

24With the new springs fitted to the brush

holder, insert the new brushes, and check that

they move freely in their guides. If they bind,

lightly polish with a very fine file or glass

paper.

25Solder the brush wire ends to the brush

holder, taking care not to allow solder to pass

to the stranded wire.

26Check the condition of the slip rings, and

if necessary clean with a rag or very fine glass

paper (see illustration).

27Refit the brush holder/voltage regulator

assembly, and tighten the securing screws.

28Where applicable, refit the alternator, as

described in Section 9

29Reconnect the battery leads.

30Refit the air trunking.

Delco-Remy “compact” series

Removal

31Remove the alternator as described in

Section 9.

32Remove the plastic cover from the rear of

the alternator.

33Undo the two bolts securing the brush

holder to the rear of the alternator, noting that

one of the bolts also secures the suppression

capacitor.

34Remove the suppression capacitor then

withdraw the brush holder, noting the flat plug

on the side.

35Check that the brushes move freely in

their holder and that the brush lengths are

within the limits given in the Specifications. If

any doubt exists regarding the condition of

the brushes, the best policy is to renew them.36Check the condition of the slip rings, and

if necessary clean with a rag or very fine glass

paper.

Refitting

37Refitting the brushes is a reversal of

removal.

12Starter motor - general

1The starter motor is mounted at the rear of

the cylinder block, and may be of either

Delco-Remy or Bosch manufacture. Both

makes are of the pre-engaged type, i.e. the

drive pinion is brought into mesh with the

starter ring gear on the flywheel before the

main current is applied.

5•8Engine electrical systems

11.15 Withdrawing the twist drill used to

retain the brushes -

Delco-Remy alternator11.20B . . .and withdraw the brush

holder/voltage regulator assembly - Bosch

alternator

11.26 Alternator slip rings (arrowed) -

Bosch alternator

11.21 Measuring the length of an

alternator brush - Bosch alternator

11.20A Remove the securing screws . . .

Page 96 of 525

2When the starter switch is operated, current

flows from the battery to the solenoid that is

mounted on the starter body. The plunger in

the solenoid moves inwards, so causing a

centrally pivoted lever to push the drive pinion

into mesh with the starter ring gear. When the

solenoid plunger reaches the end of its travel,

it closes an internal contact and full starting

current flows to the starter field coils. The

armature is then able to rotate the crankshaft,

so starting the engine.

3A special freewheel clutch is fitted to the

starter driven pinion, so that when the engine

fires and starts to operate on its own it does

not drive the starter motor.

4When the starter switch is released, the

solenoid is de-energised, and a spring moves

the plunger back to its rest position. This

operates the pivoted lever to the withdraw the

drive pinion from engagement with the starter

ring.

13Starter motor - testing

3

Note: Refer to Section 3 before proceeding

Testing

1If the starter motor fails to turn the engine

when the switch is operated, and engine

seizure is not the problem, there are several

other possible reasons:

a)The battery is faulty

b)The electrical connections between the

switch, solenoid battery and starter motor

are somewhere failing to pass the

necessary current from the battery

through the starter to earth

c)The solenoid switch is faulty

d)The starter motor is mechanically or

electrically defective

e)The starter motor pinion and/or flywheel

ring gear is badly worn, and in need of

replacement

2To check the battery, switch on the

headlamps. If they dim after a few seconds,

then the battery is in a discharged state. If the

lamps glow brightly, operate the starter switch

and see what happens to the lamps. If theydim, then power is reaching the motor, but

failing to turn it. If the starter turns slowly, go

on to the next check.

3If, when the starter switch is operated, the

lamps stay bright, then insufficient power is

reaching the motor. Disconnect the battery

and the starter/solenoid power connections,

and the engine earth strap, then thoroughly

clean them and refit them. Smear petroleum

jelly around the battery connections to

prevent corrosion. Corroded connections are

the most frequent cause of electrical system

malfunctions.

4If the preceding checks and cleaning tasks

have been carried out without success, a

clicking noise will probably have been heard

each time the starter switch was operated.

This indicates that the solenoid switch was

operating, but it does not necessarily follow

that the main contacts were closing properly

(if no clicking has been heard from the

solenoid, it is certainly defective). The

solenoid can be checked by connecting a

voltmeter across the main cable connection

on the solenoid and earth. When the switch is

operated, these should be a reading on the

voltmeter. If there is no reading, the solenoid

unit is faulty, and should be renewed.

5If the starter motor operates, but does not

turn the engine, then it is likely that the starter

pinion and/or flywheel ring gear are badly

worn. If this is the case, the starter motor will

normally be noisy in operation.

6Finally, if it is established that the solenoid

is not faulty, and 12 volts are reaching the

starter, then the motor itself is faulty, and

should be removed for inspection.

14Starter motor - removal and

refitting

3

Note: Refer to Section 3 before proceeding

Removal

1Disconnect the battery negative lead.

2Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.3On DOHC models, remove the engine

undershield, as described in Chapter 11.

4Note the wiring connections on the

solenoid, then disconnect them (see

illustration).

5Where applicable, unscrew the bolt

securing the exhaust bracket and the starter

motor mounting bracket to the cylinder block

(see illustration).

6Unscrew the two starter motor mounting

bolts. Note that the top bolt on some models

are fitted from the transmission side, and

secures a wiring harness bracket (see

illustration).

7Withdraw the starter motor.

Refitting

8Refitting is a reversal of removal, but where

applicable, ensure that the wiring harness

bracket is in place on the top mounting bolt,

and tighten all bolts to the specified torque.

15Starter motor - overhaul

5

If the starter motor is thought to be suspect,

it should be removed from the vehicle and

taken to an auto-electrician for testing. Most

auto-electricians will be able to supply and fit

brushes at a reasonable cost. However, check

on the cost of repairs before continuing as it

may prove more economical to obtain a new

or exchange motor.

16Ignition coil - removal, testing

and refitting

3

Note: Refer to Section 3 before proceeding.

An ohmmeter will be required to test the coil

Removal

1The ignition coil is either a cylindrical metal

canister or a moulded plastic unit. It is

clamped or bolted to the left-hand inner wing

panel, near the suspension strut top mounting

(under the power steering fluid reservoir, on

Engine electrical systems 5•9

14.6 Starter motor securing bolts

(arrowed) - 1.6 litre model

(engine removed)14.5 Starter motor mounting

bracket/exhaust bracket securing bolt

(arrowed) - 1.6 litre model14.4 Starter motor and solenoid viewed

from underneath the vehicle. Solenoid

wiring connections arrowed

5

Page 97 of 525

models so equipped). On 14 NV, 16 SV and

18 SV models, the ignition amplifier module is

mounted on the coil’s bracket or baseplate

(see illustration).

2Disconnect the battery negative lead.

3Carefully note the LT wiring connections

before disconnecting them (see illustration).

4Note that on models with power steering,

one of the coil securing bolts also secures the

power steering fluid reservoir bracket.

5Remove the coil.

6On models with a cylindrical type coil, the

mounting clamp can be removed from the coil

by loosening the clamp nut.

Testing

7To test the coil, first disconnect the LT

wiring and the HT lead. Test the coil’s primary

windings by connecting a multi-meter across

the LT terminals (“+” or “15” and “-” or “1”).Then the secondary windings by testing

across the HT terminal (“4”) and one of the LT

terminals (usually the “-/1” terminal, although

in some cases, either terminal may serve). On

20 XEJ models, results should closely

approximate the specified values. On all other

models, typical primary resistances are less

than 1 ohm, while secondary resistances can

be expected to be in the 4000 to 12 000 ohms

range.

8If the results obtained differ significantly

from those given, showing windings that are

shorted or open circuit, the coil must be

renewed.

Refitting

9Refitting is a reversal of removal, however

ensure correct connections. Usually they are

physically different to prevent incorrect

refitting. If not, use the terminal marks ornumbers in conjunction with the relevant

wiring diagram at the back of this manual to

ensure that the connections are correctly

remade. If the connections are reversed, so

will the coil’s polarity be. While the engine

may still run, spark plug life will be reduced

and poor starting and/or misfiring may follow.

10Where applicable, ensure that the coil

suppresser is in position before refitting the

coil securing bolts.

17Distributor cap and rotor

arm -removal and refitting

3

Note: Refer to Section 3 before proceeding

Removal

14 NV and 16 SV models

1Disconnect the battery negative lead.

2Identify each HT lead for position, so that

the leads can be refitted to their correct

cylinders, then disconnect the leads from the

spark plugs by pulling on the connectors, not

the leads. Similarly, disconnect the HT lead

from the coil. Pull the leads from the clips on

the camshaft cover.

3On the Bosch distributor, prise away the

two spring clips with a screwdriver, and lift off

the distributor cap. On the Lucas distributor,

unscrew the two small bolts and lift off the

cap (see illustrations).

4The rotor arm is a push fit on the end of the

distributor shaft.

5If needed, on the Bosch distributor, the

plastic shield can be pulled from the end of

the distributor, to allow examination of the

distributor components (see illustration).

Other models, where applicable

6Proceed as described in paragraphs 1 and 2.

7On DOHC models (except X20 XEV),

unscrew the two securing bolts and withdraw

the spark plug cover from the camshaft cover.

8Using a Torx socket, unscrew the three

captive securing screws and withdraw the

distributor cap (see illustration).

9Withdraw the plastic shield from the rotor

arm housing. The shield is fitted in the

housing, with an O-ring seal located in a

groove in its periphery. Ease out the shield,

taking care not to damage the rotor arm (see

illustration).

5•10Engine electrical systems

16.1 Ignition coil - 1.6 litre models - note

ignition timing basic adjustment coding

plug (arrowed)

17.3A Removing the distributor cap -

1.6 litre model (Bosch distributor) . . .

17.9 Removing the plastic shield from the

rotor arm housing - 2.0 litre model17.8 Unscrewing a distributor cap

securing screw - 2.0 litre model17.5 Removing the rotor arm and plastic

shield - 1.6 litre model (Bosch distributor)

17.3B . . .and 1.6 litre models (Lucas

distributor)

16.3 Disconnecting the coil LT wiring plug

- 2.0 litre model

Page 98 of 525

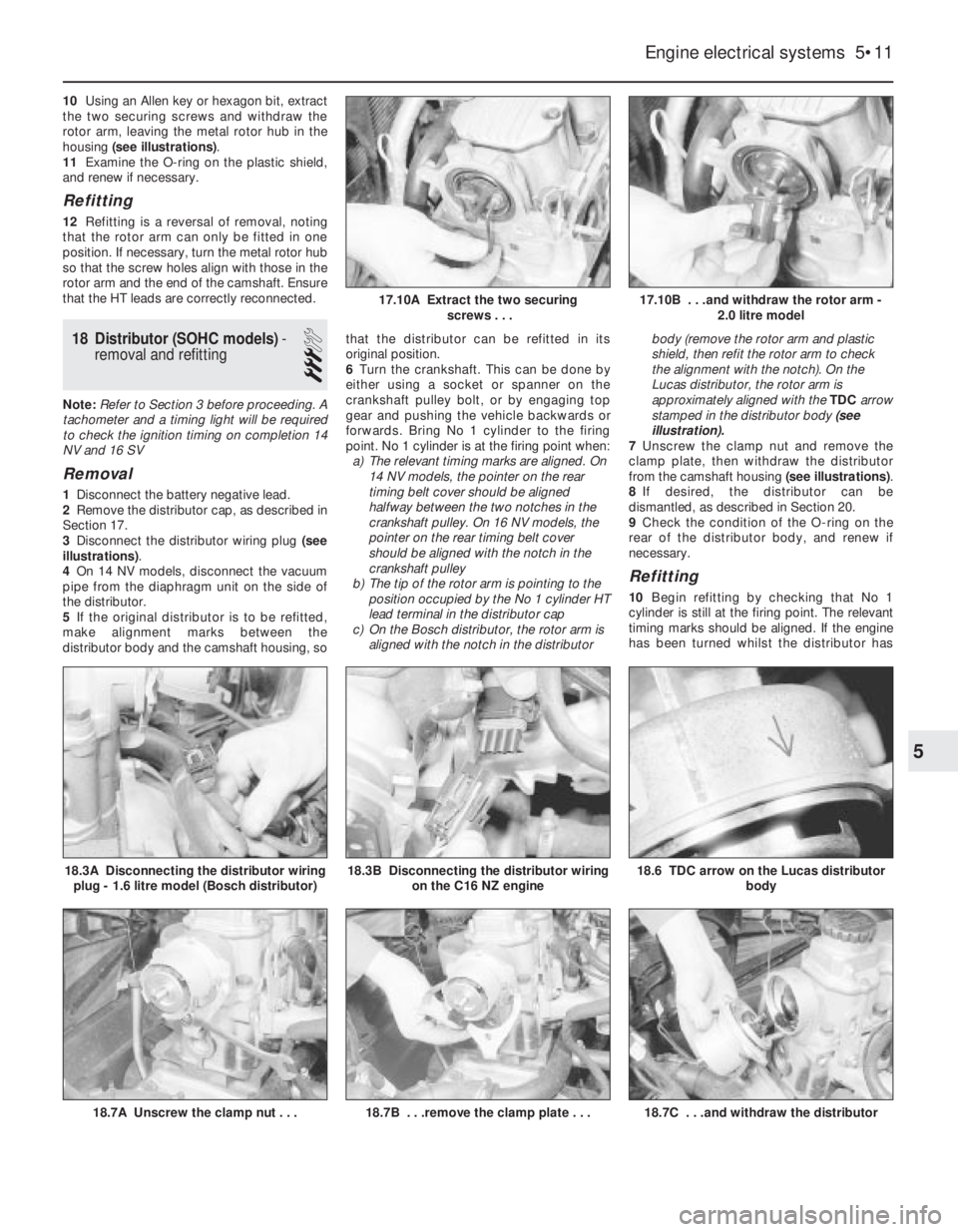

10Using an Allen key or hexagon bit, extract

the two securing screws and withdraw the

rotor arm, leaving the metal rotor hub in the

housing (see illustrations).

11Examine the O-ring on the plastic shield,

and renew if necessary.

Refitting

12Refitting is a reversal of removal, noting

that the rotor arm can only be fitted in one

position. If necessary, turn the metal rotor hub

so that the screw holes align with those in the

rotor arm and the end of the camshaft. Ensure

that the HT leads are correctly reconnected.

18Distributor (SOHC models) -

removal and refitting

3

Note: Refer to Section 3 before proceeding. A

tachometer and a timing light will be required

to check the ignition timing on completion 14

NV and 16 SV

Removal

1Disconnect the battery negative lead.

2Remove the distributor cap, as described in

Section 17.

3Disconnect the distributor wiring plug (see

illustrations).

4On 14 NV models, disconnect the vacuum

pipe from the diaphragm unit on the side of

the distributor.

5If the original distributor is to be refitted,

make alignment marks between the

distributor body and the camshaft housing, sothat the distributor can be refitted in its

original position.

6Turn the crankshaft. This can be done by

either using a socket or spanner on the

crankshaft pulley bolt, or by engaging top

gear and pushing the vehicle backwards or

forwards. Bring No 1 cylinder to the firing

point. No 1 cylinder is at the firing point when:

a)The relevant timing marks are aligned. On

14 NV models, the pointer on the rear

timing belt cover should be aligned

halfway between the two notches in the

crankshaft pulley. On 16 NV models, the

pointer on the rear timing belt cover

should be aligned with the notch in the

crankshaft pulley

b)The tip of the rotor arm is pointing to the

position occupied by the No 1 cylinder HT

lead terminal in the distributor cap

c)On the Bosch distributor, the rotor arm is

aligned with the notch in the distributorbody (remove the rotor arm and plastic

shield, then refit the rotor arm to check

the alignment with the notch). On the

Lucas distributor, the rotor arm is

approximately aligned with the TDC arrow

stamped in the distributor body (see

illustration).

7Unscrew the clamp nut and remove the

clamp plate, then withdraw the distributor

from the camshaft housing (see illustrations).

8If desired, the distributor can be

dismantled, as described in Section 20.

9Check the condition of the O-ring on the

rear of the distributor body, and renew if

necessary.

Refitting

10Begin refitting by checking that No 1

cylinder is still at the firing point. The relevant

timing marks should be aligned. If the engine

has been turned whilst the distributor has

Engine electrical systems 5•11

18.6 TDC arrow on the Lucas distributor

body

18.7C . . .and withdraw the distributor18.7B . . .remove the clamp plate . . .18.7A Unscrew the clamp nut . . .

18.3B Disconnecting the distributor wiring

on the C16 NZ engine18.3A Disconnecting the distributor wiring

plug - 1.6 litre model (Bosch distributor)

17.10B . . .and withdraw the rotor arm -

2.0 litre model17.10A Extract the two securing

screws . . .

5

Page 99 of 525

been removed, check that No 1 cylinder is on

its firing stroke by removing No 1 cylinder

spark plug and placing a finger over the plug

hole. Turn the crankshaft until compression

can be felt, which indicates that No 1 piston is

rising on its compression stroke. Continue

turning the crankshaft until the relevant timing

marks are in alignment.

11Turn the rotor arm to the position noted in

paragraph 6c, and hold the rotor arm in this

position as the distributor is fitted. Note that

the distributor driveshaft will only engage with

the camshaft in one position. If the original

distributor is being refitted, align the marks

made on the distributor body and camshaft

housing before removal.

12Refit the clamp plate and nut, but do not

fully tighten the nut at this stage.

13On the Bosch distributor, remove the rotor

arm, then refit the plastic shield and the rotor

arm.

14On 14 NV models, reconnect the vacuum

pipe to the diaphragm unit.

15Reconnect the distributor wiring plug.

16Refit the distributor cap as described in

Section 17.

17Reconnect the battery negative lead.

18Check and if necessary adjust the ignition

timing, as described in Section 21.

19Distributor (DOHC models),

where applicable - removal

and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the distributor cap, as described in

Section 17.

3Disconnect the distributor wiring plug.

4Unscrew the two securing bolts, and

remove the distributor from the cylinder head.

5Examine the O-ring on the rear of the

distributor, and renew if necessary.

Refitting

6Refitting is a reversal of removal. However,

note that the distributor should be fitted so

that the wiring plug is positioned on the upper

left-hand side of the distributor body, when

viewed from the distributor cap end.

20Distributor - dismantling,

inspection and reassembly

3

Note: Before contemplating dismantling of a

distributor, check the cost and availability of

replacement parts. It may prove more

economical to renew the complete distributor

assembly

14 NV models

Dismantling

1With the distributor removed as described

in Section 18, continue as follows.

2Pull off the rotor arm, and remove the

plastic shield.

3The top bearing plate can be removed after

unscrewing the two securing screws, however

(other than the vacuum diaphragm unit), no

spares are available for the distributor and no

adjustments are required.

4If desired, the vacuum diaphragm unit can

be removed by extracting the two securing

screws and unhooking the operating arm from

the distributor baseplate. Note that the

screws are of differing lengths, the longer

screw also secures one of the distributor cap

clips.

Inspection

5The vacuum unit can be tested by applying

suction to the vacuum port, and checking that

the operating rod moves into the unit as

suction is applied. Remove the suction, and

check that the operating rod returns to its

original position. If the operating rod does not

move as described, renew the vacuum unit.

6Check the distributor cap for corrosion of

the segments, and for signs of tracking,

indicated by a thin black line between the

segments. Make sure that the carbon brush in

the centre of the cap moves freely and stands

proud of the surface of the cap. Renew the

cap if necessary.

7If the metal portion of the rotor arm is badly

burnt or loose, renew it. If slightly burnt or

corroded; it may be cleaned with a fine file.

8Examine the seal ring at the rear of the

distributor body, and renew if necessary.

Reassembly

9Reassembly is a reversal of dismantling,

ensuring that the vacuum unit operating arm

is correctly engaged with the peg on the

baseplate, several attempts may be required

to reconnect it.

10Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

16 SV models

Dismantling

11With the distributor removed as described

in Section 18, pull off the rotor arm and, on

the Bosch distributor, remove the plastic

shield.

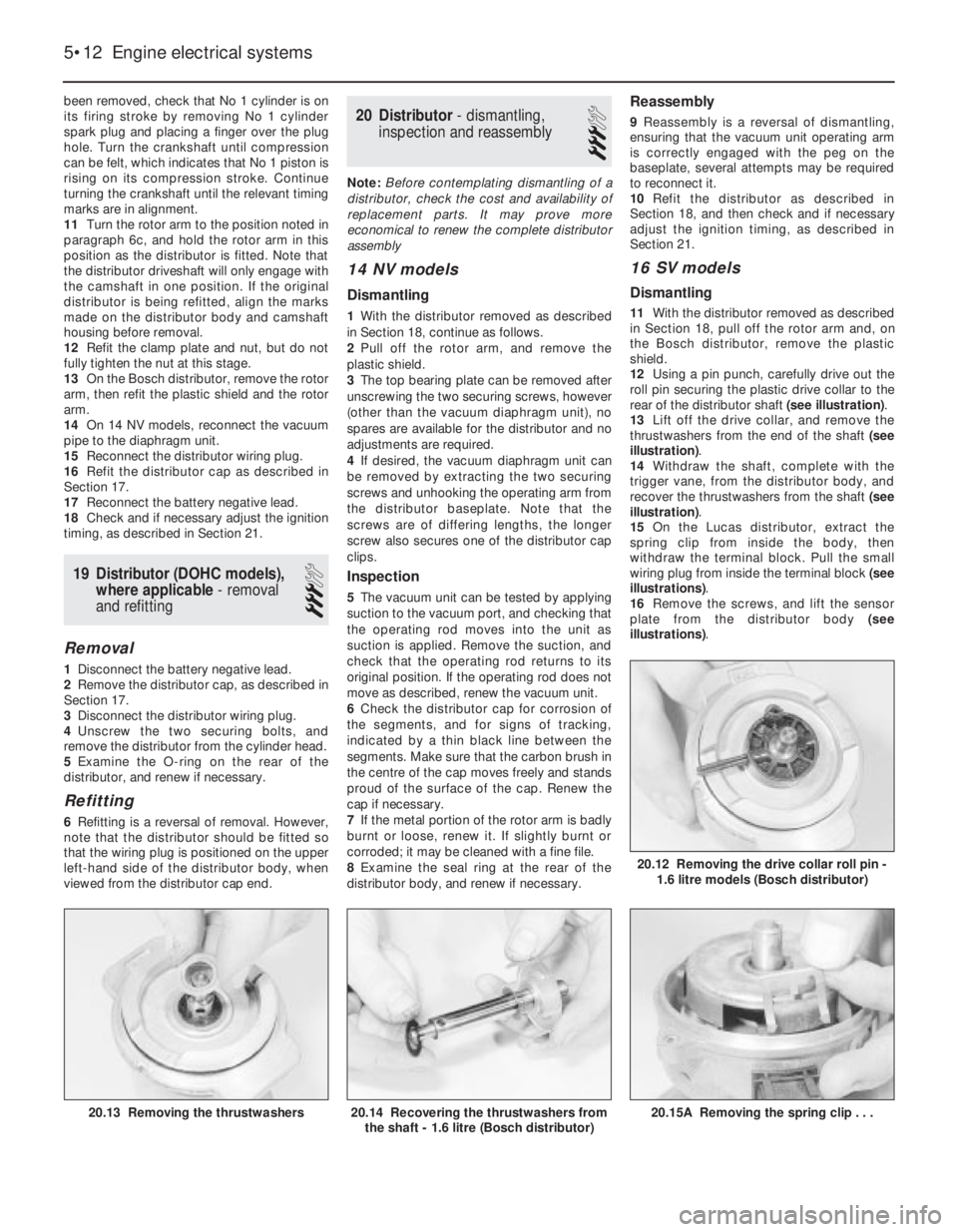

12Using a pin punch, carefully drive out the

roll pin securing the plastic drive collar to the

rear of the distributor shaft (see illustration).

13Lift off the drive collar, and remove the

thrustwashers from the end of the shaft (see

illustration).

14Withdraw the shaft, complete with the

trigger vane, from the distributor body, and

recover the thrustwashers from the shaft (see

illustration).

15On the Lucas distributor, extract the

spring clip from inside the body, then

withdraw the terminal block. Pull the small

wiring plug from inside the terminal block (see

illustrations).

16Remove the screws, and lift the sensor

plate from the distributor body (see

illustrations).

5•12Engine electrical systems

20.15A Removing the spring clip . . .20.14 Recovering the thrustwashers from

the shaft - 1.6 litre (Bosch distributor)20.13 Removing the thrustwashers

20.12 Removing the drive collar roll pin -

1.6 litre models (Bosch distributor)

Page 100 of 525

Inspection

17Examine the distributor cap and rotor arm,

as described in paragraphs 6 and 7. Examine

the O-rings at the rear of the distributor body,

and on the rear of the shaft, and renew if

necessary.

Reassembly

18Reassembly is a reversal of dismantling,

ensuring that the thrustwashers are correctly

located. Note that the drive collar should be

refitted so that the drive peg on the collar is

aligned with the groove in the top of the

distributor shaft (it is possible to fit the drive

collar 180°out of position).

19Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

DOHC models (where

applicable)

20The distributor cap and rotor arm can be

examined as described in paragraphs 6 and 7.

21Ignition timing -checking and

adjustment

4

Note: Refer to Section 3 before proceeding. A

tachometer and a timing light will be required

during this procedure. For details of ignition

timing adjustment required to operate vehicles

on unleaded petrol, refer to Section 22.

14 NV and 16 SV models

Checking

1Start the engine and run it until it reaches

normal operating temperature, then switch

off.

2On 14 NV models, disconnect the vacuum

pipe from the distributor vacuum diaphragm

unit.

3On all models use a spanner applied to the

crankshaft pulley bolt to rotate the crankshaft

clockwise until the notch in the pulley’s

inboard rim aligns with the pointer protruding

from the oil pump housing. On 14 NV models,

where two notches (indicating 10°and 5°

BTDC respectively) are found, rotate the

crankshaft until the second notch (in thedirection of rotation -i.e. 5°BTDC) aligns. Use

white paint or similar to emphasise the pointer

and notch, to make them easier to see.

4Connect a timing light to No 1 cylinder

(nearest the timing belt end of the engine) HT

lead, also a tachometer; follow the equipment

manufacturer’s instructions for connection.

5Start the engine and allow it to idle -the

speed should be between 700 and 1000 rpm.

6On 14 NV models, aim the timing light at the

pointer and check that it is aligned with the

crankshaft pulley notch.

7On early 16 SV models, disconnect the

ignition timing basic adjustment coding plug.

This can be identified by a length of Black

wire joining Brown/Red and Brown/Yellow

wires in a connector plug clipped to the wiring

or heater/cooling system hoses beneath the

battery/ignition coil (see illustration, 16.1). This

causes the MSTS-i module to adopt its basic

adjustment mode, sending a constant firing

signal corresponding to 10°BTDC and

eliminating any advance below 2000 rpm. Aim

the timing light at the pointer and check that it

is aligned with the crankshaft pulley notch.

8On later 16 SV, C 16 NZ and C 16 NZ2

models, the coding plugs are no longer fitted.

For accurate checking, special Vauxhall test

equipment must be used which causes the

MSTS module to adopt its basic adjustment

mode.

9Without access to such equipment, it is

possible to check and adjust the ignition

timing, accurate results cannot be

guaranteed. Owners are therefore advised to

have this work carried out by a suitably

equipped Vauxhall dealer; at the very least,

make the initial setting yourself and then have

it checked as soon as possible.

10If you do attempt to check the ignition

timing yourself, note that the fixed reference

mark is now an extended line embossed on

the timing belt lower outer cover.

Adjustment

11If the notch and pointer are not aligned,

loosen the distributor clamp nut and turn the

distributor body slightly in the required

direction to align.

12Tighten the distributor clamp nut, and

check that the notch and pointer are still

aligned. 13Stop the engine, and disconnect the

timing light and tachometer.

14On 16 SV models, reconnect the basic

adjustment coding plug. On 14 NV models,

reconnect the vacuum pipe to the distributor

vacuum diaphragm unit.

Other models

15No adjustment of the ignition timing is

possible on 1.8 and 2.0 litre models, as the

adjustment is carried out automatically by the

electronic control module.

16The ignition timing can be checked by a

Vauxhall dealer using specialist dedicated test

equipment, if a fault is suspected.

22Ignition timing -adjustment

for use with unleaded petrol

3

14 NV models

1All models with the 14 NV engine have the

ignition timing adjusted for use with 95 RON

unleaded petrol before they leave the factory,

and no further adjustment is required.

2Leaded petrol (98 RON) can be used if

desired, with no adverse effects.

1.6, 1.8 and 2.0 SOHC models

Note: Models equipped with a catalytic

converter must be operated on 95 R0N

unleaded petrol at all times, and although an

octane coding plug may be fitted, it should

not be tampered with

3Models, other than 14 NV, are equipped

with an octane coding plug, which is located

Engine electrical systems 5•13

20.16B . . .and withdraw the sensor plate -

1.6 litre (Bosch distributor)

20.16C Sensor plate screw (arrowed) -

1.6 litre (Lucas distributor)

20.16A Remove the securing screws . . .20.15B . . .and disconnecting the small

wiring plug - 1.6 litre (Lucas distributor)

5