check engine OPEL VECTRA 1988 Service Manual Online

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 208 of 525

14Working under the vehicle, unscrew and

remove the two nuts securing the

engine/transmission rear mounting to the front

subframe, and the three bolts securing the

mounting bracket to the transmission, then

withdraw the mounting bracket (see

illustrations).

15Carefully swing the engine/transmission

assembly across the engine compartment as

necessary, to allow the assembly to be lifted

vertically from the vehicle by raising the hoist.

Take care not to damage any of the

surrounding components in the engine

compartment.

Separation

16With the engine/transmission assembly

removed, support the assembly on blocks of

wood positioned on a workbench, or failing

that, on a clean area of the workshop floor.

17Clean away any external dirt using

paraffin or a water-soluble solvent and a stiff

brush.

18Unbolt and remove the transmission

bellhousing cover plate.

19Ensure that both engine and transmission

are adequately supported, then unscrew and

remove the engine-to-transmission bolts.

20Carefully withdraw the transmission from

the engine, ensuring that the weight of the

transmission is not allowed to hang on the

input shaft while it is engaged with the clutch

friction disc. Note that the transmission

locates on dowels positioned in the cylinder

block.

21On automatic models unbolt the

transmission bellhousing cover plate (three

bolts), then use chalk or a felt-tip pen to mark

the relationship of the torque converter to the

flexplate before unbolting the torque

converter. Note:If the torque converter is

removed (even partially) from the transmission,

a considerable amount of the fluid inside it will

leak out. To prevent this, when prising the

transmission off its locating dowels and

removing it, be careful to keep the torque

converter pressed firmly into the transmission.

If the transmission is to be removed for some

time, retain the torque converter by bolting a

strip of metal across the bellhousing mating

surface. Applying a spanner to the crankshaft

pulley/sprocket bolt, rotate the crankshaft

until the first bolt appears, then use ascrewdriver or similar to jam the flexplate ring

gear teeth to prevent it from rotating as the

bolt is unscrewed. Unscrew each of the three

bolts in turn and remove them.

Reconnection

22Before beginning the refitting operations,

check that the two original bolts that secured

the left-hand transmission rubber mounting to

the vehicle body rotate freely in their threaded

bores in the body. If necessary, re-cut the

threaded bores using an M10 x 1.25 mm tap.

23Where applicable, if the clutch assembly

has been removed from the flywheel, it will

prove easier to refit after the transmission has

been refitted.

24On automatics, if any fluid was spilled from

the torque converter, be careful to refill it as

much as possible. Wipe clean the converter’s

spigot to prevent damage to the transmission’s

input shaft oil seal as the converter is installed,

and ensure that the converter engages

correctly on the fluid pump shaft.

25If the transmission has been renewed, be

careful to flush clean the radiator fluid cooler

passages. Vauxhall recommend the use of

low-pressure compressed air, but this will

require great care to avoid deforming the

radiator.

26Be very careful to ensure that all

components are scrupulously clean, to avoid

the risk of dirt getting into the system.

27Use an M10 x 1.25 bottoming tap to clean

the threads in the torque converters threaded

bosses and ensure that new bolts are

available for reassembly, where applicable.

28Tighten all nuts and bolts to their specified

torque wrench settings.

29Refer also to Section 7, paragraphs 35

and 36.

30Carefully offer the transmission to the

engine until the bellhousing is located on the

dowels in the cylinder block, then refit the

engine-to-transmission bolts, and tighten

them to the specified torque.

31Refit the transmission bellhousing cover

plate.

Refitting

32Working under the vehicle, refit the rear

engine/transmission mounting to the

transmission, using new locking plates under

the bolt heads, and tighten the bolts to the

specified torque.

33Fit the two bolts securing the engine/

transmission rear mounting to the front

subframe, but do not fully tighten at this stage.

34Fit the right-hand engine mounting

bracket to the cylinder block, and tighten the

securing bolts to the specified torque.

35Fit new right-hand engine

mounting-to-body bolts, but do not fully

tighten them at this stage.

36Fit the left-hand transmission mounting

bracket to the transmission, and tighten the

securing bolts to the specified torque.

37Fit new left-hand transmission

mounting-to-body bolts, and tighten them to

the specified torque.

38Tighten the right-hand engine mounting-

to-body bolts and the engine/transmission

rear mounting-to-front subframe bolts to their

specified torques, then remove the lifting

tackle and hoist from the engine.

39Where applicable, the clutch can now be

fitted, and the transmission input shaft can be

pressed into engagement with the splined hub

of the clutch friction disc, (see Chapter 5).

40Reconnect the inboard ends of the

driveshafts to the differential, with reference

to the relevant paragraphs of Chapter 8, and

using new snap rings.

41Refit the front section of the exhaust

system, as described in Chapter 4C.

42Refit the crankshaft pulley, using a

reversal of the removal procedure described

in Section 7, paragraph 22, and tighten the

securing bolt(s) to the specified torque.

43On automatic models, connect the wires

to the various switches, solenoids and

sensors. Replace the transmission breather

hose and oxygen sensor (if fitted).

44Reconnect the transmission earth strap,

and tighten the securing nut.

45Lower the vehicle to the ground.

46Reconnect the speedometer cable to the

transmission, and tighten the securing sleeve.

47Reconnect the reversing lamp wiring.

48On manual transmission models, refit the

clutch cable to the bracket on the

transmission casing, then reconnect the cable

to the release lever, and adjust the cable as

described in Chapter 6. Ensure that the cable

is routed as noted during removal.

49Refit the gear selector linkage, as

described in Chapter 7A, if applicable.

50Proceed as described in Section 7,

paragraphs 41 to 52 inclusive.

51Top-up the transmission oil level, as

described in Chapters 7A and 7B.

52Adjust the selector cable on completion,

and refill the transmission with fluid (see

above).

53Reconnect the battery negative lead.

54Refer to Section 37

SOHC engine procedures 2A•11

8.14B Rear engine/transmission mounting-

to-transmission bolts (arrowed)8.14A Rear engine/transmission

mounting-to-front subframe nuts

2A

If a tap is not available, cut

two slots into the threads of

one of the old flywheel bolts

and use the bolt to remove

the locking compound from the threads.

Page 209 of 525

9Engine and transmission

mountings - renewal

3

Note: New left and right-hand

engine/transmission mounting-to-body bolts

must be used on refitting

1The engine/transmission assembly is

suspended in the engine compartment on

three mountings, two of which are attached to

the transmission, and one to the engine.

Right-hand mounting

2If not already done, apply the handbrake,

then raise the front of the vehicle, and support

securely on axle stands (see “Jacking and

Vehicle Support”)..

3Attach lifting tackle and a hoist to the

engine lifting brackets on the cylinder head,

and support the weight of the engine.

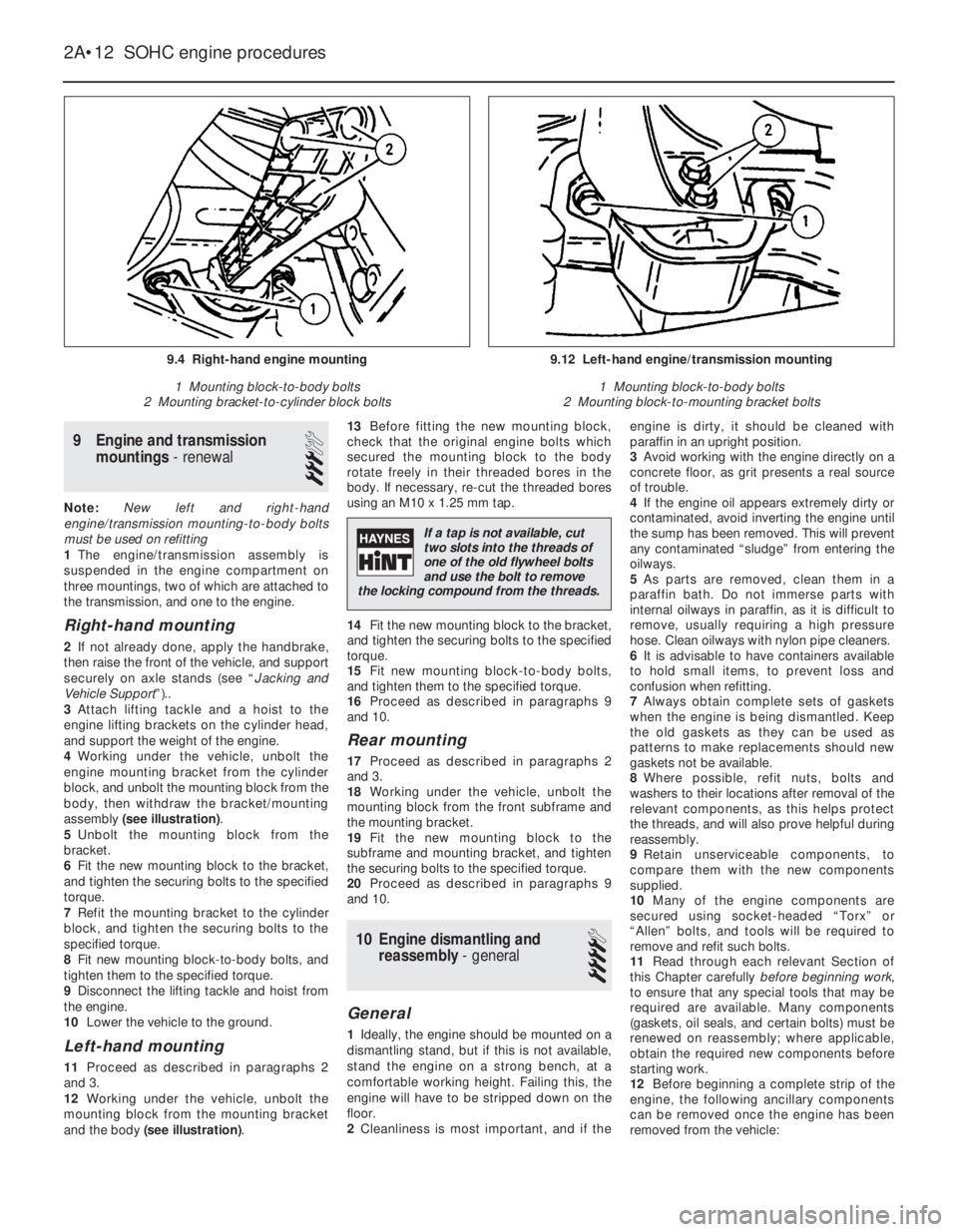

4Working under the vehicle, unbolt the

engine mounting bracket from the cylinder

block, and unbolt the mounting block from the

body, then withdraw the bracket/mounting

assembly (see illustration).

5Unbolt the mounting block from the

bracket.

6Fit the new mounting block to the bracket,

and tighten the securing bolts to the specified

torque.

7Refit the mounting bracket to the cylinder

block, and tighten the securing bolts to the

specified torque.

8Fit new mounting block-to-body bolts, and

tighten them to the specified torque.

9Disconnect the lifting tackle and hoist from

the engine.

10Lower the vehicle to the ground.

Left-hand mounting

11Proceed as described in paragraphs 2

and 3.

12Working under the vehicle, unbolt the

mounting block from the mounting bracket

and the body (see illustration).13Before fitting the new mounting block,

check that the original engine bolts which

secured the mounting block to the body

rotate freely in their threaded bores in the

body. If necessary, re-cut the threaded bores

using an M10 x 1.25 mm tap.

14Fit the new mounting block to the bracket,

and tighten the securing bolts to the specified

torque.

15Fit new mounting block-to-body bolts,

and tighten them to the specified torque.

16Proceed as described in paragraphs 9

and 10.

Rear mounting

17Proceed as described in paragraphs 2

and 3.

18Working under the vehicle, unbolt the

mounting block from the front subframe and

the mounting bracket.

19Fit the new mounting block to the

subframe and mounting bracket, and tighten

the securing bolts to the specified torque.

20Proceed as described in paragraphs 9

and 10.

10Engine dismantling and

reassembly - general

4

General

1Ideally, the engine should be mounted on a

dismantling stand, but if this is not available,

stand the engine on a strong bench, at a

comfortable working height. Failing this, the

engine will have to be stripped down on the

floor.

2Cleanliness is most important, and if theengine is dirty, it should be cleaned with

paraffin in an upright position.

3Avoid working with the engine directly on a

concrete floor, as grit presents a real source

of trouble.

4If the engine oil appears extremely dirty or

contaminated, avoid inverting the engine until

the sump has been removed. This will prevent

any contaminated “sludge” from entering the

oilways.

5As parts are removed, clean them in a

paraffin bath. Do not immerse parts with

internal oilways in paraffin, as it is difficult to

remove, usually requiring a high pressure

hose. Clean oilways with nylon pipe cleaners.

6It is advisable to have containers available

to hold small items, to prevent loss and

confusion when refitting.

7Always obtain complete sets of gaskets

when the engine is being dismantled. Keep

the old gaskets as they can be used as

patterns to make replacements should new

gaskets not be available.

8Where possible, refit nuts, bolts and

washers to their locations after removal of the

relevant components, as this helps protect

the threads, and will also prove helpful during

reassembly.

9Retain unserviceable components, to

compare them with the new components

supplied.

10Many of the engine components are

secured using socket-headed “Torx” or

“Allen” bolts, and tools will be required to

remove and refit such bolts.

11Read through each relevant Section of

this Chapter carefullybeforebeginning work,

to ensure that any special tools that may be

required are available. Many components

(gaskets, oil seals, and certain bolts) must be

renewed on reassembly; where applicable,

obtain the required new components before

starting work.

12Before beginning a complete strip of the

engine, the following ancillary components

can be removed once the engine has been

removed from the vehicle:

2A•12SOHC engine procedures

9.4 Right-hand engine mounting

1 Mounting block-to-body bolts

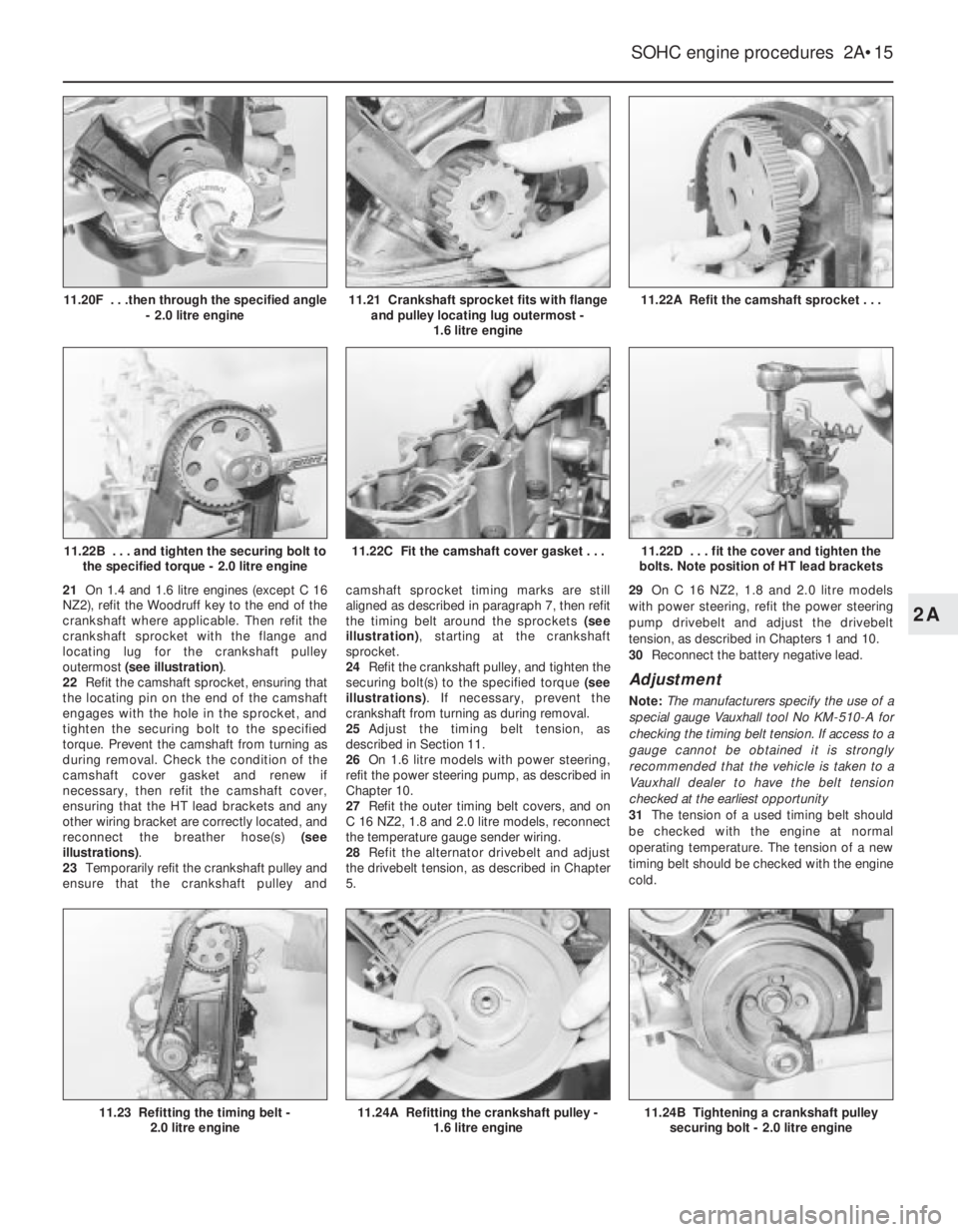

2 Mounting bracket-to-cylinder block bolts9.12 Left-hand engine/transmission mounting

1 Mounting block-to-body bolts

2 Mounting block-to-mounting bracket bolts

If a tap is not available, cut

two slots into the threads of

one of the old flywheel bolts

and use the bolt to remove

the locking compound from the threads.

Page 212 of 525

21On 1.4 and 1.6 litre engines (except C 16

NZ2), refit the Woodruff key to the end of the

crankshaft where applicable. Then refit the

crankshaft sprocket with the flange and

locating lug for the crankshaft pulley

outermost (see illustration).

22Refit the camshaft sprocket, ensuring that

the locating pin on the end of the camshaft

engages with the hole in the sprocket, and

tighten the securing bolt to the specified

torque. Prevent the camshaft from turning as

during removal. Check the condition of the

camshaft cover gasket and renew if

necessary, then refit the camshaft cover,

ensuring that the HT lead brackets and any

other wiring bracket are correctly located, and

reconnect the breather hose(s) (see

illustrations).

23Temporarily refit the crankshaft pulley and

ensure that the crankshaft pulley andcamshaft sprocket timing marks are still

aligned as described in paragraph 7, then refit

the timing belt around the sprockets (see

illustration), starting at the crankshaft

sprocket.

24Refit the crankshaft pulley, and tighten the

securing bolt(s) to the specified torque (see

illustrations). If necessary, prevent the

crankshaft from turning as during removal.

25Adjust the timing belt tension, as

described in Section 11.

26On 1.6 litre models with power steering,

refit the power steering pump, as described in

Chapter 10.

27Refit the outer timing belt covers, and on

C 16 NZ2, 1.8 and 2.0 litre models, reconnect

the temperature gauge sender wiring.

28Refit the alternator drivebelt and adjust

the drivebelt tension, as described in Chapter

5.29On C 16 NZ2, 1.8 and 2.0 litre models

with power steering, refit the power steering

pump drivebelt and adjust the drivebelt

tension, as described in Chapters 1 and 10.

30Reconnect the battery negative lead.

Adjustment

Note: The manufacturers specify the use of a

special gauge Vauxhall tool No KM-510-A for

checking the timing belt tension. If access to a

gauge cannot be obtained it is strongly

recommended that the vehicle is taken to a

Vauxhall dealer to have the belt tension

checked at the earliest opportunity

31The tension of a used timing belt should

be checked with the engine at normal

operating temperature. The tension of a new

timing belt should be checked with the engine

cold.

SOHC engine procedures 2A•15

11.22A Refit the camshaft sprocket . . .

11.24B Tightening a crankshaft pulley

securing bolt - 2.0 litre engine11.24A Refitting the crankshaft pulley -

1.6 litre engine11.23 Refitting the timing belt -

2.0 litre engine

11.22D . . . fit the cover and tighten the

bolts. Note position of HT lead brackets11.22C Fit the camshaft cover gasket . . .11.22B . . . and tighten the securing bolt to

the specified torque - 2.0 litre engine

11.21 Crankshaft sprocket fits with flange

and pulley locating lug outermost -

1.6 litre engine11.20F . . .then through the specified angle

- 2.0 litre engine

2A

Page 213 of 525

32Release the securing clips and remove the

main outer timing belt cover, then unclip the

smaller outer timing belt cover from the

coolant pump.

33Turn the crankshaft through at least

quarter of a turn clockwise using a socket or

spanner on the crankshaft sprocket bolt.

34If the special gauge is available, place the

locked gauge at the centre of the belt run

between the coolant pump and the camshaft

sprocket. The gauge should locate on the

timing belt (see illustration).

35Slowly release the operating lever on the

gauge, then lightly tap the gauge two or three

times, and note the reading on the scale (see

illustration).

36If the reading is not as specified, loosen

the three coolant pump securing bolts, and

rotate the pump in the required direction to

achieve the desired reading on the gauge.

Rotate the pump clockwise to increase the

belt tension, or anti-clockwise to decrease the

tension.

37Lightly tighten the coolant pump securing

bolts.

38Remove the tensioning gauge, and turn

the crankshaft through one full turn clockwise.

39Re-check the belt tension as described in

paragraphs 4 and 5.

40If the tension is not as specified, repeat

paragraphs 6 to 9 inclusive until the desired,

consistent, reading is obtained.

41On completion of adjustment, remove the

checking gauge, tighten the coolant pump

bolts to the specified torque, and refit the

outer timing belt covers.

42If the special checking gauge is not

available, the timing belt tension can be

checked approximately by twisting the belt

between the thumb and forefinger, at the

centre of the run between the coolant pump

and the camshaft sprocket. It should just be

possible to twist the belt through 90°using

moderate pressure (see illustration). If

adjustment is necessary, continue as

described previously in this Section, but have

the belt tension checked by a Vauxhall dealer

using the special gauge at the earliest

opportunity. If in doubt, err on the tight side

when adjusting the tension, as if the belt is too

slack, it may jump on the sprockets, which

could result in serious engine damage.12Timing belt and tensioner 1.4

and 1.6 models (not C16 NZ2) -

removal, refitting and adjustment

3

Removal

1Remove the timing belt outer covers as

described in Section 11, paragraphs 1 to 5.

2To lock the tensioner in its slackest position

for removal and refitting, move the tensioner

indicator arm clockwise until the holes align in

the baseplate and the arm. Then insert a

close-fitting pin, such as a drift, to retain them

(see illustration). The tensioner can then be

unbolted, or the belt can be removed.

3Check that the tensioner roller rotates

smoothly and easily, with no noises or signs

of free play, roughness or notchy movement.

Check also that there is no sign of physical

wear or damage. If the tensioner is faulty in

any way, or if there is any reason to doubt the

continued efficiency of its spring, the

complete assembly must be renewed.

Refitting

4On refitting, ensure that the tensioner

baseplate lug engages with the hole in the oil

pump housing, then tighten the tensioner bolt

securely and remove the locking pin; the

tensioner should be quite free to move.

5Set the belt tension as described below.

Adjustment

6Whenever the timing belt is disturbed,

whether during belt renewal or any otherengine overhaul work, its tension must be set

on assembly - note that this procedure must

only be carried out on a cold engine.

7It is assumed that the belt has been

removed and refitted, i.e. that the crankshaft

pulley and timing belt outer covers are

removed, that the tensioner is unlocked (see

above) and that No 1 cylinder is in its firing

position (just before TDC on the compression

stroke). Temporarily refit the crankshaft pulley

bolt and remove the spark plugs so that the

crankshaft can be rotated easily.

8Note also that turning the coolant pump

with the precision required is a great deal

easier if a special spanner (Kent-Moore Part

No KM-421-A) is used. Alternatives are

available from manufacturers such as

Sykes-Pickavant (Part No 031300) (see

illustration).

9With the belt refitted and correctly routed

(see Section 11), ensure that the punch mark

on the crankshaft sprocket and the stamped

line on the camshaft sprocket are aligned with

their respective timing belt rear cover notches

(see illustrations).

10Tighten the belt by slackening its three

securing bolts, and turning the coolant pump

clockwise until the holes align in the tensioner

indicator arm and baseplate (the tensioner

indicator arm will then have moved fully

clockwise to its stop). Lightly tighten the

pump securing bolts, just sufficiently to

prevent the pump from moving.

11Using a spanner applied to the crankshaft

pulley bolt, turn the crankshaft smoothly

2A•16SOHC engine procedures

11.34 Tension blade KM-510-A correctly

positioned on timing belt. Belt must pass

through points A, B and C - SOHC engines11.42 Checking timing belt tension by

twisting belt through 90º between thumb

and forefinger

12.8 Using a special spanner to adjust the

timing belt by moving the coolant pump12.2 Using a close-fitting drift to lock the

tensioner. Note baseplate lug engaged in

oil pump housing (arrowed)

11.35 Note the reading on the scale of the

tension gauge -

1.6 litre engine

Page 214 of 525

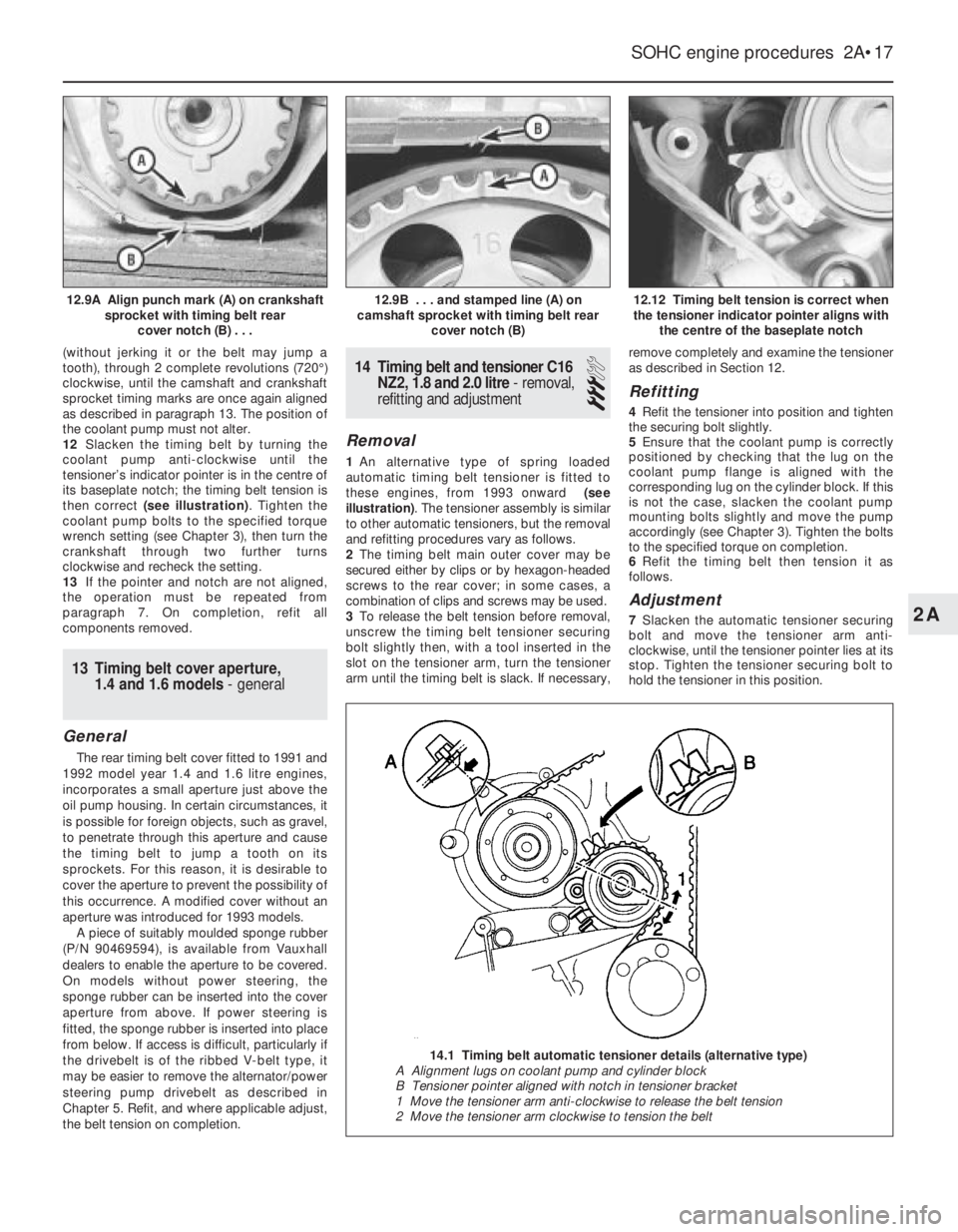

(without jerking it or the belt may jump a

tooth), through 2 complete revolutions (720°)

clockwise, until the camshaft and crankshaft

sprocket timing marks are once again aligned

as described in paragraph 13. The position of

the coolant pump must not alter.

12Slacken the timing belt by turning the

coolant pump anti-clockwise until the

tensioner’s indicator pointer is in the centre of

its baseplate notch; the timing belt tension is

then correct (see illustration). Tighten the

coolant pump bolts to the specified torque

wrench setting (see Chapter 3), then turn the

crankshaft through two further turns

clockwise and recheck the setting.

13If the pointer and notch are not aligned,

the operation must be repeated from

paragraph 7. On completion, refit all

components removed.

13Timing belt cover aperture,

1.4 and 1.6 models - general

General

The rear timing belt cover fitted to 1991 and

1992 model year 1.4 and 1.6 litre engines,

incorporates a small aperture just above the

oil pump housing. In certain circumstances, it

is possible for foreign objects, such as gravel,

to penetrate through this aperture and cause

the timing belt to jump a tooth on its

sprockets. For this reason, it is desirable to

cover the aperture to prevent the possibility of

this occurrence. A modified cover without an

aperture was introduced for 1993 models.

A piece of suitably moulded sponge rubber

(P/N 90469594), is available from Vauxhall

dealers to enable the aperture to be covered.

On models without power steering, the

sponge rubber can be inserted into the cover

aperture from above. If power steering is

fitted, the sponge rubber is inserted into place

from below. If access is difficult, particularly if

the drivebelt is of the ribbed V-belt type, it

may be easier to remove the alternator/power

steering pump drivebelt as described in

Chapter 5. Refit, and where applicable adjust,

the belt tension on completion.

14Timing belt and tensioner C16

NZ2, 1.8 and 2.0 litre - removal,

refitting and adjustment

3

Removal

1An alternative type of spring loaded

automatic timing belt tensioner is fitted to

these engines, from 1993 onward (see

illustration). The tensioner assembly is similar

to other automatic tensioners, but the removal

and refitting procedures vary as follows.

2The timing belt main outer cover may be

secured either by clips or by hexagon-headed

screws to the rear cover; in some cases, a

combination of clips and screws may be used.

3To release the belt tension before removal,

unscrew the timing belt tensioner securing

bolt slightly then, with a tool inserted in the

slot on the tensioner arm, turn the tensioner

arm until the timing belt is slack. If necessary,remove completely and examine the tensioner

as described in Section 12.

Refitting

4Refit the tensioner into position and tighten

the securing bolt slightly.

5Ensure that the coolant pump is correctly

positioned by checking that the lug on the

coolant pump flange is aligned with the

corresponding lug on the cylinder block. If this

is not the case, slacken the coolant pump

mounting bolts slightly and move the pump

accordingly (see Chapter 3). Tighten the bolts

to the specified torque on completion.

6Refit the timing belt then tension it as

follows.

Adjustment

7Slacken the automatic tensioner securing

bolt and move the tensioner arm anti-

clockwise, until the tensioner pointer lies at its

stop. Tighten the tensioner securing bolt to

hold the tensioner in this position.

SOHC engine procedures 2A•17

12.12 Timing belt tension is correct when

the tensioner indicator pointer aligns with

the centre of the baseplate notch12.9B . . . and stamped line (A) on

camshaft sprocket with timing belt rear

cover notch (B)12.9A Align punch mark (A) on crankshaft

sprocket with timing belt rear

cover notch (B) . . .

2A

14.1 Timing belt automatic tensioner details (alternative type)

A Alignment lugs on coolant pump and cylinder block

B Tensioner pointer aligned with notch in tensioner bracket

1 Move the tensioner arm anti-clockwise to release the belt tension

2 Move the tensioner arm clockwise to tension the belt

Page 215 of 525

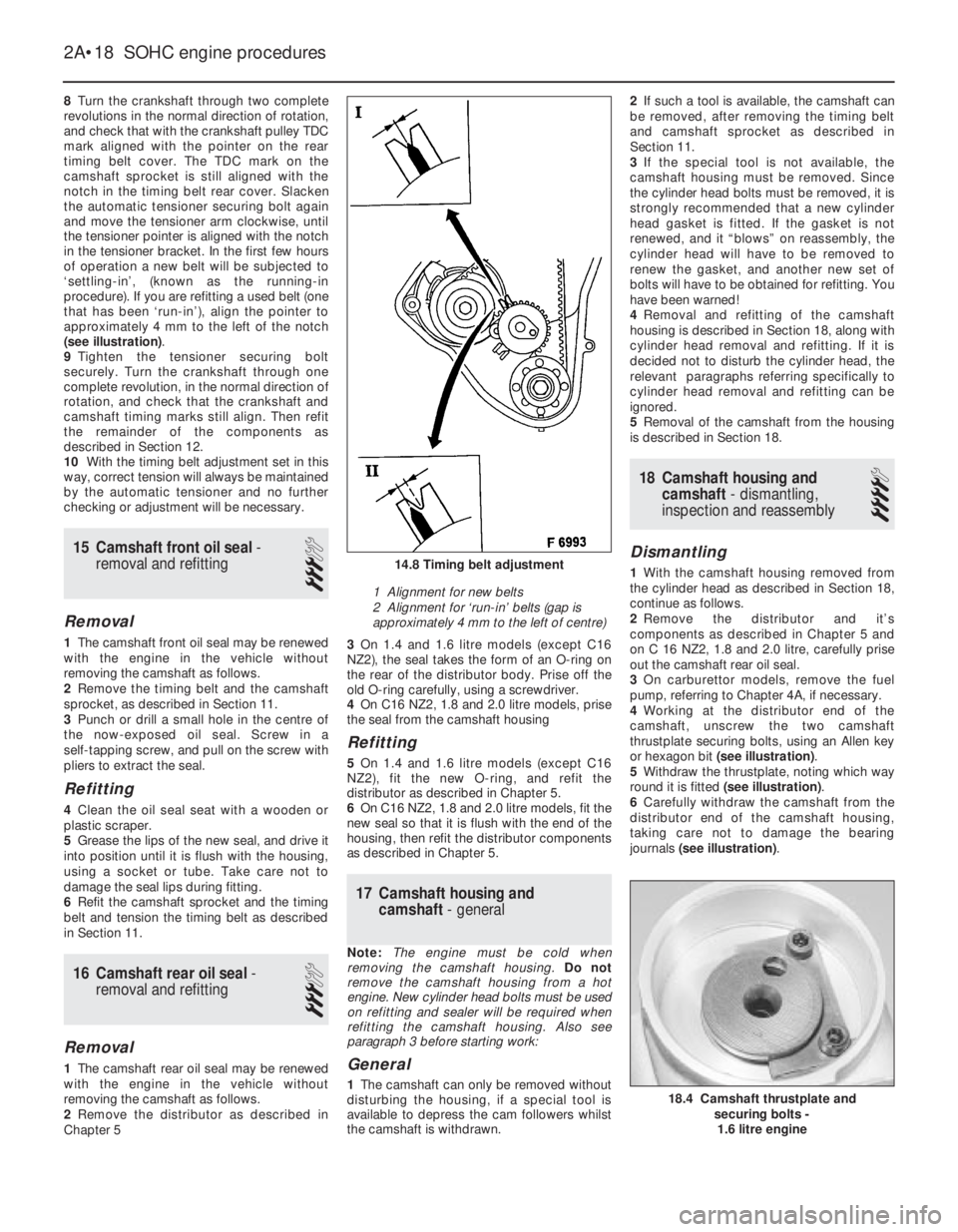

8Turn the crankshaft through two complete

revolutions in the normal direction of rotation,

and check that with the crankshaft pulley TDC

mark aligned with the pointer on the rear

timing belt cover. The TDC mark on the

camshaft sprocket is still aligned with the

notch in the timing belt rear cover. Slacken

the automatic tensioner securing bolt again

and move the tensioner arm clockwise, until

the tensioner pointer is aligned with the notch

in the tensioner bracket. In the first few hours

of operation a new belt will be subjected to

‘settling-in’, (known as the running-in

procedure). If you are refitting a used belt (one

that has been ‘run-in’), align the pointer to

approximately 4 mm to the left of the notch

(see illustration).

9Tighten the tensioner securing bolt

securely. Turn the crankshaft through one

complete revolution, in the normal direction of

rotation, and check that the crankshaft and

camshaft timing marks still align. Then refit

the remainder of the components as

described in Section 12.

10With the timing belt adjustment set in this

way, correct tension will always be maintained

by the automatic tensioner and no further

checking or adjustment will be necessary.

15Camshaft front oil seal -

removal and refitting

3

Removal

1The camshaft front oil seal may be renewed

with the engine in the vehicle without

removing the camshaft as follows.

2Remove the timing belt and the camshaft

sprocket, as described in Section 11.

3Punch or drill a small hole in the centre of

the now-exposed oil seal. Screw in a

self-tapping screw, and pull on the screw with

pliers to extract the seal.

Refitting

4Clean the oil seal seat with a wooden or

plastic scraper.

5Grease the lips of the new seal, and drive it

into position until it is flush with the housing,

using a socket or tube. Take care not to

damage the seal lips during fitting.

6Refit the camshaft sprocket and the timing

belt and tension the timing belt as described

in Section 11.

16Camshaft rear oil seal -

removal and refitting

3

Removal

1The camshaft rear oil seal may be renewed

with the engine in the vehicle without

removing the camshaft as follows.

2Remove the distributor as described in

Chapter 53On 1.4 and 1.6 litre models (except C16

NZ2), the seal takes the form of an O-ring on

the rear of the distributor body. Prise off the

old O-ring carefully, using a screwdriver.

4On C16 NZ2, 1.8 and 2.0 litre models, prise

the seal from the camshaft housing

Refitting

5 On 1.4 and 1.6 litre models (except C16

NZ2), fit the new O-ring, and refit the

distributor as described in Chapter 5.

6On C16 NZ2, 1.8 and 2.0 litre models, fit the

new seal so that it is flush with the end of the

housing, then refit the distributor components

as described in Chapter 5.

17Camshaft housing and

camshaft -general

Note: The engine must be cold when

removing the camshaft housing. Do not

remove the camshaft housing from a hot

engine. New cylinder head bolts must be used

on refitting and sealer will be required when

refitting the camshaft housing. Also see

paragraph 3 before starting work:

General

1The camshaft can only be removed without

disturbing the housing, if a special tool is

available to depress the cam followers whilst

the camshaft is withdrawn.2If such a tool is available, the camshaft can

be removed, after removing the timing belt

and camshaft sprocket as described in

Section 11.

3If the special tool is not available, the

camshaft housing must be removed. Since

the cylinder head bolts must be removed, it is

strongly recommended that a new cylinder

head gasket is fitted. If the gasket is not

renewed, and it “blows” on reassembly, the

cylinder head will have to be removed to

renew the gasket, and another new set of

bolts will have to be obtained for refitting. You

have been warned!

4Removal and refitting of the camshaft

housing is described in Section 18, along with

cylinder head removal and refitting. If it is

decided not to disturb the cylinder head, the

relevant paragraphs referring specifically to

cylinder head removal and refitting can be

ignored.

5Removal of the camshaft from the housing

is described in Section 18.

18Camshaft housing and

camshaft - dismantling,

inspection and reassembly

4

Dismantling

1With the camshaft housing removed from

the cylinder head as described in Section 18,

continue as follows.

2Remove the distributor and it’s

components as described in Chapter 5 and

on C 16 NZ2, 1.8 and 2.0 litre, carefully prise

out the camshaft rear oil seal.

3On carburettor models, remove the fuel

pump, referring to Chapter 4A, if necessary.

4Working at the distributor end of the

camshaft, unscrew the two camshaft

thrustplate securing bolts, using an Allen key

or hexagon bit (see illustration).

5Withdraw the thrustplate, noting which way

round it is fitted (see illustration).

6Carefully withdraw the camshaft from the

distributor end of the camshaft housing,

taking care not to damage the bearing

journals (see illustration).

2A•18SOHC engine procedures

14.8 Timing belt adjustment

1 Alignment for new belts

2 Alignment for ‘run-in’ belts (gap is

approximately 4 mm to the left of centre)

18.4 Camshaft thrustplate and

securing bolts -

1.6 litre engine

Page 216 of 525

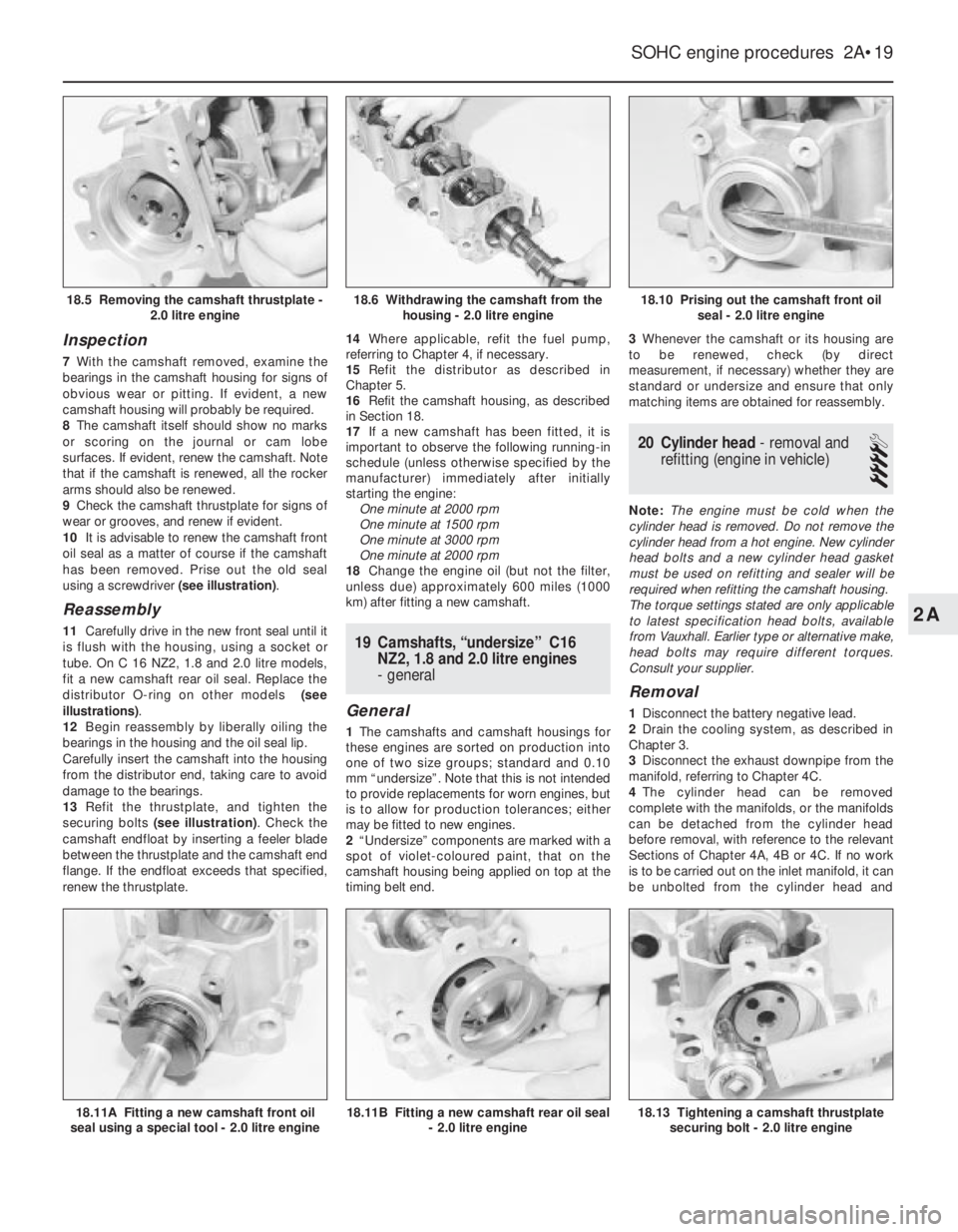

Inspection

7With the camshaft removed, examine the

bearings in the camshaft housing for signs of

obvious wear or pitting. If evident, a new

camshaft housing will probably be required.

8The camshaft itself should show no marks

or scoring on the journal or cam lobe

surfaces. If evident, renew the camshaft. Note

that if the camshaft is renewed, all the rocker

arms should also be renewed.

9Check the camshaft thrustplate for signs of

wear or grooves, and renew if evident.

10It is advisable to renew the camshaft front

oil seal as a matter of course if the camshaft

has been removed. Prise out the old seal

using a screwdriver (see illustration).

Reassembly

11Carefully drive in the new front seal until it

is flush with the housing, using a socket or

tube. On C 16 NZ2, 1.8 and 2.0 litre models,

fit a new camshaft rear oil seal. Replace the

distributor O-ring on other models (see

illustrations).

12Begin reassembly by liberally oiling the

bearings in the housing and the oil seal lip.

Carefully insert the camshaft into the housing

from the distributor end, taking care to avoid

damage to the bearings.

13Refit the thrustplate, and tighten the

securing bolts (see illustration). Check the

camshaft endfloat by inserting a feeler blade

between the thrustplate and the camshaft end

flange. If the endfloat exceeds that specified,

renew the thrustplate.14Where applicable, refit the fuel pump,

referring to Chapter 4, if necessary.

15Refit the distributor as described in

Chapter 5.

16Refit the camshaft housing, as described

in Section 18.

17If a new camshaft has been fitted, it is

important to observe the following running-in

schedule (unless otherwise specified by the

manufacturer) immediately after initially

starting the engine:

One minute at 2000 rpm

One minute at 1500 rpm

One minute at 3000 rpm

One minute at 2000 rpm

18Change the engine oil (but not the filter,

unless due) approximately 600 miles (1000

km) after fitting a new camshaft.19Camshafts, “undersize” C16

NZ2, 1.8 and 2.0 litre engines

- general

General

1The camshafts and camshaft housings for

these engines are sorted on production into

one of two size groups; standard and 0.10

mm “undersize”. Note that this is not intended

to provide replacements for worn engines, but

is to allow for production tolerances; either

may be fitted to new engines.

2“Undersize” components are marked with a

spot of violet-coloured paint, that on the

camshaft housing being applied on top at the

timing belt end.3Whenever the camshaft or its housing are

to be renewed, check (by direct

measurement, if necessary) whether they are

standard or undersize and ensure that only

matching items are obtained for reassembly.

20Cylinder head - removal and

refitting (engine in vehicle)

4

Note: The engine must be cold when the

cylinder head is removed. Do not remove the

cylinder head from a hot engine. New cylinder

head bolts and a new cylinder head gasket

must be used on refitting and sealer will be

required when refitting the camshaft housing.

The torque settings stated are only applicable

to latest specification head bolts, available

from Vauxhall. Earlier type or alternative make,

head bolts may require different torques.

Consult your supplier.

Removal

1Disconnect the battery negative lead.

2Drain the cooling system, as described in

Chapter 3.

3Disconnect the exhaust downpipe from the

manifold, referring to Chapter 4C.

4The cylinder head can be removed

complete with the manifolds, or the manifolds

can be detached from the cylinder head

before removal, with reference to the relevant

Sections of Chapter 4A, 4B or 4C. If no work

is to be carried out on the inlet manifold, it can

be unbolted from the cylinder head and

SOHC engine procedures 2A•19

18.10 Prising out the camshaft front oil

seal - 2.0 litre engine

18.13 Tightening a camshaft thrustplate

securing bolt - 2.0 litre engine18.11B Fitting a new camshaft rear oil seal

- 2.0 litre engine18.11A Fitting a new camshaft front oil

seal using a special tool - 2.0 litre engine

18.6 Withdrawing the camshaft from the

housing - 2.0 litre engine18.5 Removing the camshaft thrustplate -

2.0 litre engine

2A

Page 217 of 525

supported to one side out of the way, thus

avoiding the need to disconnect the relevant

hoses, pipes and wiring.

5If the cylinder head is to be removed

complete with the manifolds, disconnect all

relevant hoses, pipes and wiring from the inlet

manifold and associated components,

referring to Chapter 4A or 4B. On carburettor

models, disconnect the hot air hose from the

shroud on the exhaust manifold. Loosen the

alternator mountings, with reference to

Chapter 5, then unbolt the upper alternator

mounting from the inlet manifold.

6If the inlet manifold is to be left in the engine

compartment, continue as follows, otherwise

go on to paragraph 15.

7Disconnect the air cleaner trunking from the

air box on the carburettor or throttle body, or

directly from the throttle body (as applicable),

and disconnect the camshaft cover breather

hose that runs to the carburettor or throttle

body (as applicable), (see illustration).

8On C 16 NZ2, 1.8 and 2.0 litre models,

disconnect the smaller coolant hose from the

top of the thermostat housing.

9On 1.6 litre models (except C 16 NZ2),

disconnect the breather hose (which runs

from the camshaft cover to the inlet manifold)

at the camshaft cover.

10On fuel injection models, unbolt the two

wiring harnesses earth leads from the

camshaft housing (see illustration).

11On 1.4 and 1.6 litre models (except C 16

NZ2), disconnect the stub hose that connects

the crankcase breather tube to the rear of thecamshaft housing (see illustration).

12Loosen the alternator mountings, referring

to Chapter 5, then unbolt the upper alternator

mounting from the inlet manifold.

13Make a final check to ensure that all

necessary hoses, pipes and wires have been

disconnected, then unscrew the securing

nuts, noting the location of the engine lifting

bracket, and lift the inlet manifold from the

cylinder head. Ensure that the manifold is

properly supported, taking care not to strain

any of the hoses, pipes and wires, etc., which

are still connected.

14Recover the manifold gasket from the

cylinder head.

15If desired, remove the exhaust manifold,

with reference to Chapter 4C.

16Remove the timing belt and the camshaft

sprocket, as described in Section 11.

17Unscrew the two upper rear timing belt

cover securing bolts from the camshaft

housing.

18Disconnect the HT leads from the spark

plugs and the coil, labelling them if necessary

to aid refitting, and remove the distributor

cap, referring to Chapter 5. Where applicable,

disconnect the distributor wiring plug.

19If not already done, disconnect the stub

hose that connects the crankcase breather

tube to the camshaft housing. If applicable

unscrew the bolt securing the crankcase

breather tube bracket to the end of the

cylinder head (see illustrations).

20Disconnect the coolant hoses from the

thermostat housing.21On carburettor models, disconnect the fuel

hoses from the fuel pump. Be prepared for fuel

spillage, and plug the open ends of the hoses,

to prevent further fuel loss and dirt ingress.

22Make a final check to ensure that all

relevant hoses, pipes and wires, etc., have

been disconnected.

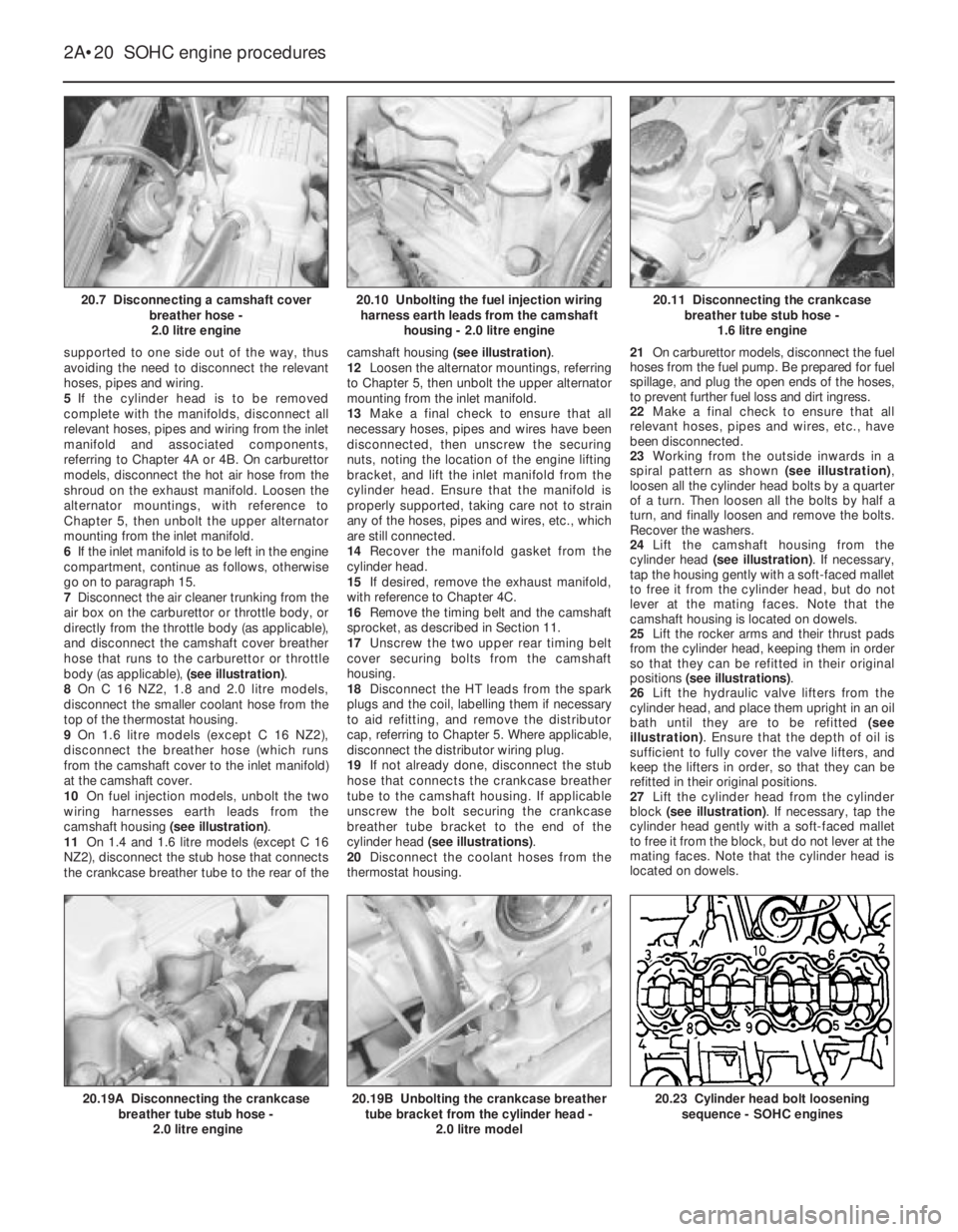

23Working from the outside inwards in a

spiral pattern as shown (see illustration),

loosen all the cylinder head bolts by a quarter

of a turn. Then loosen all the bolts by half a

turn, and finally loosen and remove the bolts.

Recover the washers.

24Lift the camshaft housing from the

cylinder head (see illustration). If necessary,

tap the housing gently with a soft-faced mallet

to free it from the cylinder head, but do not

lever at the mating faces. Note that the

camshaft housing is located on dowels.

25Lift the rocker arms and their thrust pads

from the cylinder head, keeping them in order

so that they can be refitted in their original

positions (see illustrations).

26Lift the hydraulic valve lifters from the

cylinder head, and place them upright in an oil

bath until they are to be refitted (see

illustration). Ensure that the depth of oil is

sufficient to fully cover the valve lifters, and

keep the lifters in order, so that they can be

refitted in their original positions.

27Lift the cylinder head from the cylinder

block (see illustration). If necessary, tap the

cylinder head gently with a soft-faced mallet

to free it from the block, but do not lever at the

mating faces. Note that the cylinder head is

located on dowels.

2A•20SOHC engine procedures

20.7 Disconnecting a camshaft cover

breather hose -

2.0 litre engine20.11 Disconnecting the crankcase

breather tube stub hose -

1.6 litre engine

20.23 Cylinder head bolt loosening

sequence - SOHC engines20.19B Unbolting the crankcase breather

tube bracket from the cylinder head -

2.0 litre model20.19A Disconnecting the crankcase

breather tube stub hose -

2.0 litre engine

20.10 Unbolting the fuel injection wiring

harness earth leads from the camshaft

housing - 2.0 litre engine

Page 219 of 525

40Refit the camshaft sprocket and the

timing belt and tension the timing belt as

described in Section 11.

41Where applicable, refit the manifolds to

the cylinder head, with reference to Chapter

4A, 4B or 4C, using new gaskets.

42Reconnect the exhaust downpipe to the

manifold, using a new gasket, referring to

Chapter 4C, if necessary.

43Refit the upper alternator mounting to the

inlet manifold, then adjust the alternator

drivebelt tension, as described in Chapter 5.

44Refill the cooling system, as described in

Chapter 3.

45On completion, check that all relevant

hoses, pipes and wires, etc., have been

reconnected.

46When the engine is started, check for

signs of leaks.

47Once the engine has reached normal

operating temperature, check and if

necessary adjust the idle speed (where

applicable) and the mixture (where

applicable), with reference to Chapter 4A or

4B.

21Cylinder head - removal and

refitting (engine removed)

4

Note: New cylinder head bolts and a new

cylinder head gasket must be used on

refitting, and sealer will be required when

refitting the camshaft housing.

The torque settings stated are only applicable

to latest specification head bolts, available

from Vauxhall. Earlier type or alternative make,

head bolts may require different torques.

Consult your supplier.

Removal

1The cylinder head can be removed

complete with the manifolds, or the manifolds

can be detached from the cylinder head

before removal, with reference Chapter 4A,

4B or 4C.

2Remove the timing belt and the camshaft

sprocket, as described in Section 11.

3Unscrew the two upper rear timing belt

cover securing bolts from the camshaft

housing (see illustration).4Disconnect the HT leads from the spark

plugs, labelling them if necessary to aid

refitting, and remove the distributor cap

referring to Chapter 5.

5If not already done, disconnect the stub

hose that connects the crankcase breather

tube to the camshaft housing. If applicable,

unscrew the bolt securing the crankcase

breather tube bracket to the end of the

cylinder head.

6Make a final check to ensure that all

relevant hoses, pipes and wires have been

disconnected.

Refitting

7Proceed as described in Section 21,

paragraphs 23 to 41 inclusive, but in addition

note the following.

8On completion check that all relevant

hoses, pipes and wires, etc., have been

reconnected.

22Cylinder head -dismantling

and reassembly

4

Note: A valve spring compressor tool will be

required for this operation. New valve stem oil

seals must be used on reassembly

Dismantling

1With the cylinder head removed as

described in Section 21, clean away all

external dirt.

2If not already done, remove the thermostat

housing, and on 1.4 and 1.6 litre models, thethermostat, as described in Chapter 3.

Remove the manifolds as described in

Chapter 4A, 4B or 4C. Remove the spark

plugs if not already done.

3To remove a valve, fit a valve spring

compressor tool. Ensure that the arms of the

compressor tool are securely positioned on

the head of the valve and the spring cap (see

illustration).

4Compress the valve spring to relieve the

pressure of the spring cap acting on the

collets. If the spring cap sticks on the valve

stem, support the compressor tool and give

the end a light tap with a hammer to help free

the spring cap.

5Extract the two split collets, then slowly

release the compressor tool.

6Remove the spring cap, spring, valve stem

oil seal, and the spring seat, then withdraw

the valve.

2A•22SOHC engine procedures

20.36 Fit new cylinder head bolts, ensuring

that the washers are in place20.37B Tighten the cylinder head bolts to

the specified torque . . .

22.3 Valve spring compressor tool fitted to

No 1 exhaust valve - 2.0 litre engine21.3 Upper rear timing belt cover securing

bolts (arrowed) - 1.6 litre engine

20.37C . . .then through the specified

angle - 2.0 litre engine

20.37A Cylinder head bolt tightening

sequence - SOHC engines

Page 221 of 525

23Cylinder head - inspection

and renovation

4

Note: Refer to a dealer for advice before

attempting to carry out valve grinding or valve

seat reciting operations, as these operations

may not be possible for the DIY mechanic.

This is due to the fitment of hardened valve

seats for use with unleaded petrol

Inspection

1Remember that the cylinder head is of light

alloy construction and is easily damaged, use

a blunt scraper or rotary wire brush to clean all

traces of carbon deposits from the

combustion spaces and the ports. The valve

stems and valve guides should also be freed

from any carbon deposits. Wash the

combustion spaces and ports down with

paraffin and scrape the cylinder head surface

free of any foreign matter with the side of a

steel rule, or a similar article.

2If the engine is installed in the car, clean the

pistons and the top of the cylinder bores. If

the pistons are still in the block, it is essential

that great care is taken to ensure that no

carbon gets into the cylinder bores. This could

scratch the cylinder walls or cause damage to

the pistons and rings. To ensure this does not

happen, first turn the crankshaft so that two of

the pistons are at the top of their bores. Insert

rag into the other two bores or seal them off

with paper and masking tape. The waterways

should also be covered with small pieces of

masking tape, to prevent particles of carbon

entering the cooling system and damaging the

coolant pump.

3Press a little grease into the gap between

the cylinder walls and the two pistons that are

to be worked on. With a blunt scraper,

carefully scrape away the carbon from the

piston crown, taking great care not to scratch

the aluminium. Also scrape away the carbon

from the surrounding lip of the cylinder wall.

When all carbon has been removed, scrape

away the grease that will now be

contaminated with carbon particles, taking

care not to press any into the bores. To assist

prevention of carbon build-up, the piston

crown can be polished with a metal polish.

Remove the rags or masking tape from the

other two cylinders, and turn the crankshaft

so that the two pistons that were at thebottom are now at the top. Place rag or

masking tape in the cylinders that have been

decarbonised, and continue as just described.

4Examine the heads of the valves for pitting

and burning, especially the heads of the

exhaust valves. The valve seatings should be

examined at the same time. If the pitting on

the valve and seat is very slight, the marks

can be removed by grinding the seats and

valves together with coarse, and then fine,

valve grinding paste.

5Where bad pitting has occurred to the valve

seats, it will be necessary to recut them and fit

new valves. This latter job should be entrusted

to the local dealer or engineering works. In

practice it is very seldom that the seats are so

badly worn. Normally it is the valve that is too

badly worn for refitting, and the owner can

easily buy a new set of valves and match

them to the seats by valve grinding.

Renovation

6Valve grinding is carried out as follows.

Smear a trace of coarse carborundum paste

on the seat face and apply a suction grinder

tool to the valve head. With a semi-rotary

motion, grind the valve head to its seat, lifting

the valve occasionally to redistribute the

grinding paste. When a dull matt even surface

is produced on both the valve seat and the

valve, wipe off the paste and repeat the

process with fine carborundum paste, lifting

and turning the valve to redistribute the paste

as before. A light spring placed under the

valve head will greatly ease this operation.

When a smooth unbroken ring of light grey

matt finish is produced, on both valve and

valve seat faces, the grinding operation is

complete. Carefully clean away every trace of

grinding compound, taking great care to leave

none in the ports or in the valve guides. Clean

the valves and valve seats with a

paraffin-soaked rag, then with a clean rag,

and finally, if an air line is available, blow the

valves, valve guides and valve ports clean.

7Check that all valve springs are intact. If any

one is broken, all should be renewed. Check

the free height of the springs against new

ones. If some springs are not long enough,

replace them all. Springs suffer from fatigue

and it is a good idea to renew them even if

they look serviceable. 8The cylinder head can be checked for

warping either by placing it on a piece of plate

glass or using a straight-edge and feeler

blades. If there is any doubt or if its block face

is corroded, have it re-faced by your dealer or

motor engineering works.

9On 1.8 and 2.0 litre, always renew the

sealing ring between the cylinder head and

the thermostat housing when the head is

removed for overhaul (see illustration).

Reference to Chapter 21 will show that a

considerable amount of work is involved if it is

wished to renew the sealing ring with the

cylinder head installed.

10If the oil pressure regulating valve in the

cylinder head is to be renewed, access is

gained through the circular plug covering the

end of the valve (see illustration). The old

valve must be crushed, then its remains

extracted, and a thread (M10) cut in the valve

seat to allow removal using a bolt. A new

valve and plug can then be driven into

position. In view of the intricacies of this

operation, it is probably best to have the valve

renewed by a Vauxhall dealer if necessary.

24Hydraulic valve lifters -

inspection

4

Inspection

1On engines that have covered a high

mileage, or for which the service history

(particularly oil changes) is suspect, it is

possible for the valve lifters to suffer internal

contamination. In extreme cases this may

result in increased engine top end noise and

wear. To minimise the possibility of problems

occurring later in the life of the engine, it is

advisable to dismantle and clean the hydraulic

valve lifters as follows whenever the cylinder

head is overhauled. Note that no spare parts

are available for the valve lifters, and if any of

the components are unserviceable, the

complete assembly must be renewed (see

illustration).

2With the cylinder head removed and

dismantled as described in Sections 21 and

23, first inspect the valve lifter bores in the

2A•24SOHC engine procedures

23.10 Oil pressure regulating valve (1) and

plug (2) - 2.0 litre engine23.9 Renewing the thermostat housing

sealing ring - 2.0 litre engine

Warning: The exhaust valves

fitted to 20 XEJ and C 20 XE

(DOHC) models are fitted with

sodium to improve their heat

transfer. Sodium is a highly reactive

metal, which will ignite or explode

spontaneously on contact with water

(including water vapour in the air). These

must NOT be disposed of with ordinary

scrap. Seek advice from a Vauxhall dealer

or your Local Authority, if the valves are to

be disposed of.