battery replacement OPEL VECTRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 96 of 525

2When the starter switch is operated, current

flows from the battery to the solenoid that is

mounted on the starter body. The plunger in

the solenoid moves inwards, so causing a

centrally pivoted lever to push the drive pinion

into mesh with the starter ring gear. When the

solenoid plunger reaches the end of its travel,

it closes an internal contact and full starting

current flows to the starter field coils. The

armature is then able to rotate the crankshaft,

so starting the engine.

3A special freewheel clutch is fitted to the

starter driven pinion, so that when the engine

fires and starts to operate on its own it does

not drive the starter motor.

4When the starter switch is released, the

solenoid is de-energised, and a spring moves

the plunger back to its rest position. This

operates the pivoted lever to the withdraw the

drive pinion from engagement with the starter

ring.

13Starter motor - testing

3

Note: Refer to Section 3 before proceeding

Testing

1If the starter motor fails to turn the engine

when the switch is operated, and engine

seizure is not the problem, there are several

other possible reasons:

a)The battery is faulty

b)The electrical connections between the

switch, solenoid battery and starter motor

are somewhere failing to pass the

necessary current from the battery

through the starter to earth

c)The solenoid switch is faulty

d)The starter motor is mechanically or

electrically defective

e)The starter motor pinion and/or flywheel

ring gear is badly worn, and in need of

replacement

2To check the battery, switch on the

headlamps. If they dim after a few seconds,

then the battery is in a discharged state. If the

lamps glow brightly, operate the starter switch

and see what happens to the lamps. If theydim, then power is reaching the motor, but

failing to turn it. If the starter turns slowly, go

on to the next check.

3If, when the starter switch is operated, the

lamps stay bright, then insufficient power is

reaching the motor. Disconnect the battery

and the starter/solenoid power connections,

and the engine earth strap, then thoroughly

clean them and refit them. Smear petroleum

jelly around the battery connections to

prevent corrosion. Corroded connections are

the most frequent cause of electrical system

malfunctions.

4If the preceding checks and cleaning tasks

have been carried out without success, a

clicking noise will probably have been heard

each time the starter switch was operated.

This indicates that the solenoid switch was

operating, but it does not necessarily follow

that the main contacts were closing properly

(if no clicking has been heard from the

solenoid, it is certainly defective). The

solenoid can be checked by connecting a

voltmeter across the main cable connection

on the solenoid and earth. When the switch is

operated, these should be a reading on the

voltmeter. If there is no reading, the solenoid

unit is faulty, and should be renewed.

5If the starter motor operates, but does not

turn the engine, then it is likely that the starter

pinion and/or flywheel ring gear are badly

worn. If this is the case, the starter motor will

normally be noisy in operation.

6Finally, if it is established that the solenoid

is not faulty, and 12 volts are reaching the

starter, then the motor itself is faulty, and

should be removed for inspection.

14Starter motor - removal and

refitting

3

Note: Refer to Section 3 before proceeding

Removal

1Disconnect the battery negative lead.

2Apply the handbrake, then jack up the front

of the vehicle, and support securely on axle

stands (see “Jacking and Vehicle Support”)

positioned under the body side members.3On DOHC models, remove the engine

undershield, as described in Chapter 11.

4Note the wiring connections on the

solenoid, then disconnect them (see

illustration).

5Where applicable, unscrew the bolt

securing the exhaust bracket and the starter

motor mounting bracket to the cylinder block

(see illustration).

6Unscrew the two starter motor mounting

bolts. Note that the top bolt on some models

are fitted from the transmission side, and

secures a wiring harness bracket (see

illustration).

7Withdraw the starter motor.

Refitting

8Refitting is a reversal of removal, but where

applicable, ensure that the wiring harness

bracket is in place on the top mounting bolt,

and tighten all bolts to the specified torque.

15Starter motor - overhaul

5

If the starter motor is thought to be suspect,

it should be removed from the vehicle and

taken to an auto-electrician for testing. Most

auto-electricians will be able to supply and fit

brushes at a reasonable cost. However, check

on the cost of repairs before continuing as it

may prove more economical to obtain a new

or exchange motor.

16Ignition coil - removal, testing

and refitting

3

Note: Refer to Section 3 before proceeding.

An ohmmeter will be required to test the coil

Removal

1The ignition coil is either a cylindrical metal

canister or a moulded plastic unit. It is

clamped or bolted to the left-hand inner wing

panel, near the suspension strut top mounting

(under the power steering fluid reservoir, on

Engine electrical systems 5•9

14.6 Starter motor securing bolts

(arrowed) - 1.6 litre model

(engine removed)14.5 Starter motor mounting

bracket/exhaust bracket securing bolt

(arrowed) - 1.6 litre model14.4 Starter motor and solenoid viewed

from underneath the vehicle. Solenoid

wiring connections arrowed

5

Page 99 of 525

been removed, check that No 1 cylinder is on

its firing stroke by removing No 1 cylinder

spark plug and placing a finger over the plug

hole. Turn the crankshaft until compression

can be felt, which indicates that No 1 piston is

rising on its compression stroke. Continue

turning the crankshaft until the relevant timing

marks are in alignment.

11Turn the rotor arm to the position noted in

paragraph 6c, and hold the rotor arm in this

position as the distributor is fitted. Note that

the distributor driveshaft will only engage with

the camshaft in one position. If the original

distributor is being refitted, align the marks

made on the distributor body and camshaft

housing before removal.

12Refit the clamp plate and nut, but do not

fully tighten the nut at this stage.

13On the Bosch distributor, remove the rotor

arm, then refit the plastic shield and the rotor

arm.

14On 14 NV models, reconnect the vacuum

pipe to the diaphragm unit.

15Reconnect the distributor wiring plug.

16Refit the distributor cap as described in

Section 17.

17Reconnect the battery negative lead.

18Check and if necessary adjust the ignition

timing, as described in Section 21.

19Distributor (DOHC models),

where applicable - removal

and refitting

3

Removal

1Disconnect the battery negative lead.

2Remove the distributor cap, as described in

Section 17.

3Disconnect the distributor wiring plug.

4Unscrew the two securing bolts, and

remove the distributor from the cylinder head.

5Examine the O-ring on the rear of the

distributor, and renew if necessary.

Refitting

6Refitting is a reversal of removal. However,

note that the distributor should be fitted so

that the wiring plug is positioned on the upper

left-hand side of the distributor body, when

viewed from the distributor cap end.

20Distributor - dismantling,

inspection and reassembly

3

Note: Before contemplating dismantling of a

distributor, check the cost and availability of

replacement parts. It may prove more

economical to renew the complete distributor

assembly

14 NV models

Dismantling

1With the distributor removed as described

in Section 18, continue as follows.

2Pull off the rotor arm, and remove the

plastic shield.

3The top bearing plate can be removed after

unscrewing the two securing screws, however

(other than the vacuum diaphragm unit), no

spares are available for the distributor and no

adjustments are required.

4If desired, the vacuum diaphragm unit can

be removed by extracting the two securing

screws and unhooking the operating arm from

the distributor baseplate. Note that the

screws are of differing lengths, the longer

screw also secures one of the distributor cap

clips.

Inspection

5The vacuum unit can be tested by applying

suction to the vacuum port, and checking that

the operating rod moves into the unit as

suction is applied. Remove the suction, and

check that the operating rod returns to its

original position. If the operating rod does not

move as described, renew the vacuum unit.

6Check the distributor cap for corrosion of

the segments, and for signs of tracking,

indicated by a thin black line between the

segments. Make sure that the carbon brush in

the centre of the cap moves freely and stands

proud of the surface of the cap. Renew the

cap if necessary.

7If the metal portion of the rotor arm is badly

burnt or loose, renew it. If slightly burnt or

corroded; it may be cleaned with a fine file.

8Examine the seal ring at the rear of the

distributor body, and renew if necessary.

Reassembly

9Reassembly is a reversal of dismantling,

ensuring that the vacuum unit operating arm

is correctly engaged with the peg on the

baseplate, several attempts may be required

to reconnect it.

10Refit the distributor as described in

Section 18, and then check and if necessary

adjust the ignition timing, as described in

Section 21.

16 SV models

Dismantling

11With the distributor removed as described

in Section 18, pull off the rotor arm and, on

the Bosch distributor, remove the plastic

shield.

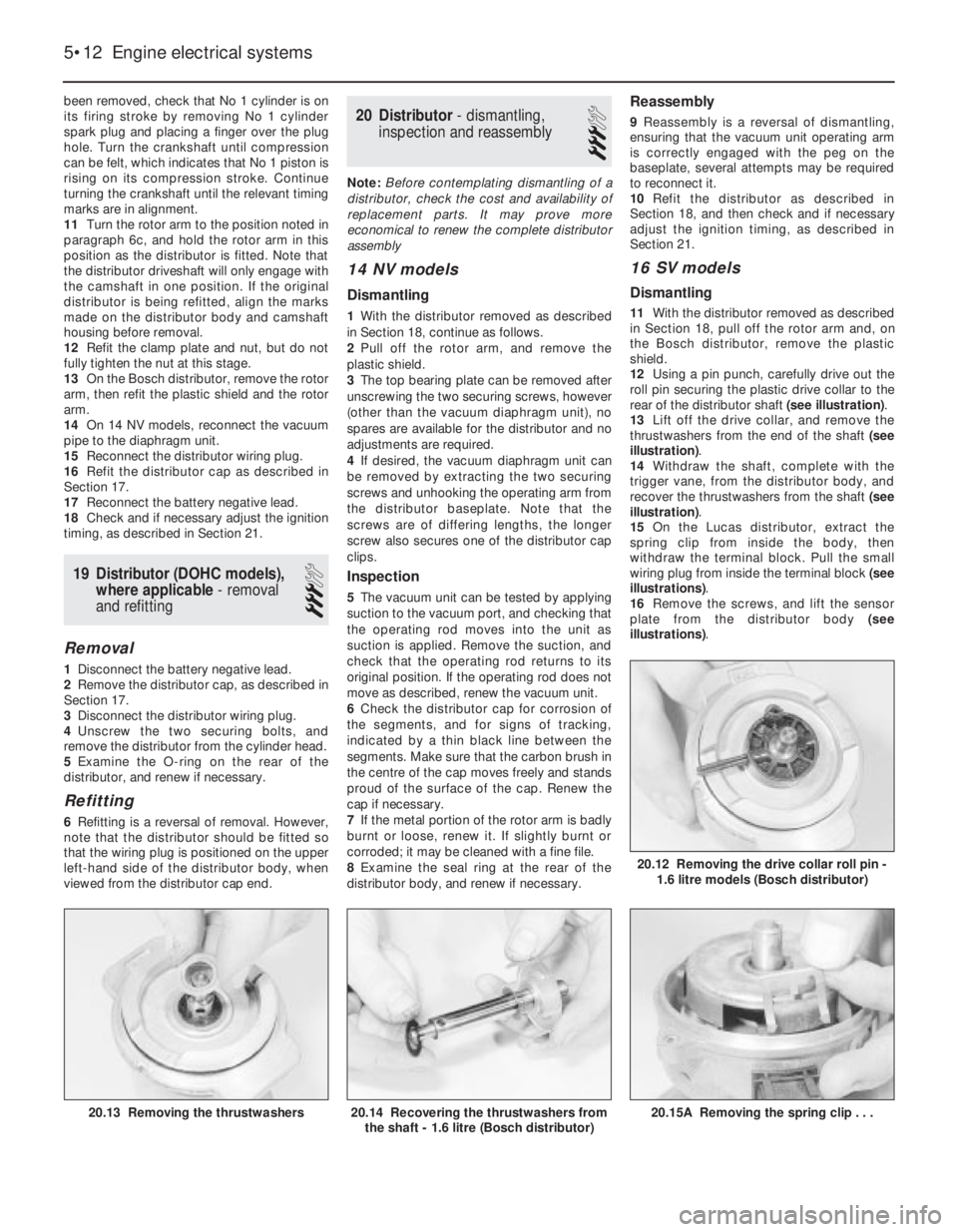

12Using a pin punch, carefully drive out the

roll pin securing the plastic drive collar to the

rear of the distributor shaft (see illustration).

13Lift off the drive collar, and remove the

thrustwashers from the end of the shaft (see

illustration).

14Withdraw the shaft, complete with the

trigger vane, from the distributor body, and

recover the thrustwashers from the shaft (see

illustration).

15On the Lucas distributor, extract the

spring clip from inside the body, then

withdraw the terminal block. Pull the small

wiring plug from inside the terminal block (see

illustrations).

16Remove the screws, and lift the sensor

plate from the distributor body (see

illustrations).

5•12Engine electrical systems

20.15A Removing the spring clip . . .20.14 Recovering the thrustwashers from

the shaft - 1.6 litre (Bosch distributor)20.13 Removing the thrustwashers

20.12 Removing the drive collar roll pin -

1.6 litre models (Bosch distributor)

Page 144 of 525

14Front brake disc shield -

removal and refitting

3

Removal

1Where applicable, remove the wheel trim,

then loosen the relevant front roadwheel bolts

and apply the handbrake. Jack up the front of

the vehicle, and support on axle stands (see

“Jacking and Vehicle Support”) positioned

under the body side members. Remove the

roadwheel.

2Remove the brake disc, as described in

Section 10.

3Using a screwdriver inserted through the

holes in the hub flange, extract the three

screws securing the disc shield to the hub

carrier.

4Using plate shears or an alternative tool, cut

a section of metal from the rear edge of the

shield to enable the shield to be withdrawn

over the hub, then remove the shield (see

illustration).

Refitting

5If a new shield is to be fitted, cut out a

section of metal, as during removal of the old

shield, to enable the shield to be fitted.

Smooth the cut edges, and coat them with

anti-corrosion paint.

6Further refitting is a reversal of removal,

remembering the following points.

7Refit the brake disc, as described in

Section 10.

8Do not fully tighten the roadwheel bolts until

the vehicle is resting on its wheels.

15Master cylinder - removal and

refitting

4

Note: Refer to the note at the beginning of

Section 3 before proceeding

Removal

1Disconnect the battery negative lead.

2Depress the footbrake pedal several times

to dissipate the vacuum in the servo unit.3Disconnect the wiring plug from the brake

fluid level sensor in the reservoir filler cap.

4If possible, use a teat pipette or an old

hydrometer to remove the brake fluid from the

reservoir. This will reduce the loss of fluid later

in the procedure.

5Locate a container beneath the master

cylinder, to catch the brake fluid that will be

released.

6Identify the brake fluid pipes for position,

then unscrew the union nuts and disconnect

the pipes from the master cylinder.

7Unscrew the two securing nuts, and

withdraw the master cylinder from the studs

on the vacuum servo unit (see illustration).

8Clean the external surfaces of the cylinder,

then using a screwdriver carefully prise the

fluid reservoir and its seals from the top of the

cylinder.

9If desired, on models without ABS, the

master cylinder can be overhauled, as

described in Section 16.

10No overhaul of the master cylinder is

possible on models with ABS, see Section 17.

Refitting

11Refitting is a reversal of removal, but use

new seals when fitting the brake fluid

reservoir, and on completion, bleed the

complete brake hydraulic system, as

described in Section 3.

16Master cylinder (non-ABS) -

overhaul

4

Note: Before dismantling the master cylinder,

check that replacement parts can be obtained

and retain the old components to compare

them with the new ones

1With the master cylinder removed as

described in Section 15, continue as follows,

according to type.

GMF type master cylinder

2Clamp the master cylinder in a soft-jawed

vice.

3Where applicable, unscrew the pressure-

proportioning valves from the base of the

cylinder.4Carefully prise out the sealing ring from the

end of the cylinder bore.

5Depress the primary piston slightly using a

piece of wood or plastic. Then hold the piston

in the depressed position by inserting a

smooth pin or rod of 3.0 mm (0.12 in) diameter

through the primary fluid reservoir port in the

cylinder (see illustration).

6Extract the circlip from the end of the

cylinder bore using a screwdriver. Take care

not to damage the piston or cylinder bore.

7Withdraw the pin or rod retaining the piston.

8Withdraw the primary piston assembly from

the cylinder, if necessary tapping the cylinder

on a wooden block to free the piston from the

bore.

9Apply low air pressure - e.g. from a foot

pump - to the front fluid reservoir port in the

cylinder, to eject the secondary piston

assembly.

10Clean all the components, in clean brake

fluid or methylated spirit only, and examine

them for wear and damage. In particular,

check the surfaces of the pistons and cylinder

bore for scoring and corrosion. If the bore

shows signs of wear, renew the complete

master cylinder assembly (see illustration).

11If the cylinder bore is in good condition,

obtain a repair kit, which will contain all the

necessary renewable items. A Vauxhall dealer

will supply a pre-assembled kit of parts, which

should be fitted as follows.

12Lubricate the cylinder bore with clean

brake fluid or brake grease, then clamp the

cylinder in a soft-jawed vice, with the bore

horizontal.

13Remove the plug from the end of the

assembly tube, and insert the short part of the

tube into the cylinder bore as far as the

shoulder on the tube.

14Use a piece of wood or plastic to push the

components out of the tube and into the

cylinder bore. Then hold the primary piston in

the depressed position by inserting the pin or

rod used during dismantling through the

cylinder primary fluid reservoir port.

15Fit a new circlip to the end of the cylinder

bore, ensuring that it seats correctly, and that

the piston is free to move.

16Depress the primary piston, and withdraw

the pin or rod from the fluid reservoir port.

Braking system 9•13

16.5 Holding the primary piston depressed

while extracting the circlip from the

cylinder body - GMF type master cylinder15.7 Master cylinder securing nut

(arrowed)14.4 Cutting a section of metal from a new

front brake disc shield prior to fitting

9

Page 172 of 525

1

Chapter 1

Routine maintenance and servicing

Air cleaner element - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Air inlet temperature control check . . . . . . . . . . . . . . . . . . . . . . . . . .28

Alternator V-belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Automatic transmission check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . . .7

Automatic transmission fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . .38

Bodywork check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Brake pad check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Brake shoe check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Clutch cable check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Distributor and HT lead check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Door lock key battery - replacement . . . . . . . . . . . . . . . . . . . . . . . . .24

Driveshaft gaiter check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Handbrake linkage check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Headlamp alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Hose and fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Idle speed and mixture - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ignition timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Intensive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Lock and hinge check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Manual transmission fluid check . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Power steering fluid check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Power steering pump drivebelt check . . . . . . . . . . . . . . . . . . . . . . . .18

Radiator inspection and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rear suspension level control system check . . . . . . . . . . . . . . . . . . .19

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Spark plug renewal (SOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Spark plug renewal (DOHC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Steering and suspension check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Throttle linkage maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 184 of 525

tighten the mounting nuts and bolts. On no

account lever at the free end of the alternator,

as serious internal damage could be caused.

3For details of replacement, see Chapter 5.

23Headlamp alignment

2

Refer to Chapter 12 for details.

24Door lock key battery -

replacement

1

1Carefully prise open the outer cover from

the key. Take care not to lose any of the

internal components, as they are loose.

2Remove the battery and discard it safely.

3Place the new battery, “+” side up (see

illustration). Check the operation of the key. If

the bulb does not light obtain a replacement.

4Replace the outer cover.

25Road test

1

Instruments and electrical

equipment

1Check the operation of all instruments and

electrical equipment.

2Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn to check that it functions

properly.

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the vehicle, and check that there are

no unusual vibrations or noises.5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6Check the performance of the engine,

clutch, transmission and driveshafts.

7Turn the radio/cassette off and listen for

any unusual noises from the engine, clutch

and transmission.

8Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

9Check that the clutch action is smooth and

progressive, that the drive is taken up

smoothly, and that the pedal travel is not

excessive. Also listen for any noises when the

clutch pedal is depressed.

10Check that all gears can be engaged

smoothly, without noise, and that the gear

lever action is not abnormally vague or

“notchy”.

11Listen for a metallic clicking sound from

the front of the vehicle, as the vehicle is driven

slowly in a circle with the steering on full lock.

Carry out this check in both directions. If a

clicking noise is heard, this indicates wear in a

driveshaft joint, in which case, the complete

driveshaft must be renewed (see Chapter 8).

26Coolant renewal

2

Refer to Chapter 3 for details.

27Air cleaner element - renewal

2

Early round type

1Release the spring clips from the perimeter

of the air cleaner cover.

2Unscrew and remove the small cross-head

screw securing the cover extension to the

main body near the inlet duct.3Unscrew and remove the three central

cross-head cap nuts securing the air cleaner

to the carburettor, taking care not to drop the

washers and seals (see illustration).

4Separate the cover from the main body,

then lift out the element (see illustration).

5Wipe clean the inside surfaces of the cover

and main body.

6Locate the new element in the air cleaner

body, and refit the cover using a reversal of

the removal procedure.

Square type with air box

7If desired, to improve access, unclip the

coolant expansion tank hose from the air

cleaner cover.

8Release the two clips from the left-hand

side of the cover, and unscrew the two

screws from the right-hand side, then lift the

cover sufficiently to remove the element.

9Wipe clean the inside surfaces of the cover

and main body.

10Refitting is a reversal of removal, noting

that the element fits with the rubber locating

flange uppermost.

Every 18 000 miles or 24 months 1•13

24.3 Replacing the battery in the door lock

key

1 Battery (note, positive ‘+’ side up)

2 Bulb

27.4 Removing the air cleaner element -

note clip for crankcase ventilation hose

(arrowed)

27.3 Air cleaner-to-carburettor mounting

cap nuts

1

Full service, every 18 000 miles (30 000 km) or 24 months

Warning: Wait until the engine is

cold before starting the

procedure. Do not allow

antifreeze to come in contact

with your skin or with painted surfaces of

the vehicle. Rinse off spills with plenty of

water. Never leave antifreeze lying around

in an open container. Always clean spilt

fluids, as it can be harmful if swallowed.

Page 190 of 525

Torque wrench settings (continued)Nmlbf ft

Starter to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4533

Starter support to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Temperature regulator plug (M20) * . . . . . . . . . . . . . . . . . . . . . . . . . . . .3022

Timing belt cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Timing belt drive gear to crankshaft: *

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250184

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by between 40°and 50°

Timing belt guide roller bracket to block . . . . . . . . . . . . . . . . . . . . . . . .2518

Timing belt guide roller to bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Timing belt guide roller to cylinder block:

Engines up to 1993

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 45°

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle tighten by 15°

1993-on engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Transfer box bracket to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . .6044

Transmission to cylinder block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6044

1General

This part of Chapter 2 describes

procedures that are specific to the DOHC

engine. It should be read in conjunction with

Part A.

The lower engine is basically the same as

the 2.0 litre SOHC. However the pistons are

attached to the connecting rods by gudgeon

pins, which are fully floating, and are secured

by circlips.

Both camshafts on these engines are driven

from the crankshaft by one toothed

composite rubber belt. Each cylinder has four

valves (two inlet and two exhaust), operated

directly from the camshafts by hydraulic

self-adjusting valve lifters. One camshaft

operates the inlet valves, and the other

operates the exhaust valves.

DOHC models are fitted with a remotely

mounted oil cooler.

The distributor is driven directly from the

exhaust camshaft.

2Engine - removal and refitting

4

Removal

1Carry out procedure in Chapter 2A, noting

the following differences.

2With the car safely raised, remove the

engine undershield.

3The fuel hoses need to be disconnected

from the fuel rail.

4Disconnect coolant hoses from the cylinder

block and cylinder head. Also disconnect the

oil cooler pipe unions from the oil pump.

5Unbolt the right-hand driveshaft centre

bearing support bracket from the rear of the

cylinder block.

Refitting

6Refitting the engine is similar to theprocedure in Chapter 2A. The exceptions

being, replacement of the right-hand

driveshaft centre bearing support bracket at

the rear of the cylinder block and retightening

the securing bolts.

7Replace the undershield.

3Engine/transmission

mountings- renewal

3

The procedure for replacing the engine/

transmission is similar to SOHC models, see

Chapter 2A. However this engine is fitted with

an undershield that needs to be removed

before replacing the mounts. Do not forget to

replace the undershield before lowering the

car.

4Timing belt, sprockets and belt

tensioner and idler pulleys-

removal, refitting and adjustment

3

Note: The timing belt should be renewed on

refitting. A two-legged puller may be required

to remove the crankshaft sprocket

Removal

1Disconnect the battery negative lead.2Disconnect the air cleaner trunking from the

airflow meter, then remove the cover and the

air cleaner element from the air cleaner. If

desired, for improved access, the complete

air cleaner assembly can be removed, as

described in Chapter 4B.

3Remove the power steering pump drivebelt,

as described in Chapter 10.

4Remove the alternator drivebelt, as

described in Chapter 5.

5Remove the three securing screws, and

withdraw the outer timing belt cover. Recover

the rubber grommets from the screw holes in

the cover if they are loose.

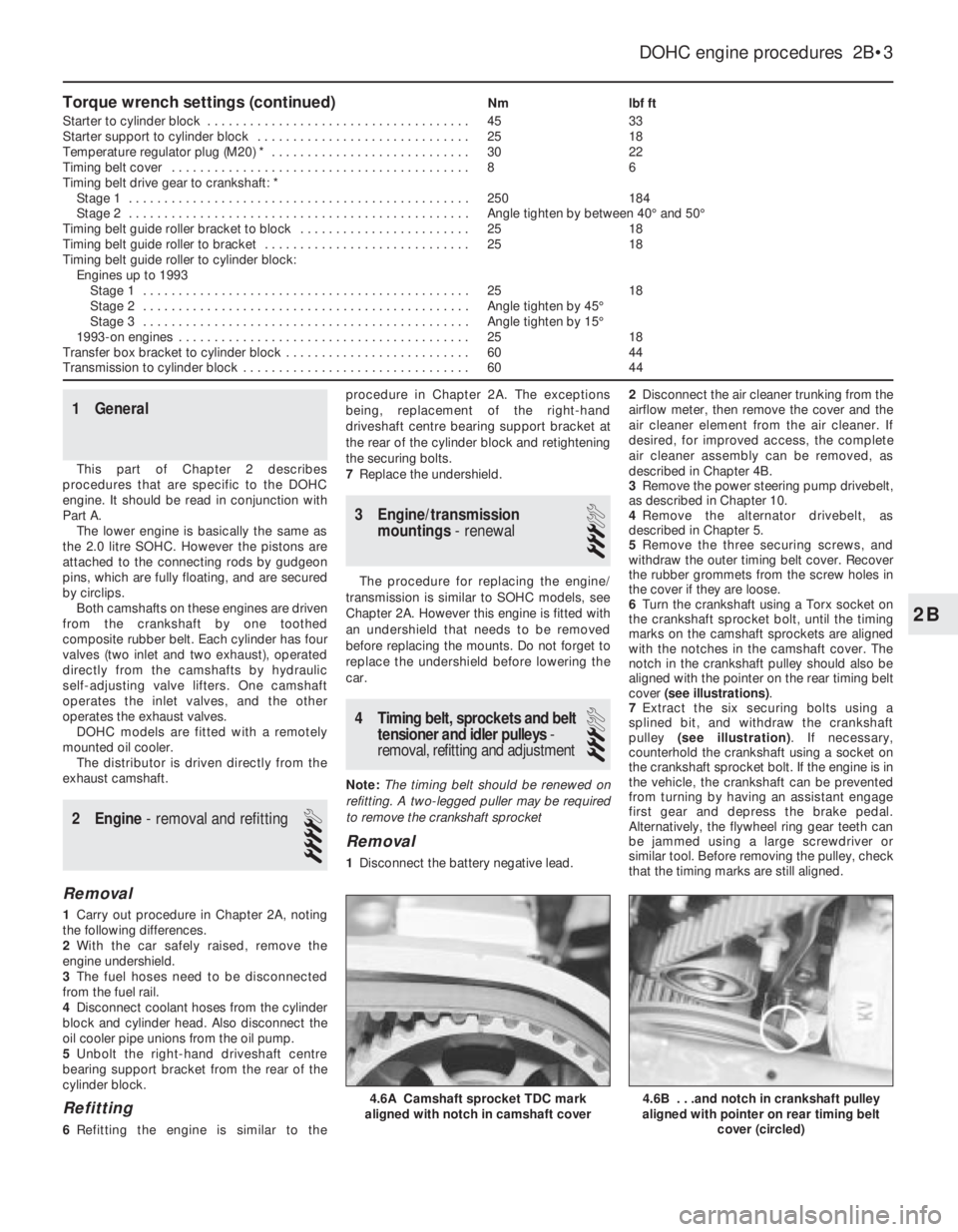

6Turn the crankshaft using a Torx socket on

the crankshaft sprocket bolt, until the timing

marks on the camshaft sprockets are aligned

with the notches in the camshaft cover. The

notch in the crankshaft pulley should also be

aligned with the pointer on the rear timing belt

cover (see illustrations).

7Extract the six securing bolts using a

splined bit, and withdraw the crankshaft

pulley (see illustration). If necessary,

counterhold the crankshaft using a socket on

the crankshaft sprocket bolt. If the engine is in

the vehicle, the crankshaft can be prevented

from turning by having an assistant engage

first gear and depress the brake pedal.

Alternatively, the flywheel ring gear teeth can

be jammed using a large screwdriver or

similar tool. Before removing the pulley, check

that the timing marks are still aligned.

DOHC engine procedures 2B•3

4.6B . . .and notch in crankshaft pulley

aligned with pointer on rear timing belt

cover (circled)4.6A Camshaft sprocket TDC mark

aligned with notch in camshaft cover

2B

Page 216 of 525

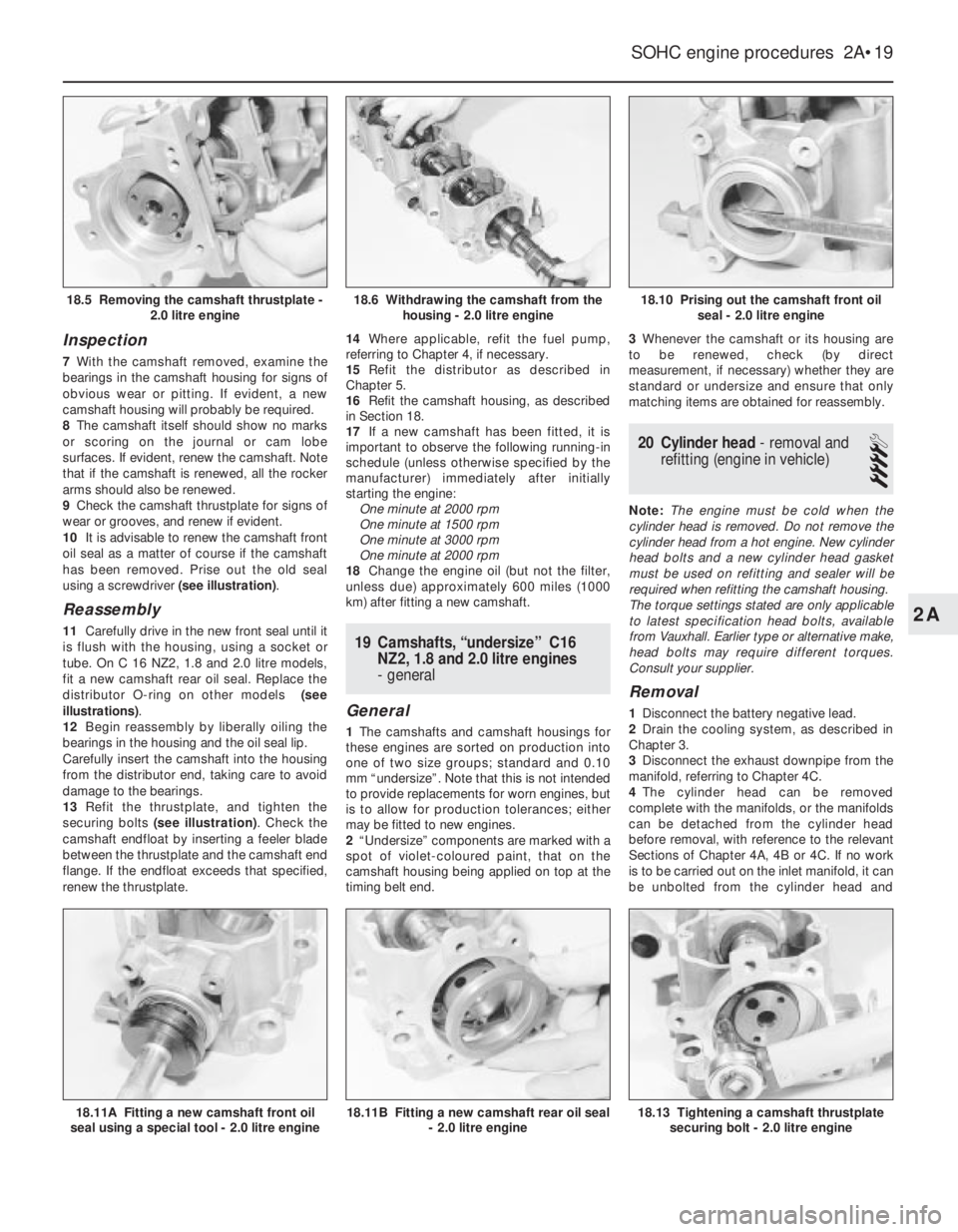

Inspection

7With the camshaft removed, examine the

bearings in the camshaft housing for signs of

obvious wear or pitting. If evident, a new

camshaft housing will probably be required.

8The camshaft itself should show no marks

or scoring on the journal or cam lobe

surfaces. If evident, renew the camshaft. Note

that if the camshaft is renewed, all the rocker

arms should also be renewed.

9Check the camshaft thrustplate for signs of

wear or grooves, and renew if evident.

10It is advisable to renew the camshaft front

oil seal as a matter of course if the camshaft

has been removed. Prise out the old seal

using a screwdriver (see illustration).

Reassembly

11Carefully drive in the new front seal until it

is flush with the housing, using a socket or

tube. On C 16 NZ2, 1.8 and 2.0 litre models,

fit a new camshaft rear oil seal. Replace the

distributor O-ring on other models (see

illustrations).

12Begin reassembly by liberally oiling the

bearings in the housing and the oil seal lip.

Carefully insert the camshaft into the housing

from the distributor end, taking care to avoid

damage to the bearings.

13Refit the thrustplate, and tighten the

securing bolts (see illustration). Check the

camshaft endfloat by inserting a feeler blade

between the thrustplate and the camshaft end

flange. If the endfloat exceeds that specified,

renew the thrustplate.14Where applicable, refit the fuel pump,

referring to Chapter 4, if necessary.

15Refit the distributor as described in

Chapter 5.

16Refit the camshaft housing, as described

in Section 18.

17If a new camshaft has been fitted, it is

important to observe the following running-in

schedule (unless otherwise specified by the

manufacturer) immediately after initially

starting the engine:

One minute at 2000 rpm

One minute at 1500 rpm

One minute at 3000 rpm

One minute at 2000 rpm

18Change the engine oil (but not the filter,

unless due) approximately 600 miles (1000

km) after fitting a new camshaft.19Camshafts, “undersize” C16

NZ2, 1.8 and 2.0 litre engines

- general

General

1The camshafts and camshaft housings for

these engines are sorted on production into

one of two size groups; standard and 0.10

mm “undersize”. Note that this is not intended

to provide replacements for worn engines, but

is to allow for production tolerances; either

may be fitted to new engines.

2“Undersize” components are marked with a

spot of violet-coloured paint, that on the

camshaft housing being applied on top at the

timing belt end.3Whenever the camshaft or its housing are

to be renewed, check (by direct

measurement, if necessary) whether they are

standard or undersize and ensure that only

matching items are obtained for reassembly.

20Cylinder head - removal and

refitting (engine in vehicle)

4

Note: The engine must be cold when the

cylinder head is removed. Do not remove the

cylinder head from a hot engine. New cylinder

head bolts and a new cylinder head gasket

must be used on refitting and sealer will be

required when refitting the camshaft housing.

The torque settings stated are only applicable

to latest specification head bolts, available

from Vauxhall. Earlier type or alternative make,

head bolts may require different torques.

Consult your supplier.

Removal

1Disconnect the battery negative lead.

2Drain the cooling system, as described in

Chapter 3.

3Disconnect the exhaust downpipe from the

manifold, referring to Chapter 4C.

4The cylinder head can be removed

complete with the manifolds, or the manifolds

can be detached from the cylinder head

before removal, with reference to the relevant

Sections of Chapter 4A, 4B or 4C. If no work

is to be carried out on the inlet manifold, it can

be unbolted from the cylinder head and

SOHC engine procedures 2A•19

18.10 Prising out the camshaft front oil

seal - 2.0 litre engine

18.13 Tightening a camshaft thrustplate

securing bolt - 2.0 litre engine18.11B Fitting a new camshaft rear oil seal

- 2.0 litre engine18.11A Fitting a new camshaft front oil

seal using a special tool - 2.0 litre engine

18.6 Withdrawing the camshaft from the

housing - 2.0 litre engine18.5 Removing the camshaft thrustplate -

2.0 litre engine

2A

Page 251 of 525

Engine

m mEngine fails to rotate when attempting to start

m mEngine rotates, but will not start

m mEngine difficult to start when cold

m mEngine difficult to start when hot

m mStarter motor noisy or excessively rough in engagement

m mEngine starts, but stops immediately

m mEngine idles erratically

m mEngine misfires at idle speed

m mEngine misfires throughout the driving speed range

m mEngine hesitates on acceleration

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mOil pressure warning light illuminated with engine running

m mEngine runs-on after switching off

m mEngine noises

Cooling system

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCorrosion

Fuel and exhaust systems

m

mExcessive fuel consumption

m mFuel leakage and/or fuel odour

m mExcessive noise or fumes from exhaust system

Clutch

m

mPedal travels to floor - no pressure or very little resistance

m mClutch fails to disengage (unable to select gears)

m mClutch slips (engine speed increases, with no increase in vehicle

speed)

m mJudder as clutch is engaged

m mNoise when depressing or releasing clutch pedal

Manual transmission

m

mNoisy in neutral with engine running

m mNoisy in one particular gear

m mDifficulty engaging gears

m mJumps out of gear

m mVibration

m mLubricant leaks

Automatic transmission

m

mFluid leakage

m mTransmission fluid brown, or has burned smell

m mGeneral gear selection problems

m mTransmission will not downshift (kickdown) with accelerator fully

depressed

m mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

Driveshafts

m mClicking or knocking noise on turns (at slow speed on full-lock)

m mVibration when accelerating or decelerating

Braking system

m

mVehicle pulls to one side under braking

m mNoise (grinding or high-pitched squeal) when brakes applied

m mExcessive brake pedal travel

m mBrake pedal feels spongy when depressed

m mExcessive brake pedal effort required to stop vehicle

m mJudder felt through brake pedal or steering wheel when braking

m mBrakes binding

m mRear wheels locking under normal braking

Suspension and steering systems

m

mVehicle pulls to one side

m mWheel wobble and vibration

m mExcessive pitching and/or rolling around corners, or during

braking

m mWandering or general instability

m mExcessively stiff steering

m mExcessive play in steering

m mLack of power assistance

m mTyre wear excessive

Electrical system

m

mBattery will not hold a charge for more than a few days

m mIgnition/no-charge warning light remains illuminated with engine

running

m mIgnition/no-charge warning light fails to come on

m mLights inoperative

m mInstrument readings inaccurate or erratic

m mHorn inoperative, or unsatisfactory in operation

m mWindscreen/tailgate wipers inoperative, or unsatisfactory in

operation

m mWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

m mElectric windows inoperative, or unsatisfactory in operation

m mCentral locking system inoperative, or unsatisfactory in operation

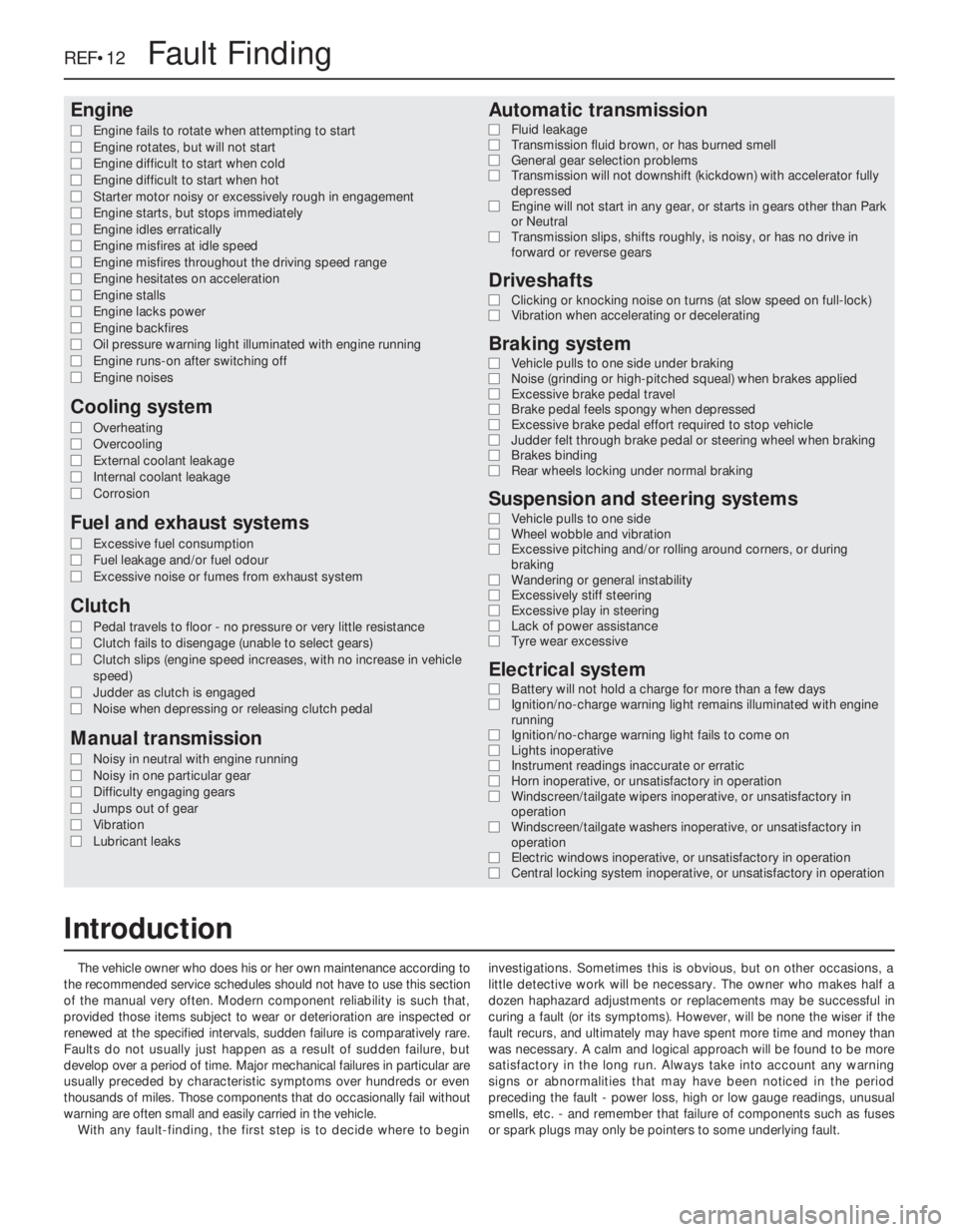

The vehicle owner who does his or her own maintenance according to

the recommended service schedules should not have to use this section

of the manual very often. Modern component reliability is such that,

provided those items subject to wear or deterioration are inspected or

renewed at the specified intervals, sudden failure is comparatively rare.

Faults do not usually just happen as a result of sudden failure, but

develop over a period of time. Major mechanical failures in particular are

usually preceded by characteristic symptoms over hundreds or even

thousands of miles. Those components that do occasionally fail without

warning are often small and easily carried in the vehicle.

With any fault-finding, the first step is to decide where to begininvestigations. Sometimes this is obvious, but on other occasions, a

little detective work will be necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in

curing a fault (or its symptoms). However, will be none the wiser if the

fault recurs, and ultimately may have spent more time and money than

was necessary. A calm and logical approach will be found to be more

satisfactory in the long run. Always take into account any warning

signs or abnormalities that may have been noticed in the period

preceding the fault - power loss, high or low gauge readings, unusual

smells, etc. - and remember that failure of components such as fuses

or spark plugs may only be pointers to some underlying fault.

REF•12Fault Finding

Introduction