spare tire OPEL VECTRA 1988 Service Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1988, Model line: VECTRA, Model: OPEL VECTRA 1988Pages: 525, PDF Size: 58.26 MB

Page 8 of 525

underside. If the distance measured exceeds,

or is less than, that specified, the float weight

is incorrect and the float must be renewed.

12When the float level is known to be

correct, reassemble the carburettor, using a

new top cover gasket. Check the idle speed

and mixture settings as described in Section

14.

13Using a pin punch, tap the float retaining

pin from the base of the top cover, and lift out

the float and needle valve.

14Inspect the components for damage, and

renew as necessary. Check the needle valve

for wear, and check the float for leaks by

shaking it to see if it contains petrol.

15Clean the mating faces of the carburettor

body and top cover.

Refitting

16Refitting is a reversal of removal,

remembering the following points.

17After refitting, check the float and needle

valve for full and free movement.

18Use a new gasket between the top cover

and the carburettor body.

19Ensure that all hoses, pipes and wires are

correctly reconnected.

20On completion, check and if necessary

top-up the coolant level, as described in

Chapter 3, and check and if necessary adjust

the idle speed and mixture, as described in

Section 14.

16Secondary throttle valve

vacuum diaphragm - testing,

removal and refitting

3

Note: The diaphragm unit must be renewed in

its entirety, as no spares are available

Testing

1If a vacuum source incorporating a gauge is

available, apply approximately 300 mbars (9 in

Hg) to the diaphragm unit, at the hose nearest

the carburettor body. Close off the vacuum

source, and check that the vacuum is held. If

there is a leak, rectify or renew the leaking

component. Alternately, testing of a suspect

vacuum unit must be by the substitution of a

known good item.

Removal

2Remove the air cleaner, on early models.

On later models, disconnect the air trunking

from the air cleaner, then disconnect the

vacuum pipe air breather hose from the air

box. Extract the three securing screws and lift

off the air box, complete with air trunking.

3Disconnect the vacuum pipe from the

diaphragm unit.

4Prise the diaphragm operating rod balljoint

from the secondary throttle valve linkage.

5On 1.6 and 1.8 litre models, remove the two

securing screws and lift the vapour separator

from the bracket. Move the vapour separator

to one side, taking care not to strain the fuel

hoses.6Remove the three securing screws, and

withdraw the diaphragm unit complete with its

bracket from the carburettor body.

Refitting

7Refitting is a reversal of removal.

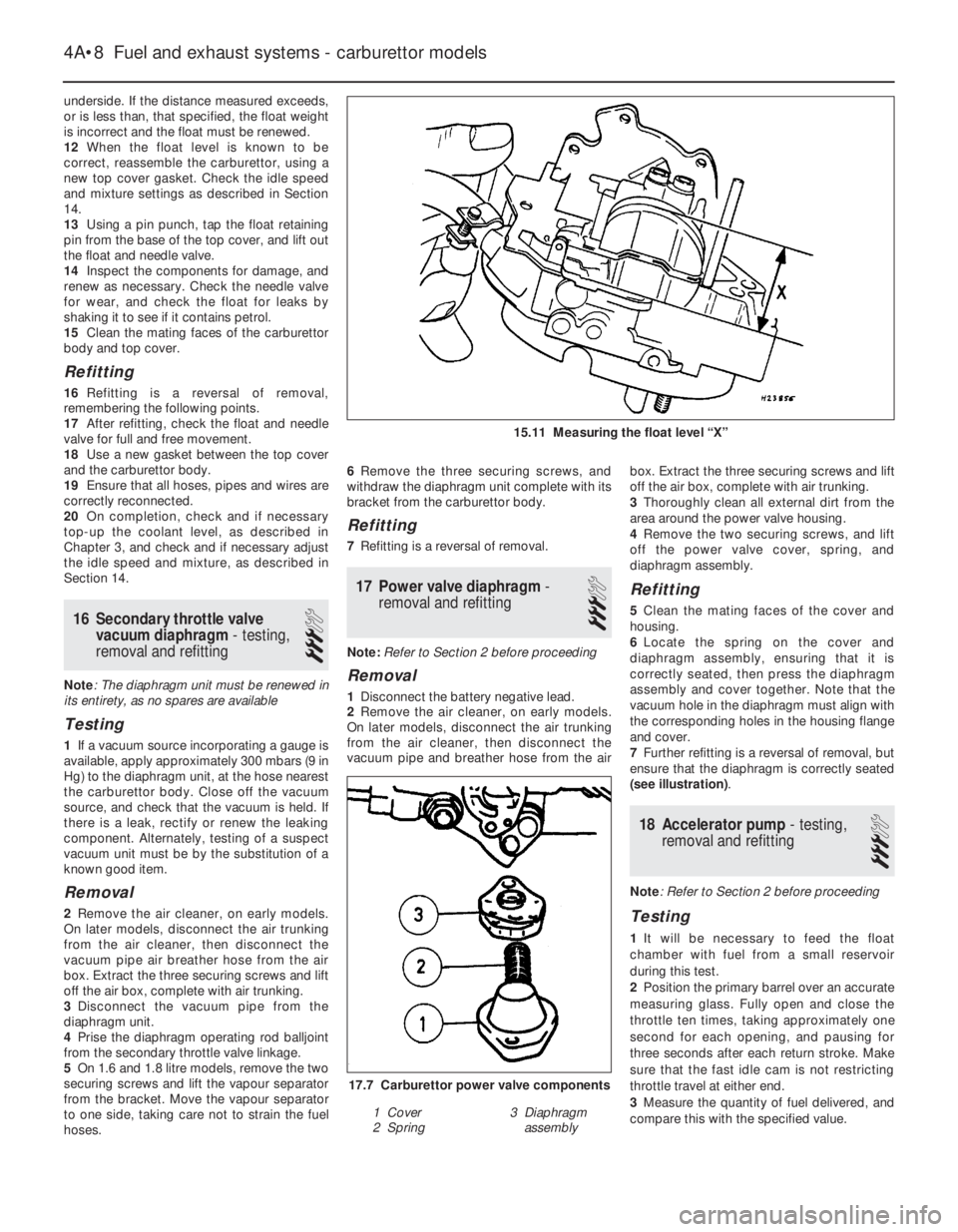

17Power valve diaphragm -

removal and refitting

3

Note: Refer to Section 2 before proceeding

Removal

1Disconnect the battery negative lead.

2Remove the air cleaner, on early models.

On later models, disconnect the air trunking

from the air cleaner, then disconnect the

vacuum pipe and breather hose from the airbox. Extract the three securing screws and lift

off the air box, complete with air trunking.

3Thoroughly clean all external dirt from the

area around the power valve housing.

4Remove the two securing screws, and lift

off the power valve cover, spring, and

diaphragm assembly.

Refitting

5Clean the mating faces of the cover and

housing.

6Locate the spring on the cover and

diaphragm assembly, ensuring that it is

correctly seated, then press the diaphragm

assembly and cover together. Note that the

vacuum hole in the diaphragm must align with

the corresponding holes in the housing flange

and cover.

7Further refitting is a reversal of removal, but

ensure that the diaphragm is correctly seated

(see illustration).

18Accelerator pump - testing,

removal and refitting

3

Note: Refer to Section 2 before proceeding

Testing

1It will be necessary to feed the float

chamber with fuel from a small reservoir

during this test.

2Position the primary barrel over an accurate

measuring glass. Fully open and close the

throttle ten times, taking approximately one

second for each opening, and pausing for

three seconds after each return stroke. Make

sure that the fast idle cam is not restricting

throttle travel at either end.

3Measure the quantity of fuel delivered, and

compare this with the specified value.

4A•8Fuel and exhaust systems - carburettor models

15.11 Measuring the float level “X”

17.7 Carburettor power valve components

1 Cover

2 Spring3 Diaphragm

assembly