OPEL VIVARO 2015 Owners Manual

Manufacturer: OPEL, Model Year: 2015, Model line: VIVARO, Model: OPEL VIVARO 2015Pages: 205, PDF Size: 4.47 MB

Page 151 of 205

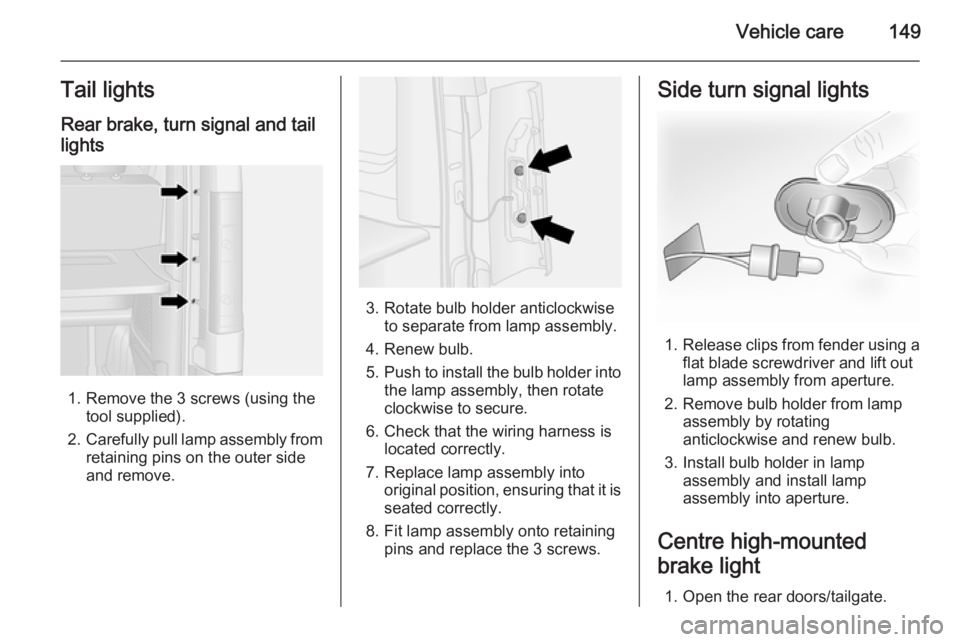

Vehicle care149Tail lightsRear brake, turn signal and tail

lights

1. Remove the 3 screws (using the tool supplied).

2. Carefully pull lamp assembly from

retaining pins on the outer side

and remove.

3. Rotate bulb holder anticlockwise to separate from lamp assembly.

4. Renew bulb.

5. Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

6. Check that the wiring harness is located correctly.

7. Replace lamp assembly into original position, ensuring that it isseated correctly.

8. Fit lamp assembly onto retaining pins and replace the 3 screws.

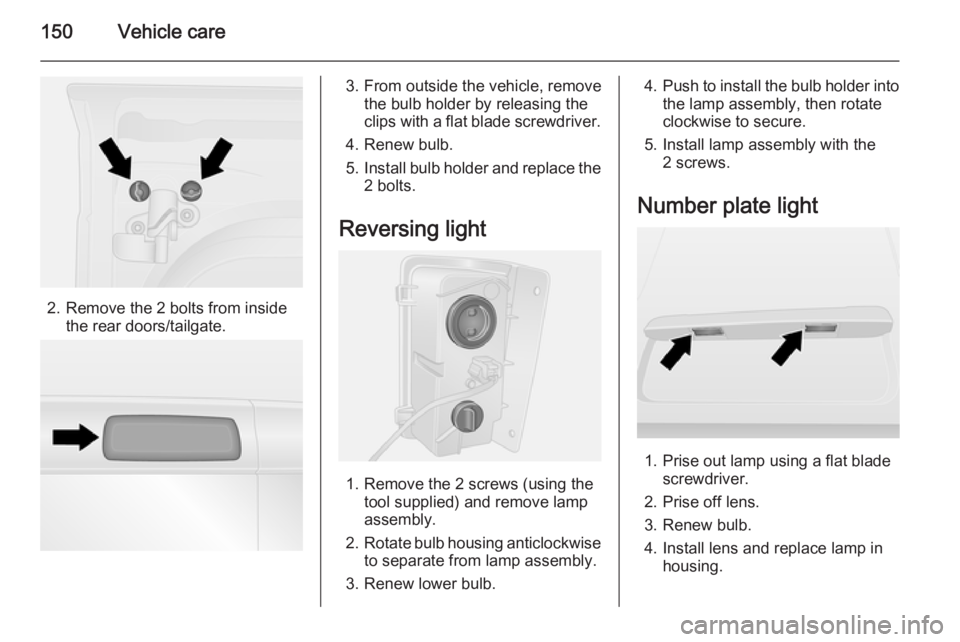

Side turn signal lights

1.Release clips from fender using a

flat blade screwdriver and lift out

lamp assembly from aperture.

2. Remove bulb holder from lamp assembly by rotating

anticlockwise and renew bulb.

3. Install bulb holder in lamp assembly and install lamp

assembly into aperture.

Centre high-mounted

brake light

1. Open the rear doors/tailgate.

Page 152 of 205

150Vehicle care

2. Remove the 2 bolts from insidethe rear doors/tailgate.

3. From outside the vehicle, removethe bulb holder by releasing the

clips with a flat blade screwdriver.

4. Renew bulb.

5. Install bulb holder and replace the

2 bolts.

Reversing light

1. Remove the 2 screws (using the tool supplied) and remove lamp

assembly.

2. Rotate bulb housing anticlockwise

to separate from lamp assembly.

3. Renew lower bulb.

4. Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

5. Install lamp assembly with the 2 screws.

Number plate light

1. Prise out lamp using a flat blade screwdriver.

2. Prise off lens.

3. Renew bulb.

4. Install lens and replace lamp in housing.

Page 153 of 205

Vehicle care151Fog tail light

1. Remove the 2 screws (using thetool supplied) and remove lamp

assembly.

2. Rotate bulb housing anticlockwise

to separate from lamp assembly.

3. Renew upper bulb.

4. Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

5. Install lamp assembly with the 2 screws.

Interior lights

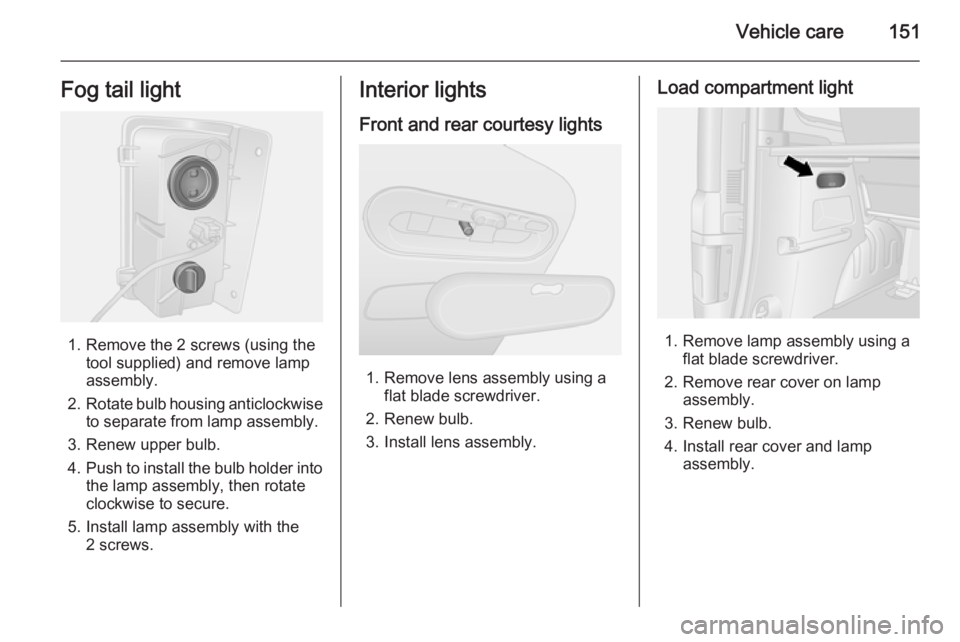

Front and rear courtesy lights

1. Remove lens assembly using a flat blade screwdriver.

2. Renew bulb.

3. Install lens assembly.

Load compartment light

1. Remove lamp assembly using a flat blade screwdriver.

2. Remove rear cover on lamp assembly.

3. Renew bulb.

4. Install rear cover and lamp assembly.

Page 154 of 205

152Vehicle care

Glovebox light

1. Remove lens assembly using aflat blade screwdriver.

2. Renew bulb.

3. Install lens assembly.

Instrument panel

illumination

Have bulbs replaced by a workshop.

Electrical system

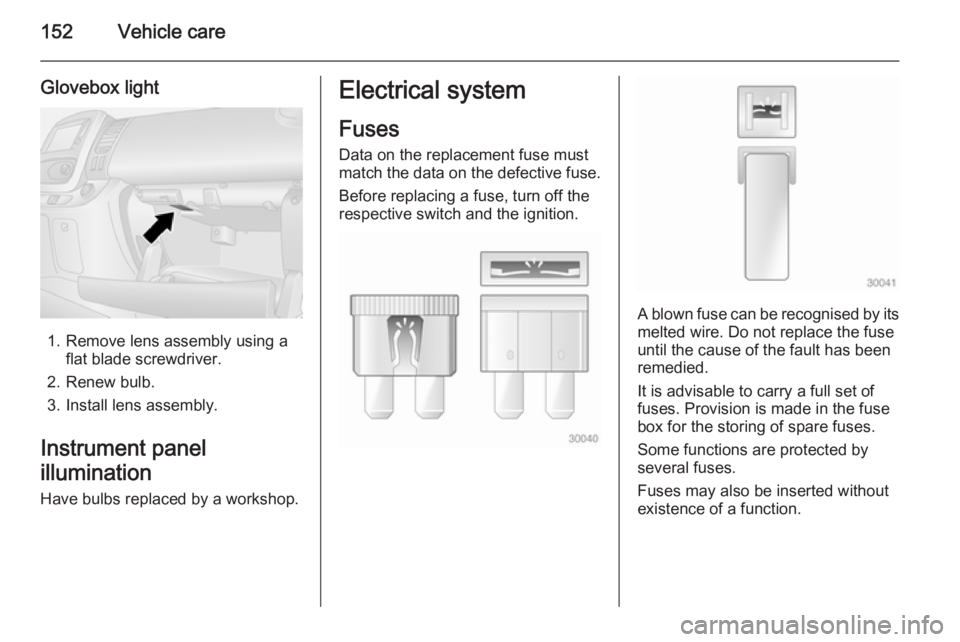

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

It is advisable to carry a full set of

fuses. Provision is made in the fuse

box for the storing of spare fuses.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Page 155 of 205

Vehicle care153

Note

Not all fuse box descriptions in this

Owner's Manual may apply to your

vehicle. Refer to the fuse box label,

where fitted.

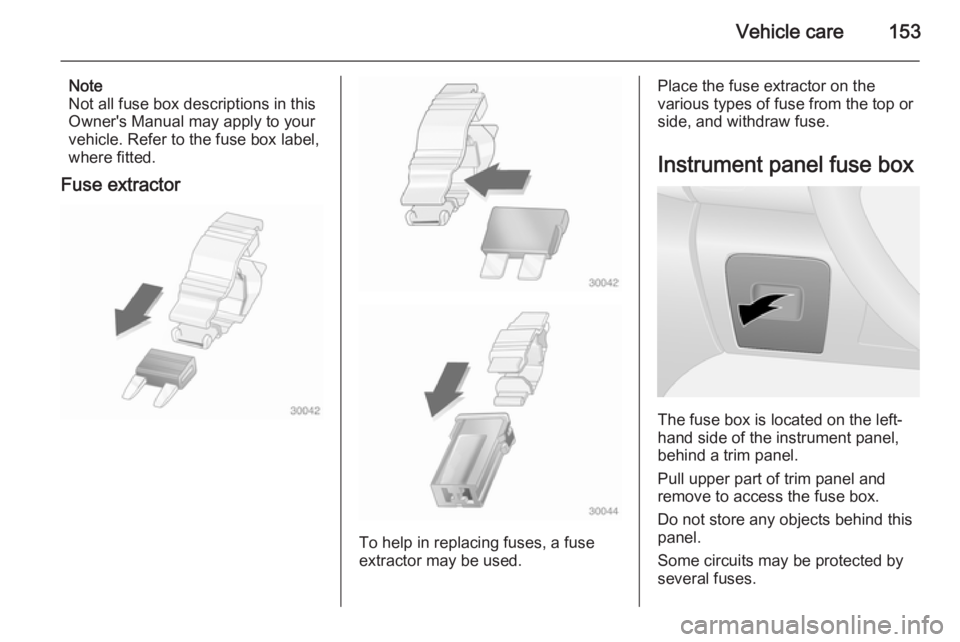

Fuse extractor

To help in replacing fuses, a fuse

extractor may be used.

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

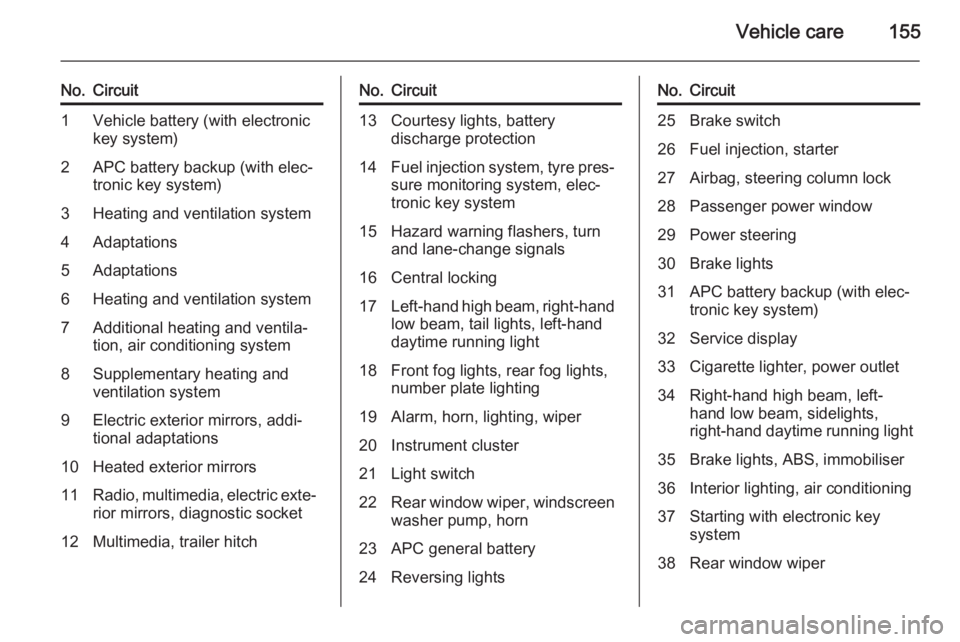

Instrument panel fuse box

The fuse box is located on the left-

hand side of the instrument panel, behind a trim panel.

Pull upper part of trim panel and

remove to access the fuse box.

Do not store any objects behind this

panel.

Some circuits may be protected by

several fuses.

Page 156 of 205

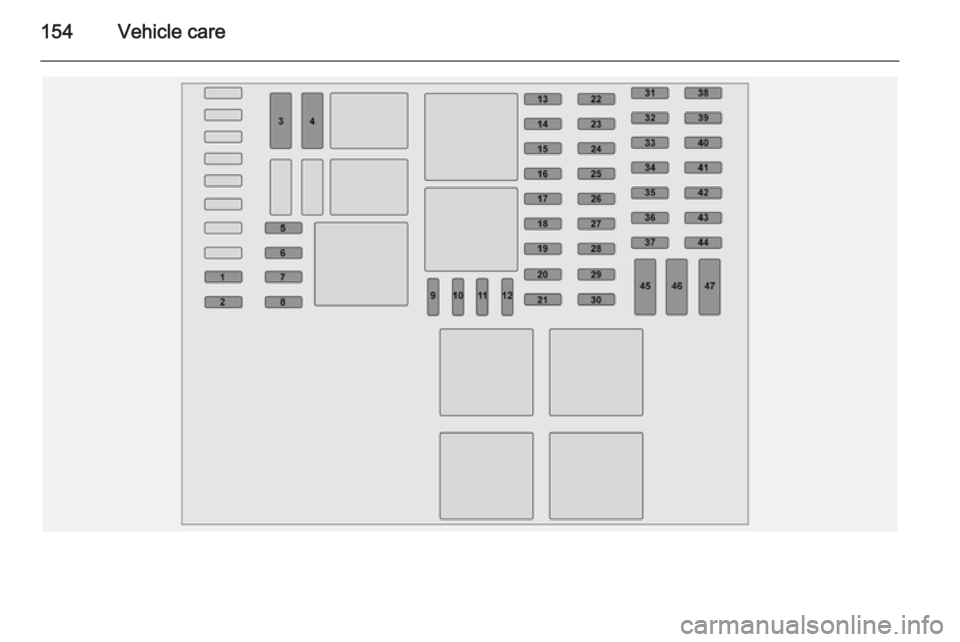

154Vehicle care

Page 157 of 205

Vehicle care155

No.Circuit1Vehicle battery (with electronic

key system)2APC battery backup (with elec‐

tronic key system)3Heating and ventilation system4Adaptations5Adaptations6Heating and ventilation system7Additional heating and ventila‐

tion, air conditioning system8Supplementary heating and

ventilation system9Electric exterior mirrors, addi‐

tional adaptations10Heated exterior mirrors11Radio, multimedia, electric exte‐ rior mirrors, diagnostic socket12Multimedia, trailer hitchNo.Circuit13Courtesy lights, battery

discharge protection14Fuel injection system, tyre pres‐ sure monitoring system, elec‐

tronic key system15Hazard warning flashers, turn and lane-change signals16Central locking17Left-hand high beam, right-hand

low beam, tail lights, left-hand

daytime running light18Front fog lights, rear fog lights,

number plate lighting19Alarm, horn, lighting, wiper20Instrument cluster21Light switch22Rear window wiper, windscreen

washer pump, horn23APC general battery24Reversing lightsNo.Circuit25Brake switch26Fuel injection, starter27Airbag, steering column lock28Passenger power window29Power steering30Brake lights31APC battery backup (with elec‐

tronic key system)32Service display33Cigarette lighter, power outlet34Right-hand high beam, left-

hand low beam, sidelights,

right-hand daytime running light35Brake lights, ABS, immobiliser36Interior lighting, air conditioning37Starting with electronic key

system38Rear window wiper

Page 158 of 205

156Vehicle care

No.Circuit39Warning chimes40Load compartment power outlet41Driver power window42Rear power outlet43Starting, body control module44Heated seats45Heating, air conditioning46Windscreen wiper47TachographVehicle toolsTools

The jack, wheel wrench, wheel bolt

sleeve, torx key, adapters, wheel

cover hook, towing eye are contained

in a unit, stowed under the driver's

seat.

Slide seat forwards and fold the

backrest forwards 3 45 to access the

tool box. The tool box may be secured

in position with a wing nut.

Wheel changing 3 165, Spare wheel

3 166.

Vehicles with tyre repair kit: The

wheel cover hook and torx key are

stored within the tyre repair kit case,

stowed under the driver's seat.

Tyre repair kit 3 162.

Page 159 of 205

Vehicle care157Wheels and tyresTyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb

when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Tyres Factory-fitted tyres are matched to

the chassis and offer optimum driving comfort and safety.Winter tyres

Winter tyres improve driving safety attemperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, a notice indicating the

maximum permissible speed for the

tyres must be affixed within the

driver's field of vision.

Tyre designations E.g. 195/65 R 16 C 88 Q195=Tyre width, mm65=Cross-section ratio (tyre height

to tyre width), %R=Belt type: RadialRF=Type: RunFlat16=Wheel diameter, inchesC=Cargo or commercial use88=Load index e.g. 88 is

equivalent to 567 kgQ=Speed code letter

Speed code letter:

Q=up to 160 km/hS=up to 180 km/hT=up to 190 km/hH=up to 210 km/hV=up to 240 km/hW=up to 270 km/h

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure Check the pressure of cold tyres atleast every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Page 160 of 205

158Vehicle care

Tyre pressures 3 192. Always inflate

tyres to the pressures shown on the

label on the driver's door frame.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 182.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 192.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The TPMS sensors monitor the air

pressure in the tyres and transmit tyre pressure readings to a receiver

located in the vehicle.

Tyre pressures in display The current tyre pressures can be

shown in the Driver Information

Centre 3 90.