tow OPEL VIVARO B 2018.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: VIVARO B, Model: OPEL VIVARO B 2018.5Pages: 241, PDF Size: 5.58 MB

Page 166 of 241

164Driving and operatingSince engine power decreases as

altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 210.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.In the case of trailer loads of

1200 kg or more, the vertical coupling load should not be less than 50 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded (including all occupants), the permissible rear

axle load (see identification plate or

vehicle documents) must not be

exceeded.

Trailer stability assist If the system detects snaking

movements, engine power is reduced

and the vehicle / trailer combination is

selectively braked until the snaking

ceases. While the system is working,

keep steering wheel as still as

possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Program (ESP® Plus

) 3 151.

Page 167 of 241

Vehicle care165Vehicle careGeneral Information...................166

Accessories and vehicle modifications .......................... 166

Vehicle storage ........................166

End-of-life vehicle recovery .....167

Vehicle checks ........................... 167

Performing work ......................167

Bonnet ..................................... 167

Engine oil ................................. 168

Engine air filter ........................ 169

Engine coolant ......................... 170

Power steering fluid .................170

Washer fluid ............................ 171

Brakes ..................................... 171

Brake fluid ............................... 171

Vehicle battery ......................... 172

Diesel fuel filter ........................174

Diesel fuel system bleeding .....174

Wiper blade replacement ........175

Bulb replacement .......................176

Headlights ............................... 176

Fog lights ................................. 177

Front turn lights .......................177

Tail lights ................................. 177

Side turn lights ......................... 178Centre high-mounted brake

light ......................................... 178

Reversing light ......................... 179

Number plate light ...................180

Fog tail light ............................. 180

Interior lights ............................ 181

Instrument panel illumination ...182

Electrical system ........................182

Fuses ....................................... 182

Instrument panel fuse box .......183

Vehicle tools .............................. 186

Tools ........................................ 186

Wheels and tyres .......................187

Tyres ....................................... 187

Winter tyres ............................. 187

Tyre designations ....................187

Tyre pressure .......................... 187

Tyre pressure monitoring system .................................... 189

Tread depth ............................. 191

Changing tyre and wheel size . 191

Wheel covers ........................... 191

Tyre chains .............................. 192

Tyre repair kit .......................... 192

Wheel changing .......................195

Spare wheel ............................ 197

Jump starting ............................. 198Towing....................................... 200

Towing the vehicle ...................200

Towing another vehicle ...........201

Appearance care .......................201

Exterior care ............................ 201

Interior care ............................. 203

Page 171 of 241

Vehicle care169Caution

Do not allow the engine oil level todrop below the minimum level!

We recommend the use of the same

grade of engine oil that was used at

the last change.

Between the MIN and MAX marks a

volume of approx. 2.1 l for engines R9M 408, R9M 413 and R9M 415

respectively approx. 3.5 l for engines

R9M 450 and R9M 452 can be filled

in.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.Caution

Overfilled engine oil must be

drained or suctioned out. If the oil exceeds the maximum level, do

not start the vehicle and contact a

workshop.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel to top-up the engine oil. Ensure funnel is

securely located onto the filler pipe.

After topping-up, put the funnel into a

plastic bag and stow it securely.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand kilometres. Only then can

the actual degree of consumption be

established.

If consumption exceeds more than

0.6 l every 1000 km after this running-

in period, consult a workshop.

Fit the cap on straight and tighten it.

Engine air filter

Engine air flow indicator

On certain models, an indicator is

located in the engine induction

system and indicates if the air-intake

to the engine is restricted.

Clear:No restrictionRed tell-tale:Restricted

If the red tell-tale is displayed when

the engine is running, consult a

workshop.

Page 188 of 241

186Vehicle careNo.Circuit40Rear power outlet41Starting / Body control module42Heated seats43Tachograph44Windscreen wiper45Heating / Air conditioning

After having changed defective fuses,

replace the trim panel.

Vehicle tools

Tools

The jack, wheel wrench, wheel bolt

sleeve, torx key, adapters, wheel

cover hook, towing eye are contained

in a unit, stowed under the driver's

seat.

Slide seat forwards and fold the

backrest forwards 3 48 to access the

tool box. The tool box may be secured

in position with a wing nut. Rotate

wing nut anticlockwise to release.

Wheel changing 3 195.

Spare wheel 3 197.

Vehicles with tyre repair kit: The wheel cover hook and torx key are

stored within the tyre repair kit case,

stowed under the driver's seat.

Tyre repair kit 3 192.

Page 191 of 241

Vehicle care189Trailer towingWhen towing a trailer with a fully

laden vehicle, the tyre pressure must

be increased by 20 kPa/0.2 bar

(3.0 psi) and the maximum speed

limited to 100 km/h.

Trailer towing 3 163.

Tyre pressure monitoring

system

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Note

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The tyre pressure monitoring system

sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

Tyre pressure chart 3 223.

Low tyre pressure conditionA detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 101 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 223.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise w flashes for

several seconds then illuminates

continuously together with control

indicator j 3 99 and a corresponding

message appears in the Driver

Information Centre.

Page 196 of 241

194Vehicle care

12. The prescribed tyre pressureshould be obtained within

15 minutes.

Tyre pressure 3 223.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 15 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 m). Reattach the tyre

repair kit and continue the filling

procedure for 15 minutes. If the

prescribed tyre pressure is still not

obtained, the tyre is too badly

damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than 15 minutes.

13. Detach the tyre repair kit.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the

driver's field of view.

16. Store the sealant bottle in the plastic bag. Return tyre repair kit

to case and stow under the driver's seat.

17. Continue driving immediately so that the sealant is evenly

distributed throughout the tyre.

After driving approx. 10 km, but no more than 10 minutes, stop and

check tyre pressure using the

compressor. Screw air hose from

compressor directly onto tyre

valve when doing this.

18. If the tyre pressure is more than 2.2 bar (220 kPa/31 psi), set it to

the correct value. Repeat the

procedure until there is no more

loss of pressure.

If the tyre pressure has fallen

below 2.2 bar (220 kPa/31 psi),

the vehicle must not be driven.

Page 197 of 241

Vehicle care195Seek the assistance of a

workshop.

19. Detach the tyre repair kit, return to

case and stow under the driver's

seat.9 Warning

Do not allow the sealant to contact

skin, eyes or clothing. If swallowed seek medical assistance

immediately.

Note

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Pay attention to storage information

and expiry date on sealant bottle. Its

sealing capability is not guaranteed

after this time.

Replace the used sealant bottle.

Dispose of the sealant bottle as

prescribed by applicable laws.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 192.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear.

● Remove the spare wheel 3 197.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for a seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Remove heavy objects out of the

vehicle before jacking up.● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts / nuts and thread with a clean cloth before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover (using the hook supplied).

Vehicle tools 3 186.

Page 199 of 241

Vehicle care19711. Stow the replaced wheel 3 197

and the vehicle tools 3 186.

12. Have the new wheel balanced on the vehicle.

Check the tyre pressure of the

installed tyre 3 223.

Check the wheel bolt torque.

Have the defective tyre renewed or repaired as soon as possible.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 192.

The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a

flat rear tyre.

Wheel changing 3 195.

The spare wheel is mounted under

the rear underbody and may be

secured using a security bolt that can

only be removed using the wheel bolt sleeve supplied.

Vehicle tools 3 186.9 Warning

Due to the weight of the tyre

assembly, exercise caution when

releasing the spare wheel carrier.

Do not fully remove bolt 1.

Support the spare wheel with a

suitable object to prevent the

wheel falling suddenly when

loosening the carrier bolts - risk of injury!

To release the spare wheel carrier,fully remove bolt 2 then loosen bolt 1,

ensuring it is not fully removed. Then

move the spare wheel carrier up and

down and from side to side, until it

clears bolt 1, and lower the carrier

assembly.

When installing the wheel ensure that

the spare wheel carrier is correctly

positioned before tightening the bolts.

Page 202 of 241

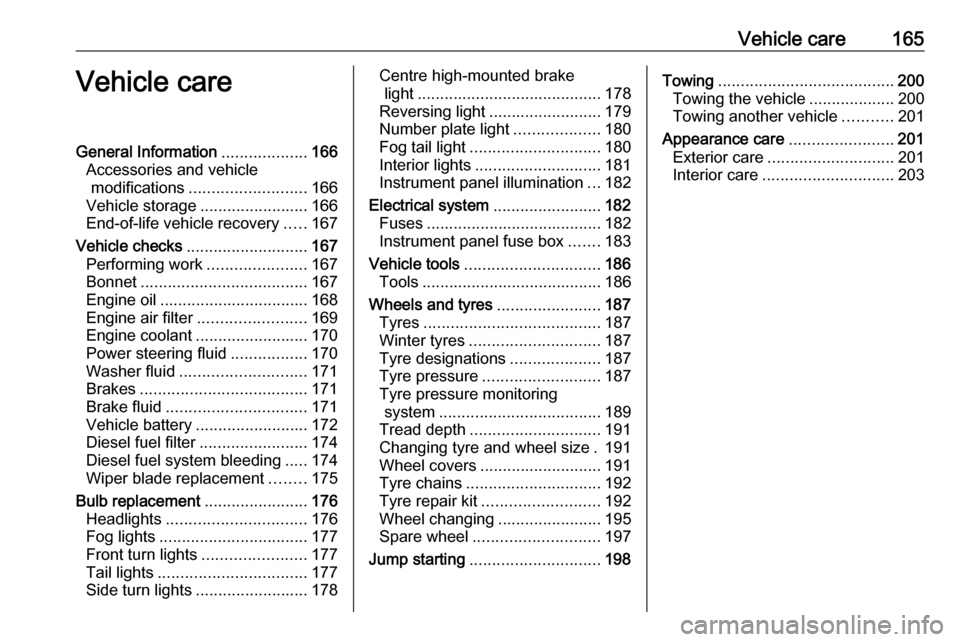

200Vehicle careTowingTowing the vehicle

The towing eye is stowed with the

vehicle tools 3 186.

Release cap using a suitable tool.

Screw the towing eye clockwise into

the front towing point and tighten fully

using the wheel wrench.

Attach a tow rope - or better still a tow rod - to the towing eye, never to the

bumper or front suspension units.

Caution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Caution

Activate the child locks in the rear

doors if the rear seats are

occupied.

Child locks 3 32.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Note

Depending on version, it may be

necessary to switch on the engine to

permit operation of brake lights.

Move the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

Switch on hazard warning flashers

3 113.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system 3 119 and

close the windows.

Seek the assistance of a workshop.

After towing, unscrew the towing eye

and replace cap.

Page 203 of 241

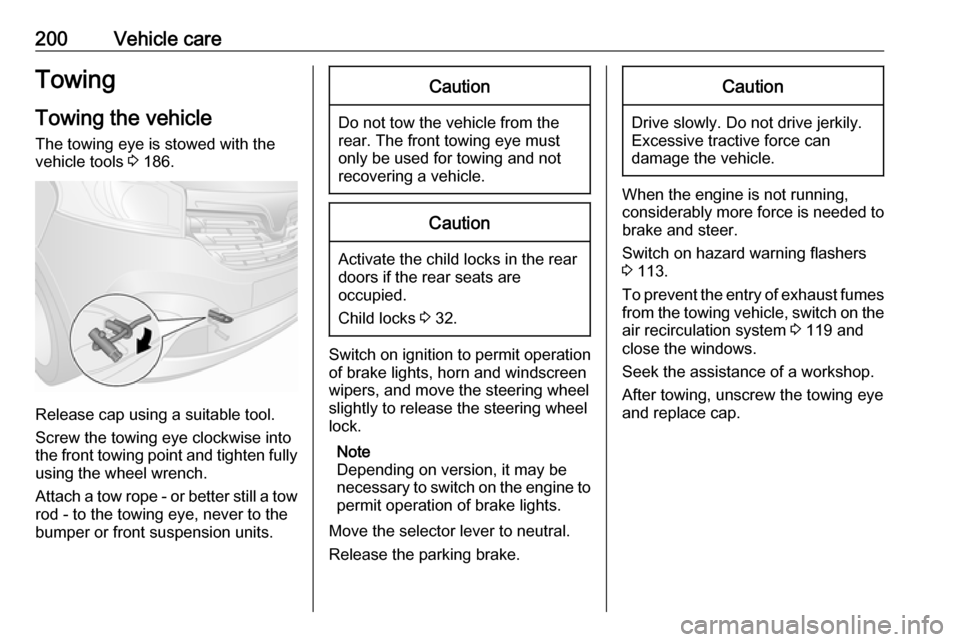

Vehicle care201Towing another vehicle

The fixed towing eye is located underthe rear bumper, on the left vehicle

side.

Attach a tow rope - or better still a tow

rod - to the rear towing eye, never to

the rear axle and suspension units.

The rear towing eye must only be

used for towing and not recovering a

vehicle.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

Trailer hitch 3 163.

Appearance care

Exterior care

Locks The locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has adegreasing effect and impairs lockfunction. After using a de-icing agent,

have the locks regreased by a

workshop.

Washing

The paintwork of your vehicle is

exposed to environmental influences, therefore wash your vehicle regularly.

When using automatic vehicle

washes, we recommend one with

textile brushes and a programme

without wax additives. Restrictions for

filmed or matt painted body parts or

decor tapes, see "Polishing and

waxing".

Never use a steam-jet or high-

pressure jet cleaner for the engine

compartment.