ignition OPEL ZAFIRA TOURER 2015 Manual PDF

[x] Cancel search | Manufacturer: OPEL, Model Year: 2015, Model line: ZAFIRA TOURER, Model: OPEL ZAFIRA TOURER 2015Pages: 299, PDF Size: 9.13 MB

Page 247 of 299

Vehicle care245

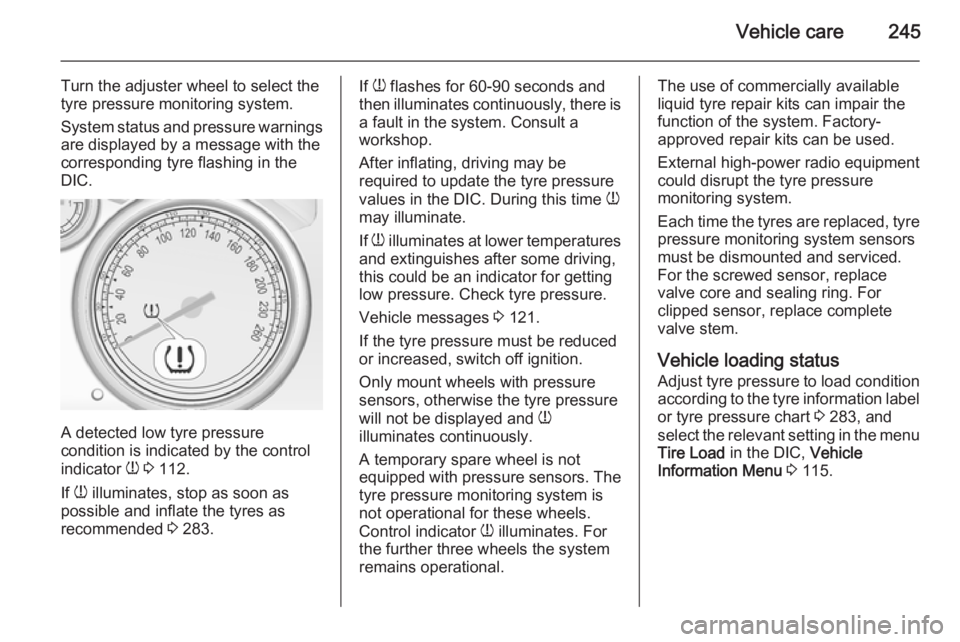

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

DIC.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 112.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 283.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for getting

low pressure. Check tyre pressure.

Vehicle messages 3 121.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A temporary spare wheel is not

equipped with pressure sensors. The

tyre pressure monitoring system is

not operational for these wheels.

Control indicator w illuminates. For

the further three wheels the system

remains operational.The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

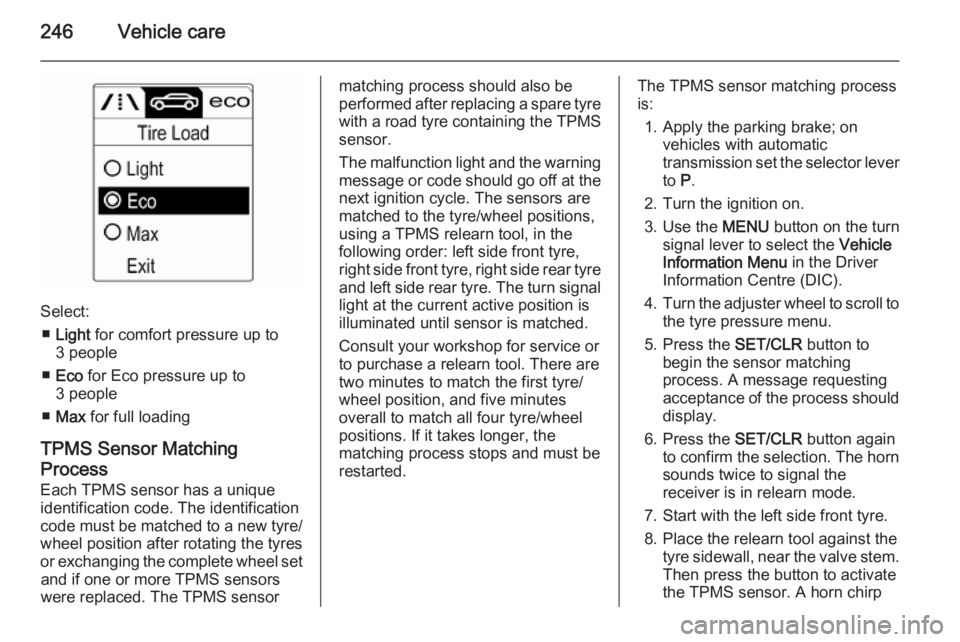

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 283, and

select the relevant setting in the menu

Tire Load in the DIC, Vehicle

Information Menu 3 115.

Page 248 of 299

246Vehicle care

Select:■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: left side front tyre,

right side front tyre, right side rear tyre and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

Page 249 of 299

Vehicle care247

confirms that the sensoridentification code has been

matched to this tyre and wheel

position.

9. Proceed to the right side front tyre,

and repeat the procedure in

Step 8.

10. Proceed to the right side rear tyre,

and repeat the procedure in

Step 8.

11. Proceed to the left side rear tyre, and repeat the procedure inStep 8. The horn sounds twice to

indicate the sensor identification

code has been matched to the left

side rear tyre, and the TPMS

sensor matching process is no

longer active.

12. Turn off the ignition.

13. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

label.

14. Ensure the tyre loading status is set according selected pressure

3 115.Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the DIC shows the actual tyre

pressure. Therefore it is important to

check tyre pressure with cold tyres.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Page 262 of 299

260Vehicle care

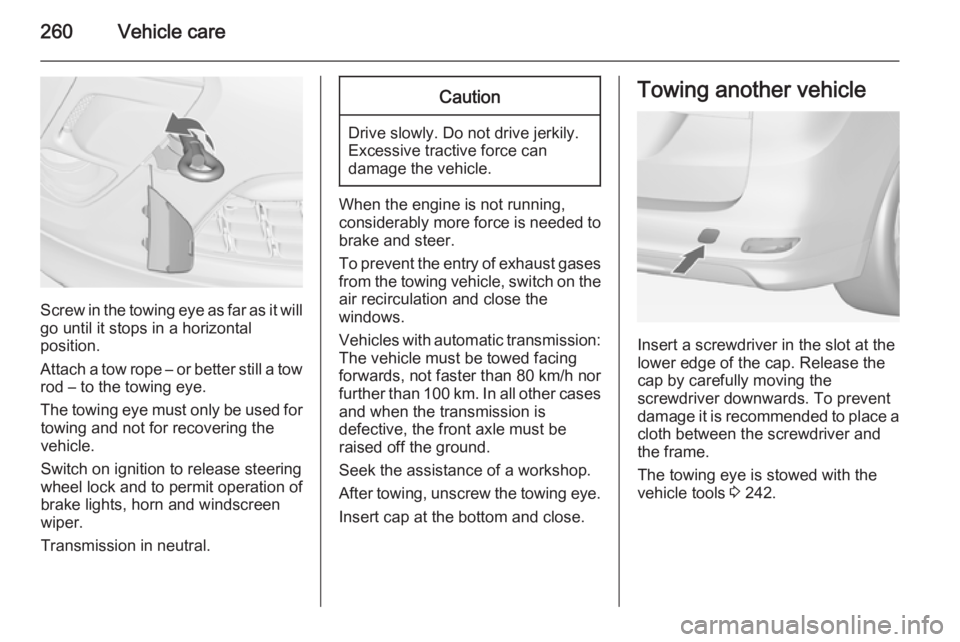

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 80 km/h nor further than 100 km. In all other cases

and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap at the bottom and close.

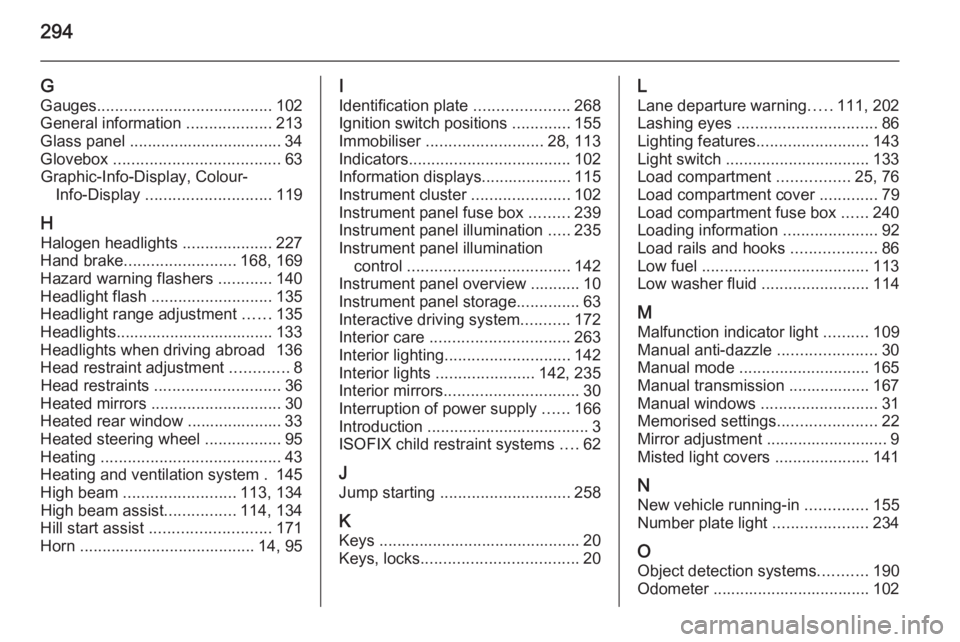

Towing another vehicle

Insert a screwdriver in the slot at the

lower edge of the cap. Release the

cap by carefully moving the

screwdriver downwards. To prevent

damage it is recommended to place a cloth between the screwdriver and

the frame.

The towing eye is stowed with the vehicle tools 3 242.

Page 292 of 299

290Customer information

■ Vehicle reactions in particulardriving situations (e.g. inflation of

an airbag, activation of the stability

regulation system)

■ Environmental conditions (e.g. temperature)

These data are exclusively technical

and help identifying and correcting

errors as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty

cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may be associated with a specific person -

possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular vehicle data from the vehicle.Radio Frequency

Identification (RFID) RFID technology is used in somevehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in Opel

vehicles does not use or record

personal information or link with any

other Opel system containing

personal information.

Page 296 of 299

294

GGauges ....................................... 102

General information ...................213

Glass panel .................................. 34

Glovebox ..................................... 63

Graphic-Info-Display, Colour- Info-Display ............................ 119

H Halogen headlights ....................227

Hand brake ......................... 168, 169

Hazard warning flashers ............140

Headlight flash ........................... 135

Headlight range adjustment ......135

Headlights................................... 133

Headlights when driving abroad 136

Head restraint adjustment .............8

Head restraints ............................ 36

Heated mirrors ............................. 30

Heated rear window ..................... 33

Heated steering wheel .................95

Heating ........................................ 43

Heating and ventilation system . 145

High beam ......................... 113, 134

High beam assist ................114, 134

Hill start assist ........................... 171

Horn ....................................... 14, 95I

Identification plate .....................268

Ignition switch positions .............155

Immobiliser .......................... 28, 113

Indicators .................................... 102

Information displays.................... 115

Instrument cluster ......................102

Instrument panel fuse box .........239

Instrument panel illumination .....235

Instrument panel illumination control .................................... 142

Instrument panel overview ........... 10

Instrument panel storage ..............63

Interactive driving system ...........172

Interior care ............................... 263

Interior lighting ............................ 142

Interior lights ...................... 142, 235

Interior mirrors .............................. 30

Interruption of power supply ......166

Introduction .................................... 3

ISOFIX child restraint systems ....62

J Jump starting ............................. 258

K Keys ............................................. 20

Keys, locks ................................... 20L

Lane departure warning .....111, 202

Lashing eyes ............................... 86

Lighting features .........................143

Light switch ................................ 133

Load compartment ................25, 76

Load compartment cover .............79

Load compartment fuse box ......240

Loading information .....................92

Load rails and hooks ...................86

Low fuel ..................................... 113

Low washer fluid ........................114

M Malfunction indicator light ..........109

Manual anti-dazzle ......................30

Manual mode ............................. 165

Manual transmission .................. 167

Manual windows ..........................31

Memorised settings ......................22

Mirror adjustment ........................... 9

Misted light covers .....................141

N New vehicle running-in ..............155

Number plate light .....................234

O

Object detection systems ...........190

Odometer ................................... 102